Cloth soaking and coloring automatic equipment and operation method thereof

An automatic equipment and cloth technology, applied in the field of cloth processing, can solve the problems of uneven color of cloth, low drying efficiency, affecting the efficiency of cloth production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

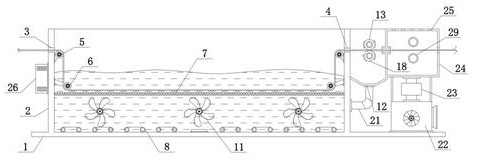

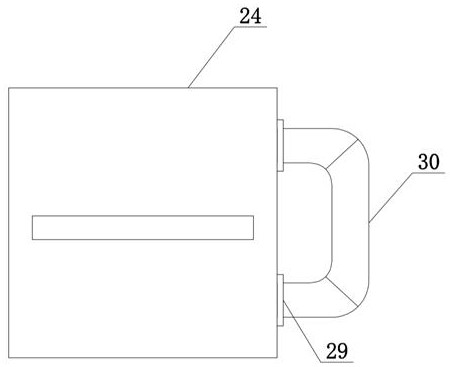

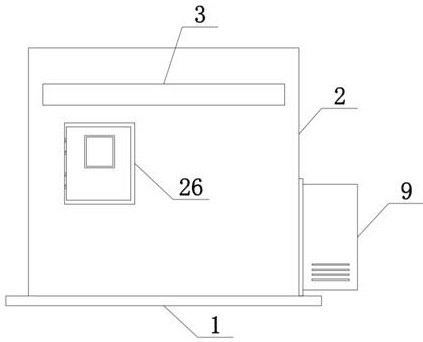

[0041] see Figure 1-Figure 3 , an automatic equipment for soaking and coloring cloth and its operation method, comprising a base 1, the upper end of the base 1 is fixedly connected with a dye tank 2, and the two sides of the upper end of the fuel tank are respectively provided with a material inlet 3 and a material outlet 4. Both sides of the inner wall of the dye box 2 are fixedly connected with a first guide roller 5 and a second guide roller 6, and the first guide roller 5 is fixedly connected with the lower end of the feed port 3 and the discharge port 4, so Described second guide roller 6 is arranged on the below of first guide roller 5, and described first guide roller 5 is higher than the liquid level of dye tank 2 inside, and described second guide roller 6 is lower than the liquid level of dye tank 2 inside, The cloth passes through the first guide roller 5 and the second guide roller 6 in turn, so that the cloth can be evenly soaked in the inside of the fuel tank, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com