Robot capable of achieving building wall surface plastering

A robot and wall surface technology, which is applied in the direction of construction and building construction, can solve the problems of difficult disassembly and transportation, high labor intensity, long preparation time, etc., and achieve the goal of improving comprehensive economic benefits, improving plastering quality, and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

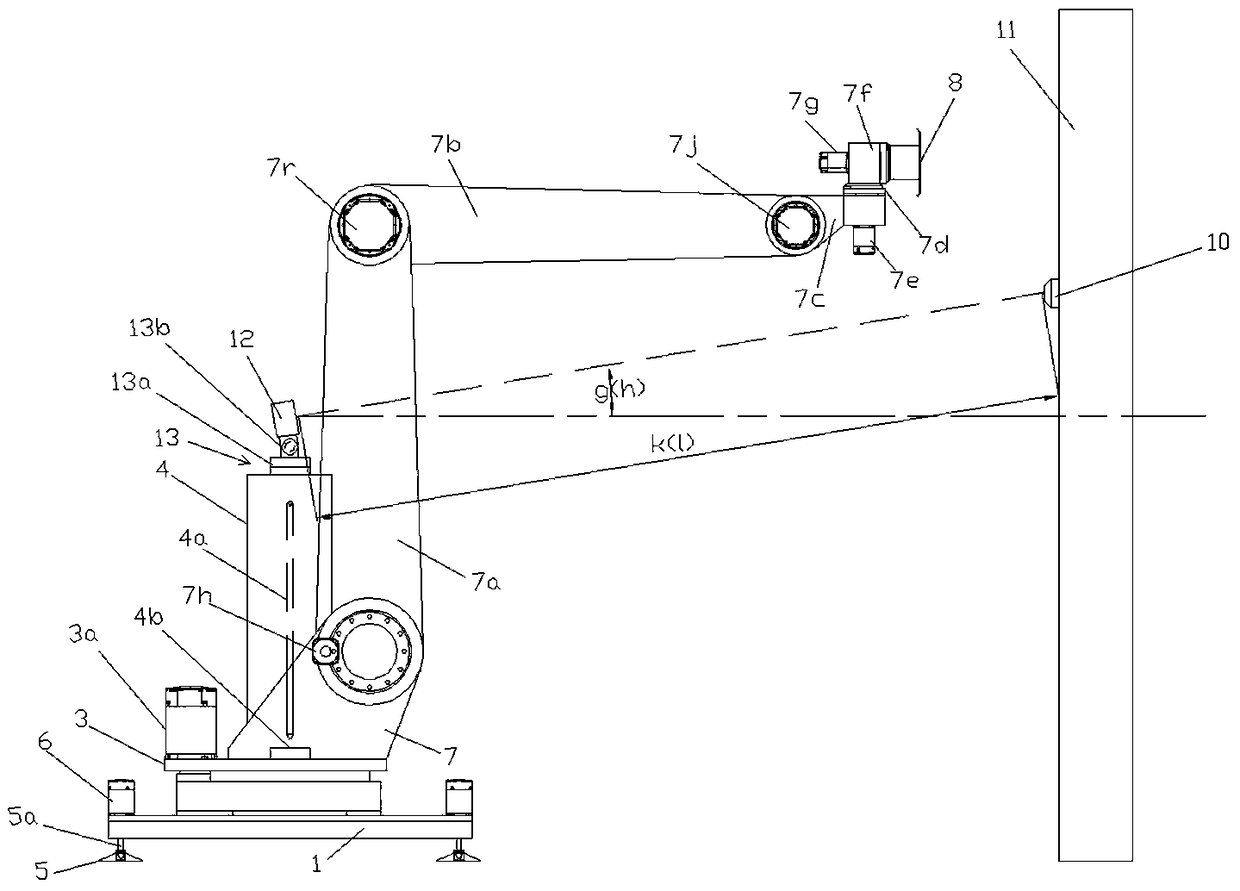

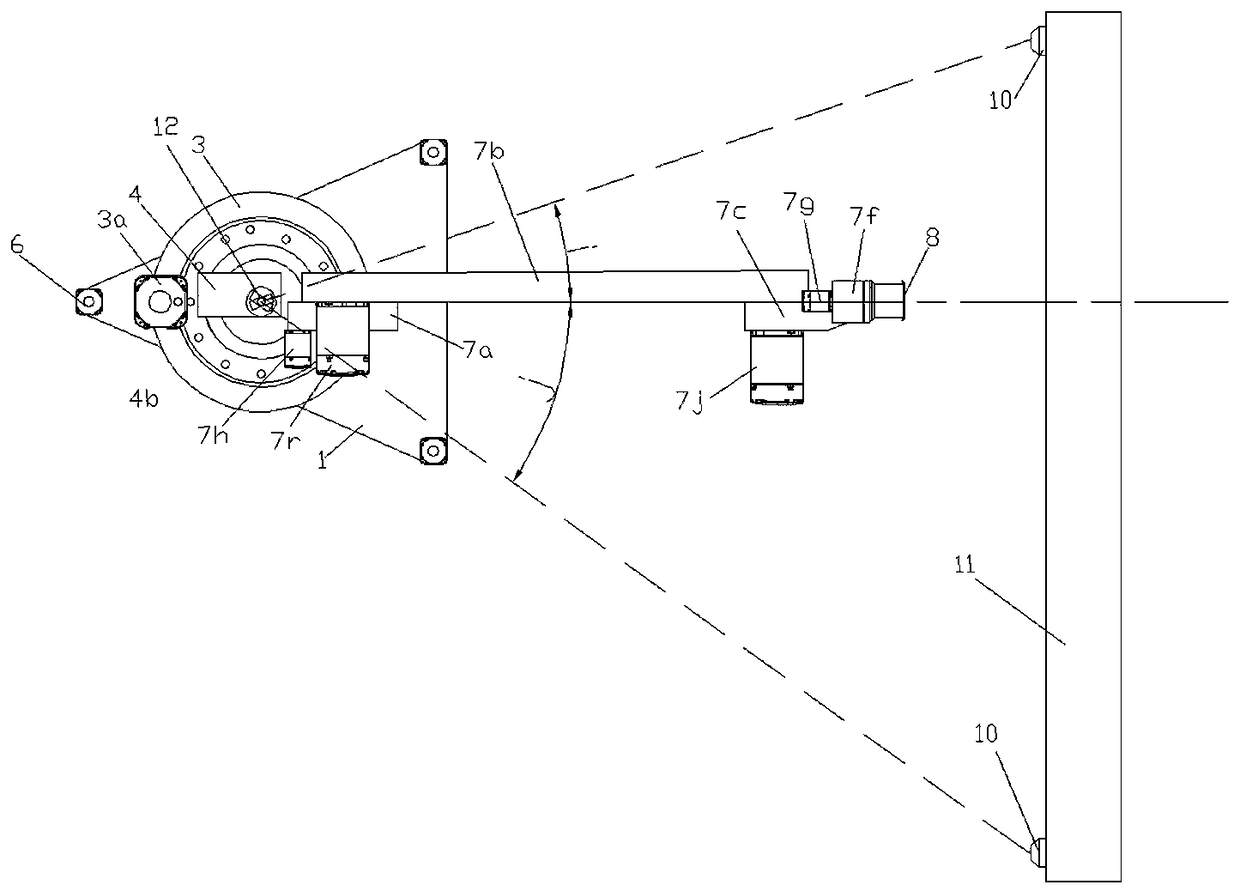

[0016] like Figure 1-3 Shown, a kind of robot that can realize building wall plastering, it comprises triangular base 1, is provided with a horizontal distribution on the upper surface of base 1 and is provided with rotating disc 3, and corresponding to rotating disc 3 The matching servo motor 3a, the servo motor 3a controls the rotation of the rotating disk 3, and forms an electrical signal connection and cooperation with the control module mentioned below.

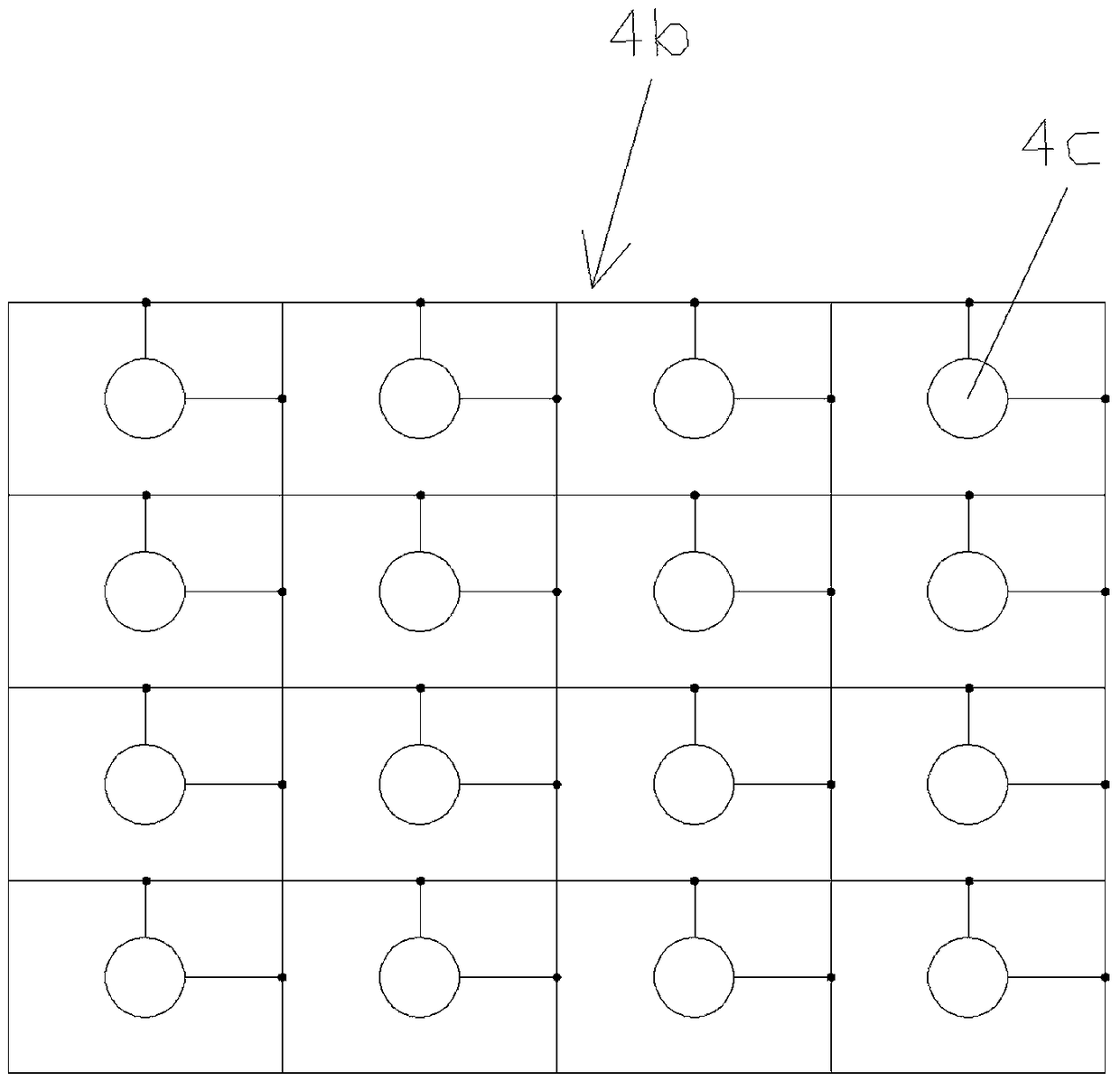

[0017] A support 4 is provided on the rotating disk 3, and a control module not shown in the figure is provided on the support 4. In the cavity in the support 4, a plumb 4a is arranged in the cavity, a laser generator is arranged at the lower end of the plumb 4a, and a photosensitive matrix board 4b is arranged on the bottom surface of the cavity below the ray emitting end of the laser generator. The photosensitive matrix plate 4b includes a plate body, which is a photosensitive plate, and a group of photosensitive ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com