Pasting machine

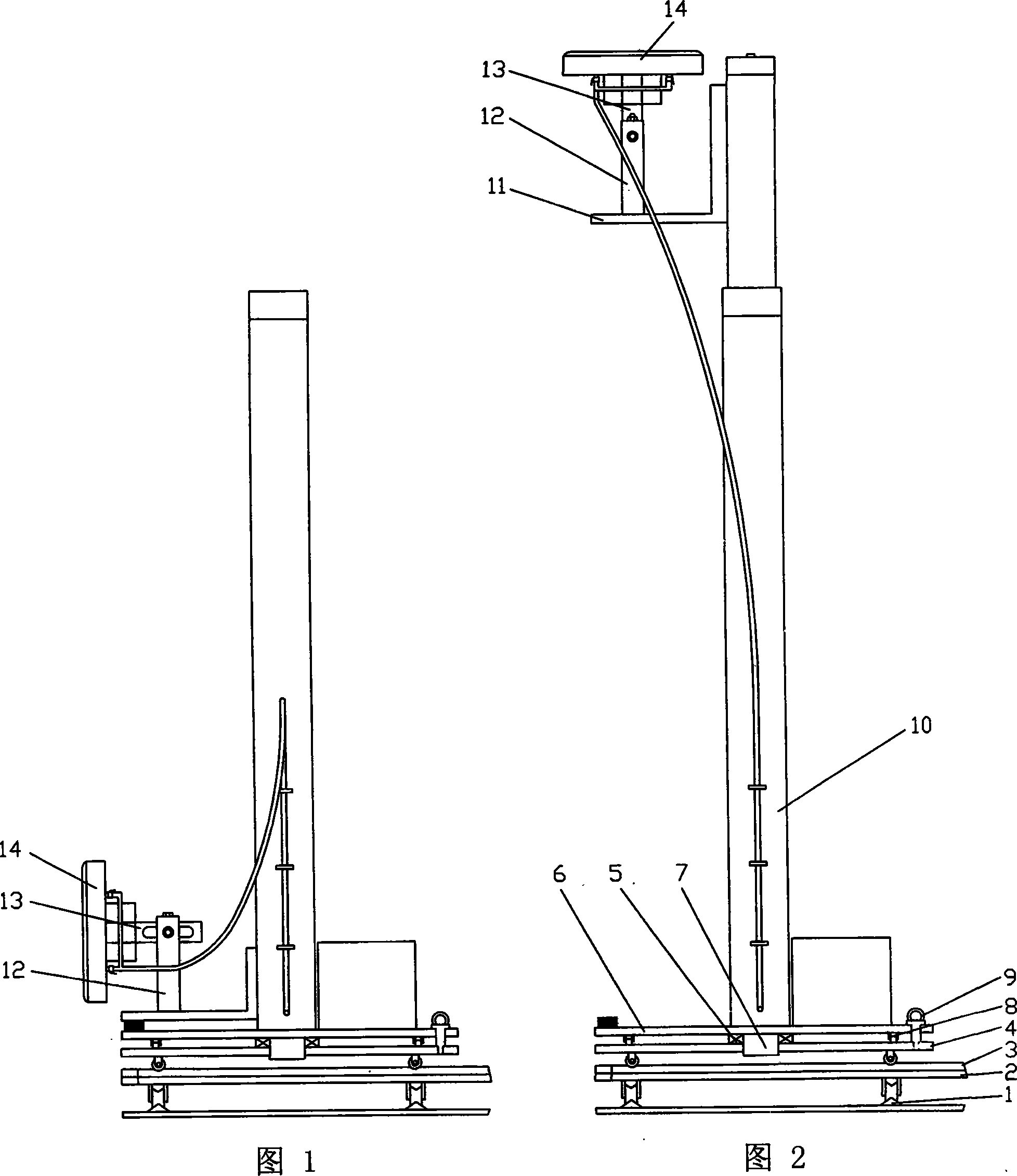

The technology of a plastering machine and a lifting mechanism, which is applied in the directions of construction and building structure, can solve the problems of inability to plaster the wall, small working range, uneven plastering layer, etc., and achieves good plastering quality and application scope. Wide and easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

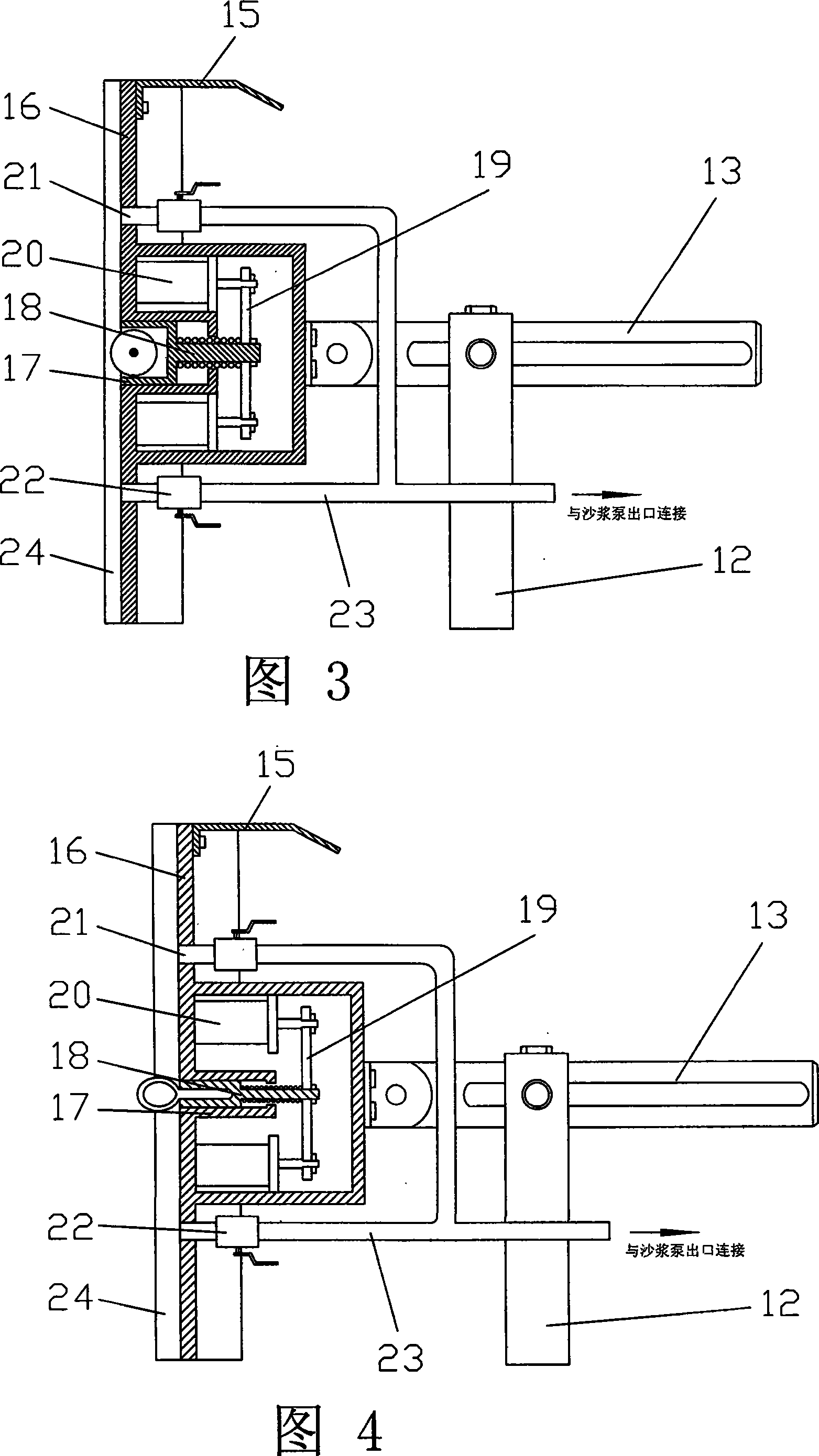

[0025] Embodiment 1: Referring to Fig. 3, Fig. 4, Fig. 9 and Fig. 10, a plastering machine, the upper part of the plastering device 14 is equipped with a baffle plate 15, the middle part is a working panel 16, and the upper middle part of the working panel 16 is provided with There is a spacer groove 17, and a spacer device 18 is installed in the spacer groove 17. The spacer device 18 is connected to the cylinder 20 on the back of the plastering device 14 through a connecting rod 19, and the middle part of the two working panels separated by the spacer device 18 is provided with an outlet. A slurry port 21, the slurry outlet 21 communicates with the valve 22 on the back of the plastering device 14, and communicates with the pipeline 23 and the ash supply system through the valve 22, and the vertical two sides of the working panel 16 of the plastering device 14 are equipped with sealing devices twenty four. In practical application, according to the actual situation of the wall...

Embodiment 2

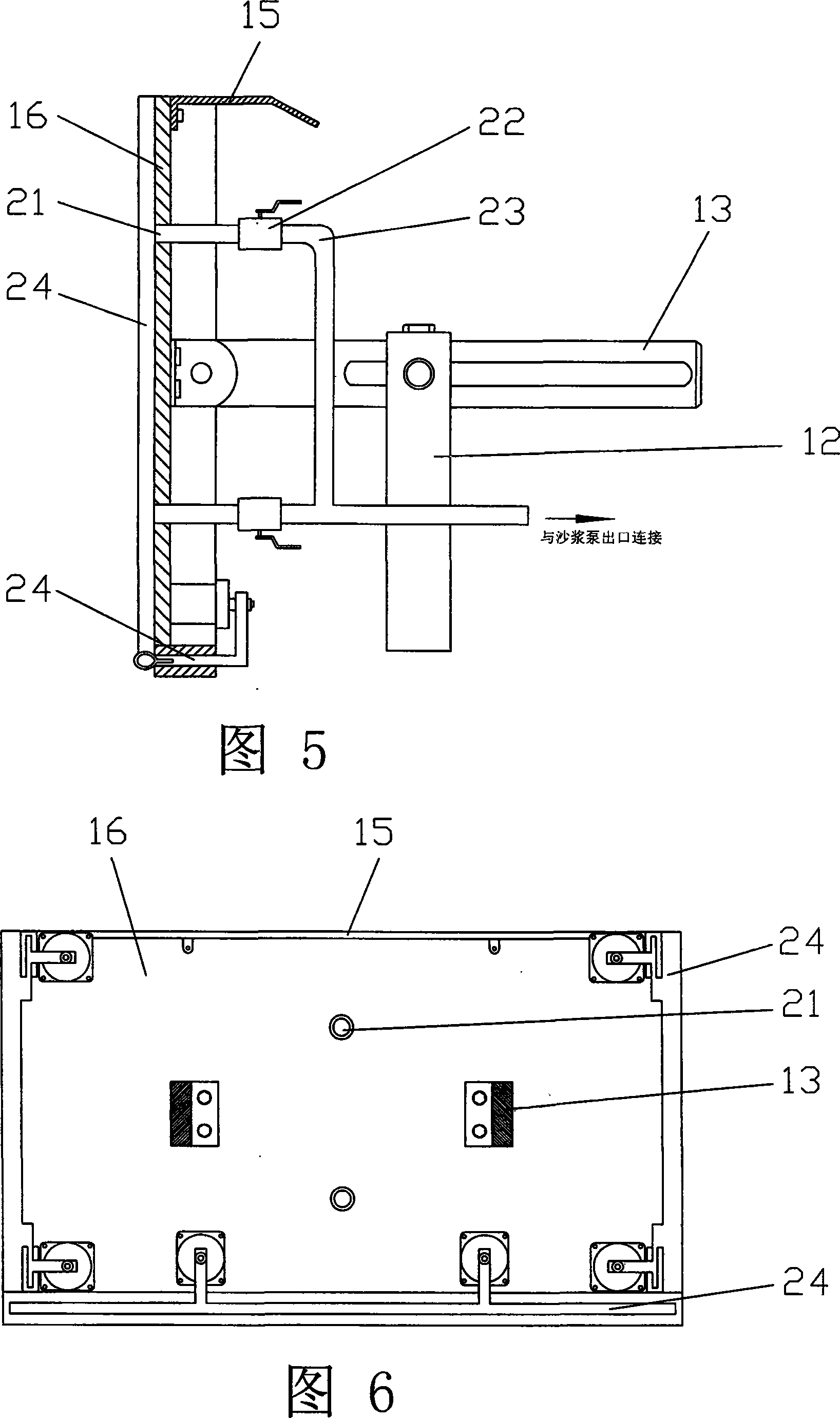

[0026] Embodiment 2: Referring to Fig. 5 and Fig. 6, a kind of plastering machine, the upper part of described plastering device 14 is equipped with baffle plate 15, and the working panel 16 of this plastering device 14 is a single plane, on the vertical plane of working panel 16 Sealing devices 24 are installed on both sides and the bottom, and a slurry outlet 21 is provided in the middle of the working panel 16. The slurry outlet 21 communicates with the valve 22 on the back of the plastering device 14, and through the valve 22 and the pipeline 23, it is connected to the ash supply system. In the same way, if the surface of the wall is relatively flat and the area is large, the plastering device 14 of this structure can be selected, and the efficiency can be effectively improved.

Embodiment 3

[0027] Embodiment 3: Referring to FIG. 7, a plastering machine, the working panel 16 of the plastering device 14 is an outer right-angle working panel 25 structure, and sealing devices 24 are installed on the two outer sides of the outer right angle of the plastering device 14, and the outer right-angle The two working panels 25 are provided with a slurry outlet 21, the slurry outlet 21 communicates with the valve 22 on the back of the plastering device 14, and communicates with the pipeline 23 and the ash supply system through the valve 22; The plastering device 14 can effectively plaster the inner corner wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com