Plastering machine

A plastering machine and plastering board technology, which can be applied in construction, building structure and other directions, can solve problems such as reducing efficiency, affecting efficiency, pollution, etc., and achieving the improvement of plastering quality and efficiency, simple and reasonable structure, and good adaptability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in conjunction with the accompanying drawings of the above-mentioned embodiments

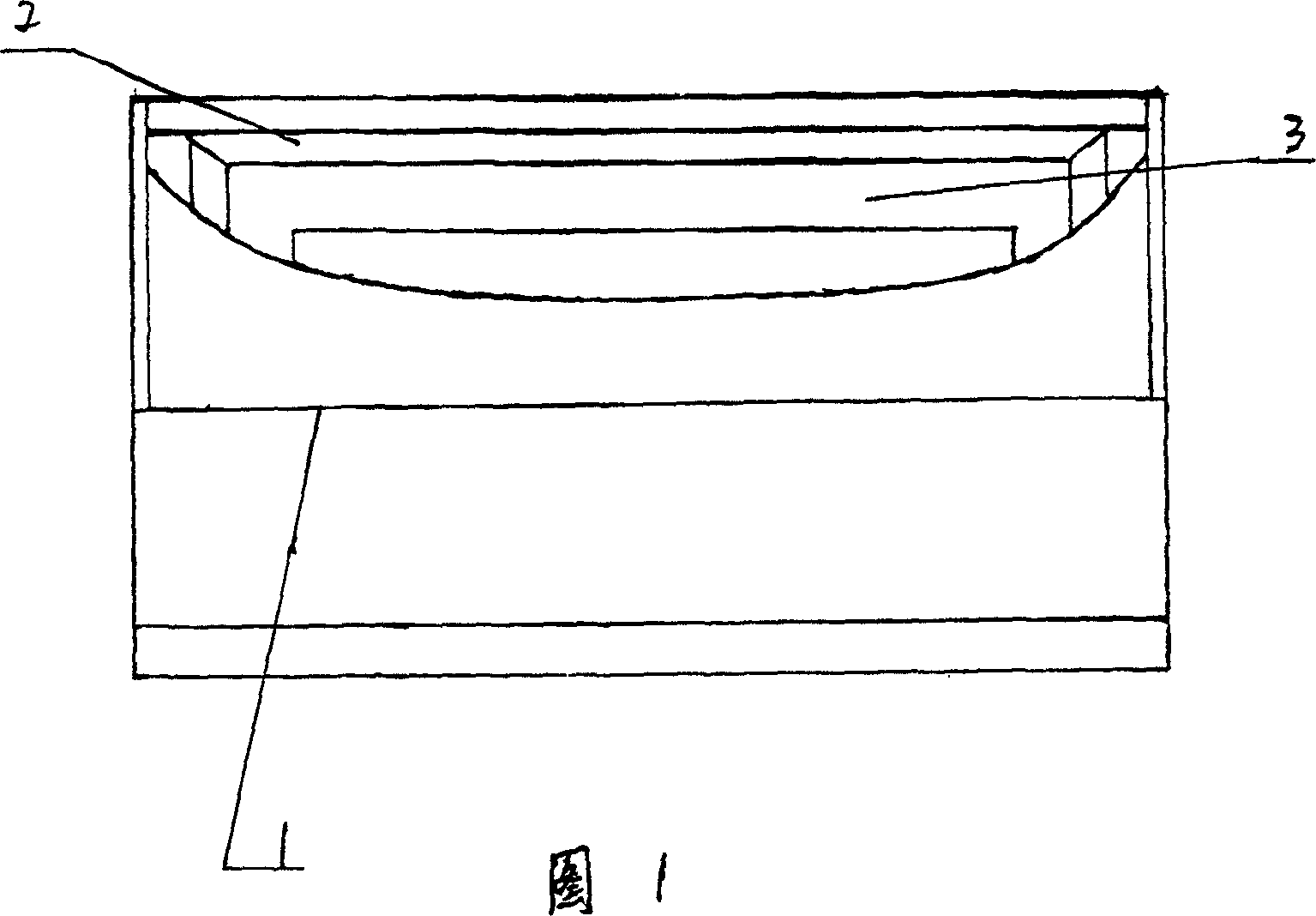

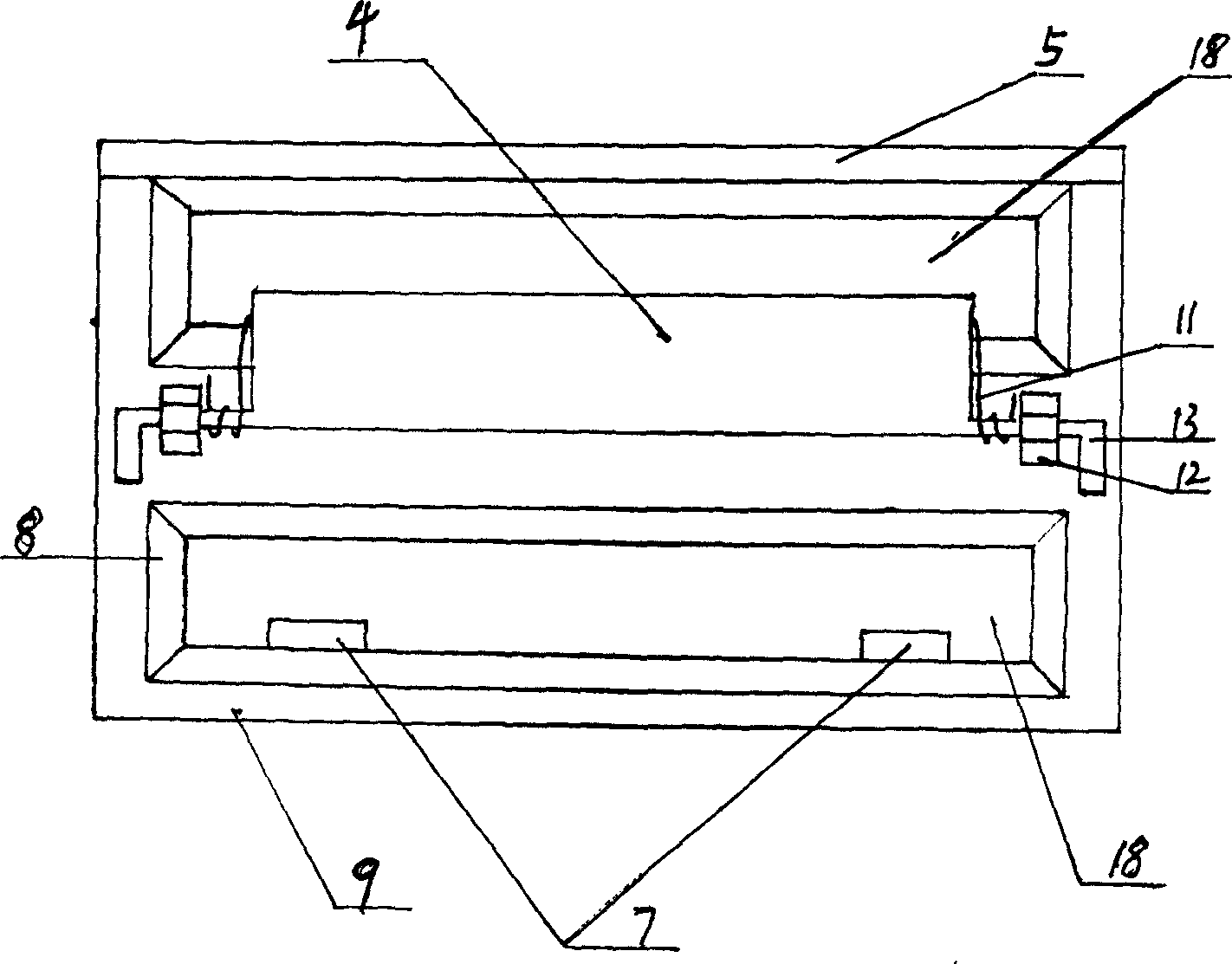

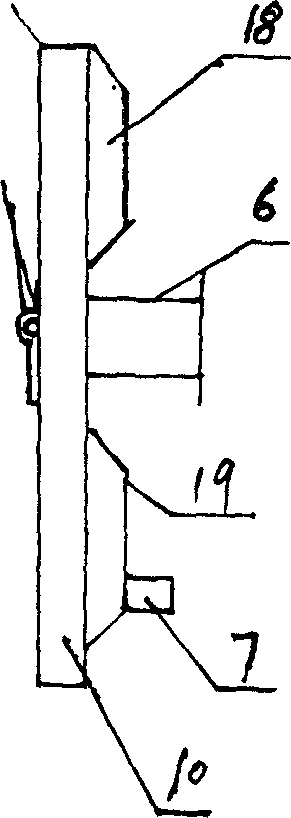

[0021] As shown in Figures 1, 2 and 4, the plastering machine according to the present invention includes a lifting device, an ash supply device and a plastering device. The plastering device consists of a support 6, a face seal 1 and a plastering board 2. The plastering board is rectangular. There is a feeding port 7 on the plastering board, and there is a recessed material storage chamber 18 formed by a main body frame 8 and a bottom plate 19. The main body frame 8 is equipped with a pre-spatter 4 controlled by a clip 12, a torsion spring 11 and a leg 13. There are fixed forming spatulas 5 . The two sidewalls 15 of the face seal 1 are connected as a whole by a crossbeam 17, an upper edge 14 and a lower flange 16, and the upper edge 14 is a sunken meniscus and is made of an elastic wear-resistant material. The lower flanging 16 is a flex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com