Patents

Literature

46results about How to "Meet width requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

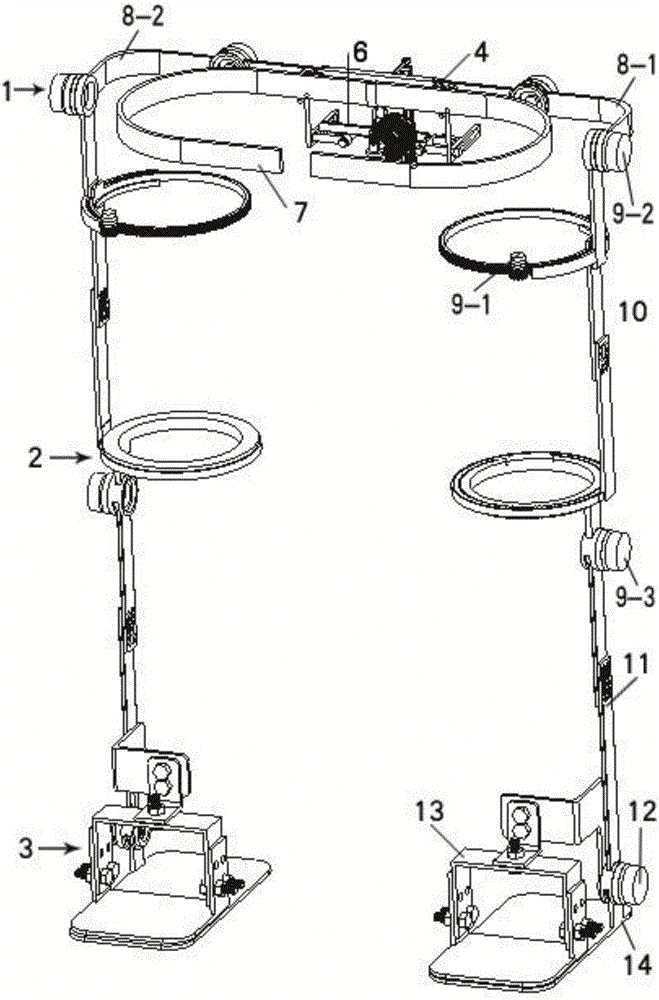

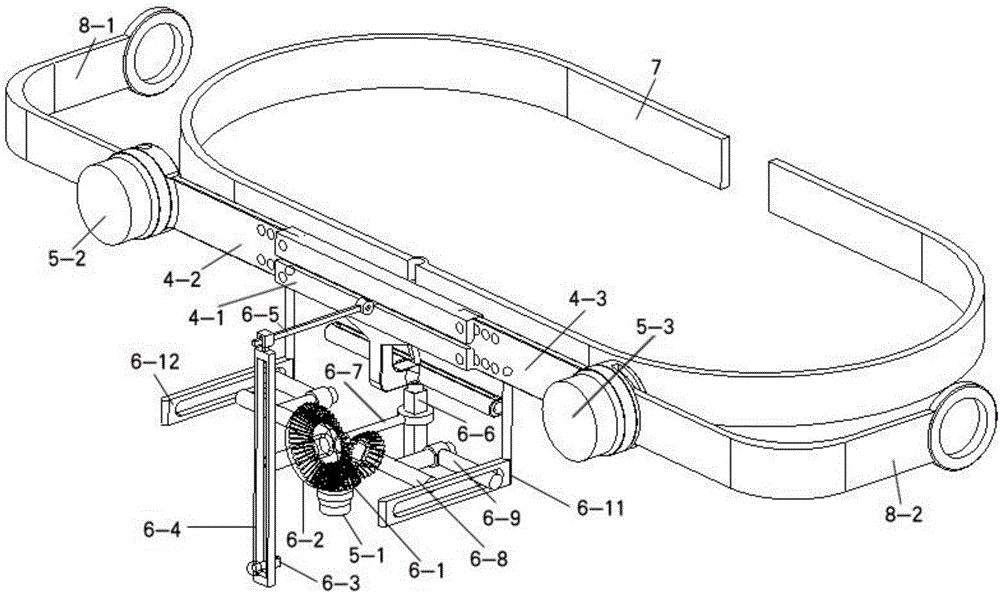

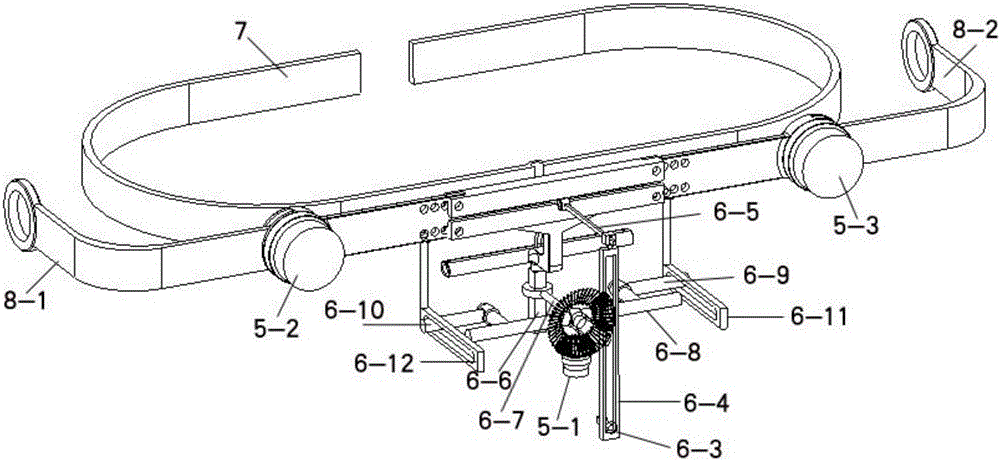

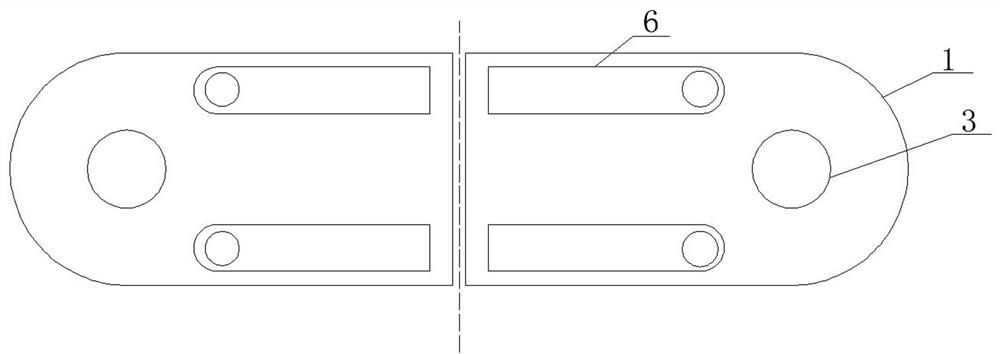

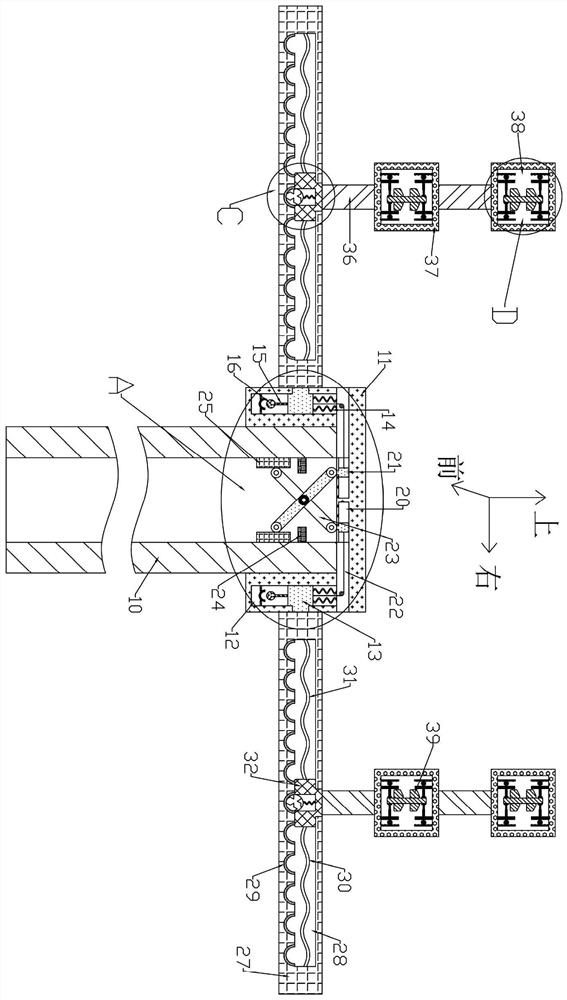

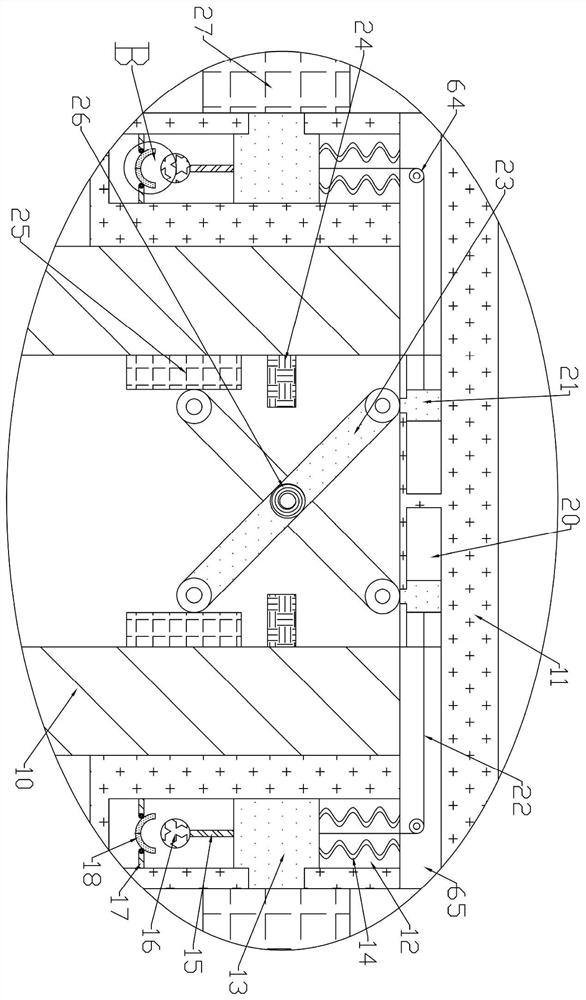

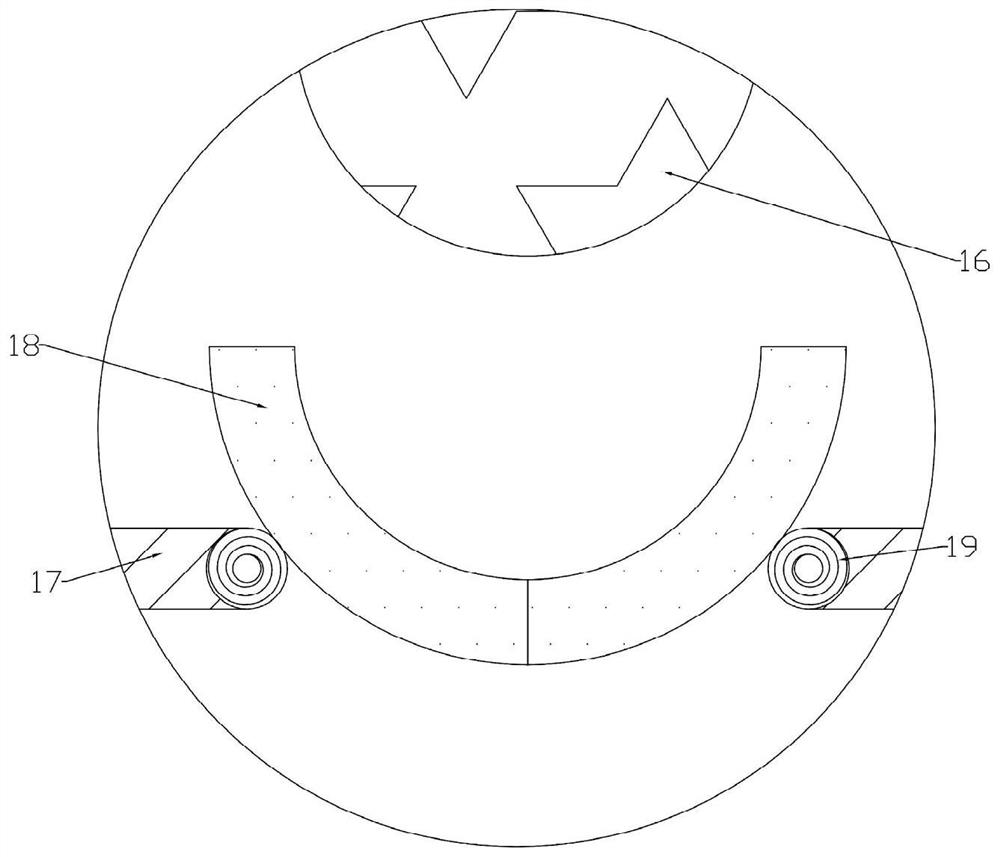

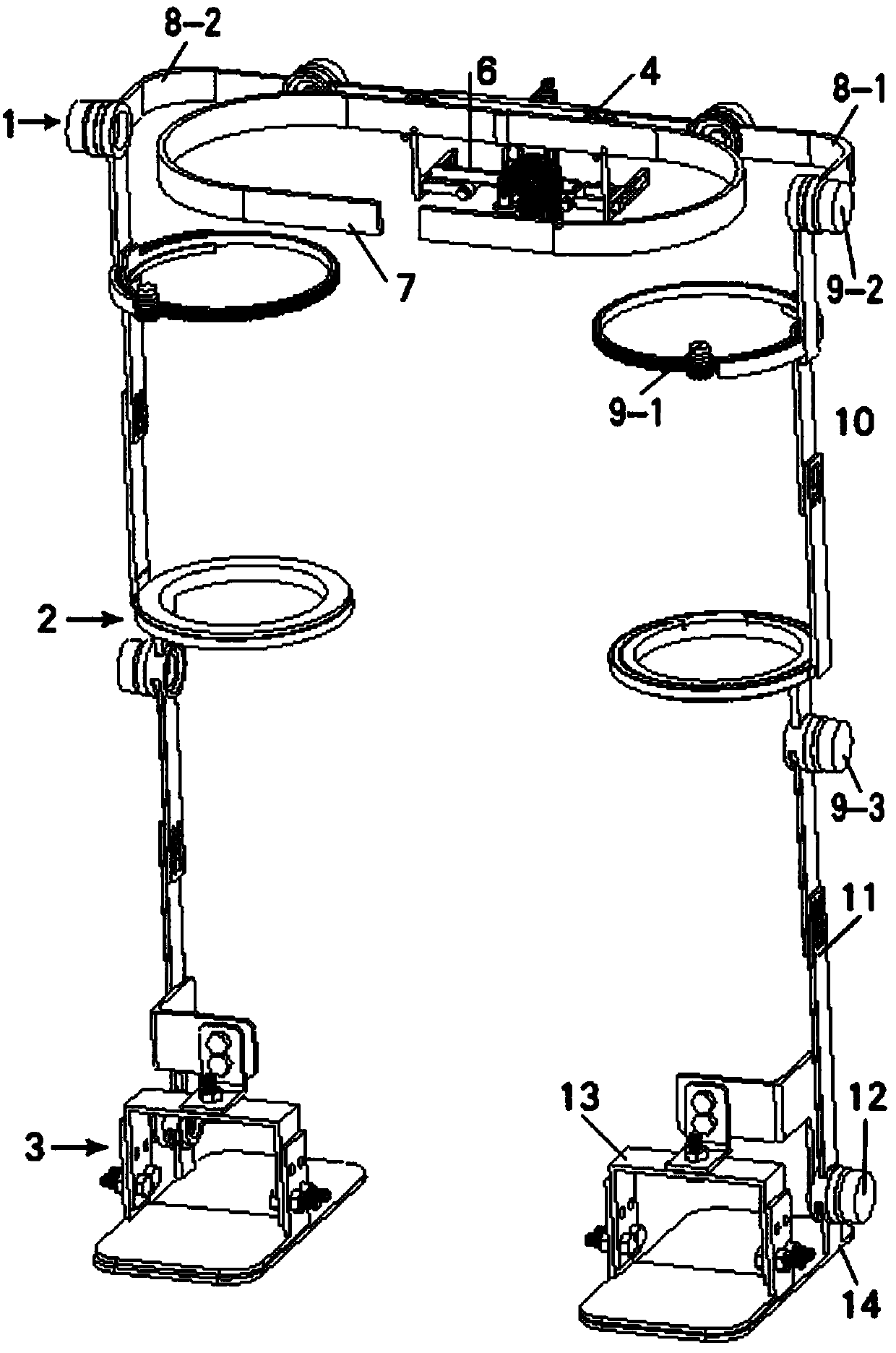

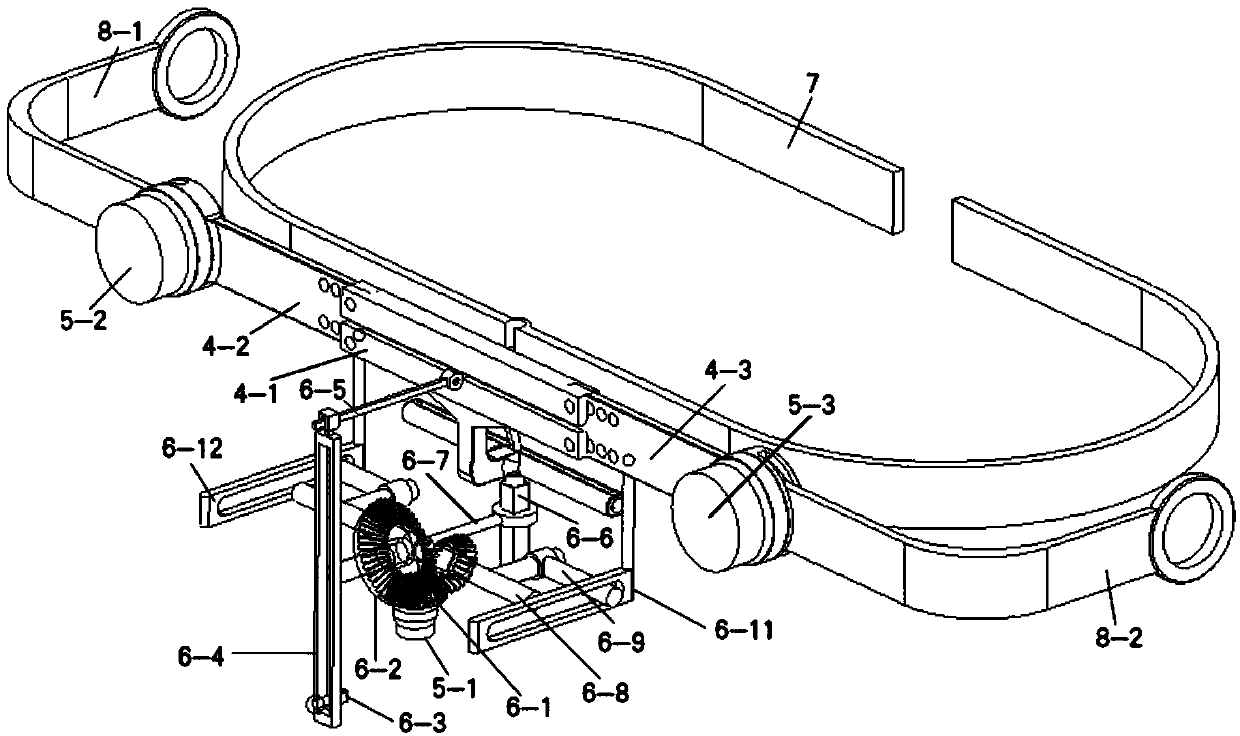

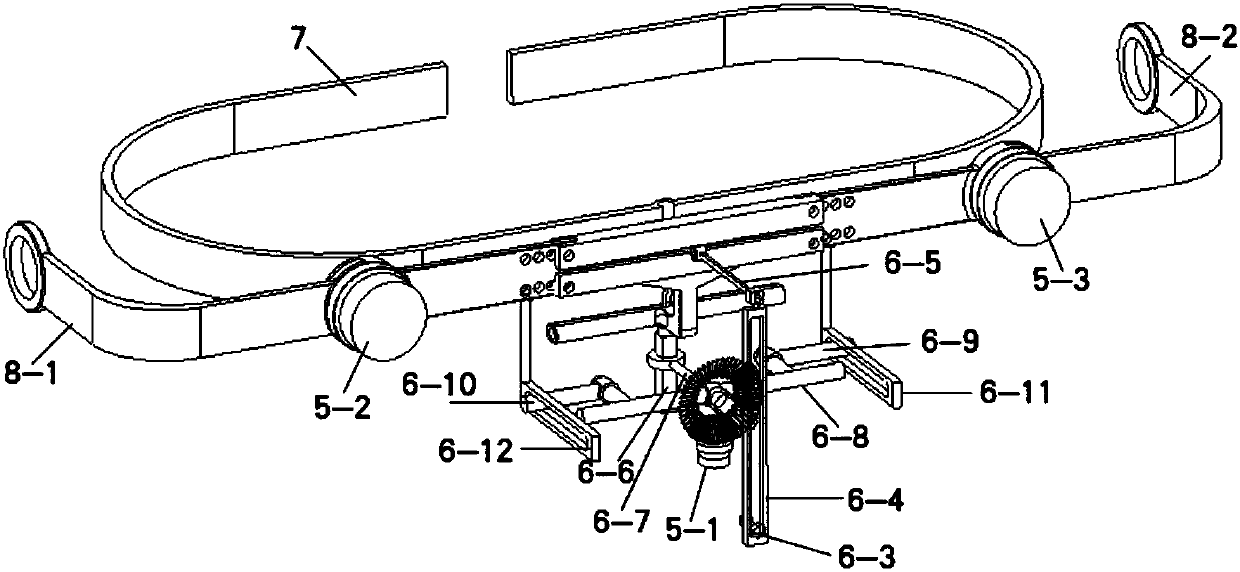

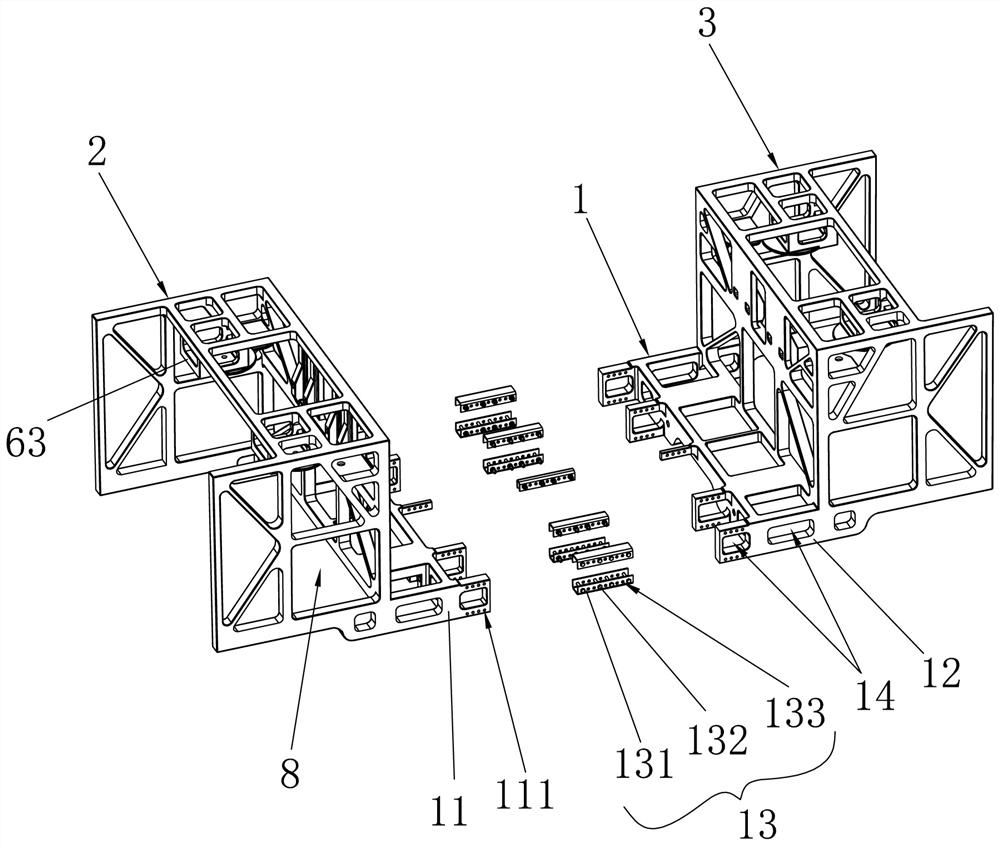

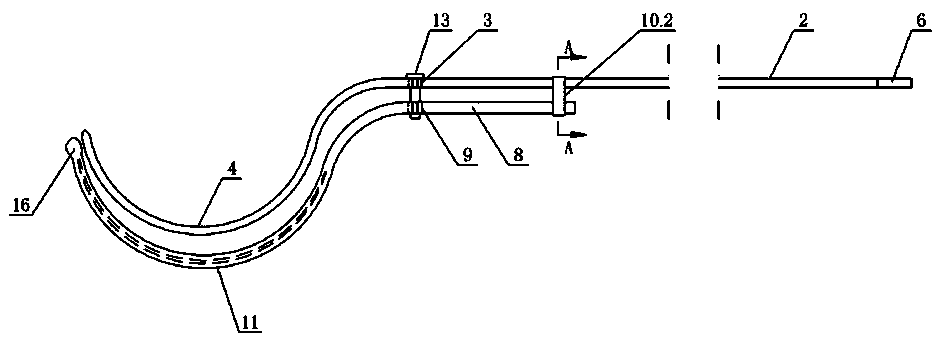

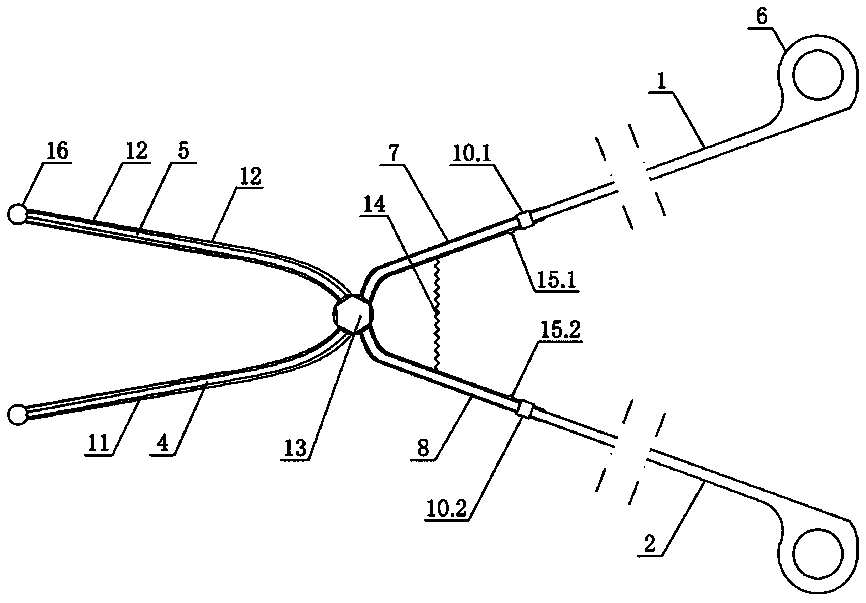

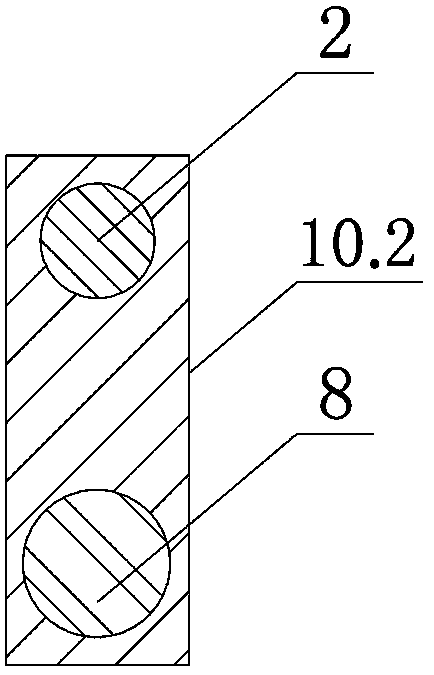

An exoskeleton-based wearable lower limb rehabilitation robot

InactiveCN105997441AMeet rehabilitation pace requirementsMeet width requirementsWalking aidsHuman bodyOlder people

The invention provides an exoskeleton-based wearable lower limb rehabilitation robot comprising a waist device, two leg devices in left-right symmetry and two foot devices in left-right symmetry. The waist device is worn on a waist part of a human body and comprises a waist support part, a waist drive device, a waist movement component, a waist band and leg connecting members. The leg devices are in hinge joint with the waist device and are tightly tied to the legs of the human body via flexible tying belts, and each leg device comprises a leg drive device, a thigh part and a shank part. The foot devices are worn on the feet of the human body and are in hinge joint with the leg devices; each foot device comprises a foot drive device, a foot support and a bottom plate. The exoskeleton-based wearable lower limb rehabilitation robot can assist patients or old people in completing lower limb rehabilitation training including waist movement and improves the lower limb rehabilitation training effect; the robot is simple and compact in structure, is convenient to wear, can be worn by people of different body forms through an adjusting mechanism, and is wide in application range; the waist mechanism can meet the waist movement rules under different paces.

Owner:NANJING UNIV OF SCI & TECH

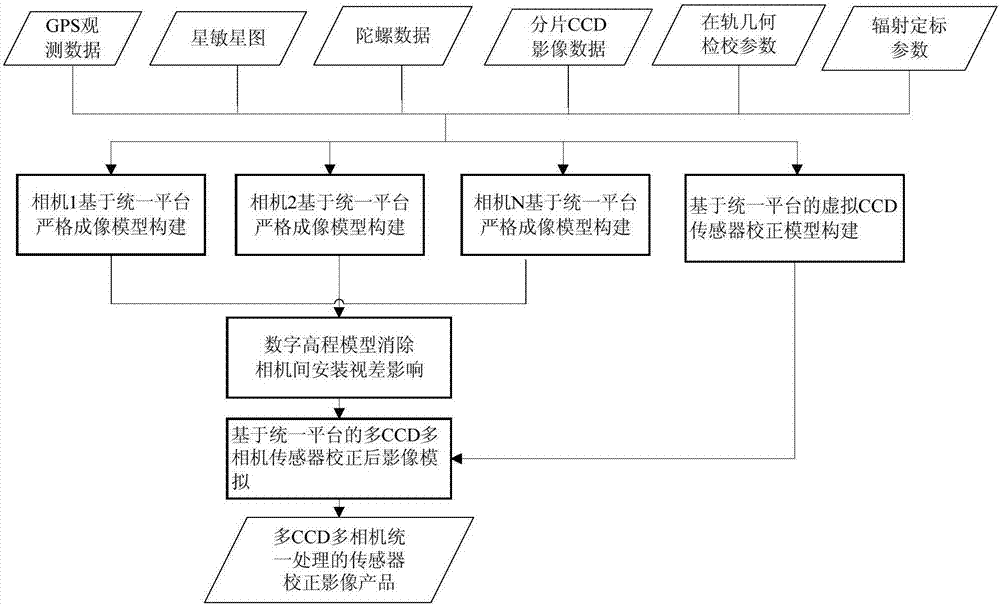

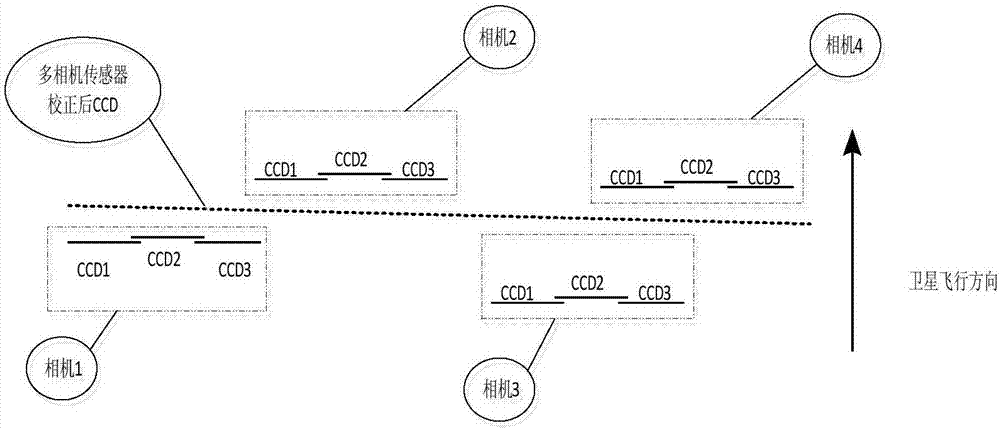

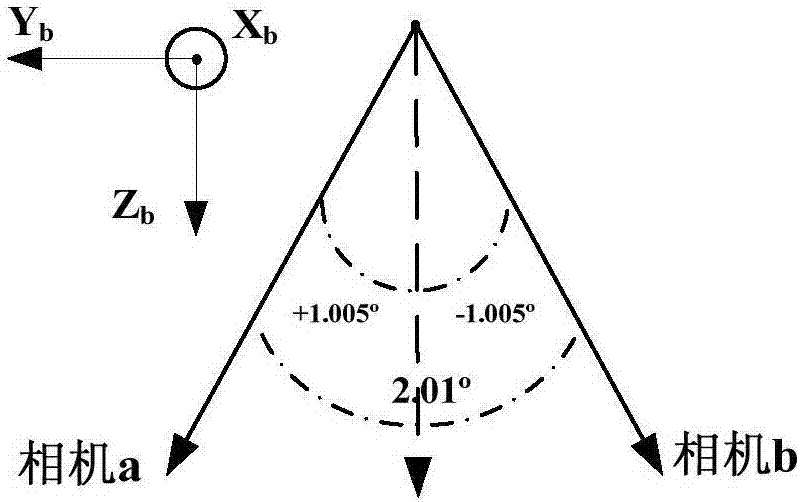

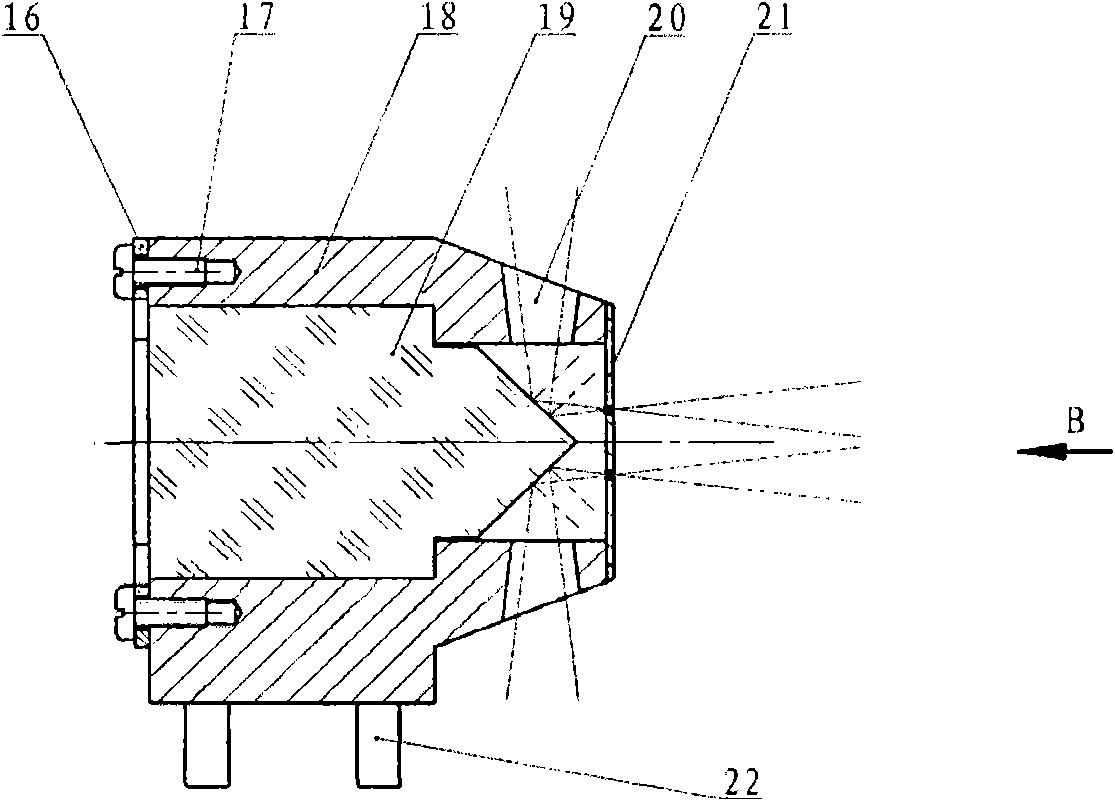

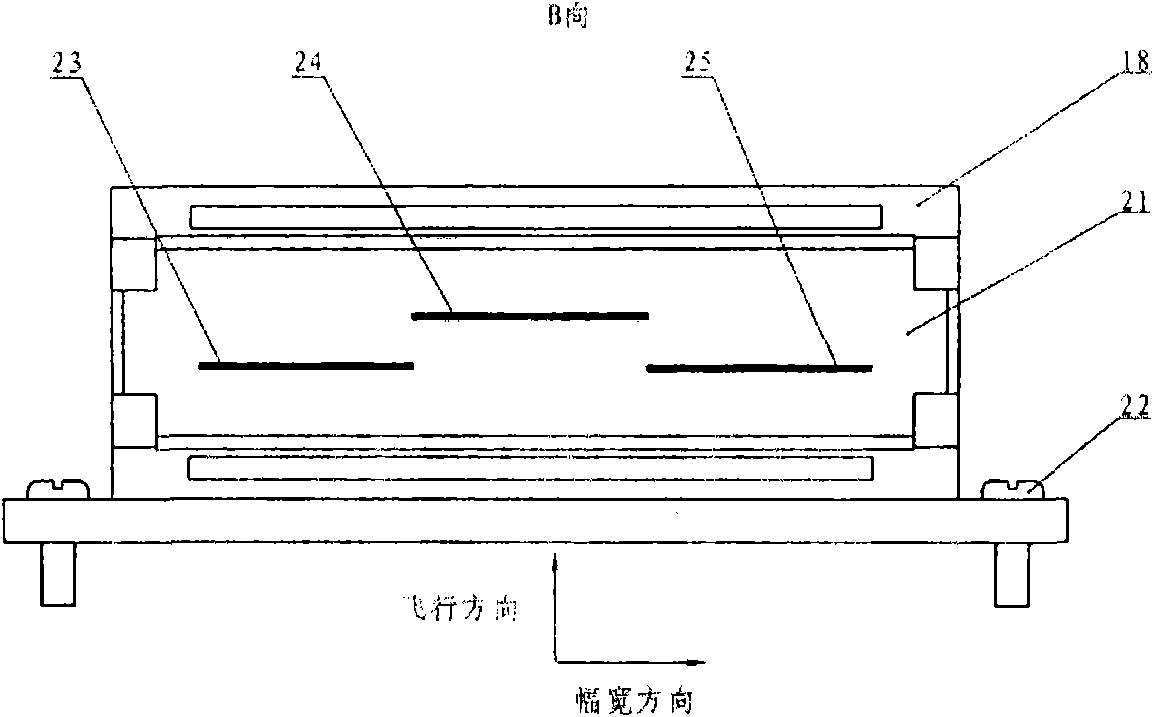

Sensor calibration method for optical remote sensing satellite multi-CCD multi-camera unified processing

ActiveCN106895851ARegistration accuracy cannot be guaranteedMeet width requirementsPhotogrammetry/videogrammetryMulti cameraDirect transformation

The invention relates to a sensor calibration method for optical remote sensing satellite multi-CCD multi-camera unified processing. The sensor calibration method comprises the following steps: firstly taking mounting positions of CCD linear arrays of multiple cameras on an optical remote sensing satellite platform along the direction of a track as benchmark, constructing a virtual CCD linear array, and mounting the virtual CCD linear array on a center line of multiple cameras along the direction of the track; secondly, establishing a strict imaging model of a unified platform; thirdly, constructing a strict imaging model of each CCD; fourthly, for each image point on the virtual CCD linear array, according to direct transformation of the strict imaging model of the unified platform, calculating plane coordinates of a ground point of the image point, and assigning a value to the average elevation of the ground point, so that geographic coordinates of the ground point are obtained; fifthly, according to the strict imaging model of each CCD and the geographic coordinates, calculated in the step four, of the ground point, calculating image point coordinates of the image point by adopting strict imaging model inverse transformation, and assigning a value to a virtual CCD image point; and sixthly, repeating the steps four and five until processing of all the image elements on a virtual CCD is completed.

Owner:CHINA CENT FOR RESOURCES SATELLITE DATA & APPL

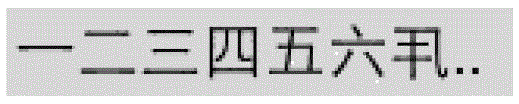

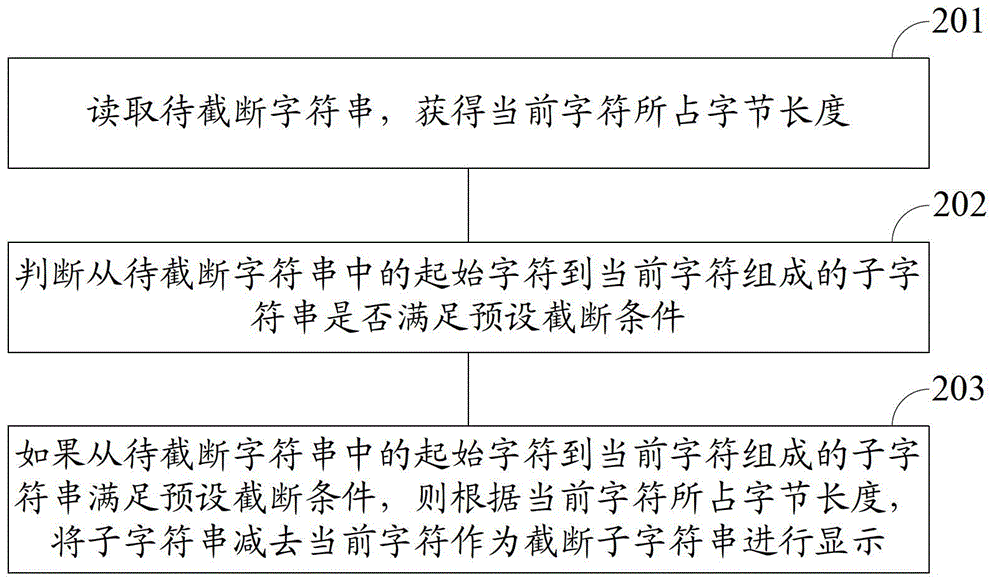

Character string truncation method and device

ActiveCN104063362AWill not display garbled charactersMeet width requirementsNatural language data processingSpecial data processing applicationsByteSubstring

The invention discloses a character string truncation method which is used for preventing messy codes in a character string truncation process. The method comprises steps as follows: reading a to-be-truncated character string, and acquiring a byte length occupied by a current character; judging whether a substring consisting of characters between an initial character and the current character in the to-be-truncated character string meets a preset truncation condition; if the character substring consisting of characters between the initial character and the current character in the to-be-truncated character string meets the preset truncation condition, subtracting the current character from the substring according to the byte length occupied by the current character, taking a product as a truncated substring, and displaying the truncated substring. The invention discloses a character string truncation device.

Owner:TENCENT TECH (SHENZHEN) CO LTD

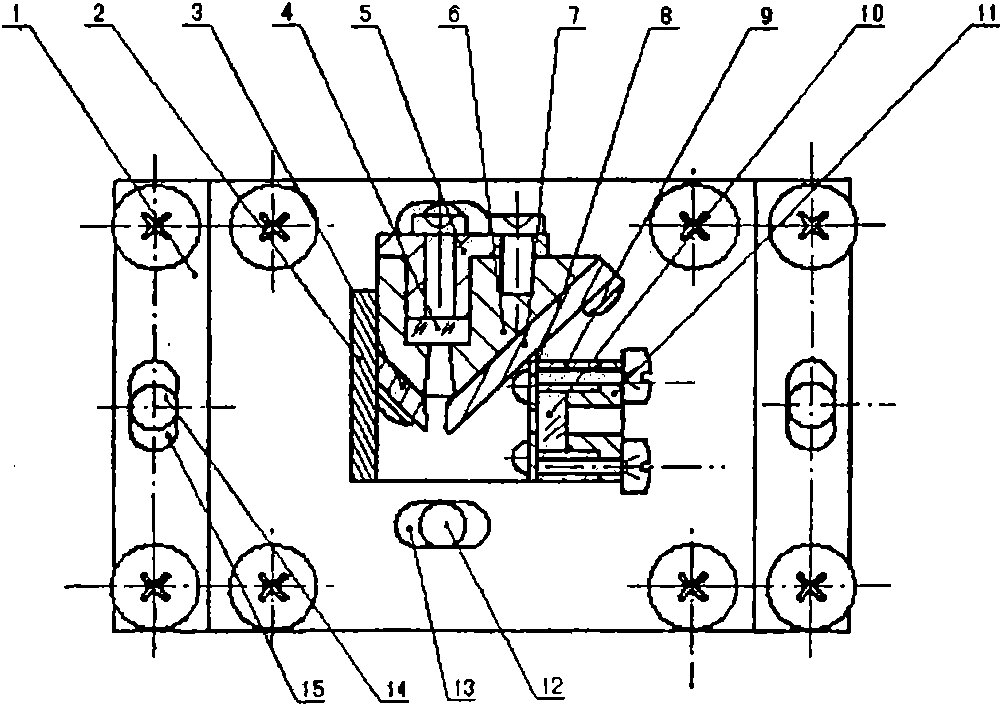

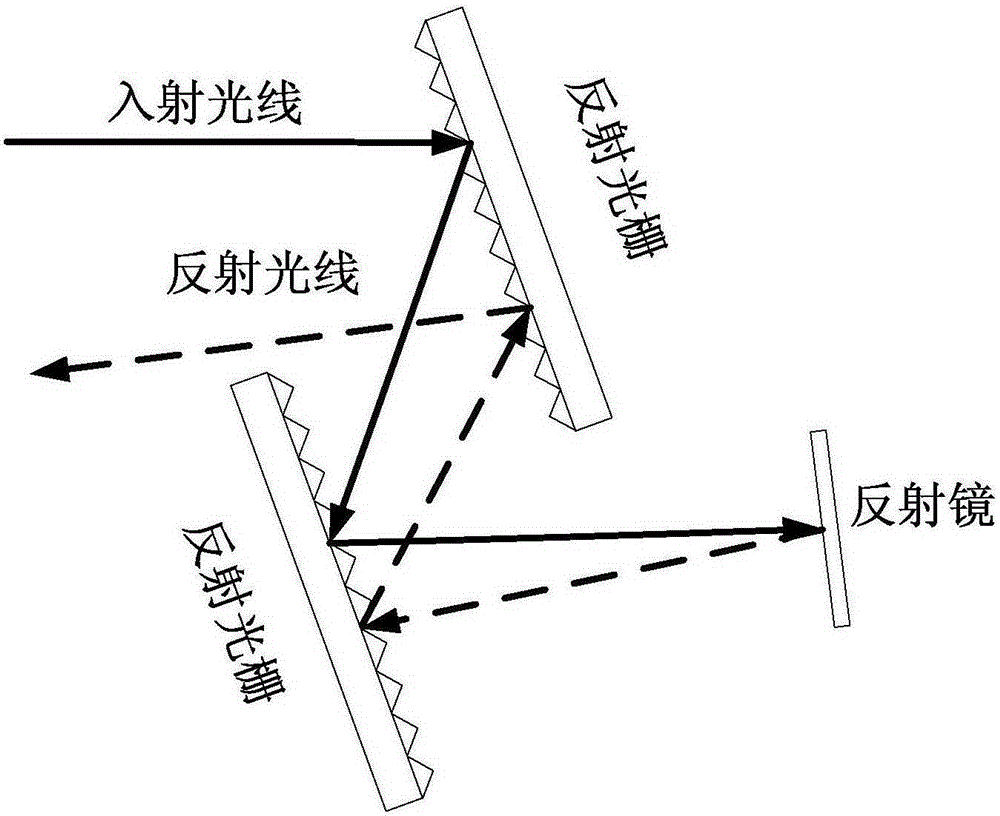

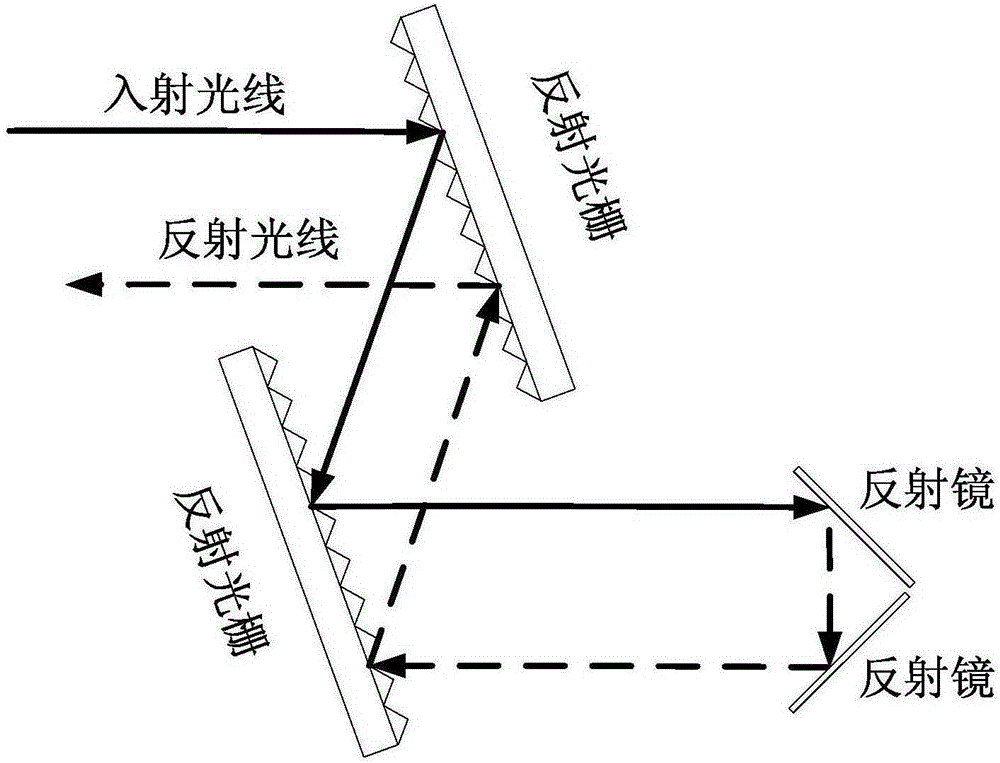

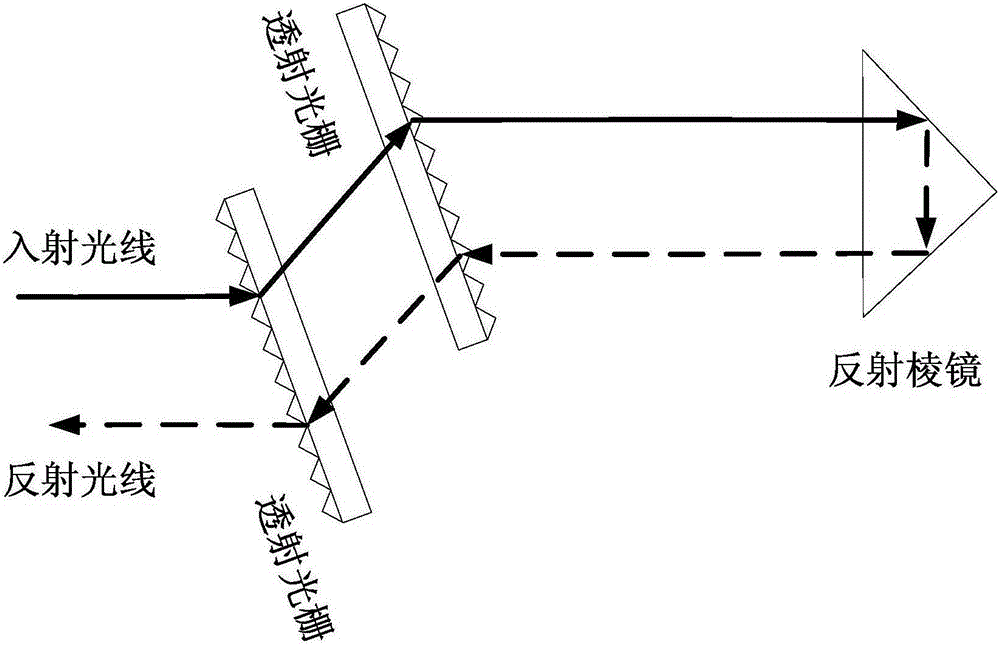

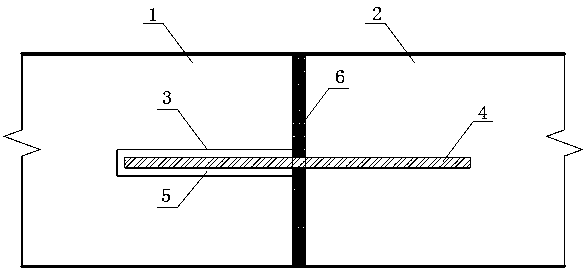

Field-of-view beam splitter of wide-width imaging spectrograph

InactiveCN101943602AIncrease or decrease quantityMeeting Imaging NeedsRadiation pyrometrySpectrometry/spectrophotometry/monochromatorsBeam splitterSpectrograph

The invention discloses a field-of-view beam splitter of a wide-width imaging spectrograph, belonging to the field of onboard and spaceborne optical remote sensing, the field-of-view beam splitter of the wide-width imaging spectrograph comprises a spectroscope lock block, spectroscope lock block fixing screw, a base, a spectroscope, a base aperture, a slit plate and a base fixing screw, wherein the slit plate is provided with a first slit, a second slit and a third slit, and the amount of the slits on the slit plate is set as required; the spectroscope is stuck and installed in the cavity of the base in an unstressed mode; the spectroscope lock block presses a reflector on the tail end of the base; the spectroscope lock block is fixedly connected with the base by the pectroscope lock block fixing screw; and the slit plate is stuck on the front end with the base aperture of the base in an unstressed mode. Under the condition that a large-size two-dimensional matrix array detector is hard to obtain, high-resolution and wide-width spectrum imaging remote sensing of the imaging spectrograph can be realized through field-of-view separation and splicing.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

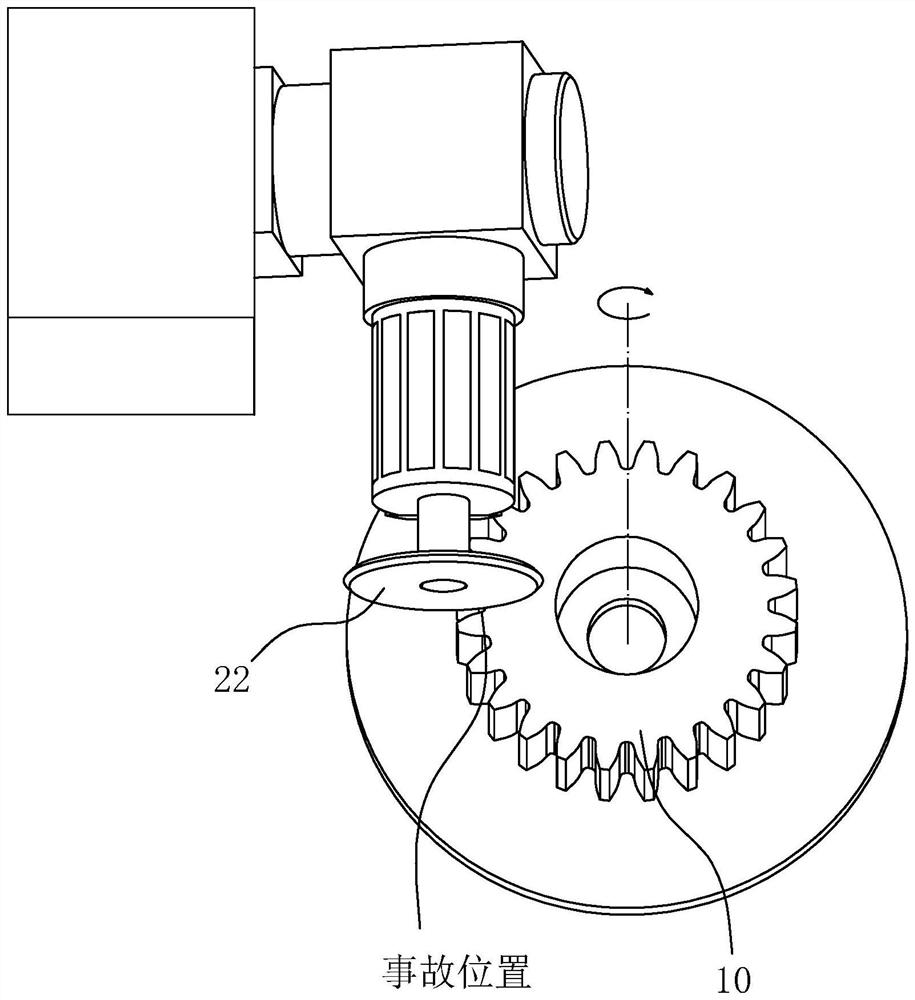

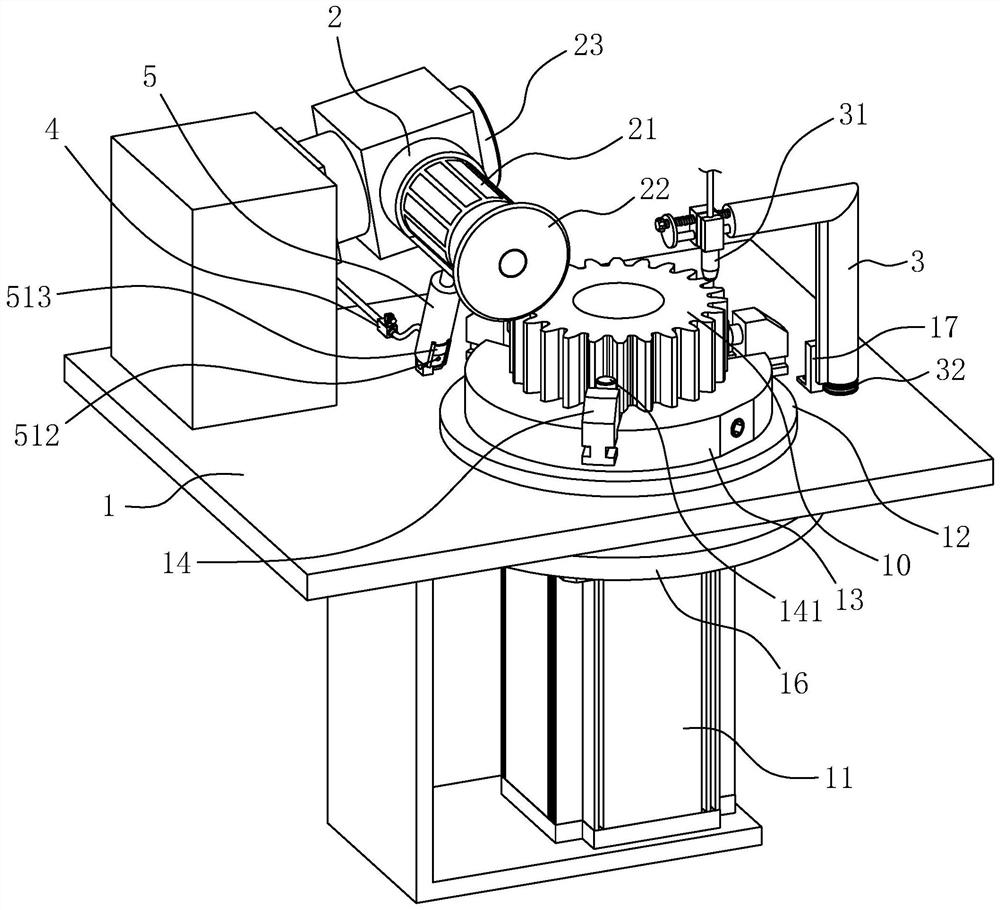

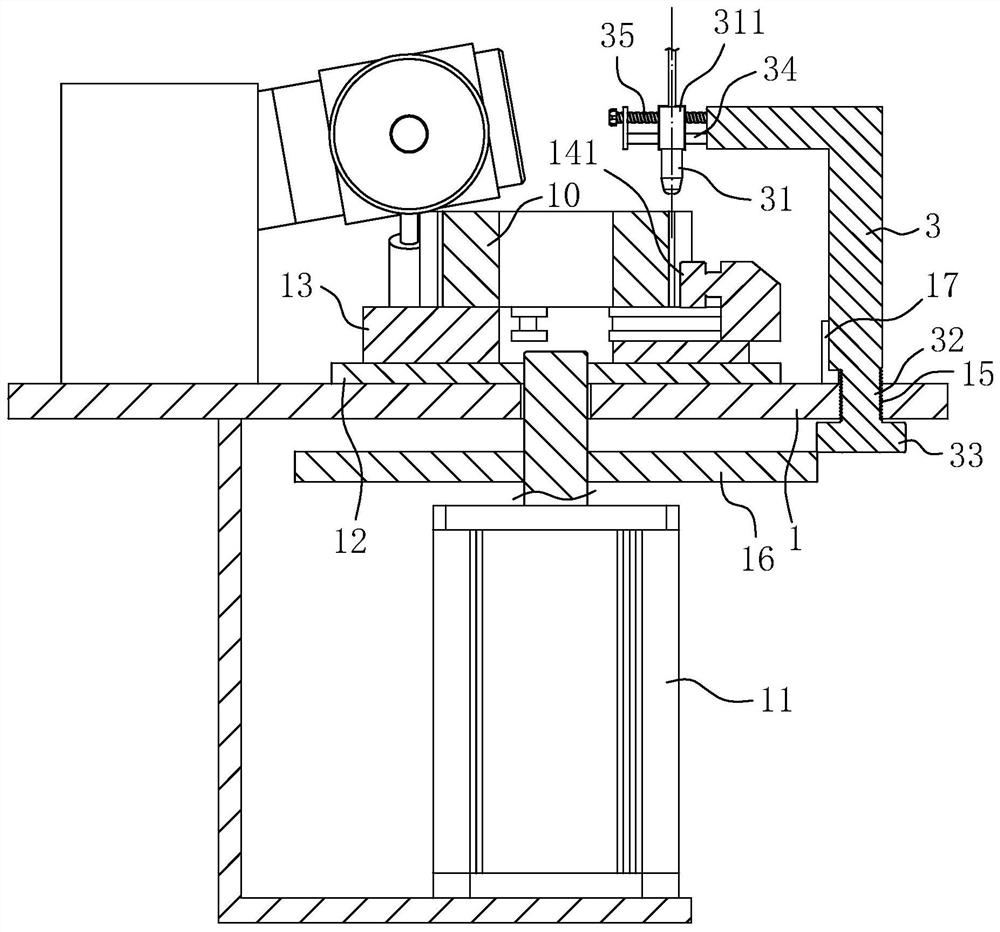

Grinding machine for gear machining

ActiveCN111761444AReduce breakageReduce the chance of flying out accidentsEdge grinding machinesGrinding drivesGear wheelElectric machinery

The invention relates to the field of gear machining, in particular to a grinding machine for gear machining. The grinding machine comprises a base, wherein a first motor, and a rotating seat driven by the first motor to rotate are arranged on the base, a swing arm is rotationally connected to the base through a first hinge shaft, a second motor and a grinding wheel driven by the second motor to rotate are arranged on the swing arm, a detection mechanism for detecting the tooth position of a gear workpiece are arranged on the base, an elastic mechanism are further arranged on the base, and theelastic mechanism is connected with the swing arm; and when the detection mechanism detects that the grinding wheel is located at the position where the bottom of a tooth groove of the gear workpieceenters a tooth root part, the elastic mechanism applies force to the swing arm to enable the pressure acting on the gear workpiece by the grinding wheel to be reduced. The grinding wheel of the grinding machine locally relieves the downward pressure at the position where the bottom of the tooth groove enters the tooth root part, so that the grinding wheel is not prone to clamp at the position, and the accident probability of the grinding wheel breakage is reduced; and after the rotating speed of the first motor is increased, the grinding efficiency of the gear workpiece can be improved, and after the rotating speed of the first motor changes, the grinding machine can still play a role in reducing the accident probability.

Owner:浙江三欢齿轮有限公司

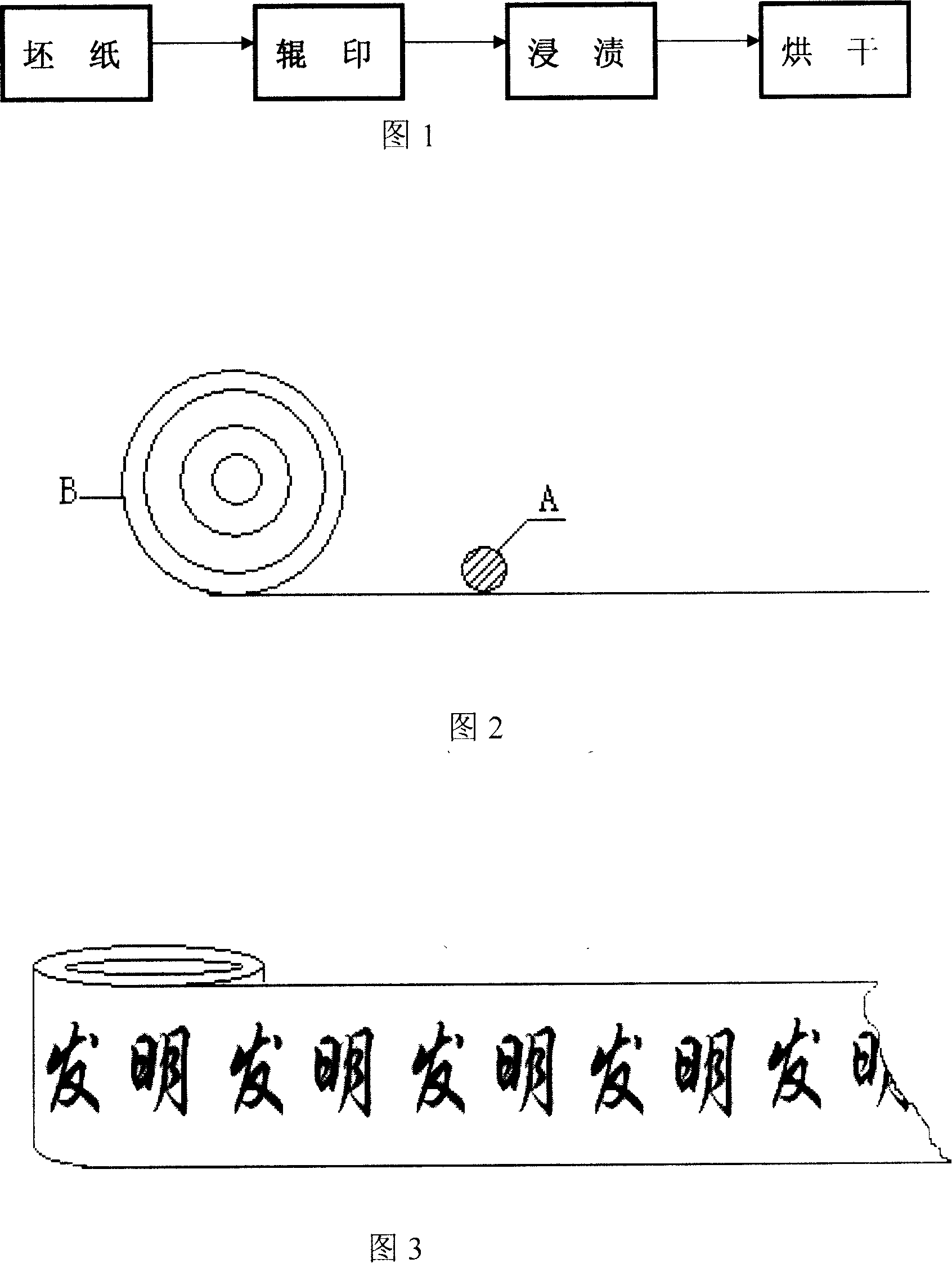

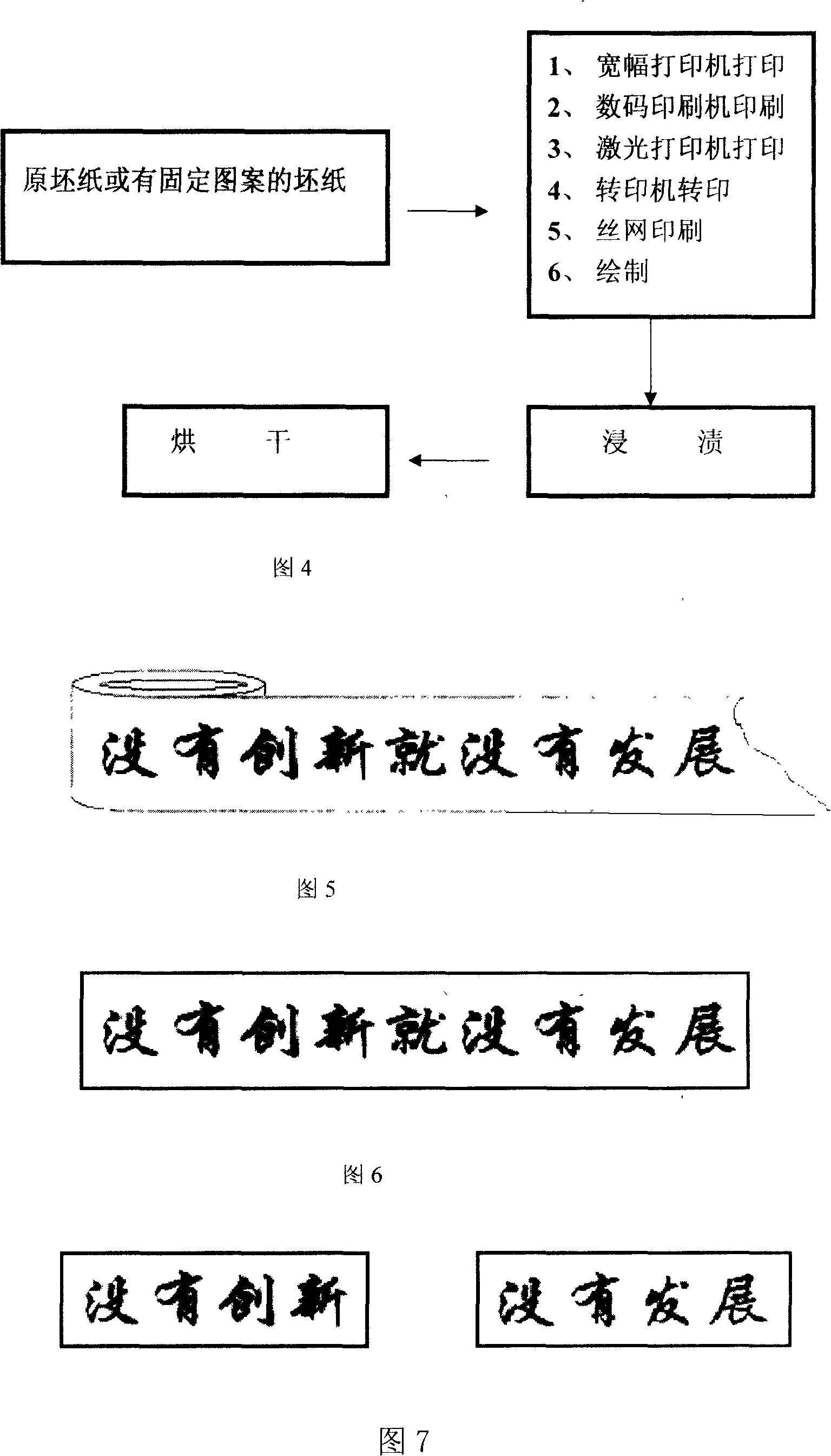

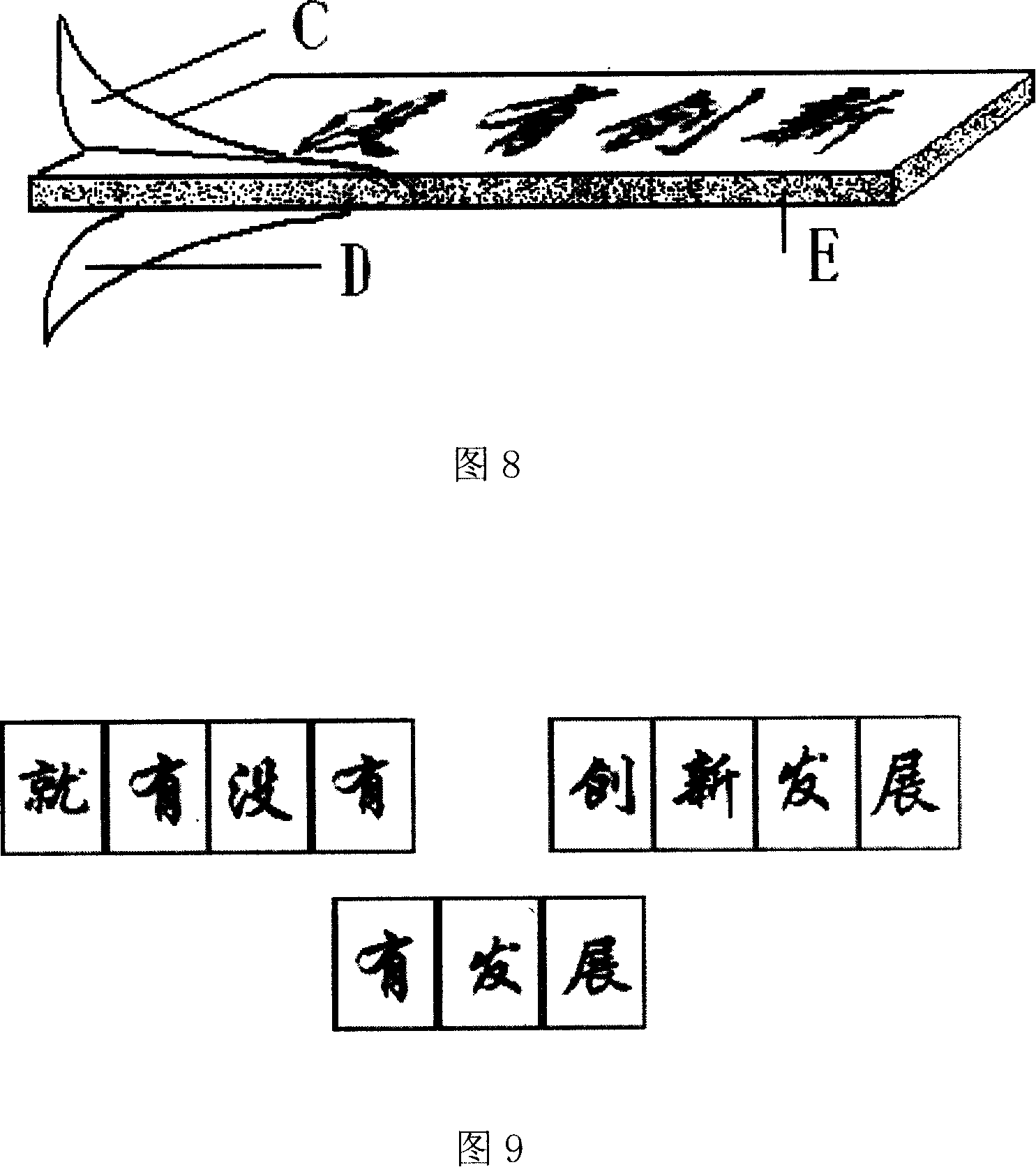

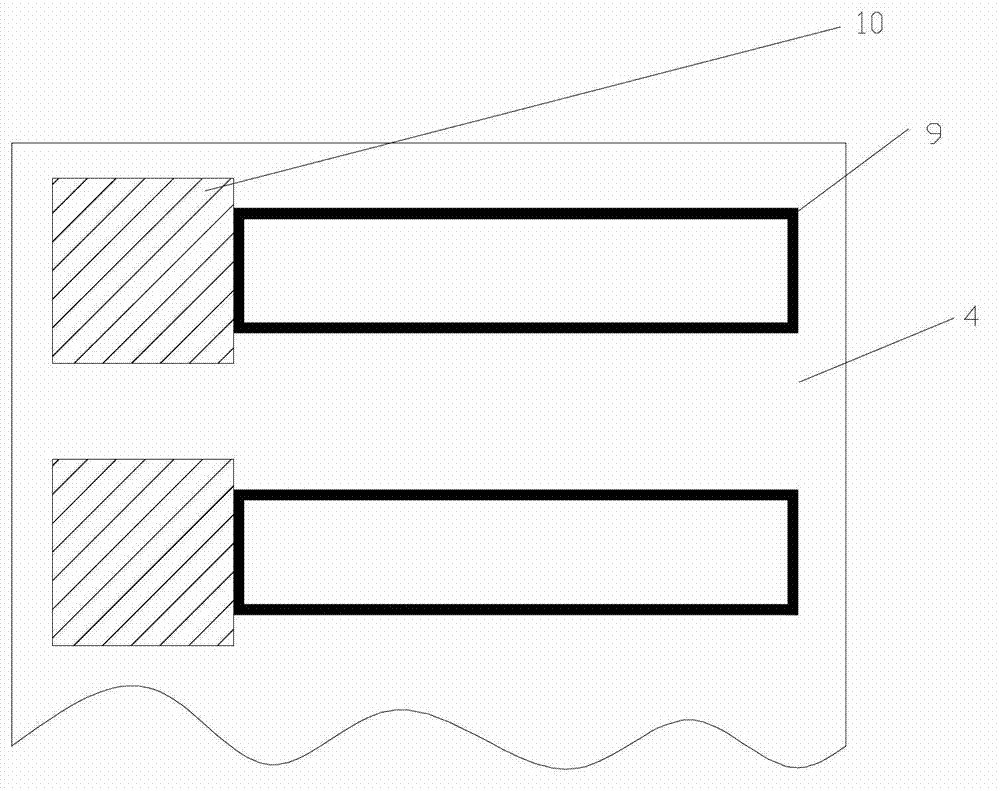

Multi-pattern melamine dipping decorative paper, manufacturing method and application thereof

InactiveCN101148848AFacilitate rearrangementEasy to combineNon-fibrous pulp additionSpecial paperMelamine resinPolyresin

The present invention is one kind of melamine dipped decoration paper with different patterns and its making process and application. The melamine dipped decoration paper with different patterns is made with a paper base of 5-5000 m length, and through printing and / or drawing to form texts and / or graphics, and dipping in urea-formaldehyde glue, melamine glue or melamine resin to form protective polymer layer. It is applied as the decoration material for furniture and artificial board.

Owner:赵国强

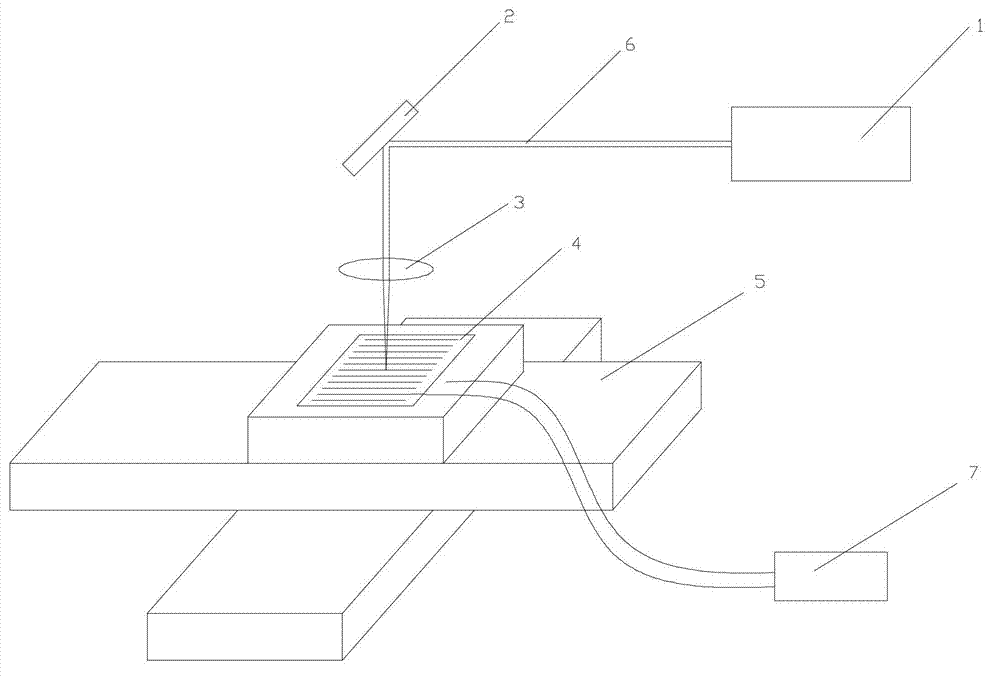

Detection method of selective doping region property

ActiveCN102856225AMeet width requirementsHigh resolutionSemiconductor/solid-state device testing/measurementPhotocurrentLaser beams

The invention discloses a detection method of a selective doping region property. The method comprises the steps of scanning a selective doping region and a peripheral region thereof by utilizing a focusing laser beam; and meanwhile, measuring photoelectrical current generated by each point, and comparing and analyzing the change of the photoelectrical current before and after selective doping to characterize the uniformity and the resistance of the selective doping. Therefore, a process of preparing a selective emission electrode is guided to be improved.

Owner:广东铨镁能源集团有限公司

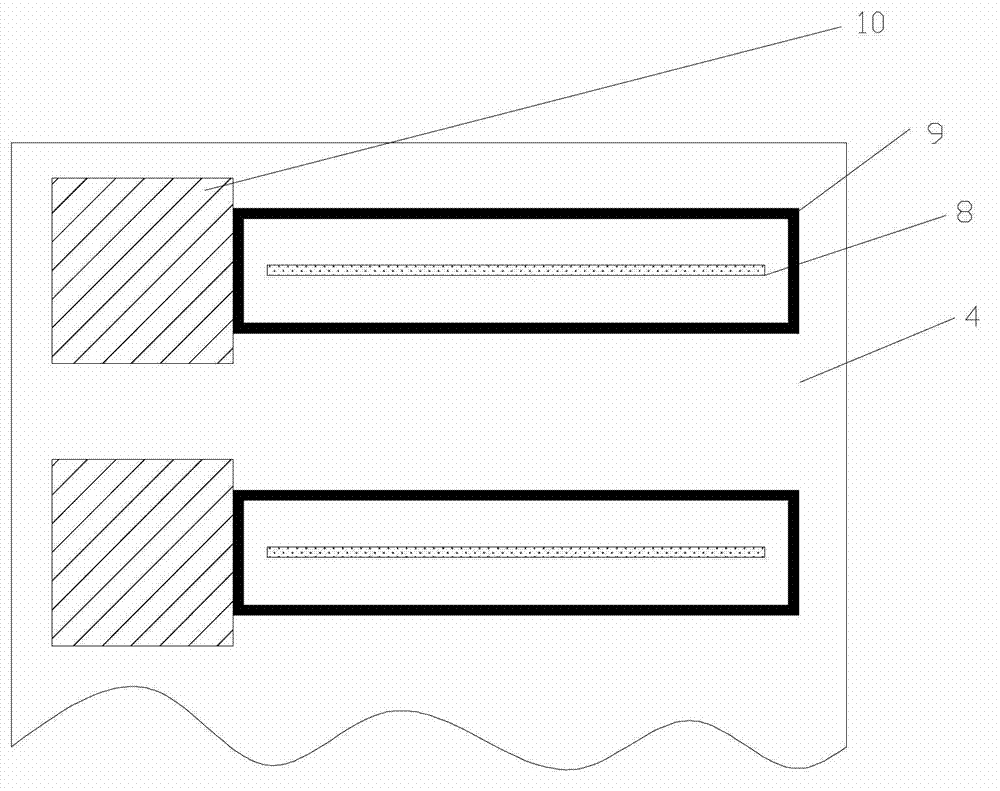

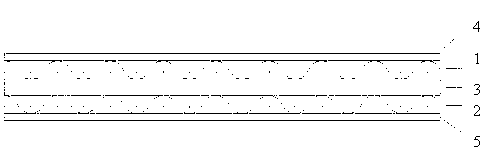

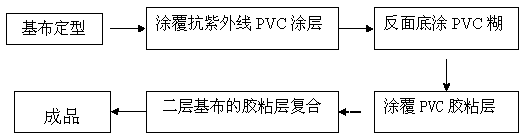

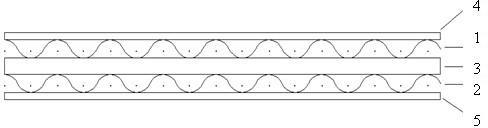

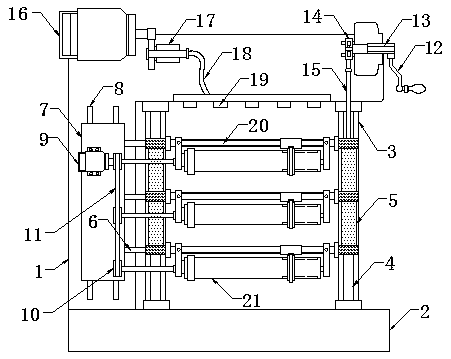

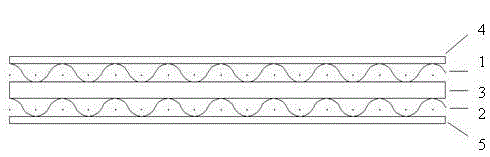

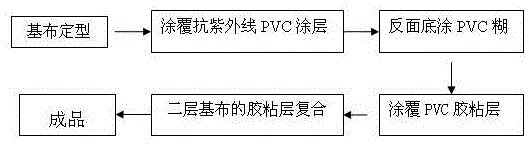

Industrial non-directional curtain belt and manufacturing method thereof

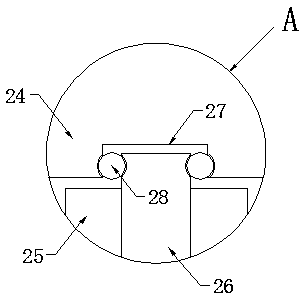

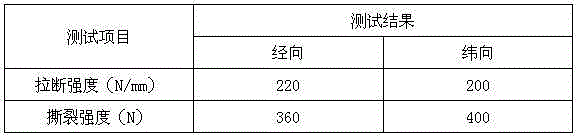

ActiveCN102704822AMeet width requirementsAvoid widening processShutters/ movable grillesFibre treatmentPolyesterPolyvinyl chloride

Owner:SHANGHAI YONGLI BELTING +1

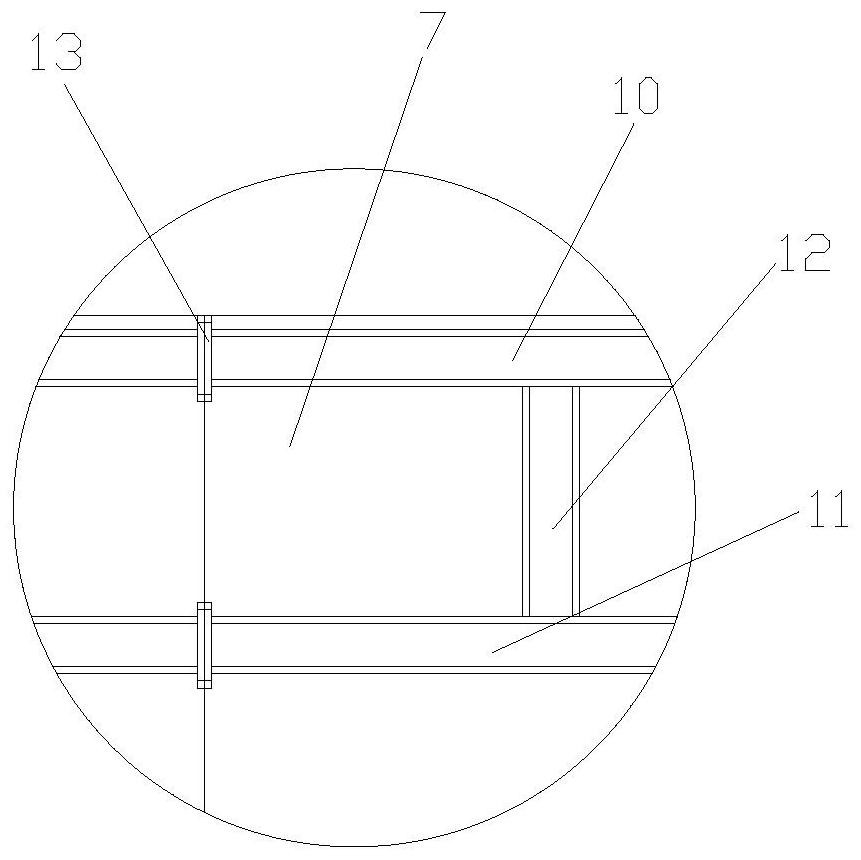

Femtosecond laser pulse compression module

The present invention relates to a femtosecond laser pulse compression module. The femtosecond laser pulse compression module adopts the transmission-type grating pair, a reflecting assembly adopts a right angle emission prism, and the grating pair are spaced and adjustable. A pulse compression module comprises a grating 11, a grating clamp 13, a grating 22 and a grating clamp 24, the right angle emission prism 6 and a prism fixing clamp orderly. The femtosecond laser pulse compression module of the present invention adopts the transmission-type gratings, is high in efficiency, at the same time, the gratings are spaced and adjustable, so that the femtosecond pulse output of different pulse widths can be obtained, and the different pulse width demands can be satisfied.

Owner:HUBEI JIEXUN PHOTOELECTRIC

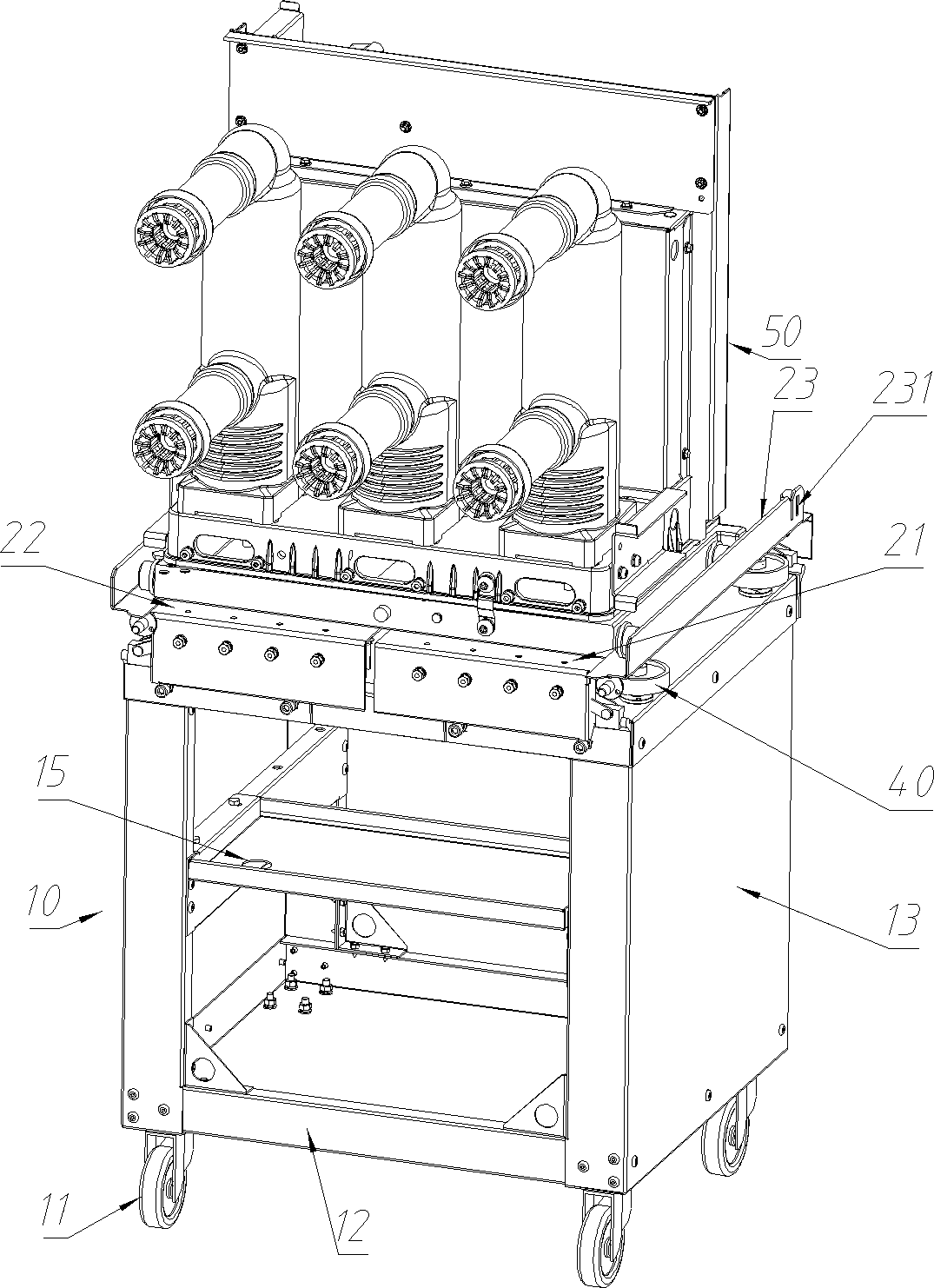

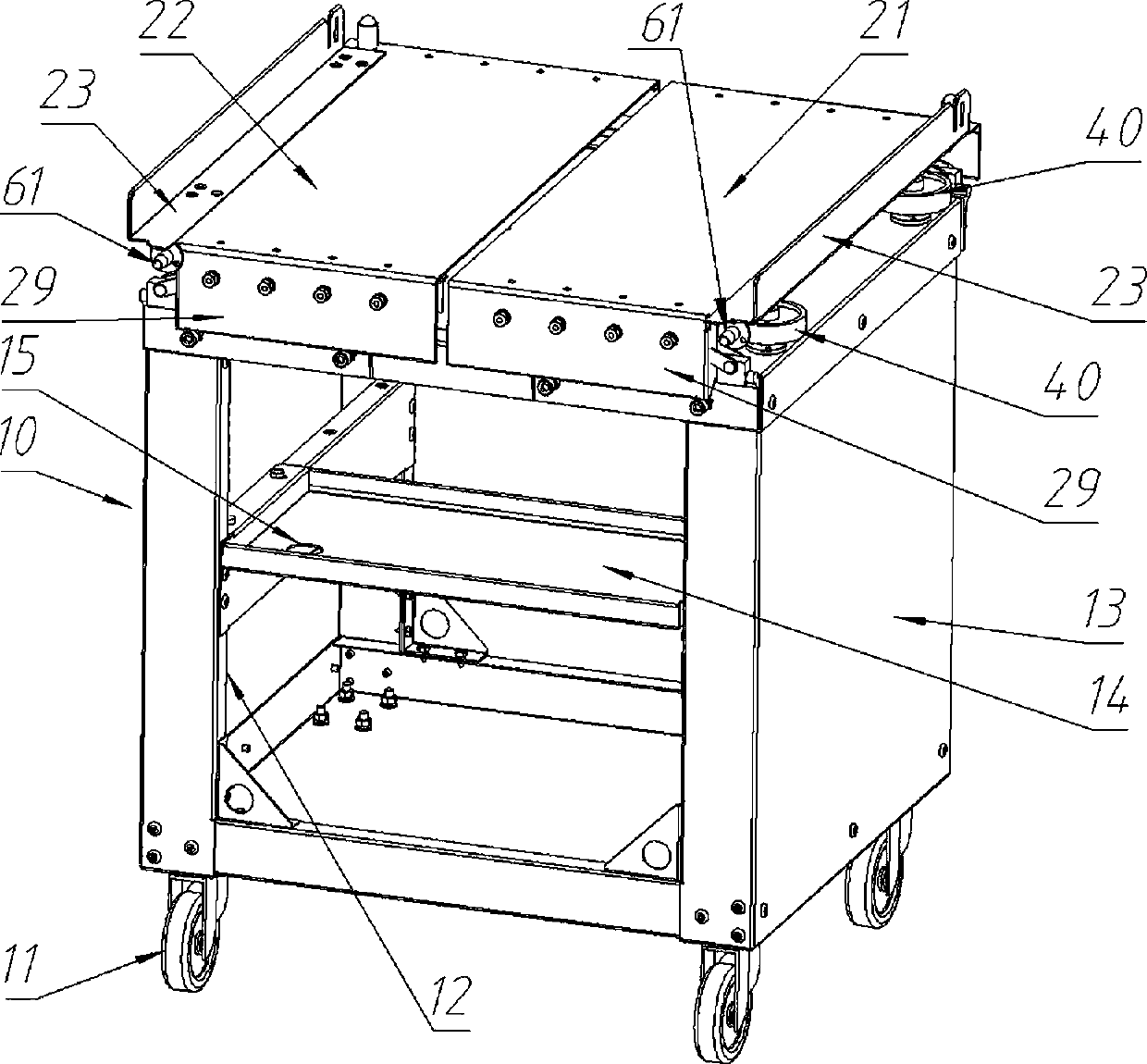

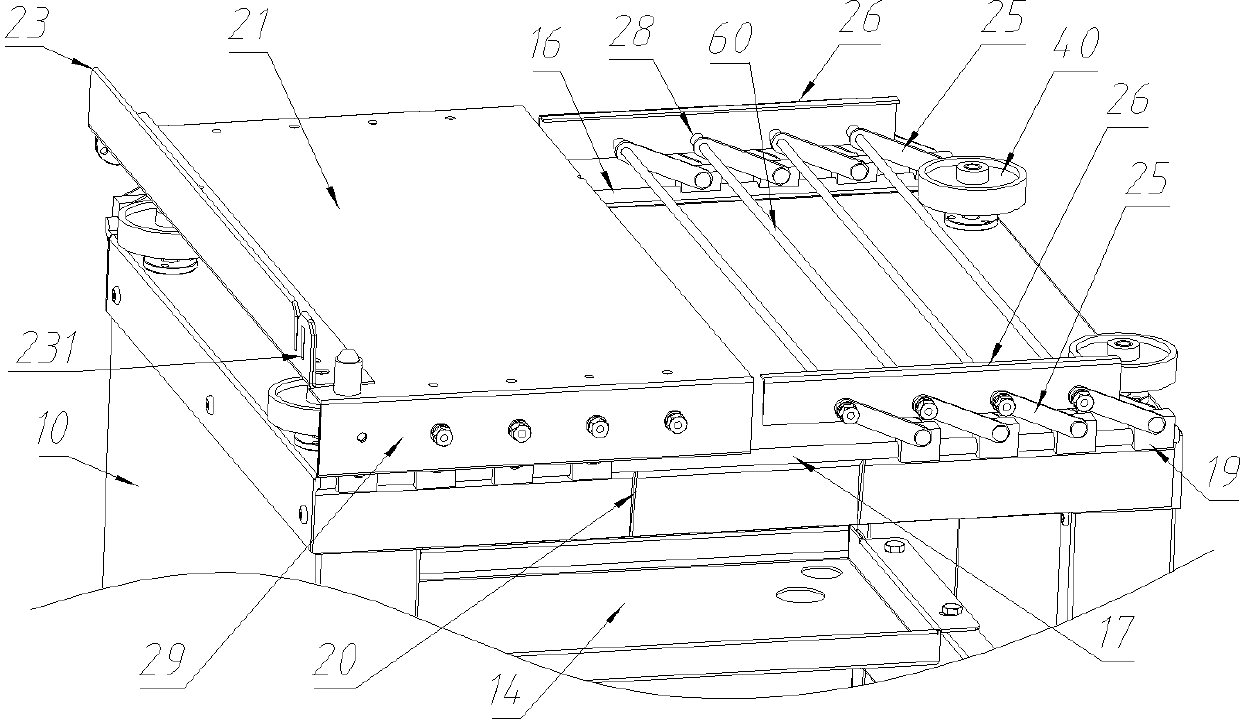

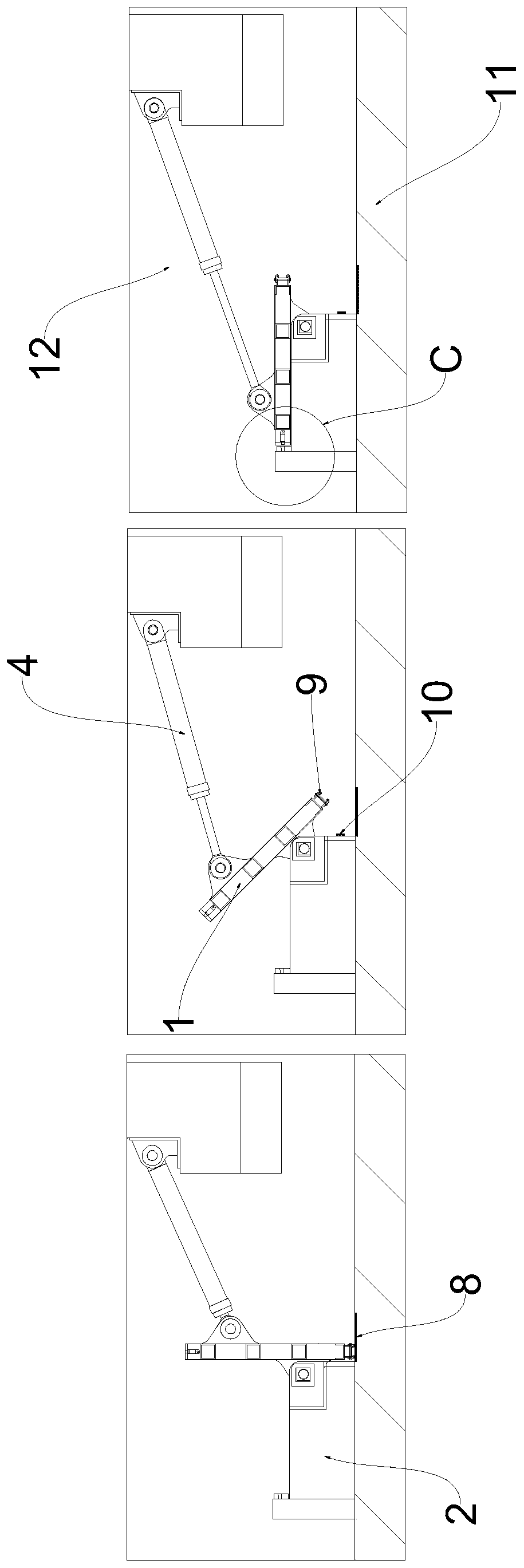

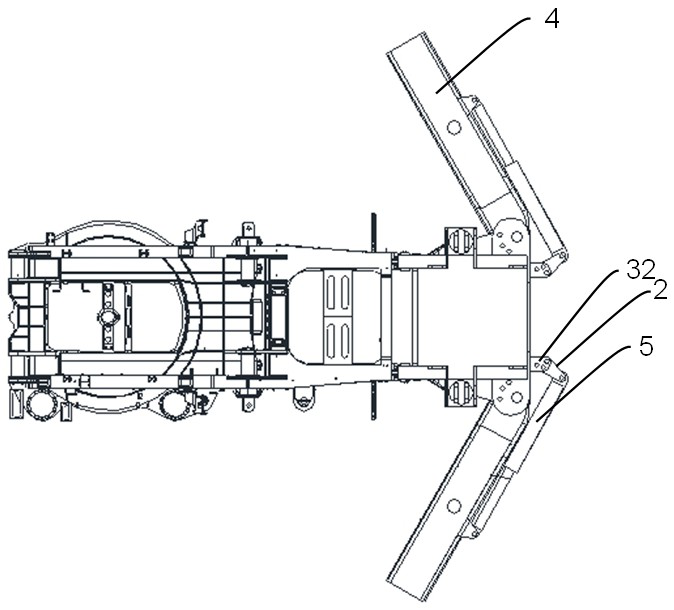

Circuit breaker transfer trolley

ActiveCN109747694ASpacing adjustmentGuaranteed spacingHand carts with multiple axesArchitectural engineeringCircuit breaker

The invention relates to a circuit breaker transfer trolley, which comprises a trolley frame and a bearing table arranged on the trolley frame. Handcart guide rails used for supporting and guiding a circuit breaker handcart are arranged on the bearing table in a left-right spaced mode, the bearing table comprises a left bearing table and a right bearing table, and the left bearing table and the right bearing table are mutually independent and are hinged to the trolley frame through corresponding left connecting rods and corresponding right connecting rods. The trolley frame and the bearing tables and the connecting rods on the corresponding sides form parallelogram mechanisms, and the left bearing table and the right bearing table have narrow bearing positions and wide bearing positions along with swing of the corresponding connecting rods, wherein at the narrow bearing positions, the left bearing table and the right bearing table are close to each other, and at the wide bearing positions, the left bearing table and the right bearing table are away from each other. The left bearing table and the right bearing table can swing left and right through the parallelogram mechanisms, andthe distance between the handcart guide rails can be conveniently guaranteed while width requirements of different switch cabinets are met. Compared with the prior art, operation is convenient, the structure is simple and the cost is low.

Owner:HENAN PINGGAO GENERAL ELECTRIC CO LTD +2

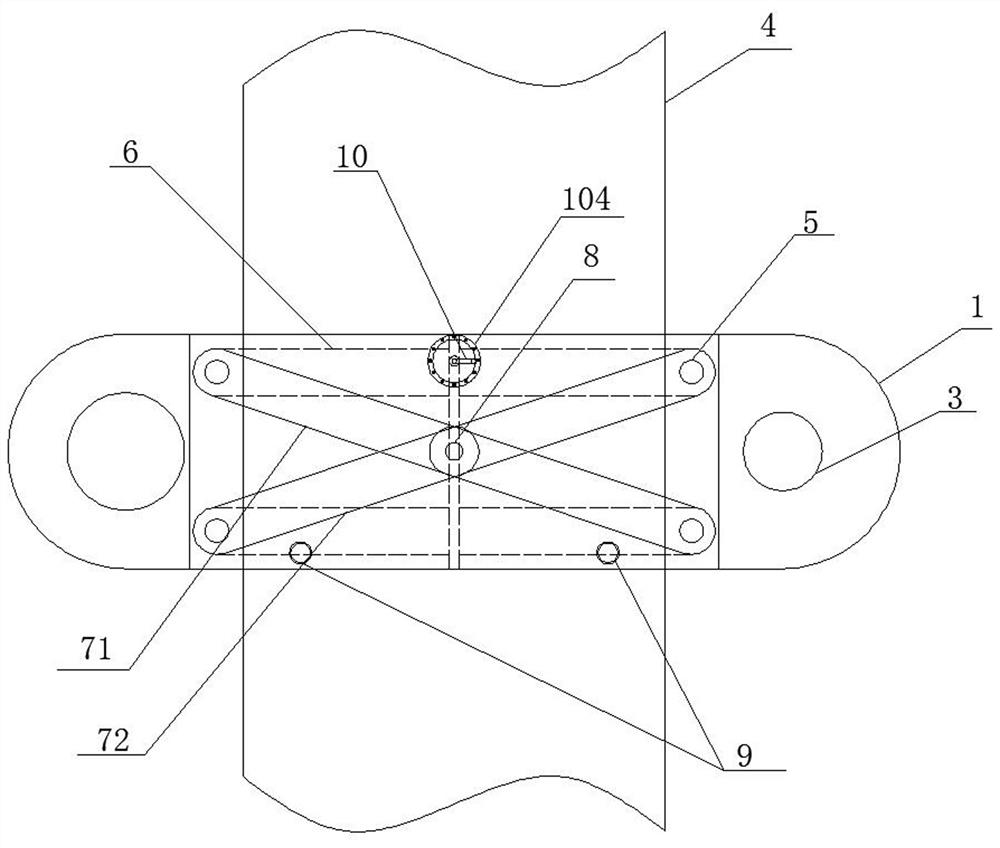

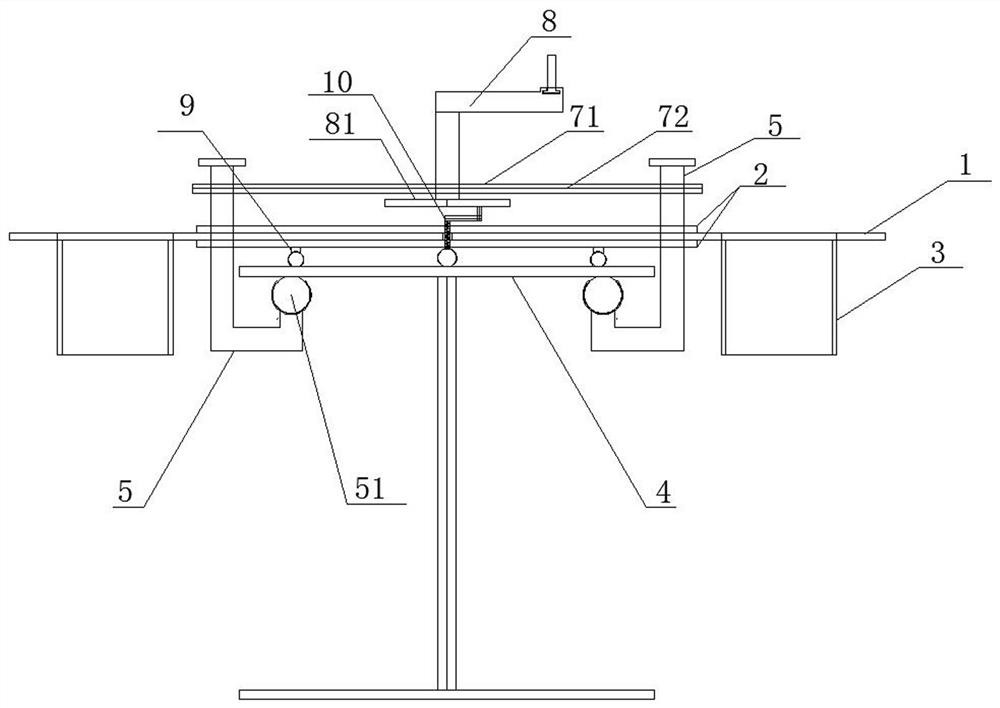

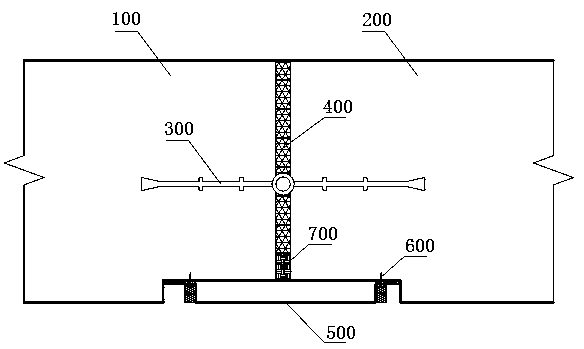

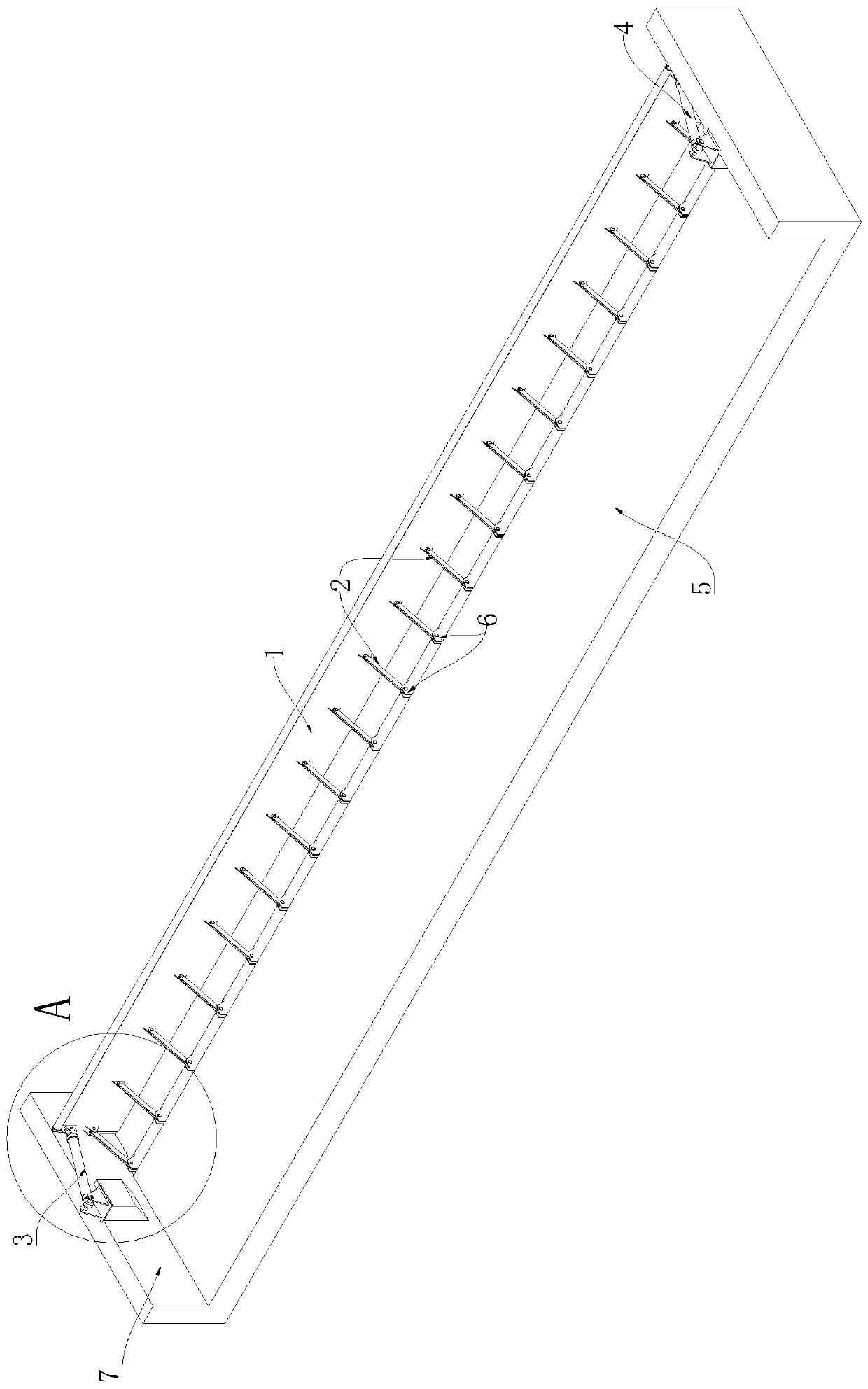

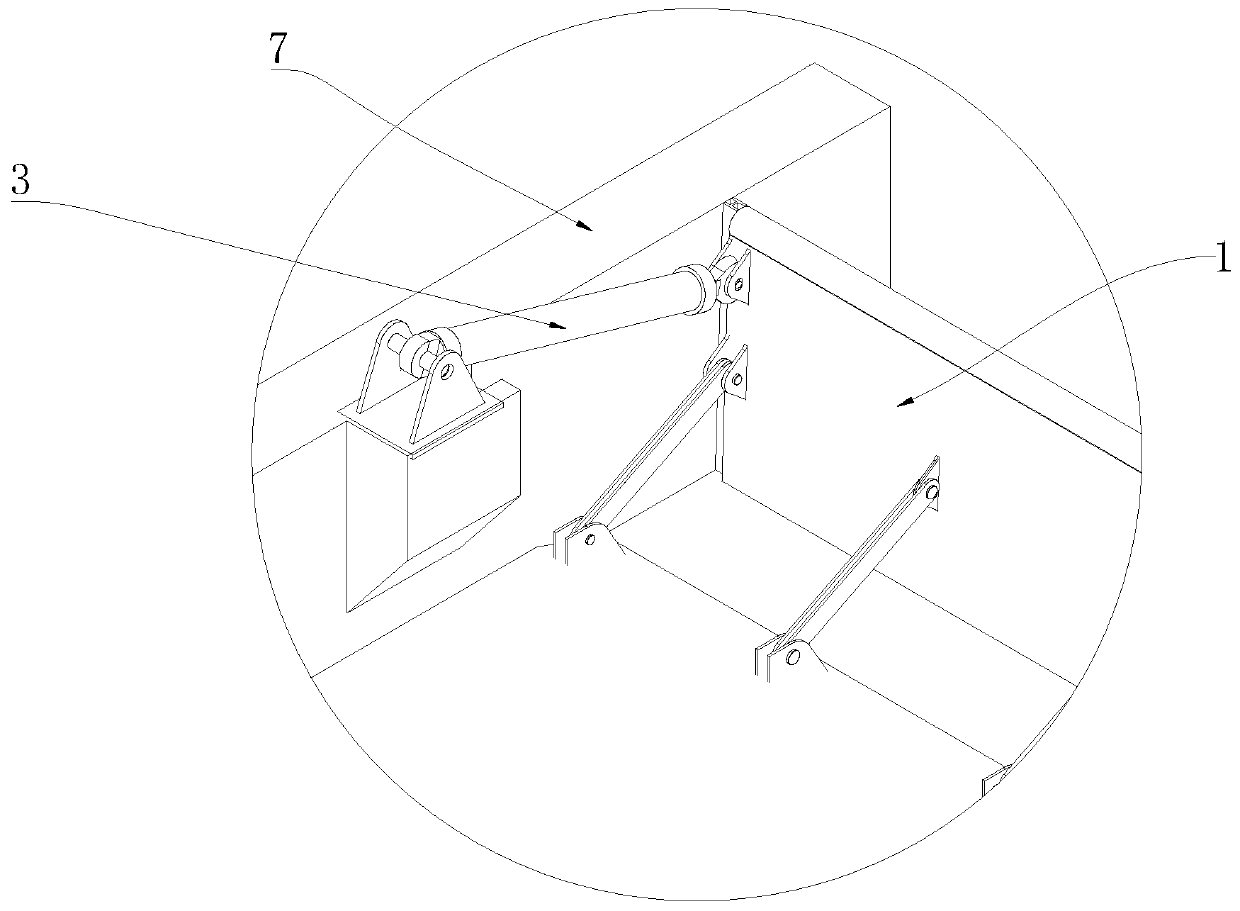

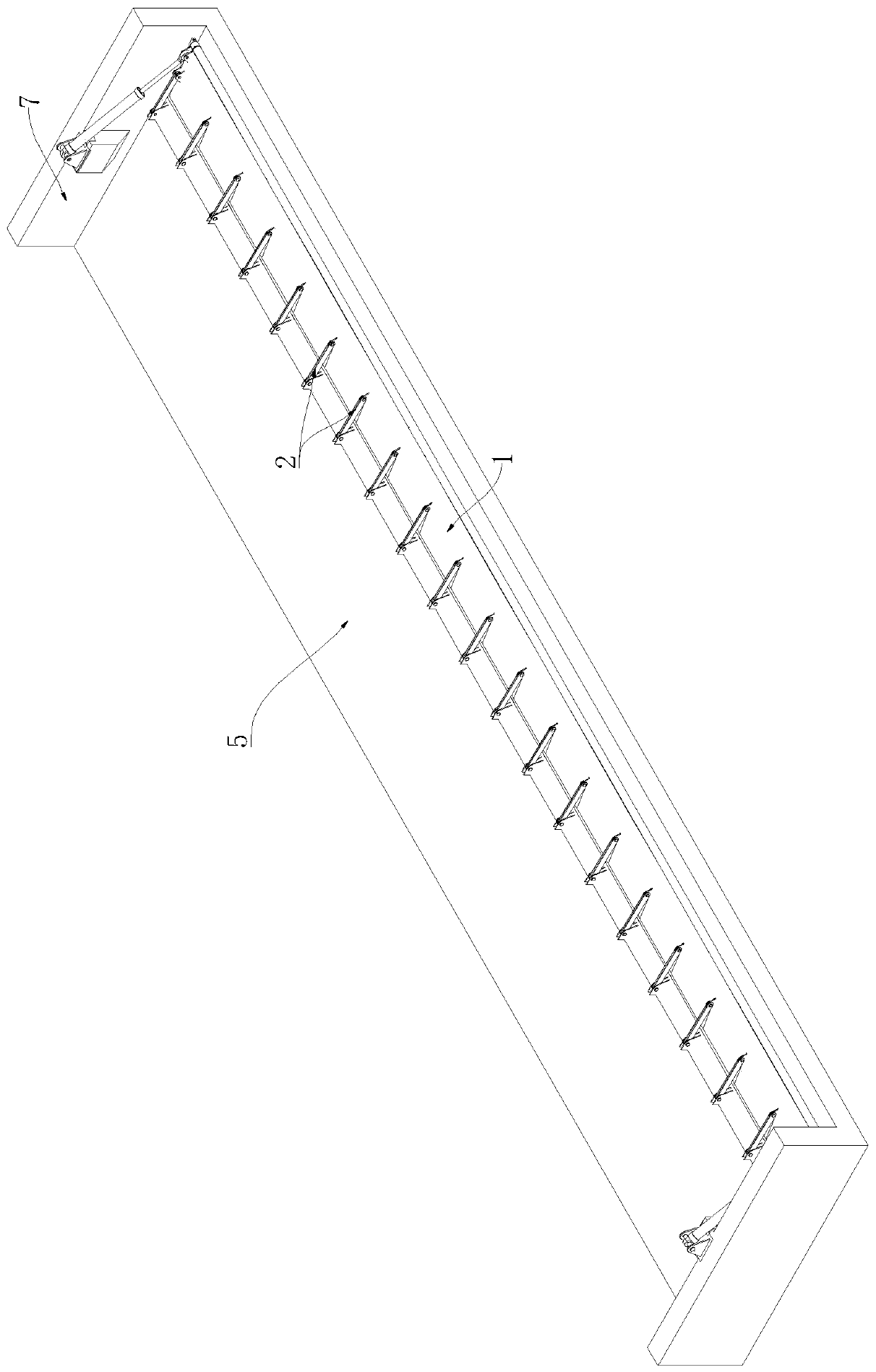

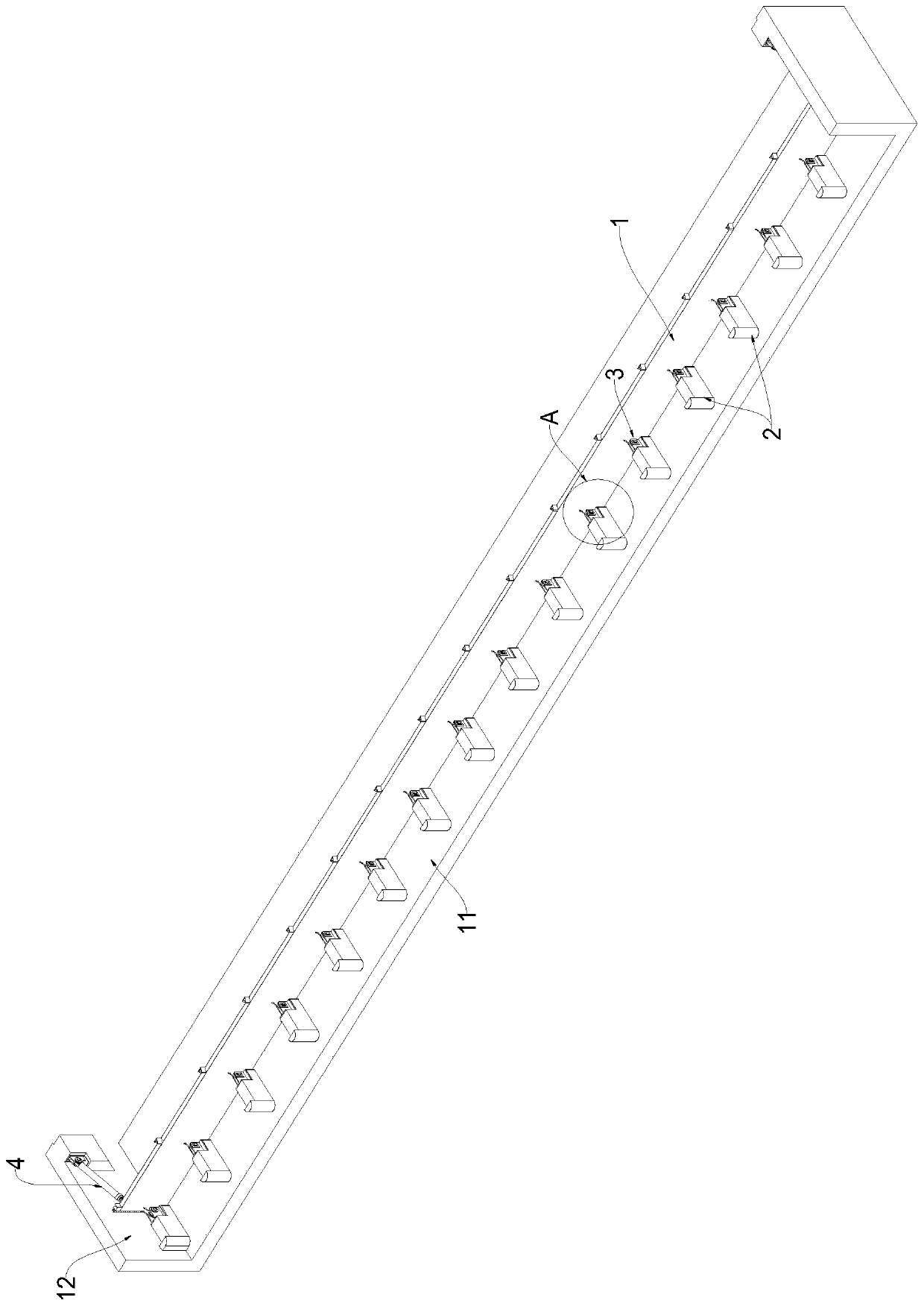

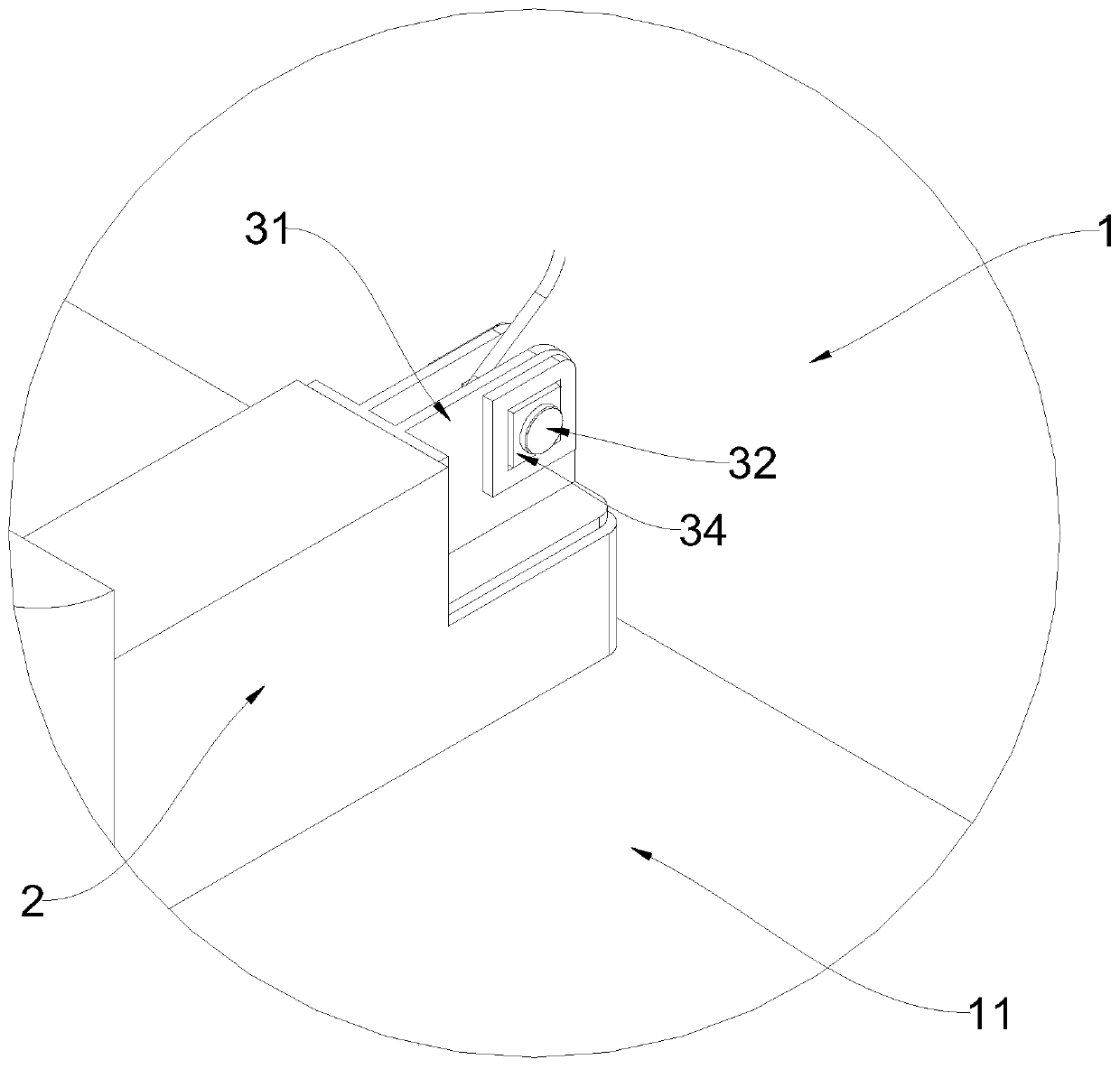

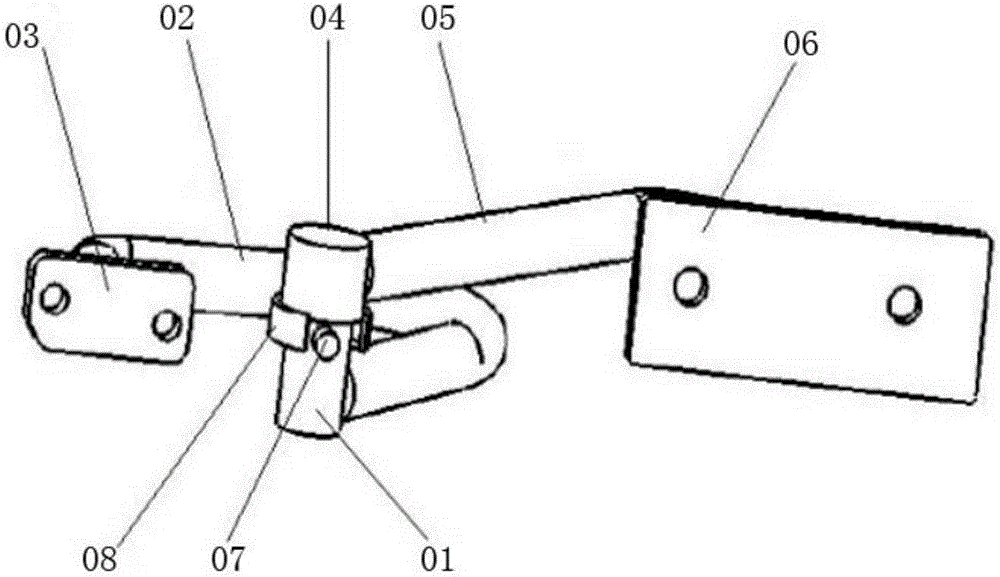

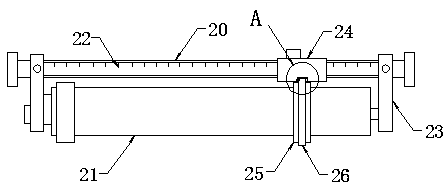

Positioning device and positioning method for drilling of anchor rod of tunnel primary support steel arch

ActiveCN112901077APrecisely control the installation angleControl installation angleUnderground chambersDerricks/mastsRock boltGuide tube

The invention belongs to the technical field of tunnels, and particularly relates to a positioning device and a positioning method for drilling of an anchor rod of a tunnel primary support steel arch. The positioning device comprises a positioning mechanism and a fastening mechanism; and after the positioning device is installed, a guide pipe of the positioning mechanism is used as an anchor rod positioning hole, a drilling machine drills through the positioning hole, the positioning device is disassembled after drilling is finished, the anchor rod is inserted into the anchor rod positioning hole, then grouting is carried out on the anchor rod, and the anchor rod is fixedly connected with the steel arch. According to the positioning device and the positioning method, the width requirements of different I-shaped steel can be met, the drilling angle can be accurately controlled, and therefore the installation angle of the anchor rod can be accurately controlled.

Owner:CHINA RAILWAY NO 9 GRP NO 7 ENG CO LTD

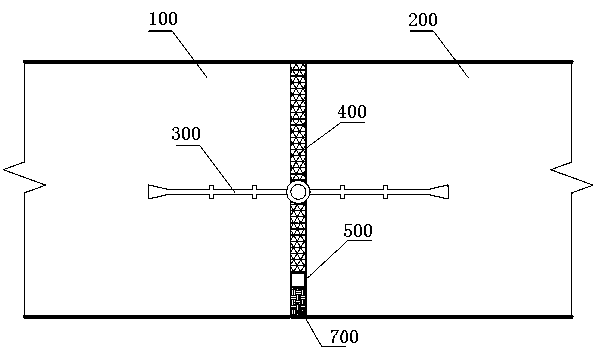

Tunnel deformation joint structure and construction method thereof

The invention belongs to the technical field of tunnel engineering, and particularly relates to a tunnel deformation joint structure. The tunnel deformation joint structure comprises a tunnel structure pre-casting section and a tunnel structure post-casting section. A viscous waterproof material is arranged in a deformation joint between the tunnel structure pre-casting section and the tunnel structure post-casting section; a steel sleeve with an opening toward the tunnel structure post-casting section is embedded in the tunnel structure pre-casting section, a steel bar is inserted in the steel sleeve, and one end of the steel bar passes through the viscous waterproof material and is anchored into the tunnel structure post-casting section. The invention further provides a construction method of the tunnel deformation joint structure. The construction method comprises the steps that construction of the tunnel structure pre-casting section is conducted at first and the steel sleeve is buried, and the viscous waterproof material is affixed on a cross section; then the steel sleeve is filled with butter and the like, and one end of the steel bar is inserted into the steel sleeve; and then construction of the tunnel structure post-casting section is conducted, and the steel bar is anchored into the tunnel structure post-casting section. By arranging the viscous waterproof material in the deformation joint, through viscosity of the material and the anchoring effect of the steel bar, deformation joint filler and a water receiving box can be prevented from dropping, and the construction process is simple and of high quality.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Cement telegraph pole branching frame

InactiveCN112260196AImprove vibrationImprove up and down vibration effectSuspension arrangements for electric cablesTowersControl theoryBilateral symmetry

The invention provides a cement telegraph pole branching frame, and belongs to the technical field of telegraph poles. The telegraph pole branching frame solves the problem that the service life of the telegraph pole branching frame is shortened when external force applied to cables is increased. The cement telegraph pole branching frame comprises a telegraph pole body with openings in the upper end and the lower end, a cover plate mechanism is arranged at the opening in the upper end of the telegraph pole body, supporting mechanisms triggering the cover plate mechanism to work are arranged atthe left end and the right end of the cover plate mechanism, and the two supporting mechanisms are distributed in a bilateral symmetry mode relative to the center line of the telegraph pole body. Andtwo guide mechanisms are arranged on each supporting mechanism. The cement telegraph pole branching frame is safer to use and longer in service life.

Owner:杭州佑滨科技有限公司

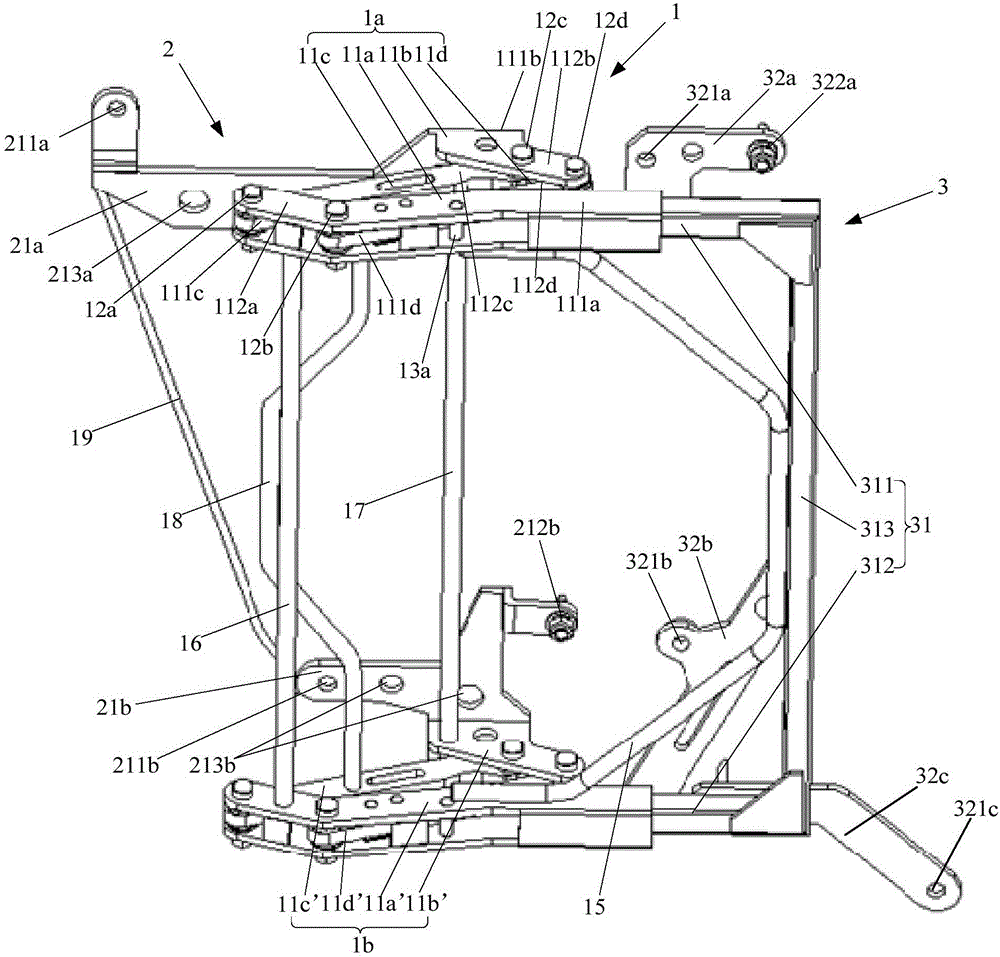

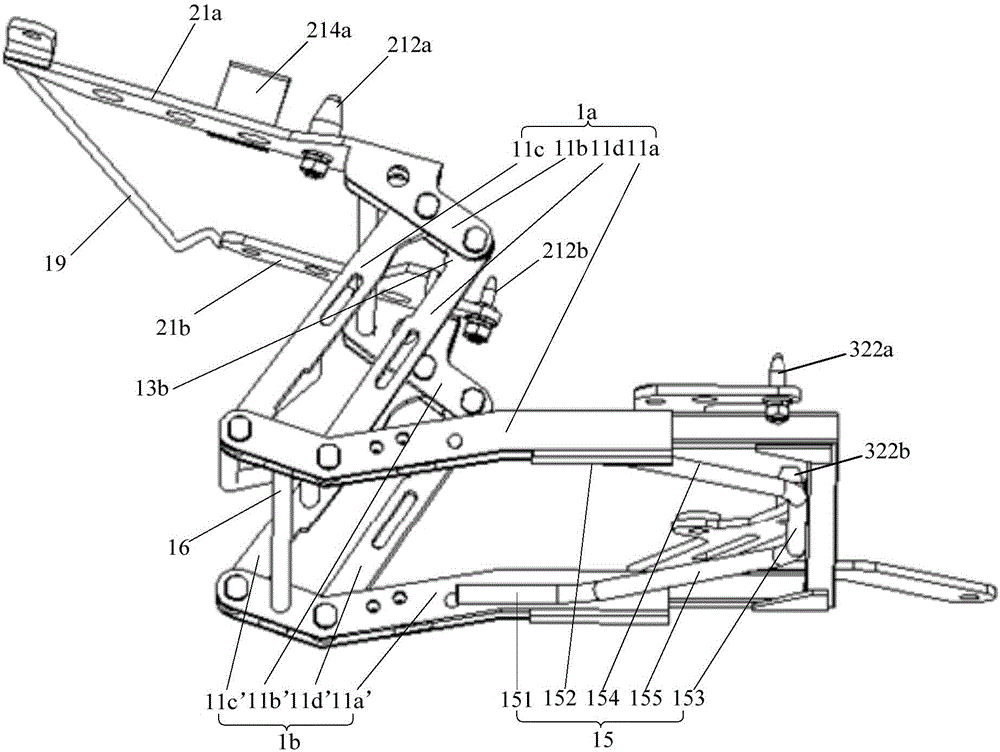

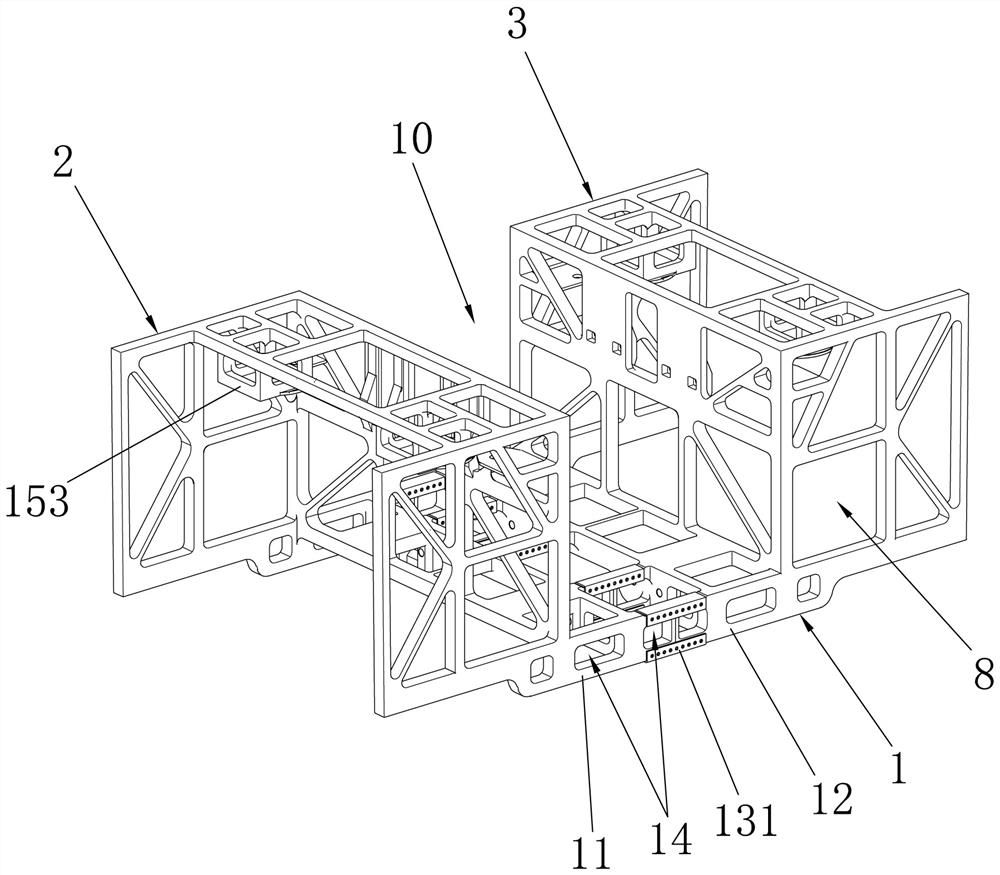

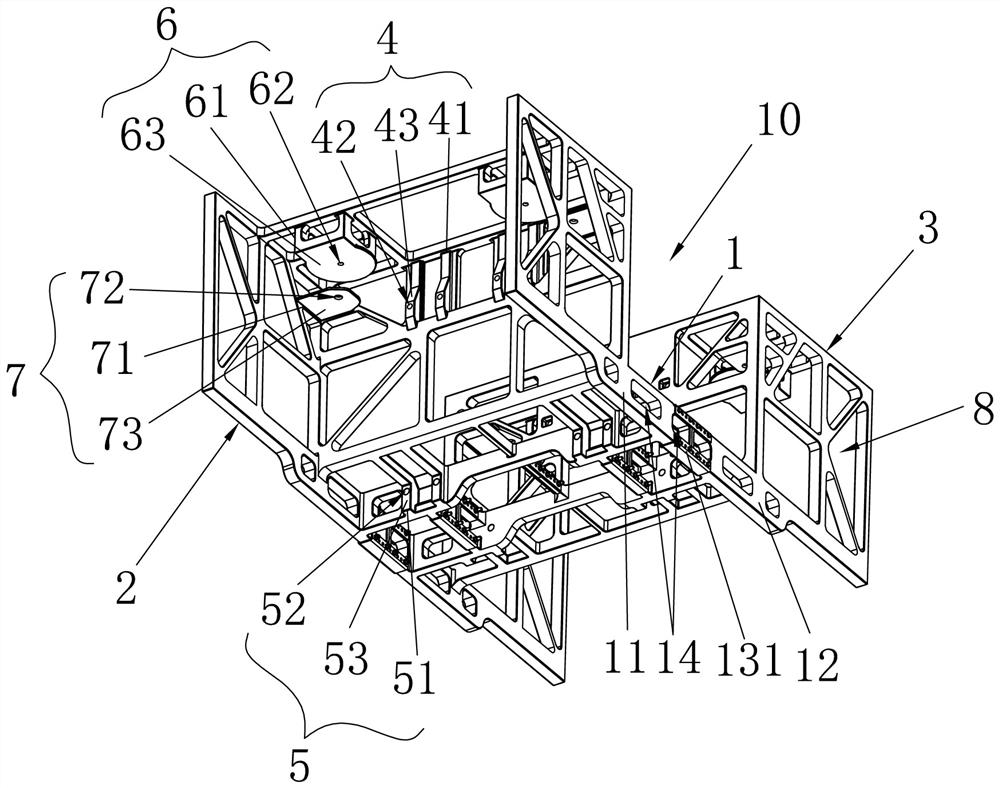

Wearable lower limb rehabilitation robot based on exoskeleton

InactiveCN105997441BMeet rehabilitation pace requirementsMeet width requirementsWalking aidsHuman bodyOlder people

The invention provides an exoskeleton-based wearable lower limb rehabilitation robot comprising a waist device, two leg devices in left-right symmetry and two foot devices in left-right symmetry. The waist device is worn on a waist part of a human body and comprises a waist support part, a waist drive device, a waist movement component, a waist band and leg connecting members. The leg devices are in hinge joint with the waist device and are tightly tied to the legs of the human body via flexible tying belts, and each leg device comprises a leg drive device, a thigh part and a shank part. The foot devices are worn on the feet of the human body and are in hinge joint with the leg devices; each foot device comprises a foot drive device, a foot support and a bottom plate. The exoskeleton-based wearable lower limb rehabilitation robot can assist patients or old people in completing lower limb rehabilitation training including waist movement and improves the lower limb rehabilitation training effect; the robot is simple and compact in structure, is convenient to wear, can be worn by people of different body forms through an adjusting mechanism, and is wide in application range; the waist mechanism can meet the waist movement rules under different paces.

Owner:NANJING UNIV OF SCI & TECH

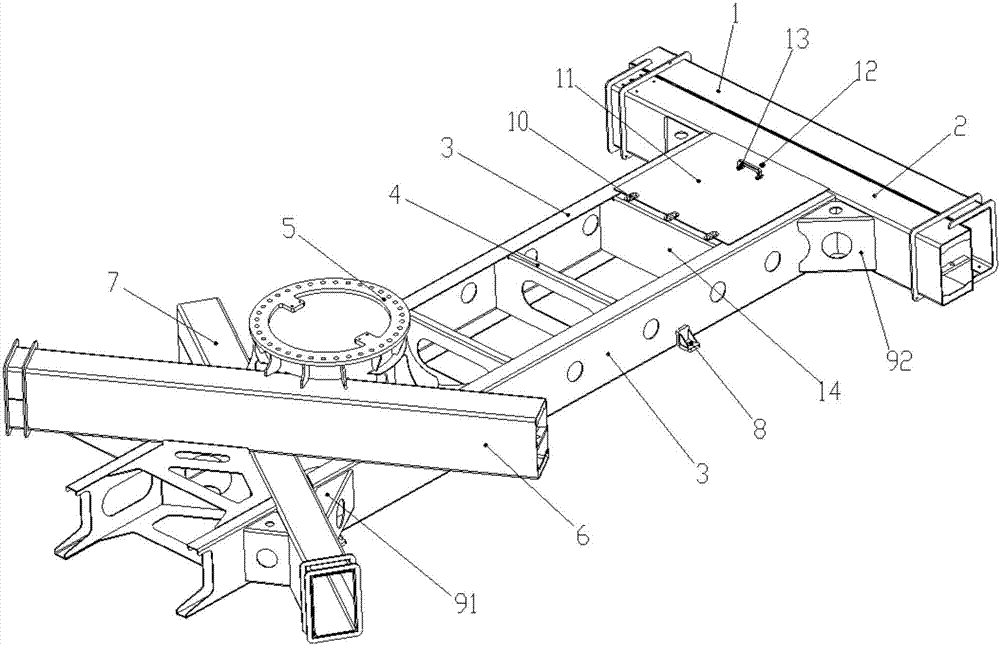

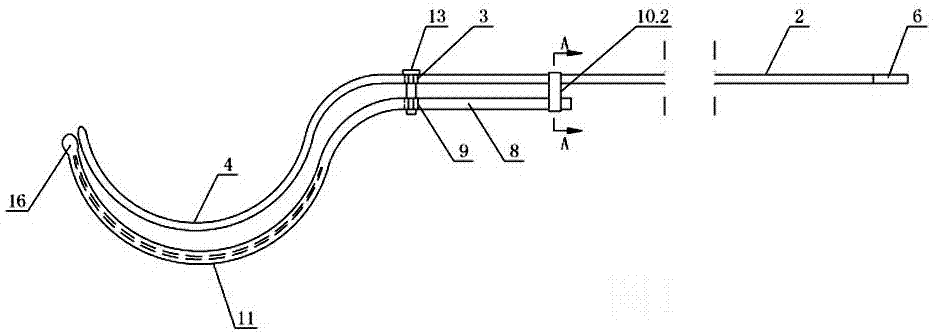

Auxiliary frame of hydraulic aerial cage

Owner:HUNAN SINOBOOM HEAVY IND

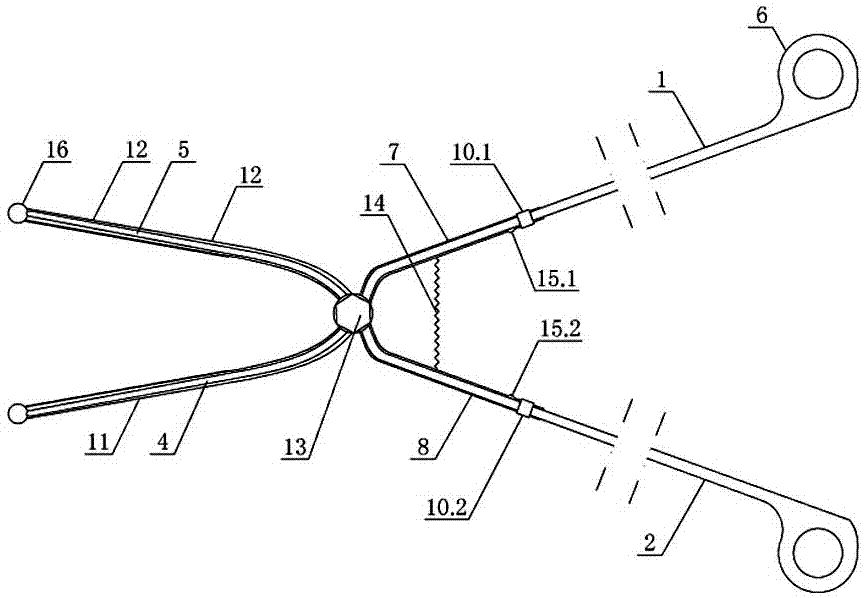

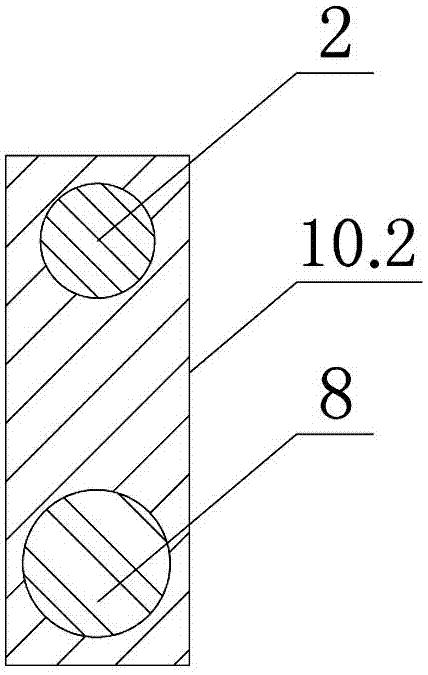

Tube side wall scissors and forceps set

ActiveCN107307894APrevent pruningGuaranteed distanceSurgical scissorsSurgical forcepsForcepsEngineering

The invention discloses a tube side wall scissors and forceps set comprising tissue scissors and clamping forceps. The tissue scissors comprise a first tool arm and a second tool arm which are hinged into a whole through a first hinge shaft, and a first blade and a second blade are arranged at the front ends of the first tool arm and the second tool arm respectively. The clamping forceps comprise a first forceps arm and a second forceps arm hinged into a whole through a second hinge shaft, and the first hinge shaft and the second hinge shaft are arranged in an up-down corresponding manner and connected into a whole in a screwed manner through an adjusting bolt. A locating sleeve is arranged on each of the first and second tool arms in a penetrating manner. The first forceps arm and the second forceps arm are connected with the first tool arm and the second tool arm respectively through the locating sleeves. A locking structure is arranged between the first forceps arm and the second forceps arm. A first forceps tip and a second forceps tip bending in the same direction are arranged at the front ends of the first forceps arm and the second forceps arm respectively. The tube side wall scissors and forceps set have clamping effect and shearing effect at the same time, the tissue scissors and the clamping forceps are arranged in a vertically spaced manner, and the distance between the tube residual ends is assured; the tissue scissors and the clamping forceps are removable, so that gravity to tubes during suturing is alleviated, overturn of tube sutured openings is avoided, and suturing quality is assured.

Owner:THE FIRST AFFILIATED HOSPITAL OF ZHENGZHOU UNIV

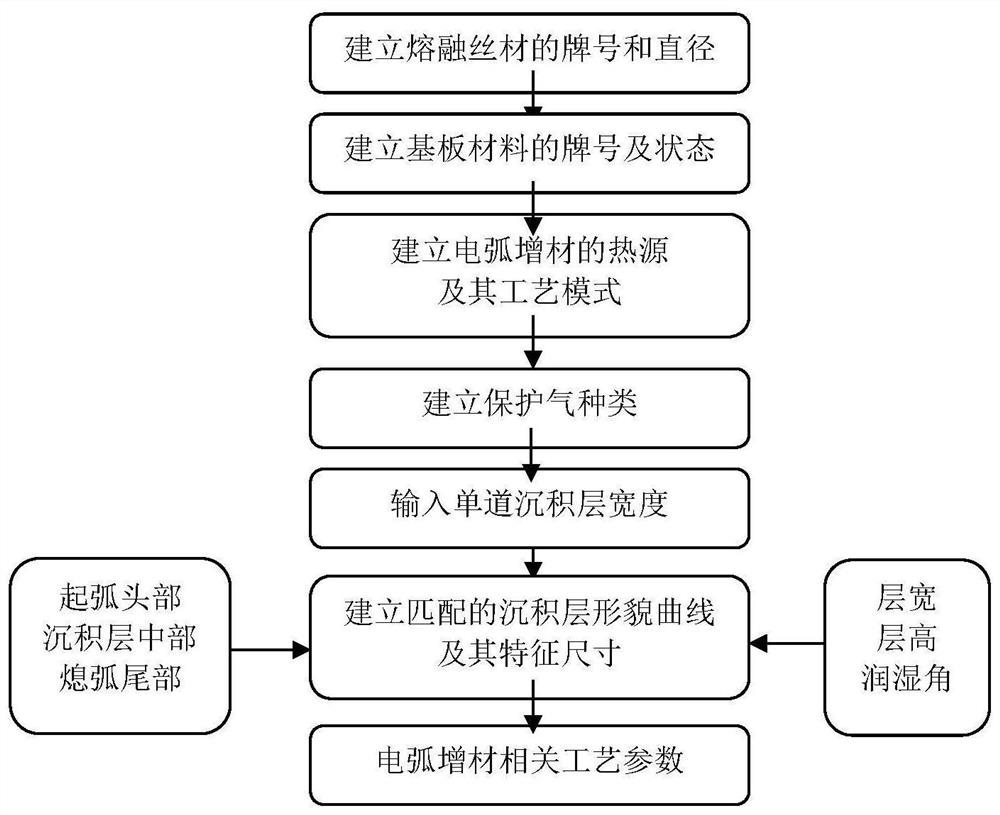

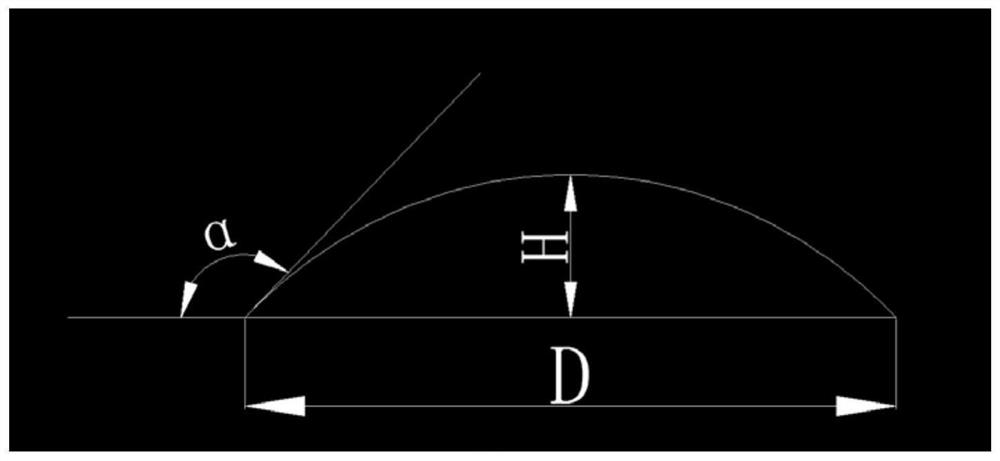

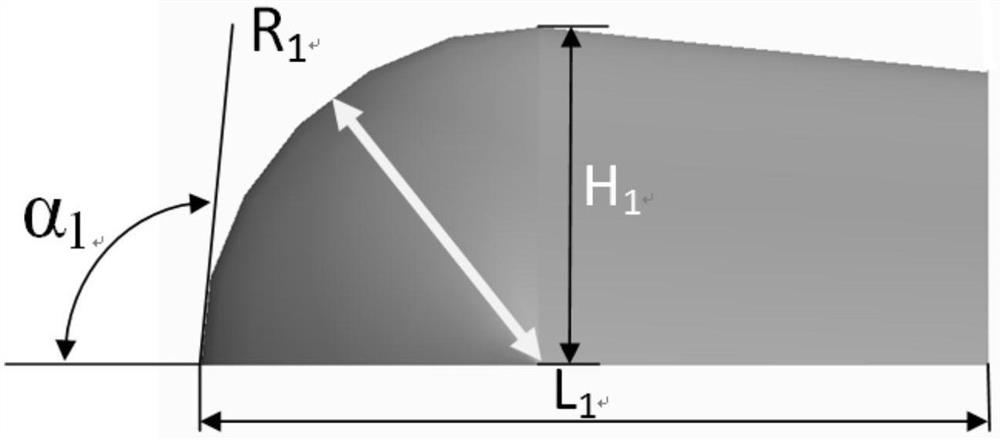

Process database construction method for electric arc additive manufacturing deposition layer

PendingCN113792028AMeet width requirementsImprove surface qualityArc welding apparatusEnergy efficient computingShielding gasMechanical engineering

The embodiment of the invention provides a process database construction method for an electric arc additive manufacturing deposition layer. The method is characterized by comprising the following steps of: establishing corresponding marks and diameters according to the types of used molten wires; establishing a mark corresponding to a substrate material; establishing an electric arc additive heat source type and a process mode thereof; establishing a shielding gas type; inputting the width of a single-channel deposition layer; establishing a matched deposition layer morphology curve and a feature size thereof; and establishing related process parameters of an electric arc additive. Matching of the morphology and the size of an arc additive manufacturing deposition layer with the material and the state of the substrate, the type of an arc additive heat source and process mode parameters, a swing parameter, an arc starting / extinguishing parameter, the distance between the end face of a contact tube and the deposition layer, an interlayer temperature range, the initial temperature of the substrate and the flow velocity of protective gas is realized; the requirement for the width of the preset deposition layer is met, meanwhile, active control over the arc additive manufacturing forming quality is achieved, morphology change rules of the deposition layer can be predicted, the surface quality, forming precision and forming efficiency of an electric arc additive manufacturing formed part are improved, and the mechanical property of the formed part can be guaranteed.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

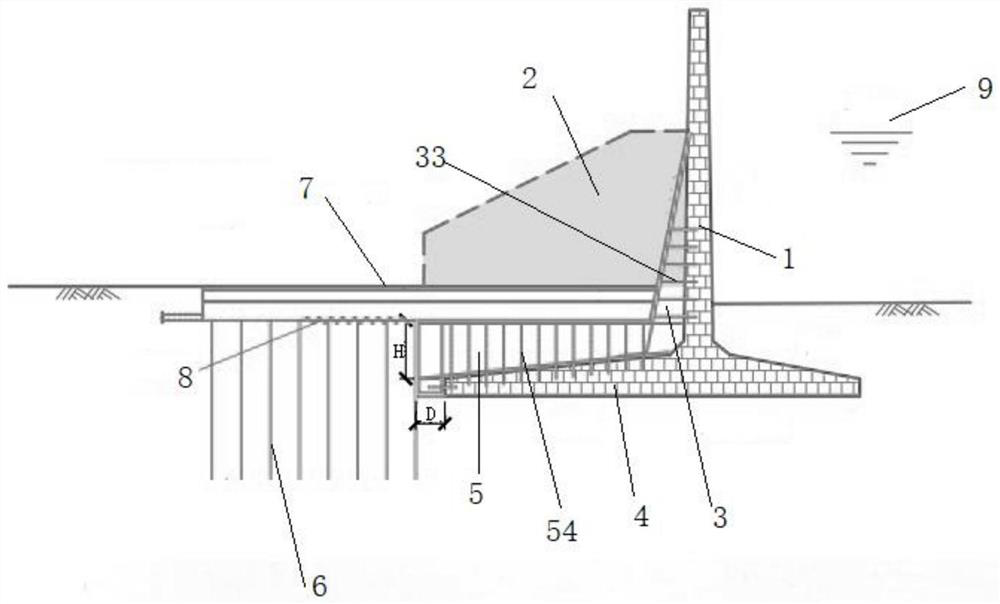

Integral horizontal rotary dam

PendingCN110409380ASimple structureMeet width requirementsBarrages/weirsHydraulic cylinderLeaking water

The embodiment of the invention discloses an integral horizontal rotary dam and relates to the field of water conservancy projects. The integral horizontal rotary dam comprises a retaining dam body, aplurality of connecting rotary rods and a driving device. The retaining dam body is arranged above a dam base and stretches along the width direction of a riverway, the connecting rotary rods are arranged in a spaced manner along the width direction of the riverway, one ends of the connecting rotary rods are hinged to one side of the retaining dam body and the other ends of the connecting rotaryrods are separately hinged to a plurality of supports pre-buried on the dam base correspondingly one by one; and the driving device is connected to the retaining dam body. The integral horizontal rotary dam not only overcomes defects that a rubber dam is easy to damage and age, long in dam lifting and collapsing time, low in safety, poor in reliability, short in service life and the like, but alsosolves the problems that a hydraulic dam side stops and leaks water, a hydraulic cylinder and an oil pipe are failed easily in the riverway and are hard to overhaul and the like, and also overcomes the defects that a conventional steel dam gate is clumsy in bed shaft, unscientific in stress, poor in sand washover effect, high in cost and the like.

Owner:李正方

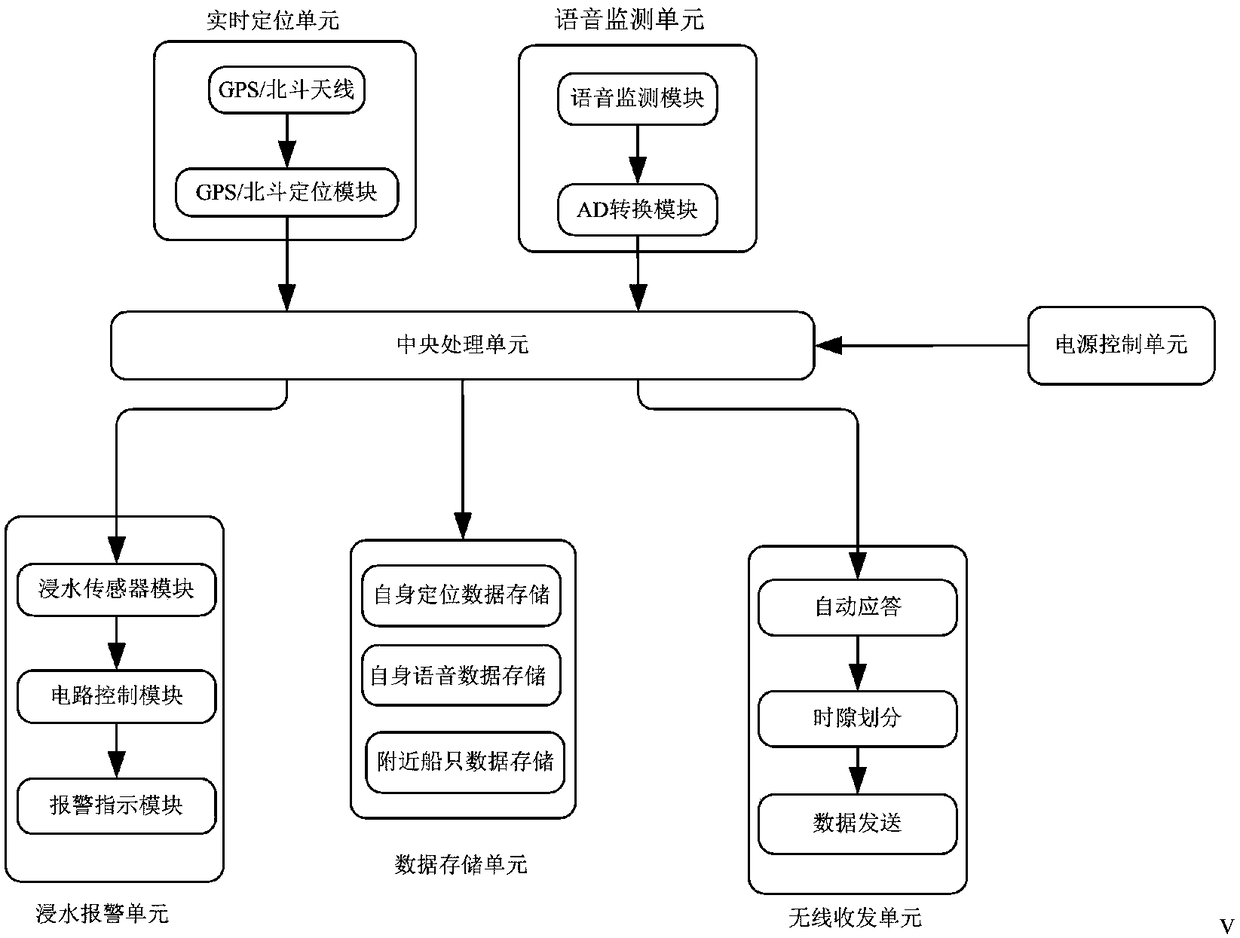

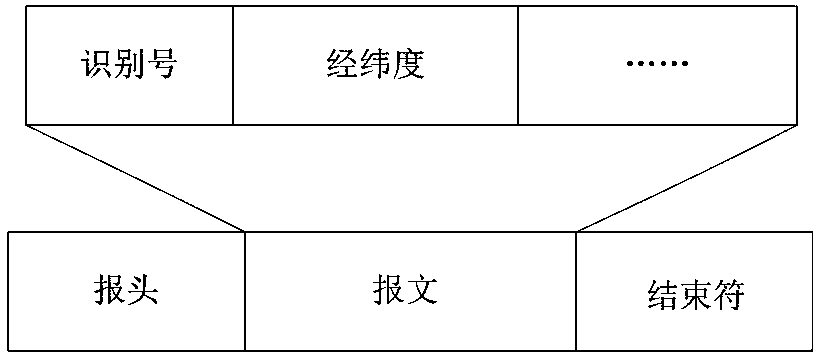

GPS/Beidou system based marine monitoring system for navigation ships of river and using method of monitoring system

InactiveCN108072398AReduce energy consumptionExtended working hoursSynchronisation arrangementTime-division multiplexPower controlWork period

The invention discloses a GPS / Beidou system based marine monitoring system for navigation ships of a river and a using method of the monitoring system. The monitoring system comprises a central processing unit, a real time positioning unit, a voice monitoring unit, an immersion alarm unit, a data storage unit, a wireless transmitting-receiving unit and a power control unit. The monitoring system is low in energy consumption, long in work time, mini, convenient and green, a user needs not to set the monitoring system tediously, problems in management of civil ships and search and rescue work are solved, and onsite information can be reserved and provide help for accident analysis later.

Owner:DALIAN MARITIME UNIVERSITY

Integral horizontal rotary dam

PendingCN110777742ASimple structureMeet width requirementsBarrages/weirsHydraulic cylinderRiver routing

The embodiment of the invention discloses an integral horizontal rotary dam, and relates to the field of water conservancy projects. The integral horizontal rotary dam comprises a retaining dam body,at least two fixing piers and a dam body driving device, wherein the retaining dam body is arranged above a dam foundation and extends in the width direction of a river channel; the fixing piers are arranged on one side of the dam body at intervals along the width direction of the river channel and are connected with the dam foundation; and each fixing pier is hinged to one side of the dam body through a hinge device. According to the integral horizontal rotary dam, the defects that a rubber dam is easy to damage and age, the time for dam lifting and collapsing is long, the safety is low, thereliability is poor, the service life is short and the like can be overcome; furthermore, the problems that leakage occurs among side water-block rubber of a hydraulic dam, hydraulic cylinders and oilpipes are prone to failure in the river channel, the overhaul is difficult and the like can be solved; and meanwhile, the problems that a bottom shaft of a traditional steel dam gate is rough, not scientific in stress bearing, poor in sand punching effect and high in manufacturing cost and the like can be overcome.

Owner:李正方

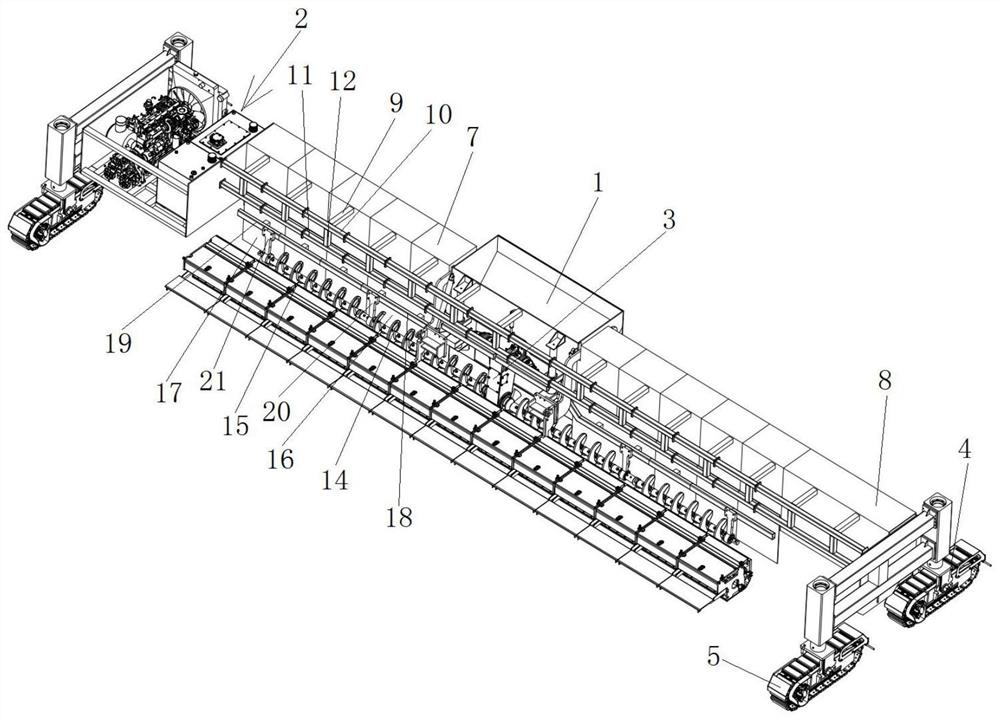

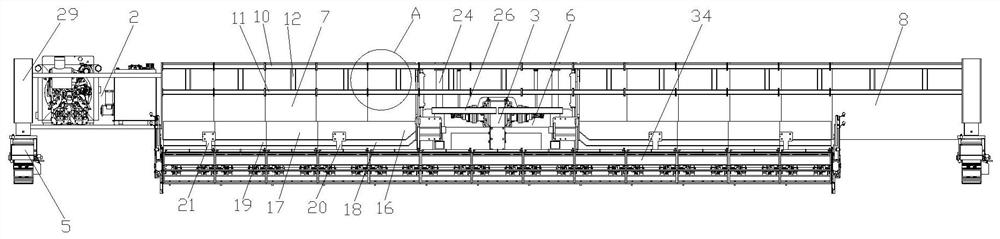

Paver and use method thereof

The invention discloses a paver and a use method thereof. The paver comprises a rack, a hopper, a spiral conveyor, an ironing plate, a power box, a crawler walking device and a hydraulic lifting device. The use method comprises the following steps: 1, mounting the paver; 2, adjusting the position of the paver; 3, performing feeding of a paver; 4, performing pavement paving; 5, judging whether a track beam exists on the pavement to be paved or not; 6, enabling the paver to cross the track beam. The paver is novel and reasonable in design, the length of the rack is adjusted according to the width of a pavement to be paved, and then the lengths of the spiral conveyor and the screed plate which are mounted on the rack are adjusted, so that the paving of the pavement to be paved can be completed by moving the paver along the pavement to be paved once, the time is saved, and the construction progress is accelerated; the hydraulic lifting device is arranged to adjust the ground clearance of the spiral conveyor, and the crawler wheel lifter is arranged to drive the front crawler wheel and the rear crawler wheel to move up and down, so that the whole paver can conveniently enter and exit from an area to be paved.

Owner:CCCC XIAN ROAD CONSTR MACHINERY

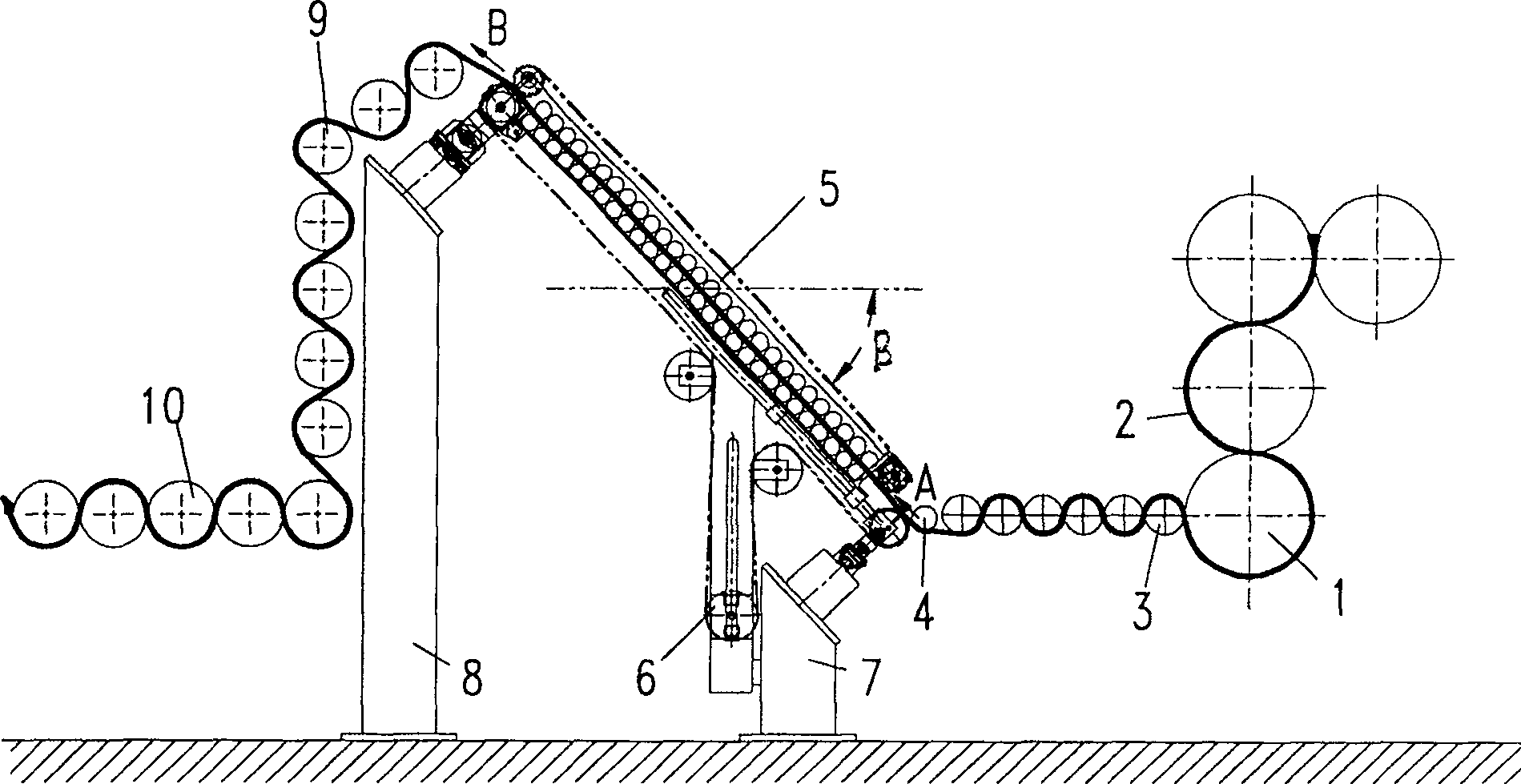

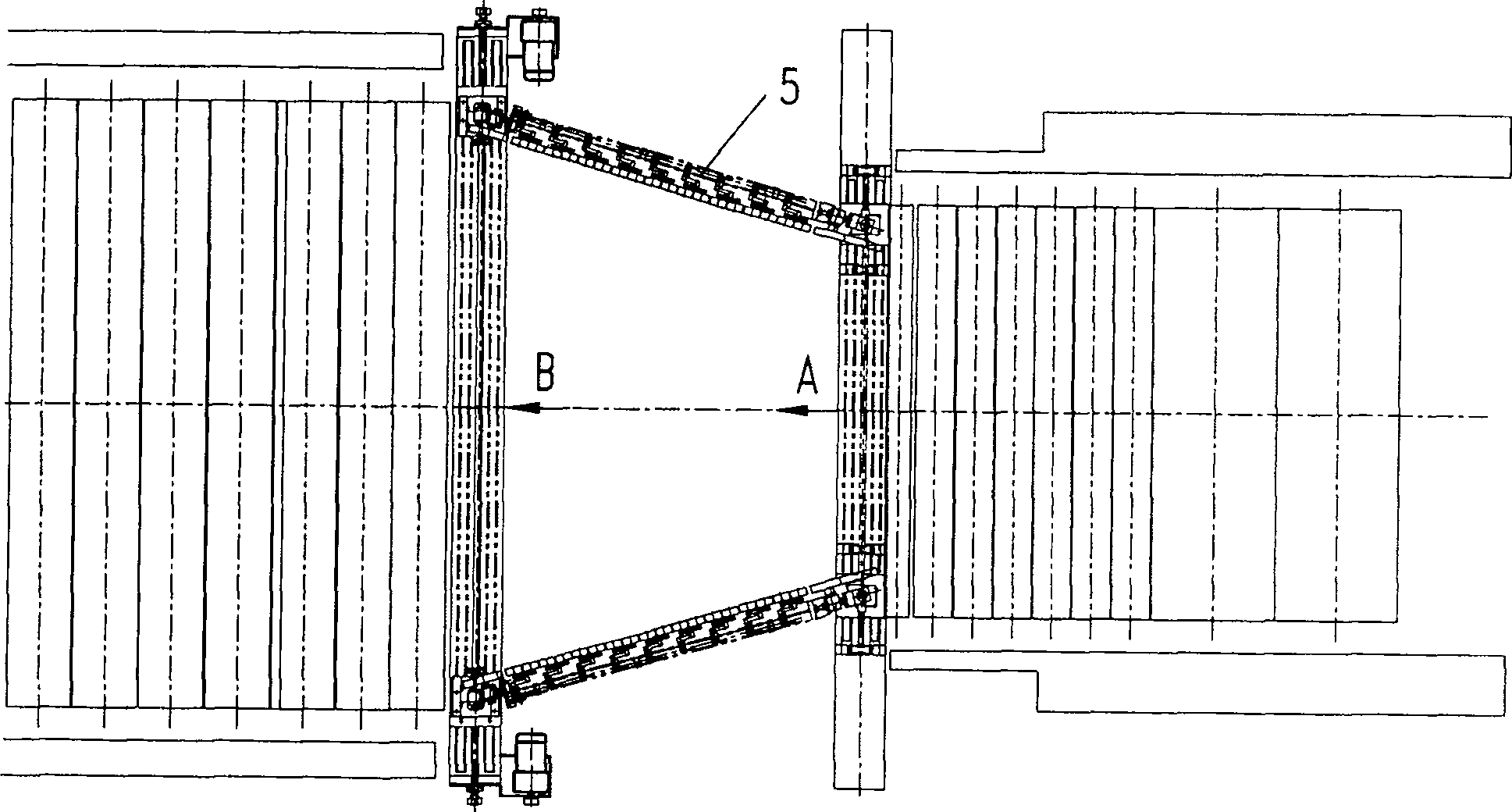

Widening process and apparatus for rolled plastic film and sheet

InactiveCN100519150CReduce the horizontal projection surfaceReduce local stretchingPlastic filmMaterials science

The present invention relates to a process and facility for stretching plastic films and sheets by calendering. The stretching equipment in the known calendering method is horizontally arranged, and its disadvantage is that the projection surface of the horizontal plane is too large, due to the weight of plastic films and sheets The reason is that the horizontal width is too wide to sag and be vertically stretched by its own weight, so that the flatness of the plastic film and the sheet product is not good after being shaped, which limits the width of the finished product to be too wide. Wheels, guide wheels, widening equipment, clamping force tensioning system, tempering wheel and cooling wheel set, the widening equipment is changed from the original horizontal placement to the inclined placement, and the additional installation adopts the counterweight wheel With advanced clamping force tensioning system and adjustable guide wheels up and down, the improved stretching equipment can produce wide products with better flattening and width between 4200mm-16000mm.

Owner:宏轮机械(上海)有限公司

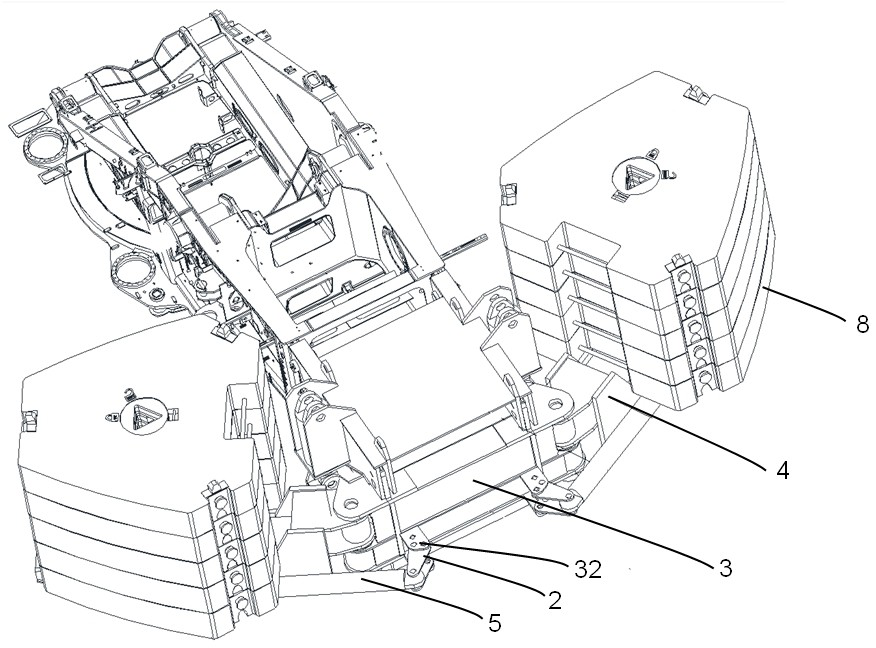

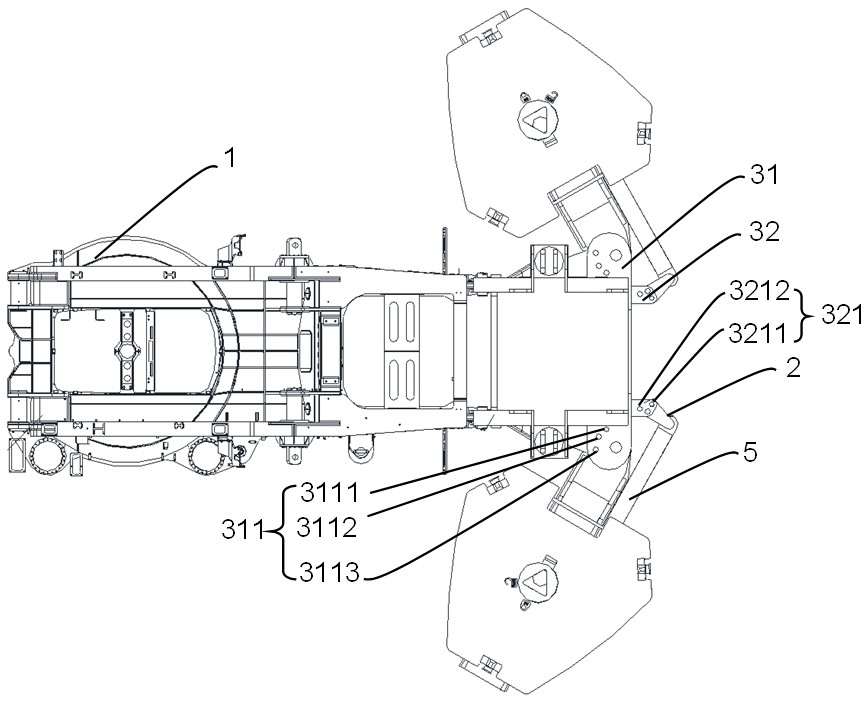

Balancing weight mechanism of engineering machinery, engineering machinery and shifting method of balancing weight mechanism

ActiveCN114604785ALarge rotation rangeRaised tipping momentCounterweightsWind energy generationEngineeringGravity center

The invention discloses a counterweight mechanism, engineering machinery and a counterweight mechanism displacement method. The balance weight mechanism comprises a base frame, a balance weight, a bracket, a swing rod and a telescopic mechanism. The base frame is installed on the rear side of a rotary platform of the engineering machine. The bracket is used for bearing the balance weight, and one end of the bracket is rotatably connected to the base frame. The first end of the swing rod is rotatably connected to the base frame. The first end of the telescopic mechanism is rotatably connected to the bracket, and the second end of the telescopic mechanism is rotatably connected to the second end of the swing rod. The first end and the second end of the telescopic mechanism are telescopically arranged to drive the bracket and the swing rod to rotate relative to the base frame so as to adjust the position of the balance weight. According to the scheme, the rotating range of the bracket is enlarged by arranging the swing rod, and therefore the gravity center adjusting range of the balance weight is enlarged.

Owner:XUZHOU HEAVY MASCH CO LTD

Sliding door tool

InactiveCN106076702AMeet width requirementsMeet passability size requirementsSpraying apparatusFixed frameEmbedded system

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

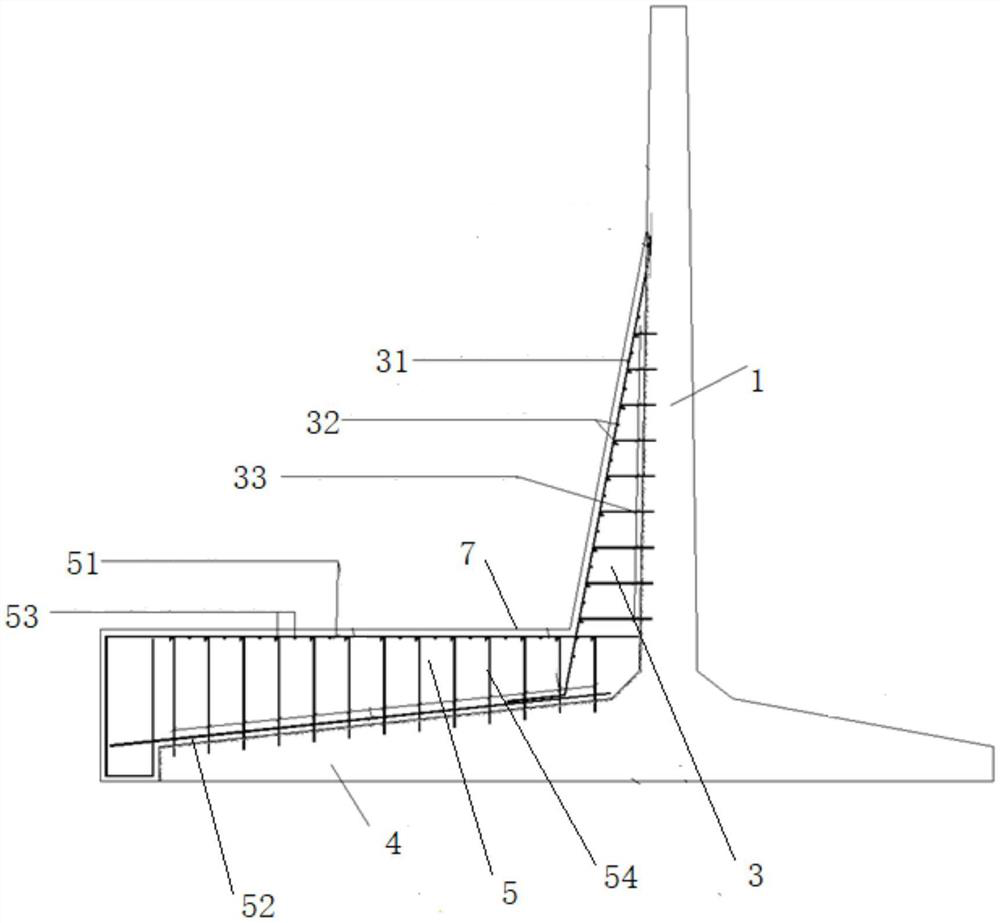

Urban road reconstruction method and structure jointly built with anti-flood wall and rear berm

PendingCN114293430AMeet width requirementsGuaranteed functionDamsIn situ pavingsSoil mixingStructural engineering

The invention discloses a reconstruction method for an urban road jointly built with a flood wall and a rear berm and a road structure. Filling soil of the rear berm of a local road section is excavated, and after the filling soil of the rear berm is excavated, a vertical wall of the flood wall and a thick heel slab are reinforced; then, cement-soil mixing piles are arranged on the outer sides of the wall heels; a road surface is newly built on the anti-flood wall heel slab reinforcing part and the cement-soil mixing piles; according to the method, the Binjiang road is widened, the width requirement for reconstruction and improvement of the urban Binjiang road is met, and the complete function and quality of the Binjiang road are guaranteed compared with local non-motorized vehicle lane canceling or sidewalk width compressing.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

Integrated passenger car driving shaft framework with adjustable width

PendingCN114179921AAchieving Width AdjustmentMeet width requirementsSuperstructure connectionsPassenger vehicle superstructuresDrive shaftCar passenger

The width-adjustable integrated passenger car driving shaft framework comprises a framework body, the framework body is provided with a middle framework, a left wheel cover framework and a right wheel cover framework, and the left wheel cover framework and the right wheel cover framework are symmetrically arranged on the two sides of the middle framework, so that an in-car passageway is formed above the middle framework; the middle framework comprises a left framework, a right framework and a connecting assembly; the left framework and the left wheel cover framework are integrally cast, and the right framework and the right wheel cover framework are integrally cast; the left framework and the right framework are connected through a connecting assembly, and width adjustment of an aisle in a vehicle is achieved. The driving shaft framework of the passenger car is formed by splicing the left framework and the right framework which are integrally cast and formed, high integration can be achieved, the width of an aisle in the car can be adjusted, the width requirements of different car types can be met, and the driving shaft framework of the passenger car is convenient to use. The automatic assembling machine has the advantages of high assembling efficiency, high positioning precision, good universality, low failure rate, high structural strength and the like.

Owner:XIAMEN KING LONG UNITED AUTOMOTIVE IND CO LTD

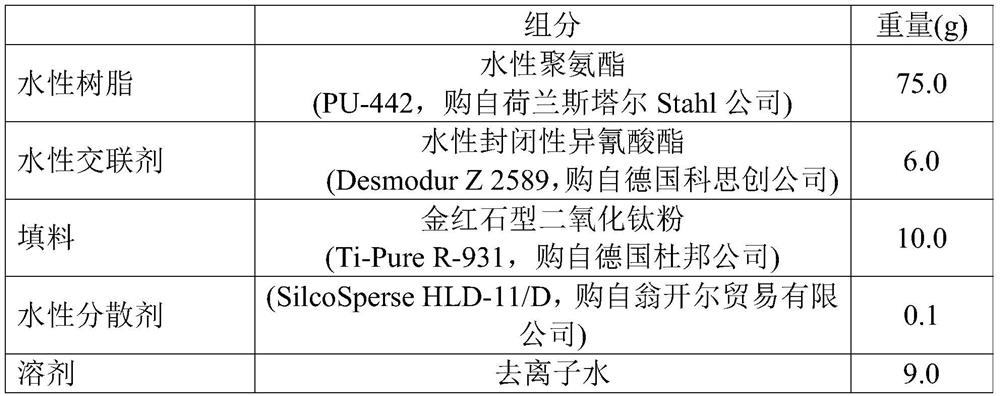

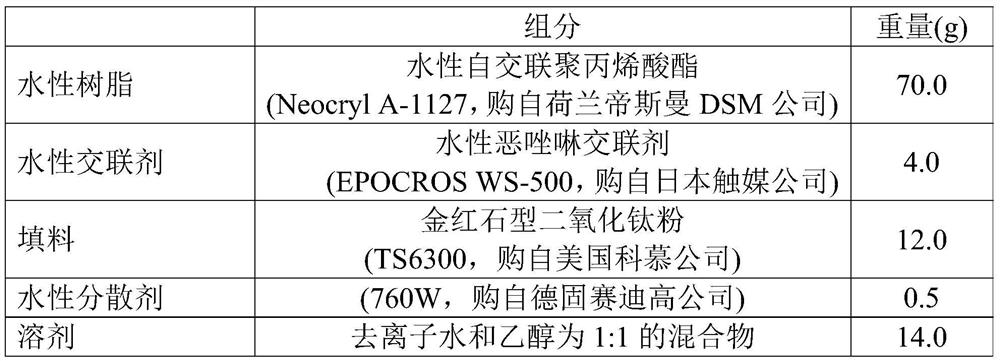

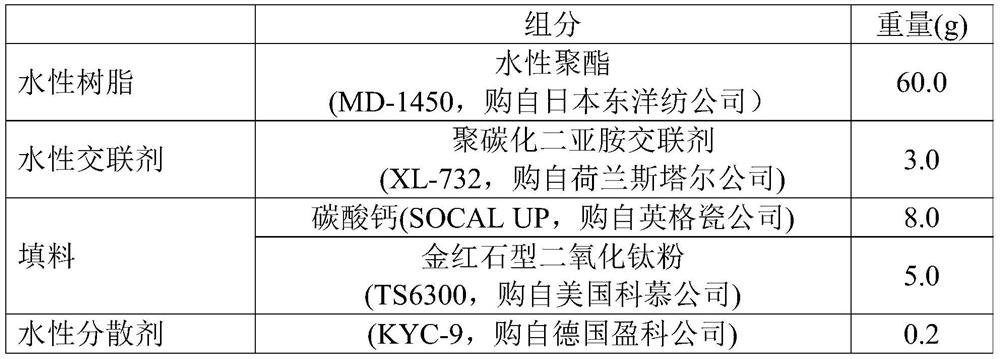

Composition for preparing water-based anti-corrosion ink, water-based anti-corrosion ink, preparation method and application thereof and demetallization method

The invention relates to the field of water-based anti-corrosion ink, and discloses a composition for preparing water-based anti-corrosion ink, the composition comprises the following components in percentage by weight: 32 to 88 percent of water-based resin, 0.01 to 12 percent of water-based cross-linking agent, 0.01 to 20 percent of filler, 0 to 5 percent of water-based dispersing agent and 0.01 to 68 percent of solvent, wherein the sum of the hydroxyl value and the acid value of the water-based resin is less than 100 mg KOH / g, and the weight-average molecular weight is not less than 1000. The water-based anti-corrosion ink prepared from the composition is suitable for demetalization protection of a metallized anti-counterfeiting device, realizes chemical corrosion resistance protection of the metal layer, and has the advantages of high fineness of printed images and texts, strong anti-sticking property, strong acid and alkali resistance, good covering degree and strong adhesive force.

Owner:ZHONGCHAO SPECIAL SECURITY TECH +1

pipe side wall pliers

ActiveCN107307894BPrevent pruningGuaranteed distanceSurgical scissorsSurgical forcepsForcepsEngineering

The invention discloses a tube side wall scissors and forceps set comprising tissue scissors and clamping forceps. The tissue scissors comprise a first tool arm and a second tool arm which are hinged into a whole through a first hinge shaft, and a first blade and a second blade are arranged at the front ends of the first tool arm and the second tool arm respectively. The clamping forceps comprise a first forceps arm and a second forceps arm hinged into a whole through a second hinge shaft, and the first hinge shaft and the second hinge shaft are arranged in an up-down corresponding manner and connected into a whole in a screwed manner through an adjusting bolt. A locating sleeve is arranged on each of the first and second tool arms in a penetrating manner. The first forceps arm and the second forceps arm are connected with the first tool arm and the second tool arm respectively through the locating sleeves. A locking structure is arranged between the first forceps arm and the second forceps arm. A first forceps tip and a second forceps tip bending in the same direction are arranged at the front ends of the first forceps arm and the second forceps arm respectively. The tube side wall scissors and forceps set have clamping effect and shearing effect at the same time, the tissue scissors and the clamping forceps are arranged in a vertically spaced manner, and the distance between the tube residual ends is assured; the tissue scissors and the clamping forceps are removable, so that gravity to tubes during suturing is alleviated, overturn of tube sutured openings is avoided, and suturing quality is assured.

Owner:THE FIRST AFFILIATED HOSPITAL OF ZHENGZHOU UNIV

A paper delivery device for a printing press

Owner:颍上科技印刷有限公司

Non-directional door curtain tape for industrial use and manufacturing method thereof

ActiveCN102704822BMeet width requirementsAvoid widening processSynthetic resin layered productsPolyesterPolyvinyl chloride

Owner:SHANGHAI YONGLI BELTING +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com