Sensor calibration method for optical remote sensing satellite multi-CCD multi-camera unified processing

An optical remote sensing and multi-camera technology, applied in the direction of instruments, photogrammetry/video metrology, measuring devices, etc., can solve problems such as splicing errors, inability to eliminate the parallax of two cameras, and split the relationship between sensors, so as to improve the use efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below with reference to the drawings and examples.

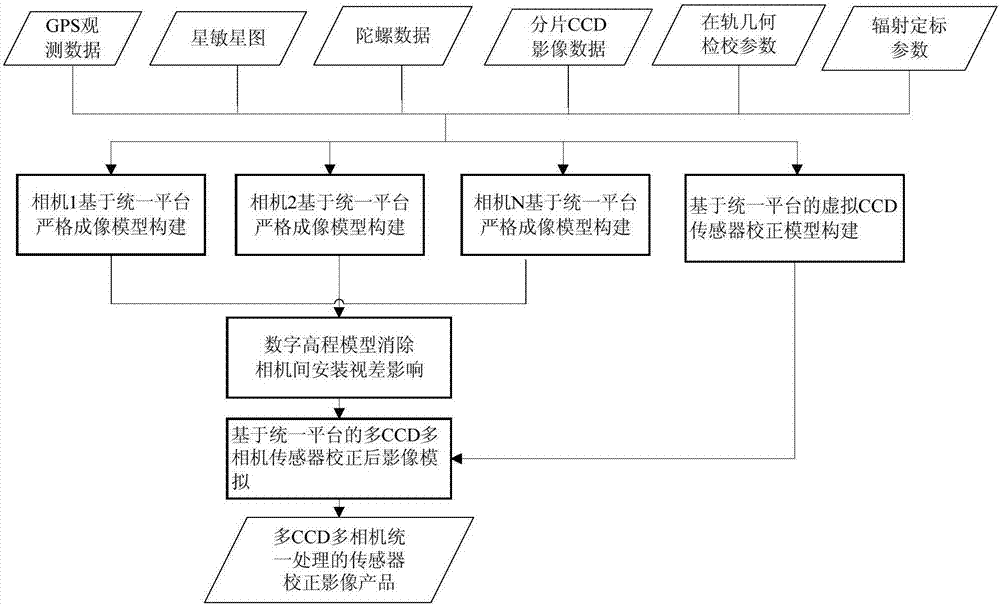

[0046] An optical remote sensing satellite multi-CCD multi-camera unified processing sensor calibration method, the steps are as follows:

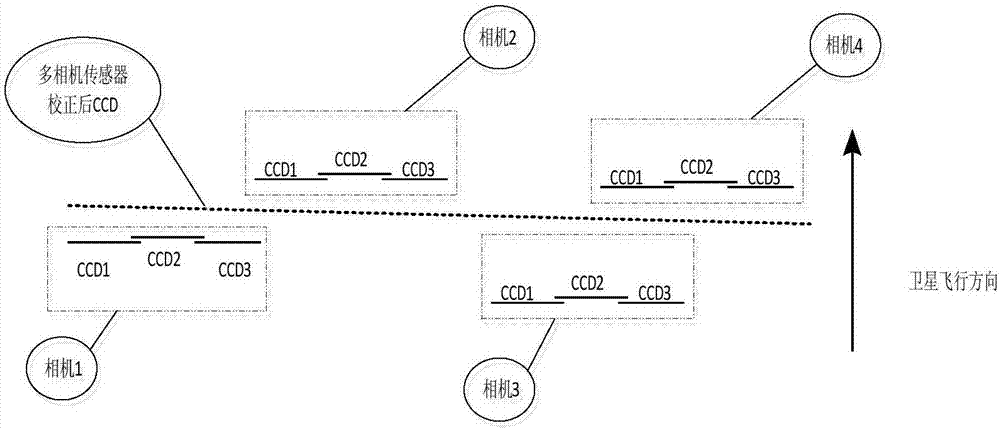

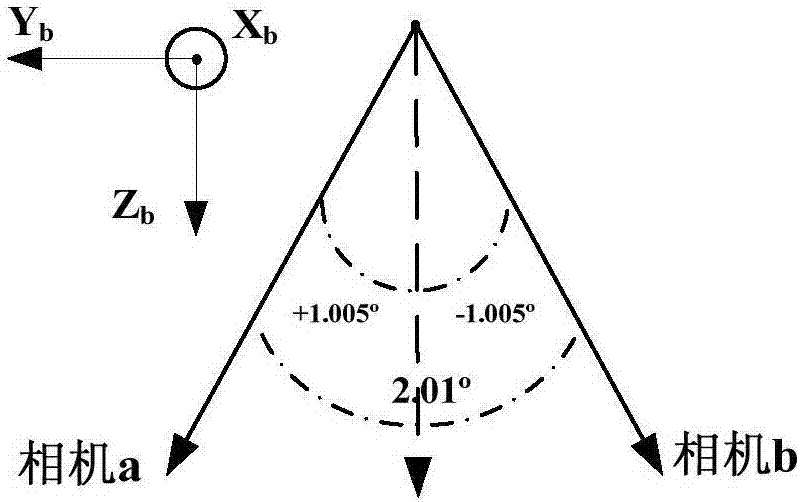

[0047] The first step is to construct a virtual CCD linear array based on the installation position of each CCD linear array of multiple cameras on the optical remote sensing satellite platform along the orbital direction, and install the virtual CCD linear array on the centerline of the multiple cameras along the orbital direction;

[0048] (1) Features and advantages of sensor calibration image based on a unified platform

[0049] a. The vertical orbit direction is ideal, distortion-free center projection imaging, and the size of each CCD detector is the same;

[0050] b. The integration time along the orbit is the same, and there is no integration time jump; there is no geometric distortion along the orbit;

[0051] c. No radiation differe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com