Non-directional door curtain tape for industrial use and manufacturing method thereof

A directional and door curtain belt technology, which is applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of uneven width door curtain belts, inability to change directions, and large investment in equipment, etc. To achieve the effect of avoiding widening process, reducing unqualified products, and reducing enterprise costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

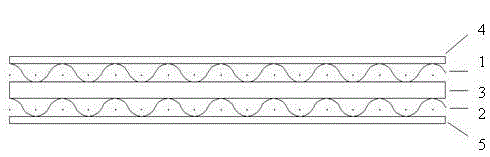

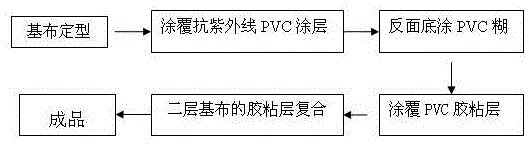

[0031] like figure 1 As shown in the schematic cross-section of the non-directional industrial door curtain belt, a non-directional industrial door curtain belt uses polyester fabric as the base fabric, including polyester base fabrics 1 and 2 with no lateral stability on the upper and lower sides, and coating between the two base fabrics PVC adhesive layer 3, the door curtain belt is coated with upper and lower anti-ultraviolet coatings 4, 5, wherein, in the polyester base cloth with no lateral stability up and down, the fabric does not contain monofilament, and the warp and weft density of the fabric is 4030, wherein, the warp and weft To ultra-low shrinkage polyester multifilaments with a fineness of 1000D, twisted at 60 turns / m.

[0032] Since the fabric has no lateral stability, in order to ensure the stiffness of the product in use, the PVC adhesive layer 3 has a relatively large hardness formula with a hardness of shoreA65°~75°, calculated in parts by weight: The speci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com