Integrated passenger car driving shaft framework with adjustable width

An adjustable and integrated technology, applied in the field of vehicles, can solve the problems of difficult control of welding process, four-wheel alignment deviation, insufficient welding strength, etc., and achieve the effect of solving four-wheel alignment deviation, high positioning accuracy and high assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described below with reference to the accompanying drawings. In order to provide a comprehensive understanding of the present invention, many details are described below, but it will be apparent to those skilled in the art that the present invention can be practiced without these details.

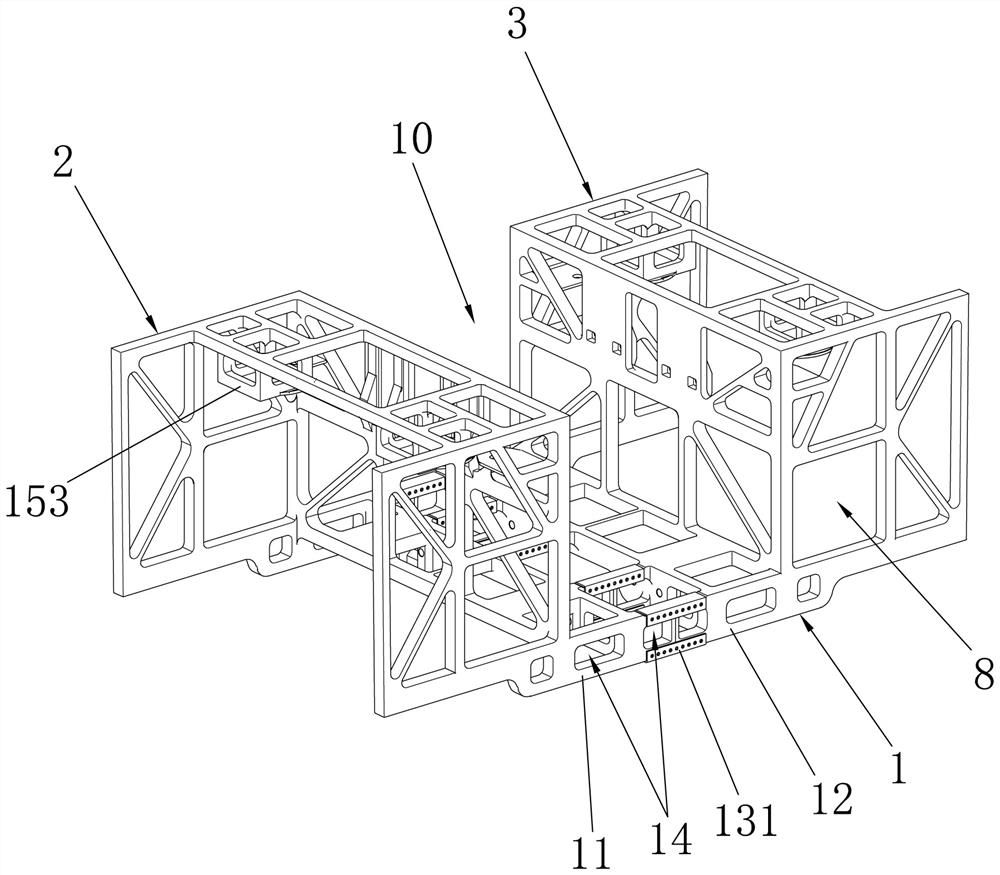

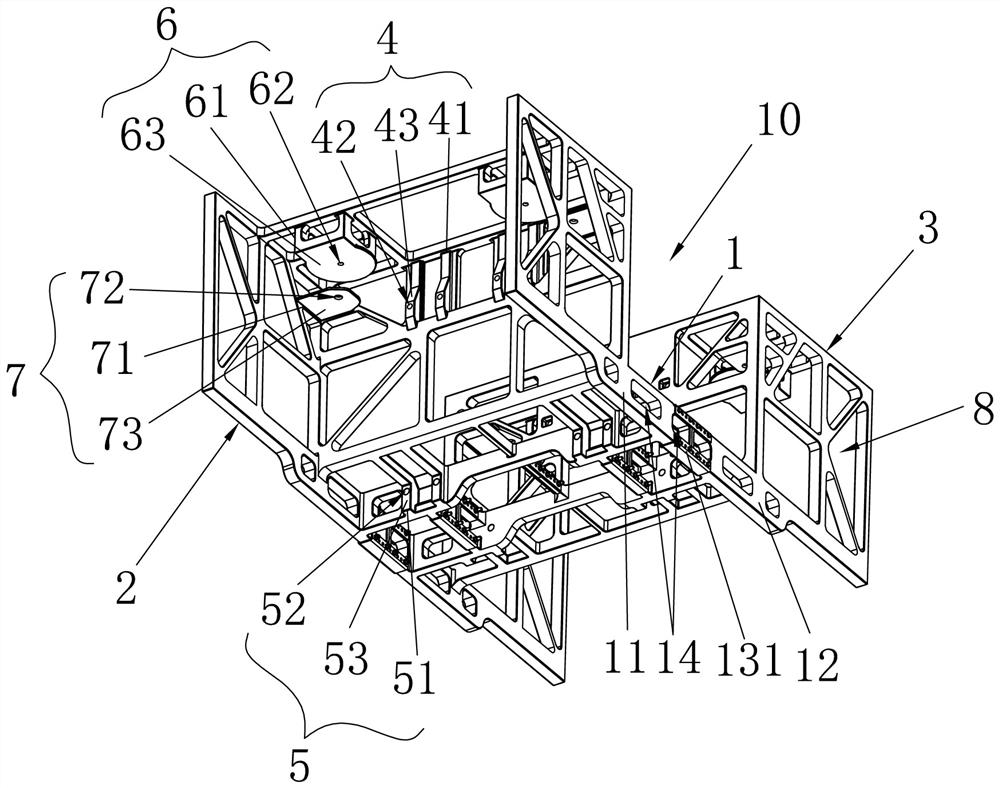

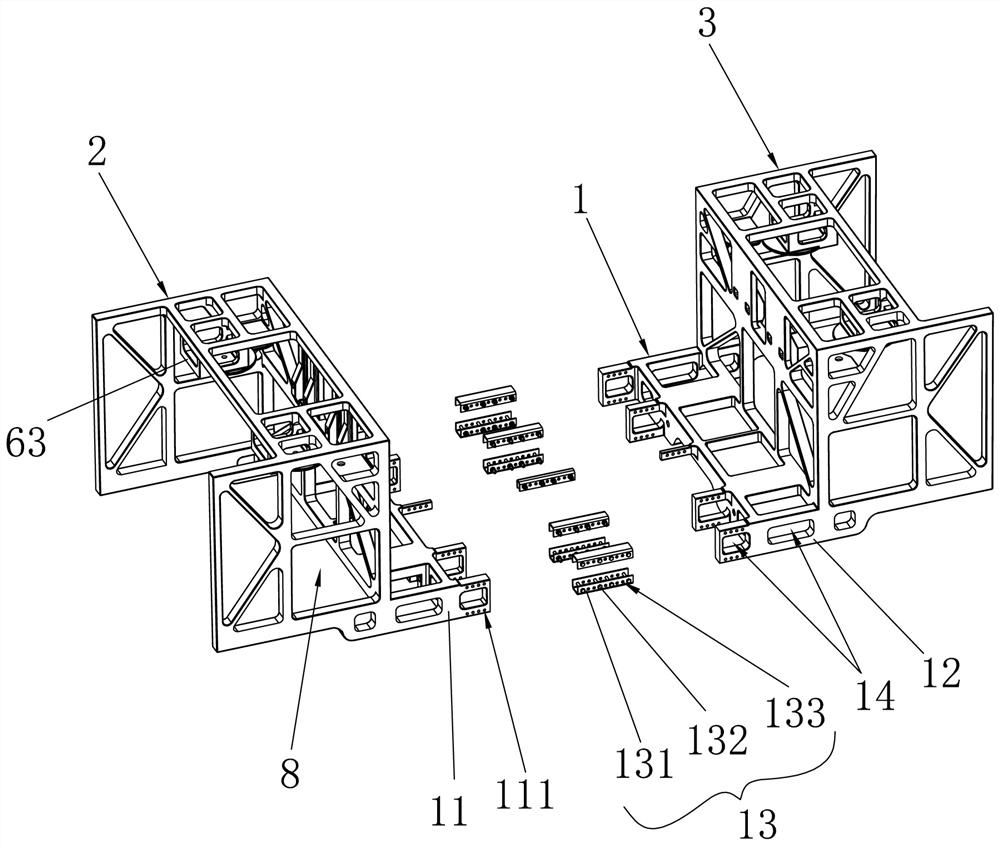

[0023] refer to Figure 1 to Figure 3 , a width-adjustable integrated bus drive shaft skeleton, including a skeleton body, the skeleton body has a middle skeleton 1, a left wheelhouse skeleton 2 and a right wheelhouse skeleton 3, and the left wheelhouse skeleton 2 and the right wheelhouse skeleton 3 are mutually symmetrically arranged On both sides of the middle frame 1, the aisle 10 is formed above the middle frame 1; the middle frame 1 includes a left frame 11, a right frame 11 and a connecting assembly 13; the left frame 11 and the left wheelhouse frame 2 are integrally cast, The right frame 12 and the right wheelhouse frame 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com