Prefabricated building wall truss structure

A technology for building walls and prefabrication, which is applied to truss structures, building components, building structures, etc. It can solve problems such as inconformity with on-site installation conditions and the inability to adjust the width of trusses, achieving good convenience and good practicability , Enhance the effect of supporting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following is further described in detail through specific implementation methods:

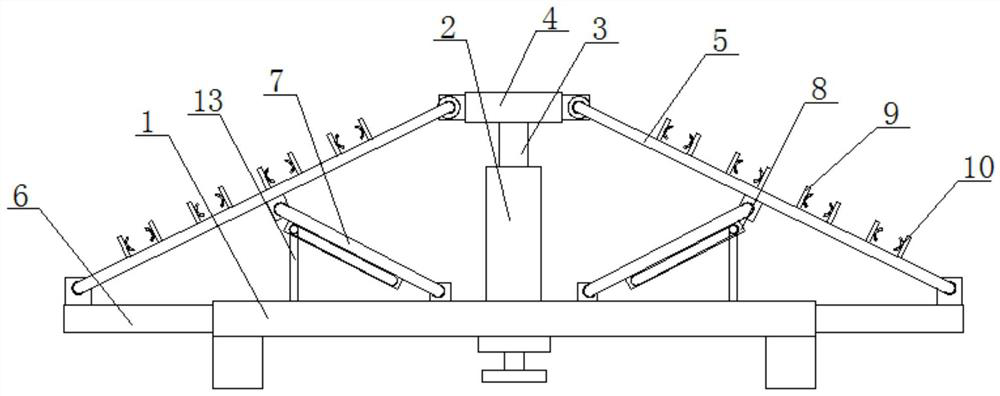

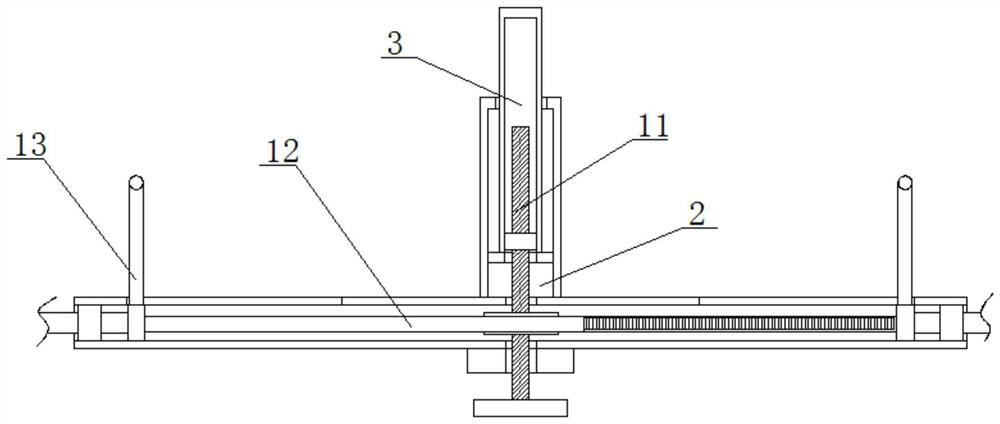

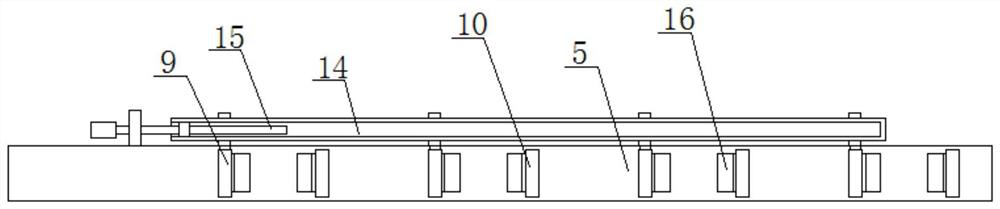

[0029] Such as Figure 1-6 A prefabricated building wall truss structure shown includes a support tube 1, a support cover 2 is fixedly installed on the top of the support tube 1, and a lift cover 3 is slidably connected to the support cover 2, and the top of the lift cover 3 extends to The top of the support cover 2 is fixedly installed with a connecting pipe 4, and both sides of the connecting pipe 4 are rotatably connected with a supporting beam 5, and two moving columns 6 are symmetrically slidingly connected in the supporting tube 1, and the two moving columns 6 are far away from each other. One end extends to the outside of the support tube 1 and is respectively connected to the two support beams 5 in rotation. The inner wall of the support tube 1 is rotatably connected to a drive screw 11, and the top end of the drive screw 11 extends into the lift cover 3 and is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com