Composition for preparing water-based anti-corrosion ink, water-based anti-corrosion ink, preparation method and application thereof and demetallization method

A composition and water-based technology, which can be used in inks, applications, household appliances, etc., can solve problems such as corrosion of the protected aluminum layer, and achieve the effects of corrosion prevention, safe use, and high printing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0029] According to a preferred embodiment of the present invention, the sum of the hydroxyl value and the acid value of the water-based resin is less than 50 mg KOH / g, and the weight average molecular weight is not less than 5000. Under this preferred embodiment, the prepared water-based anti-corrosion ink is more conducive to protecting the metal layer and has better corrosion resistance.

[0030] According to the present invention, preferably, the water-based resin is at least one selected from water-based polyurethane, water-based self-crosslinking polyacrylate, water-based epoxy emulsion and water-based polyester.

[0031] According to the present invention, preferably, the aqueous crosslinking agent is at least one selected from isocyanate compounds, oxazoline compounds, carbodiimide compounds and aqueous titanate chelates.

[0032] In the present invention, the water-based cross-linking agent can be selected in a wide range, preferably, the deblocking temperature of the...

Embodiment 1

[0061] Adopt the method provided by the invention to prepare water-based anticorrosion ink, concrete steps comprise:

[0062] (1) At room temperature, under stirring conditions, introduce the water-based dispersant into the solvent to obtain a uniform solution, introduce the filler and continue to stir for 0.5h, and after uniform grinding, the first solution is obtained;

[0063] (2) Under the condition of stirring, the water-based resin and the water-based crosslinking agent are introduced in sequence, and after continuous stirring for 0.5 h, the water-based anti-corrosion ink is obtained.

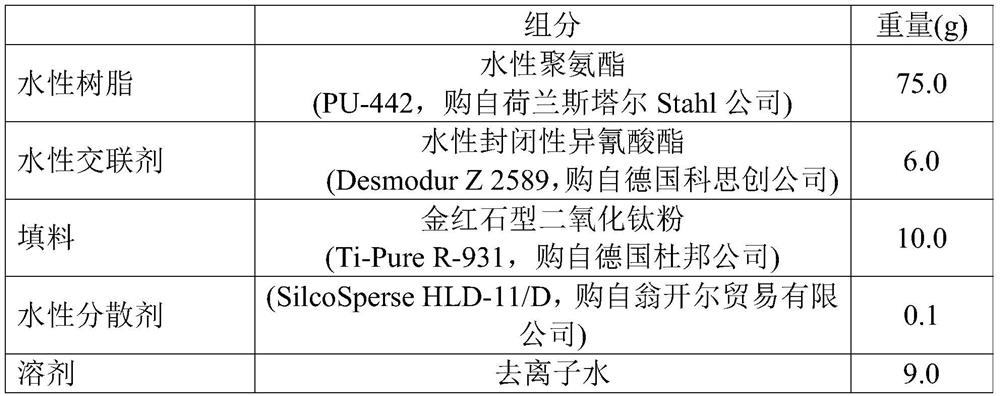

[0064] The types and dosages of compositions for preparing water-based anticorrosion inks are listed in Table 1.1.

[0065] Table 1.1

[0066]

[0067] Note: It has been determined that the sum of the hydroxyl value and acid value of the waterborne polyurethane is 15 mg KOH / g.

Embodiment 2

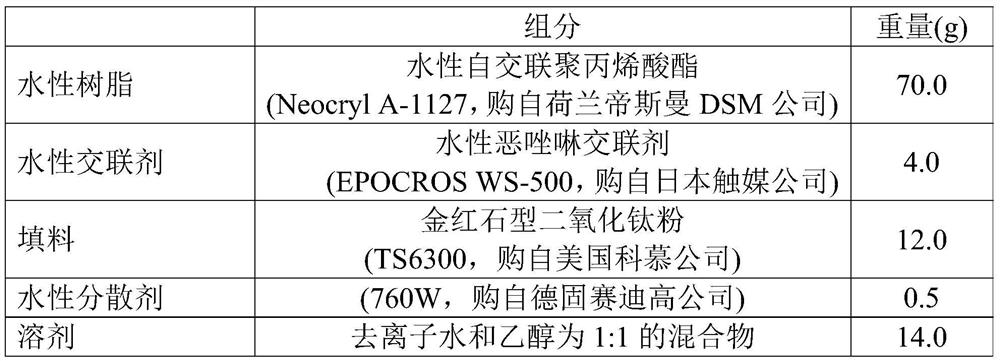

[0069] According to the method of Example 1, the difference is that the type and amount of the water-based anti-corrosion ink composition are different, and the specific type and amount of the composition are listed in Table 1.2.

[0070] Table 1.2

[0071]

[0072] Note: It has been determined that the sum of the hydroxyl value and acid value of the aqueous self-crosslinking polyacrylate is 35 mgKOH / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com