Process database construction method for electric arc additive manufacturing deposition layer

An additive manufacturing and construction method technology, applied in manufacturing tools, database design/maintenance, arc welding equipment, etc., can solve the problem that the process parameter database of arc additive manufacturing deposition layer has not been established, so as to improve surface quality and ensure mechanical performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

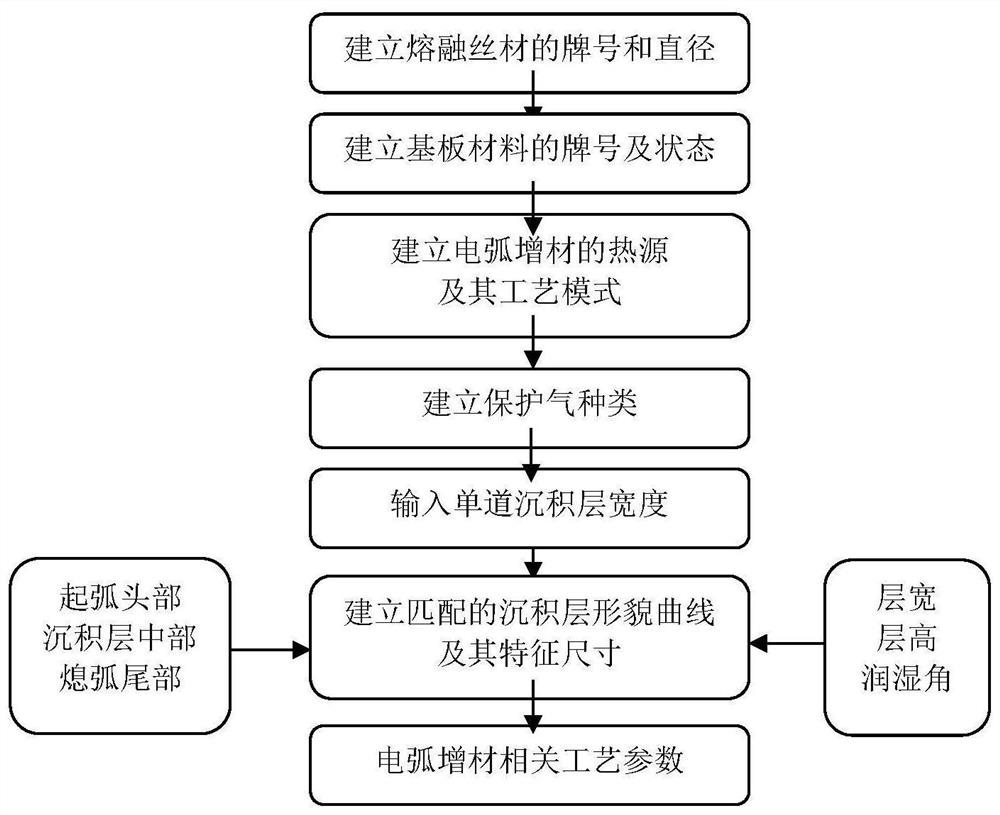

[0026] The invention provides a process database construction method for arc additive manufacturing deposition layer, which is characterized in that, comprising the steps:

[0027] Step 1: Establish the corresponding grade and diameter according to the type of fused wire used;

[0028] Step 2: Establish the grade corresponding to the substrate material;

[0029] Step 3: Establish the type of heat source for arc additive materials and its process mode;

[0030] Step 4; Establish the type of protective gas;

[0031] Step 5: Input the width of the single deposition layer;

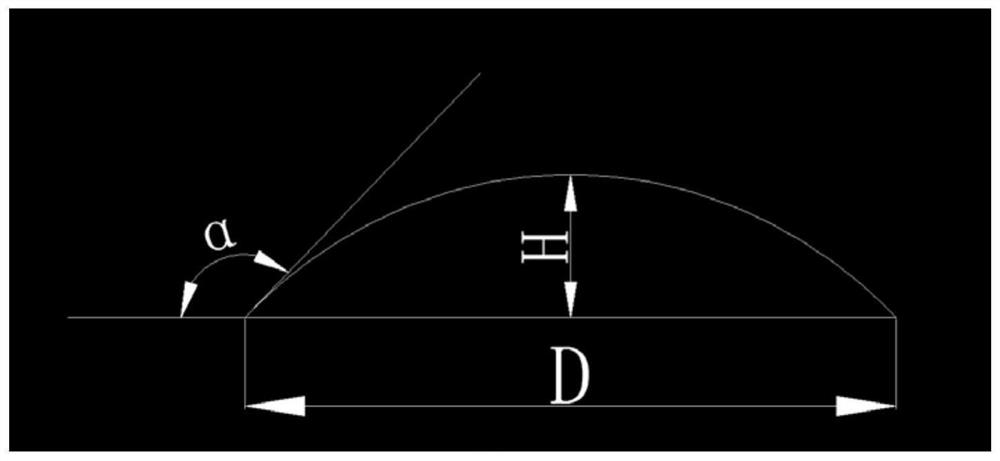

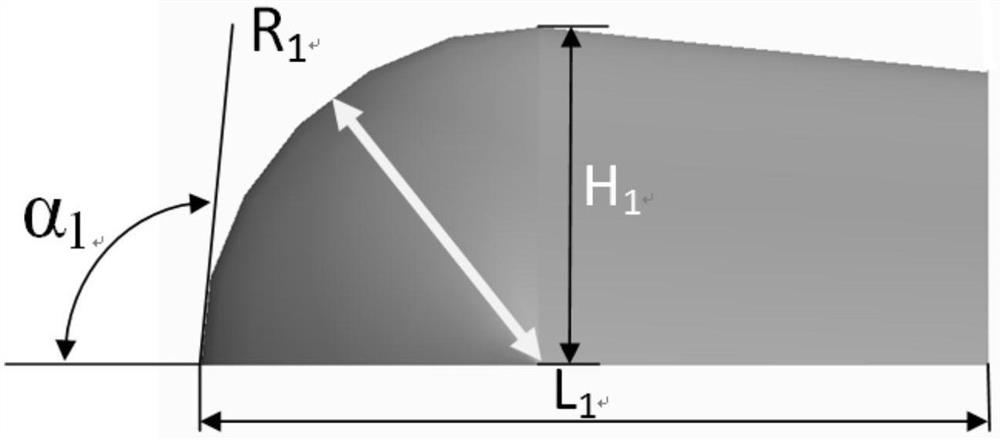

[0032] Step 6: Establish a matching sedimentary layer morphology curve and its characteristic size;

[0033] Step 7: Establish relevant process parameters for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com