Widening process and apparatus for rolled plastic film and sheet

A plastic film and sheet widening technology, which is applied in the field of expanding and widening technology and equipment, can solve the problems of not meeting the requirements of wide-width products, poor flattening degree, and affecting product quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

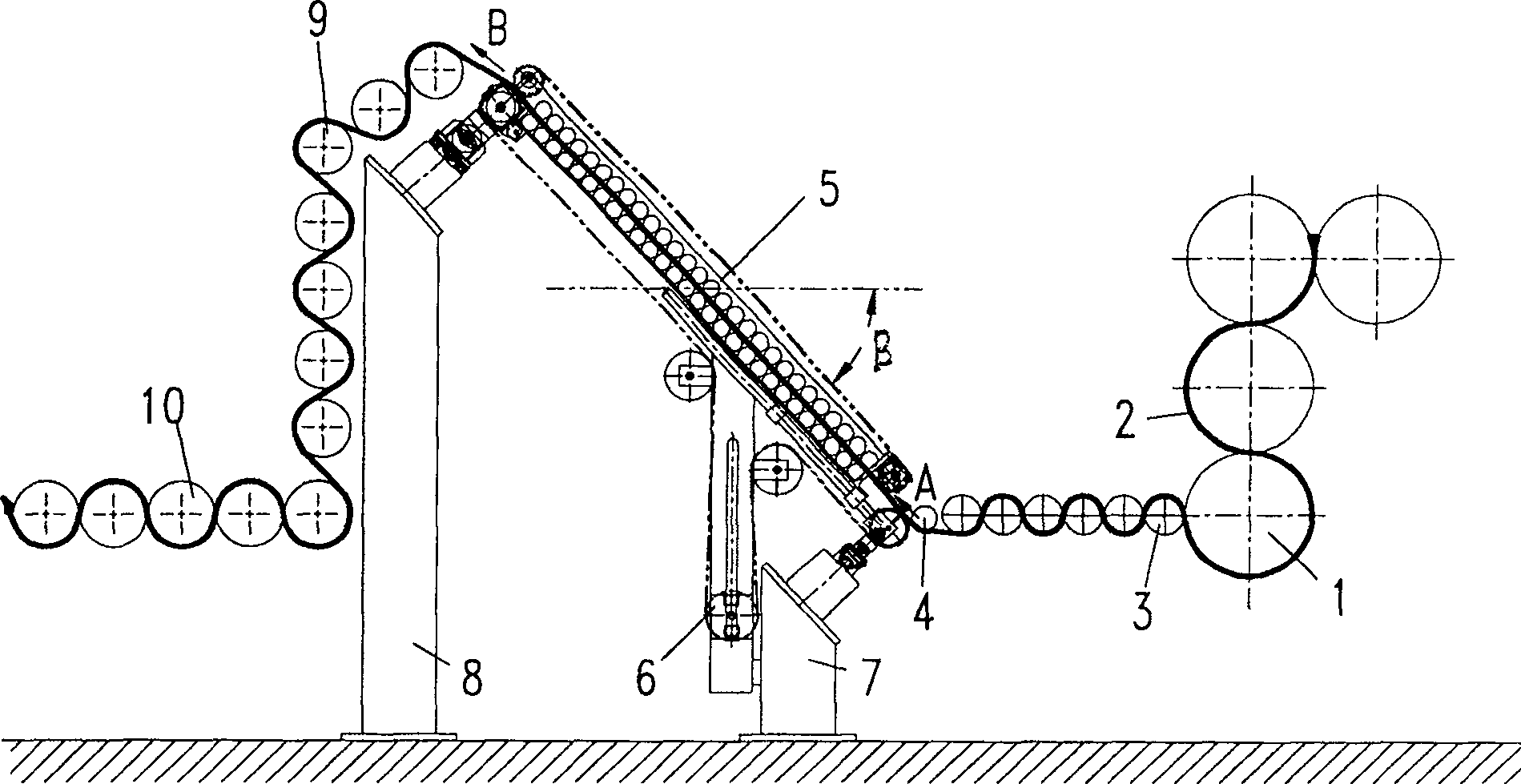

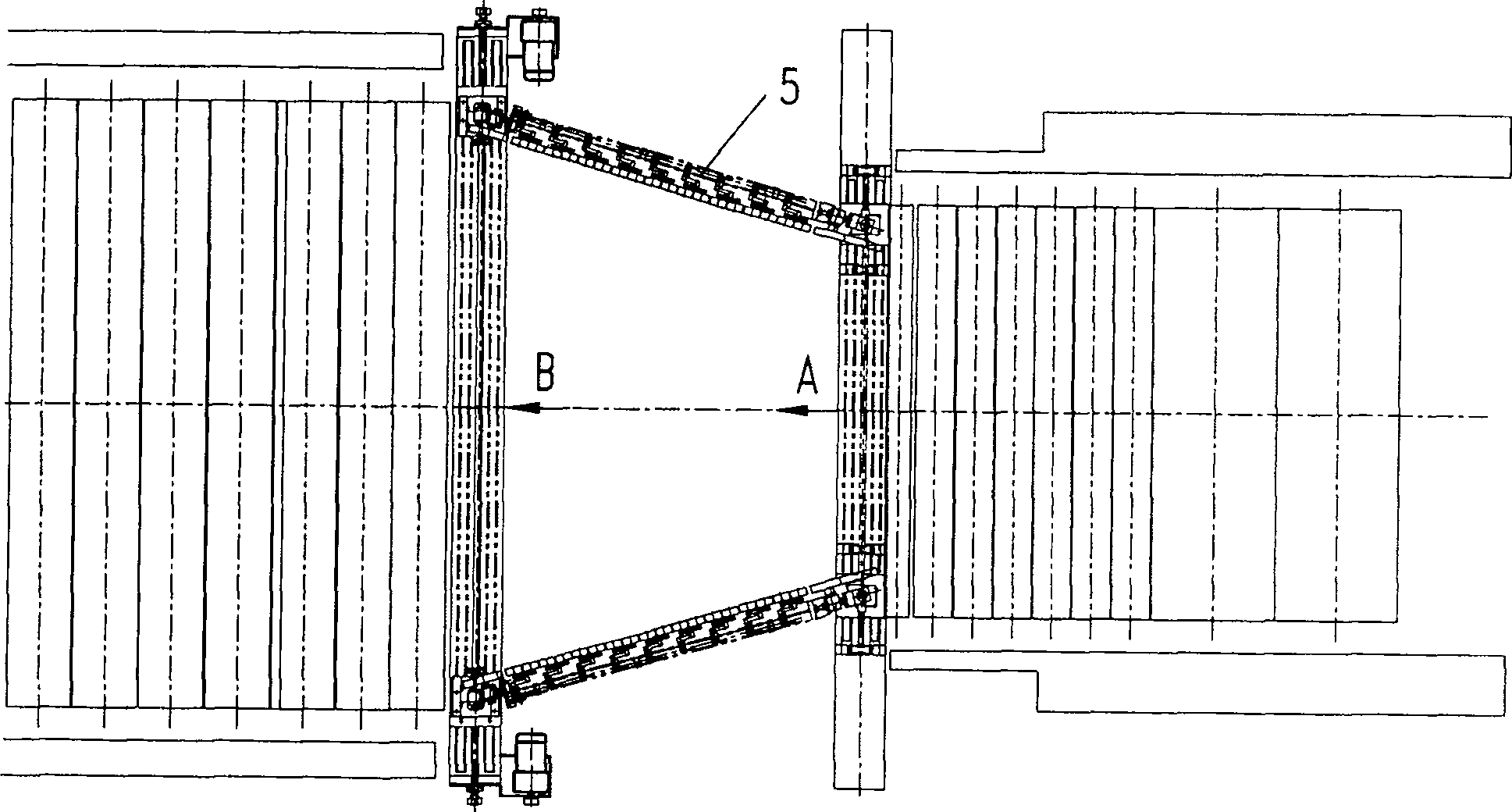

[0010] The present invention is described further in conjunction with embodiment and accompanying drawing:

[0011] This embodiment is a calendering widening device for producing 5500mm wide plastic film. It uses four groups of calendering wheels 1 to longitudinally calender and stretch the plastic film 2 when the width is 2000mm, and then passes through six groups of drawing wheels 3 in the horizontal direction. Repeated stretching, guided by the guide wheel 4 into the entrance A end of the stretching equipment 5 with an upward slope of β=40° and a length of 3500mm, the width of the A end is adjusted to 2000mm, and the two sides of the plastic film 2 are clamped in the stretching In the interlayer of the upper and lower V-belts wrapped around the upper and lower clamping wheels on both sides of the device 5, it is stretched wide during the forward stretching process until it reaches the B end of the widening device 5, and the width of the B end is adjusted to 5500mm, a clampi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com