Patents

Literature

102 results about "Filler - product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Micronized perlite filler product

ActiveUS20060075930A1High blue lightness brightnessLow oil absorptionCoatingsPlastic filmFiller - product

Micronized perlite filler product, methods of producing the micronized expanded perlite products, and methods of use thereof are provided. The micronized expanded perlite product has, for example, a small median particle size (for example, less than 11 microns), a high blue light brightness (for example, higher than 84) and low oil absorption (for example, less than 70 percent in volume). The micronized expanded perlite product may be used in a variety of applications such as anti-block filler in plastic films and reinforcement filler in polymers.

Owner:IMERYS USA INC

Process of preparing natural rubber filler with solid waste oil shale

The present invention relates to natural rubber filler, and is especially process of preparing natural rubber filler with solid waste oil shale. The process includes the following steps: 1. crushing and grinding solid waste oil shale to obtain solid waste oil shale powder; 2. surface modifying the solid waste oil shale powder with surface modifier in the amount of 0.8-3 wt% of the solid waste oil shale powder at 80-200 deg.c for 15-30 min to obtain modified solid waste oil shale powder; and 3. mixing the modified solid waste oil shale powder and anti-ageing agent in the weight ratio of 10-60 to 2-4 to obtain the natural rubber filler product. The anti-ageing agent contains at least one component capable of deactivating heavy metal elements. The present invention has simple preparation process and low cost.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

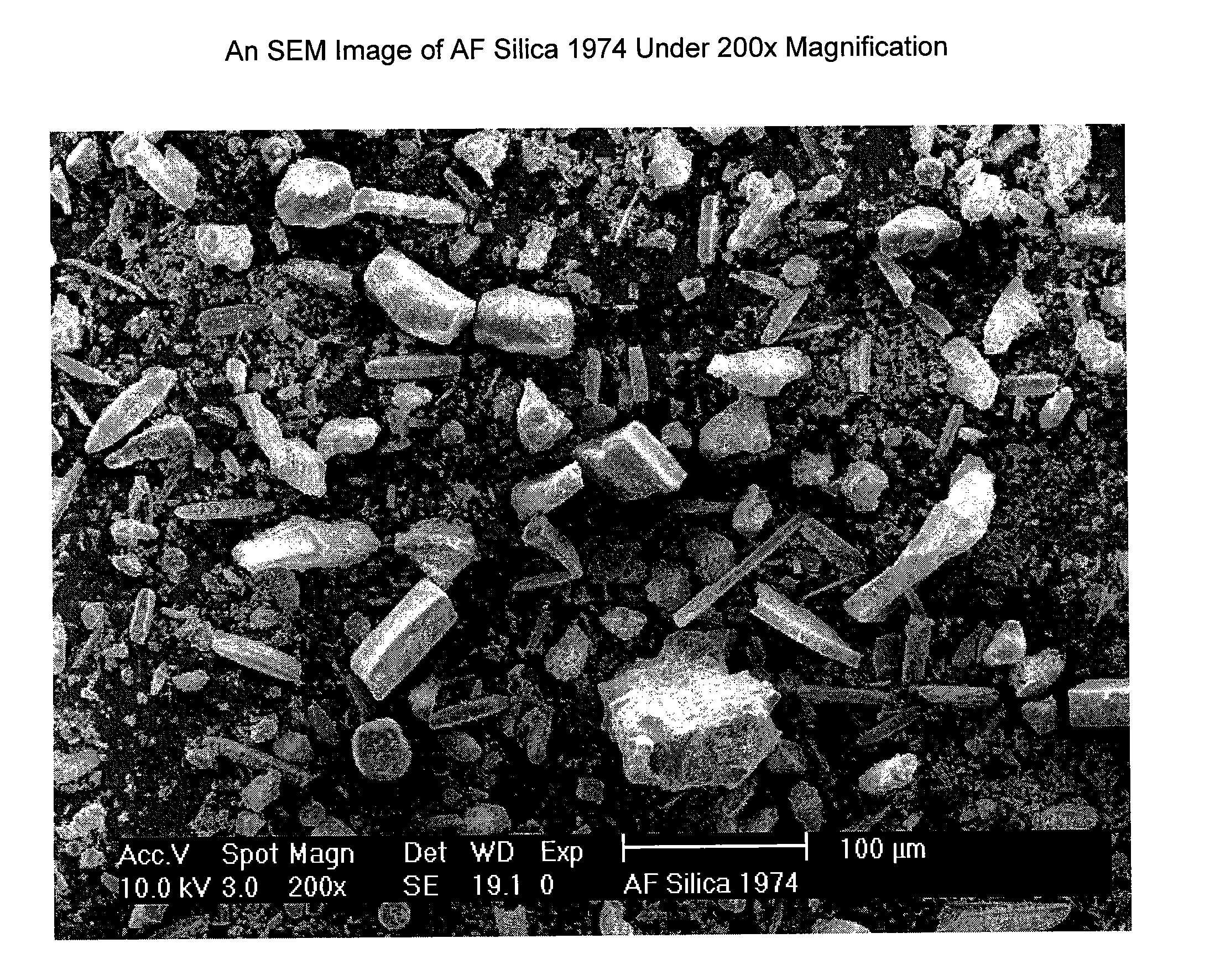

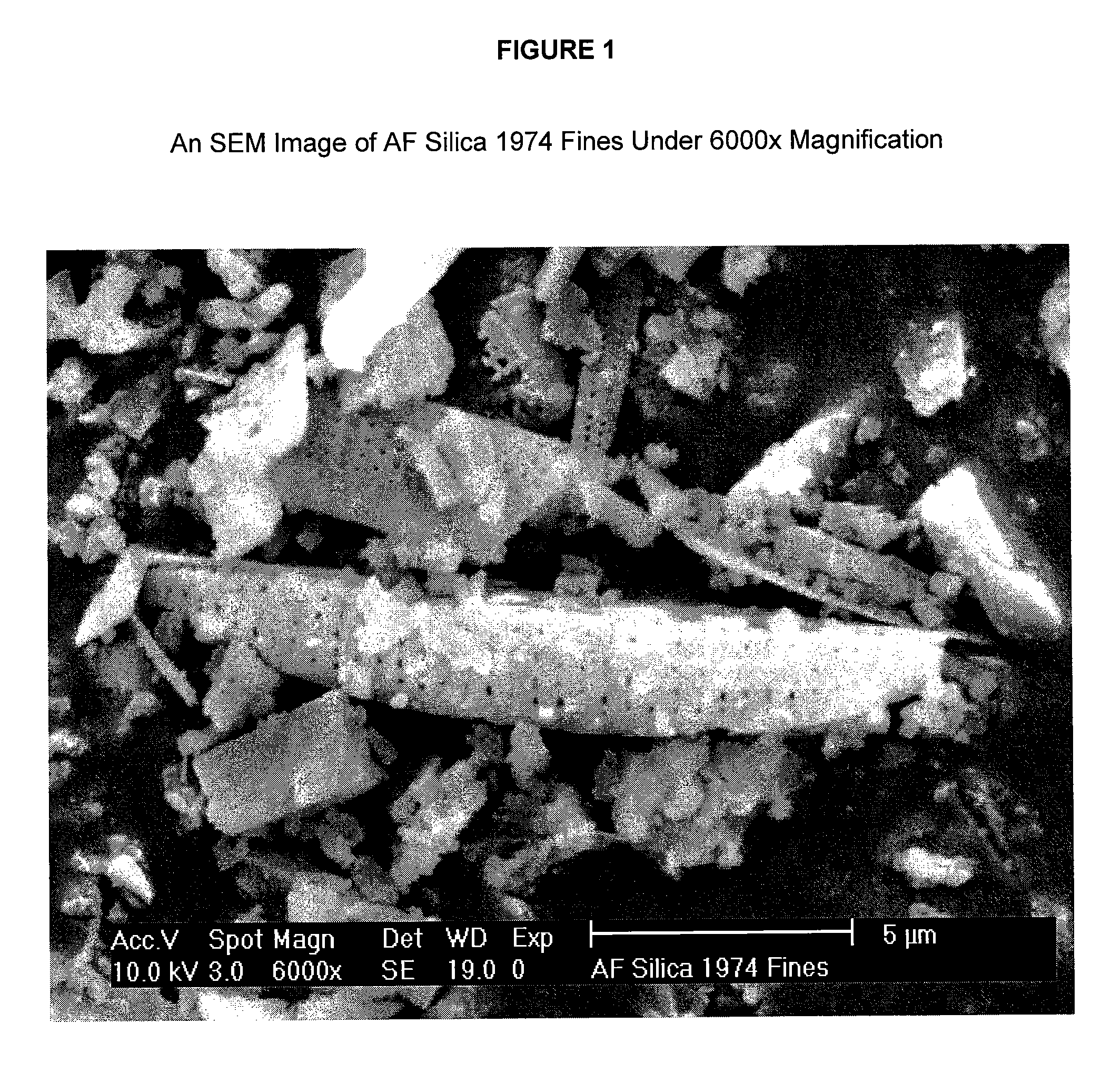

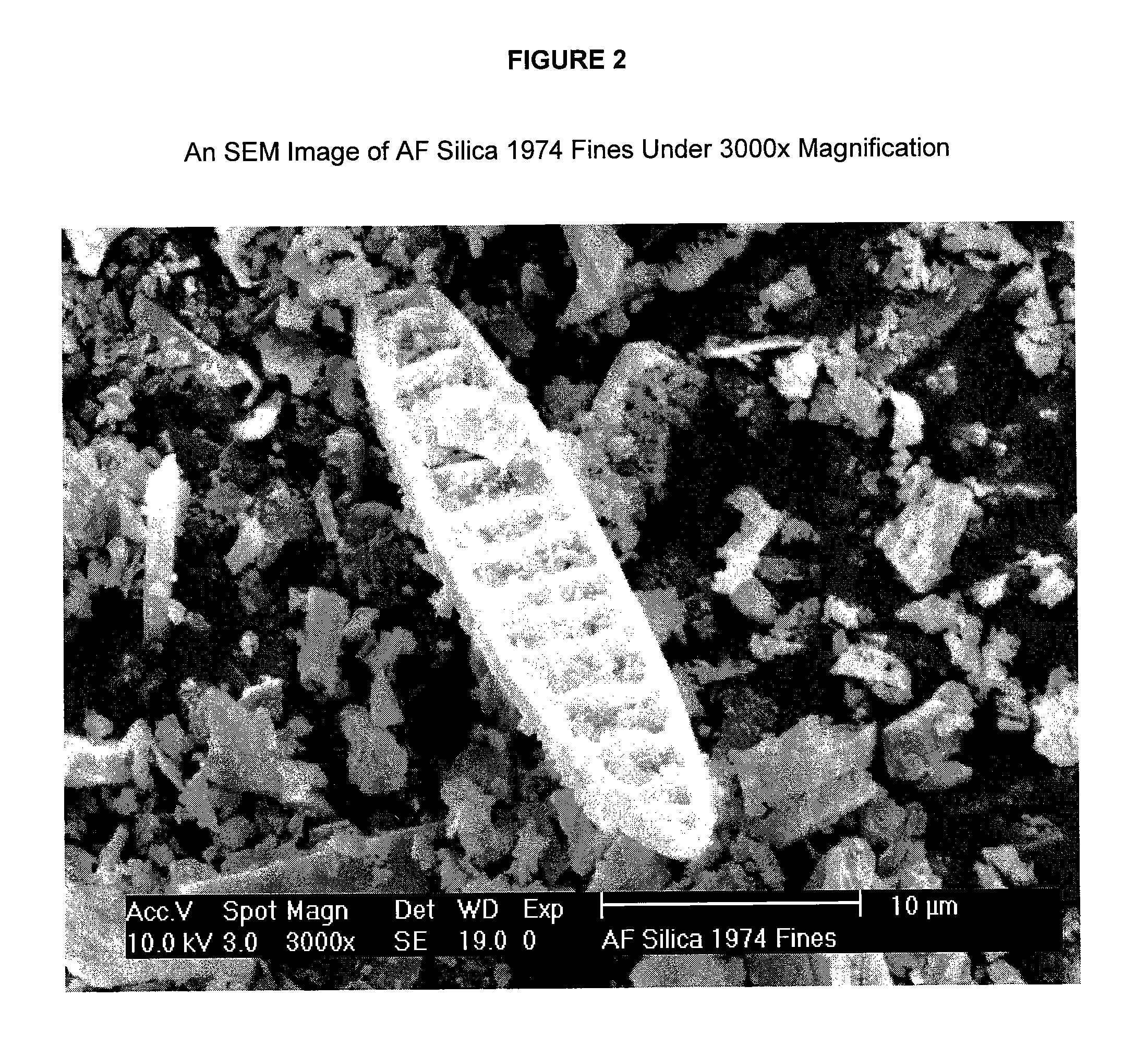

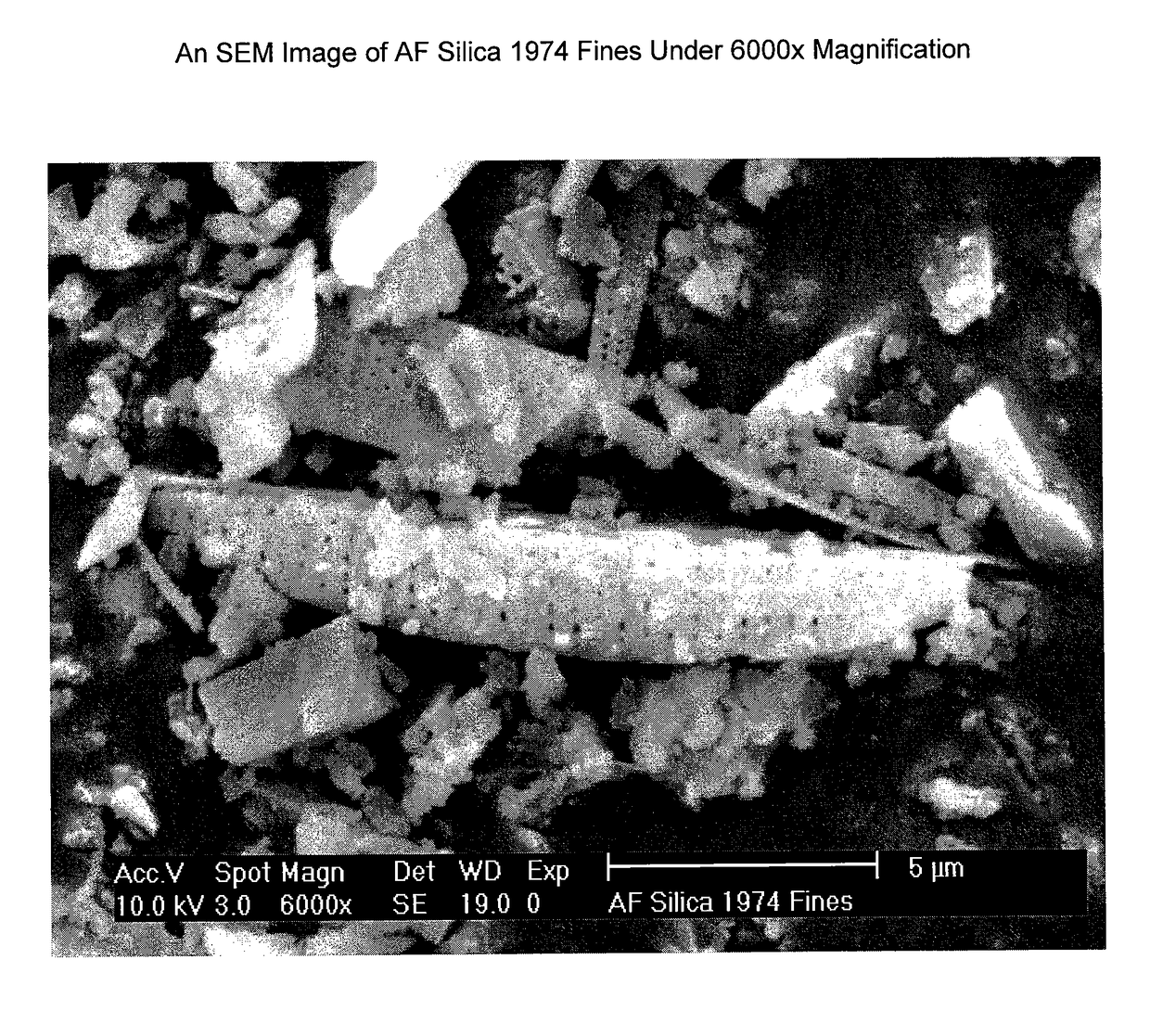

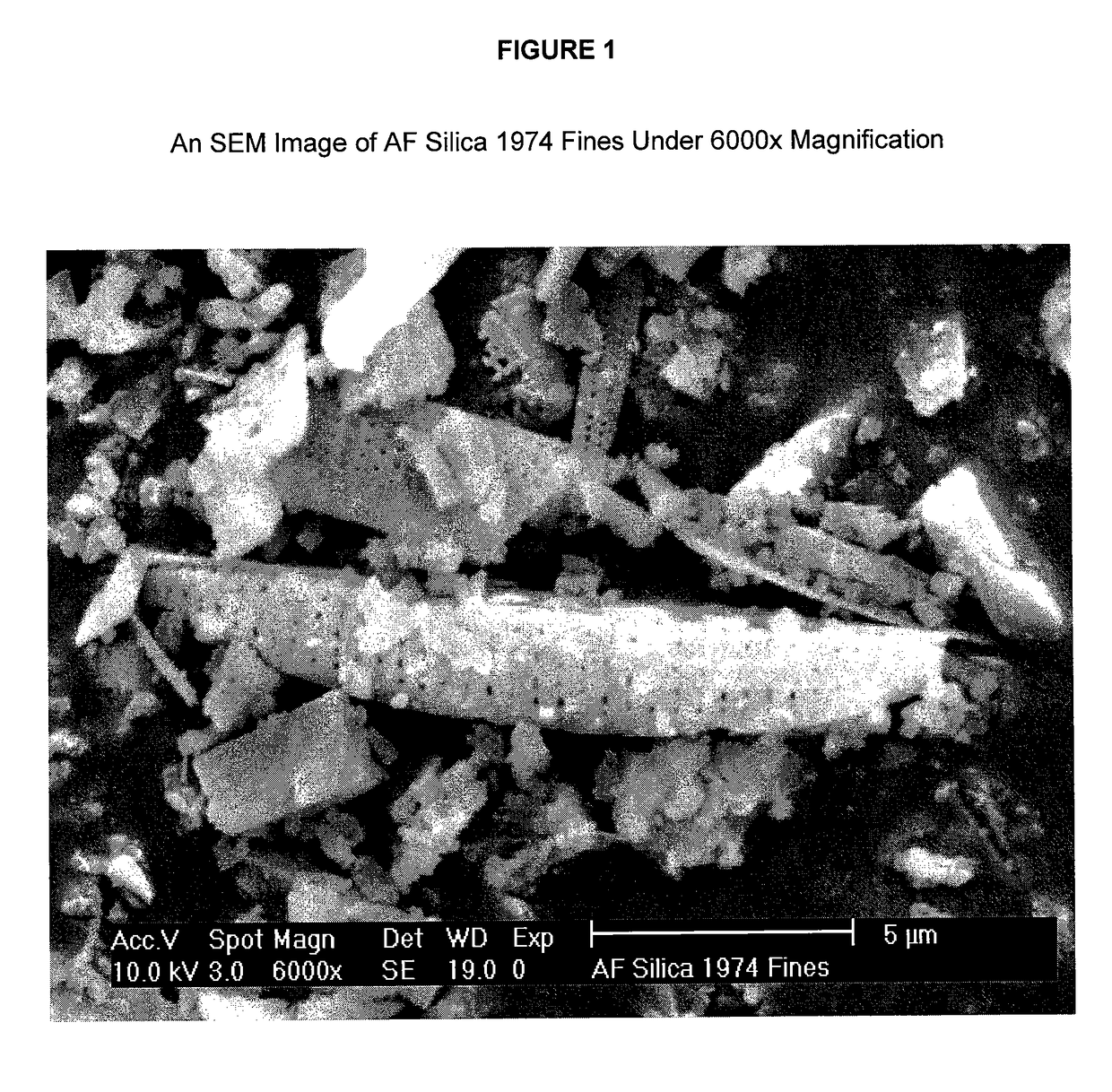

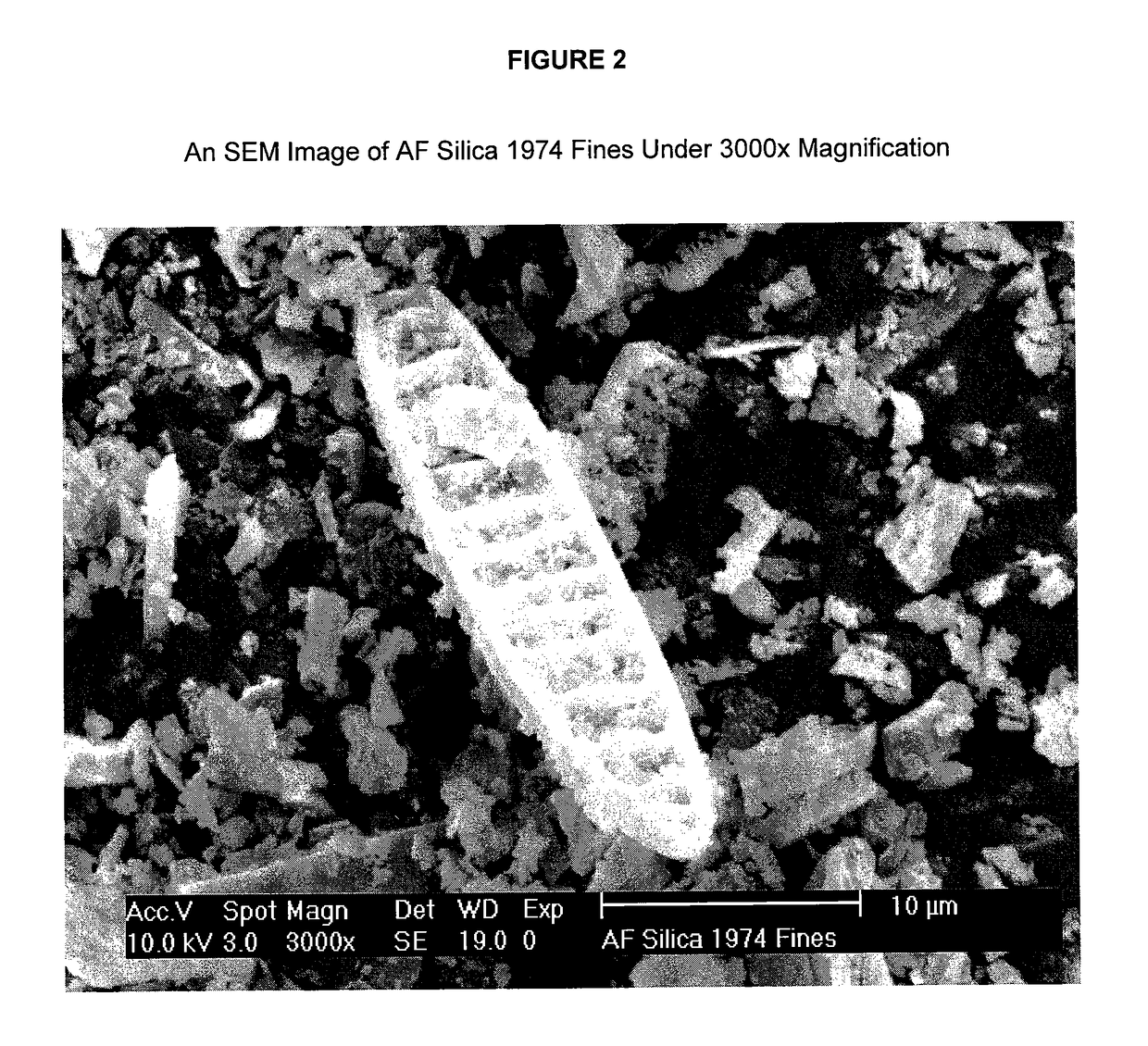

Natural amorphous silica filler products

ActiveUS20120048145A1Increase brightnessReduce absorptionPigmenting treatmentSpecial tyresSilicon dioxideSealant

Natural amorphous silica filler products featuring high brightness, low oil absorption, fine particle size, and low crystalline silica content are described. Methods for making, using, and measuring the properties of the natural amorphous silica filler products are also described. The natural amorphous silica filler products described herein may be useful in a variety of products including, but not limited to, polymers, sealants, paints, caulks, latex, architectural coatings, industrial coatings, pozzolan, glass catalysts, ceramic glazes, and anti-blocking applications.

Owner:IMERYS USA INC

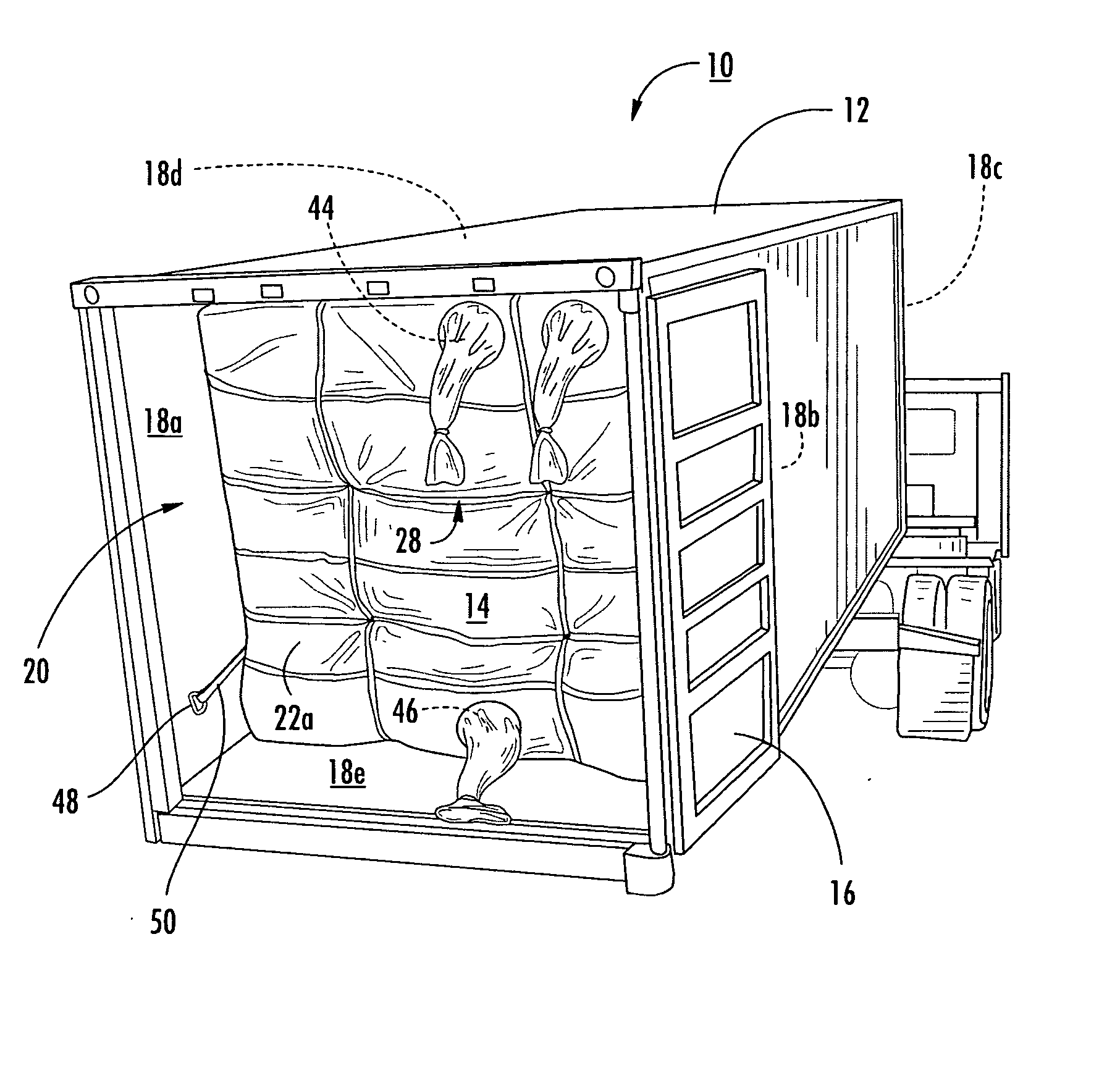

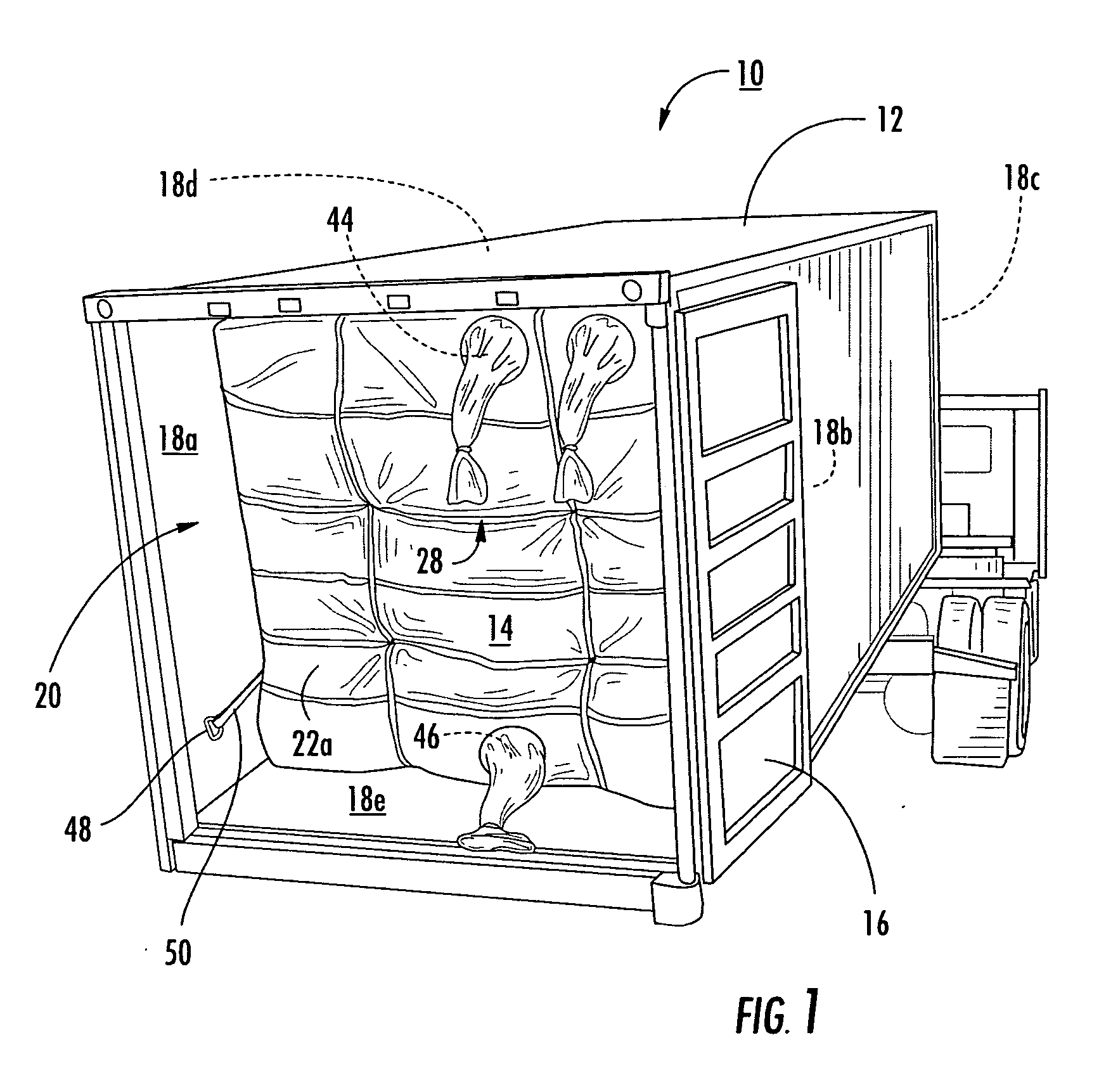

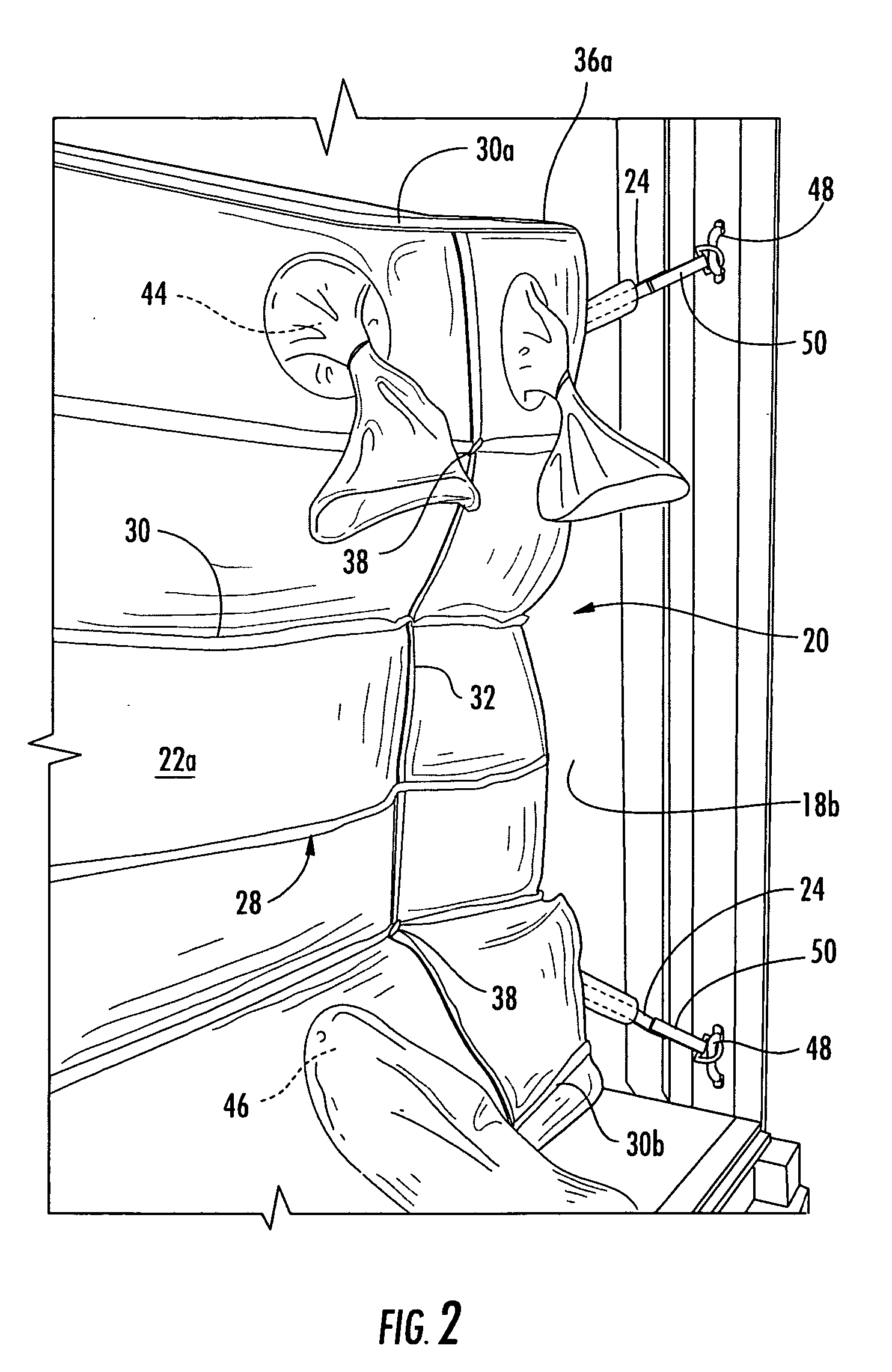

Braceless liner

InactiveUS20060175324A1Simple and economical to manufacture and assemble and useAvoid contactLarge containersLinings/internal coatingsShipping containerLoad bearing

A container system having a bulkhead liner and method of using the bulkhead liner includes a pliable body with an exterior surface and an interior surface forming a cavity therein. At least one loading aperture is formed through the exterior and interior surfaces for loading a product in the cavity. When filled with the product, the pliable body substantially assumes a shape complementary to the shipping container shape. In one aspect of the invention, a lattice having a plurality of straps is affixed to the exterior surface to resist an expansion force exerted by the product from within the cavity. At least one load-bearing band is situated within the cavity of the pliable body shrouded by a sheath to protect the product from contamination by external elements to which the load-bearing band may be exposed. The load-bearing band is freely movable within the sheath to prevent damage to the pliable body when the product fills the cavity and imparts an expansion force against the pliable body. The load-bearing band is attached to a portion of the lattice to provide additional resistance against the expansion force exerted by the product in the cavity.

Owner:POWETEX

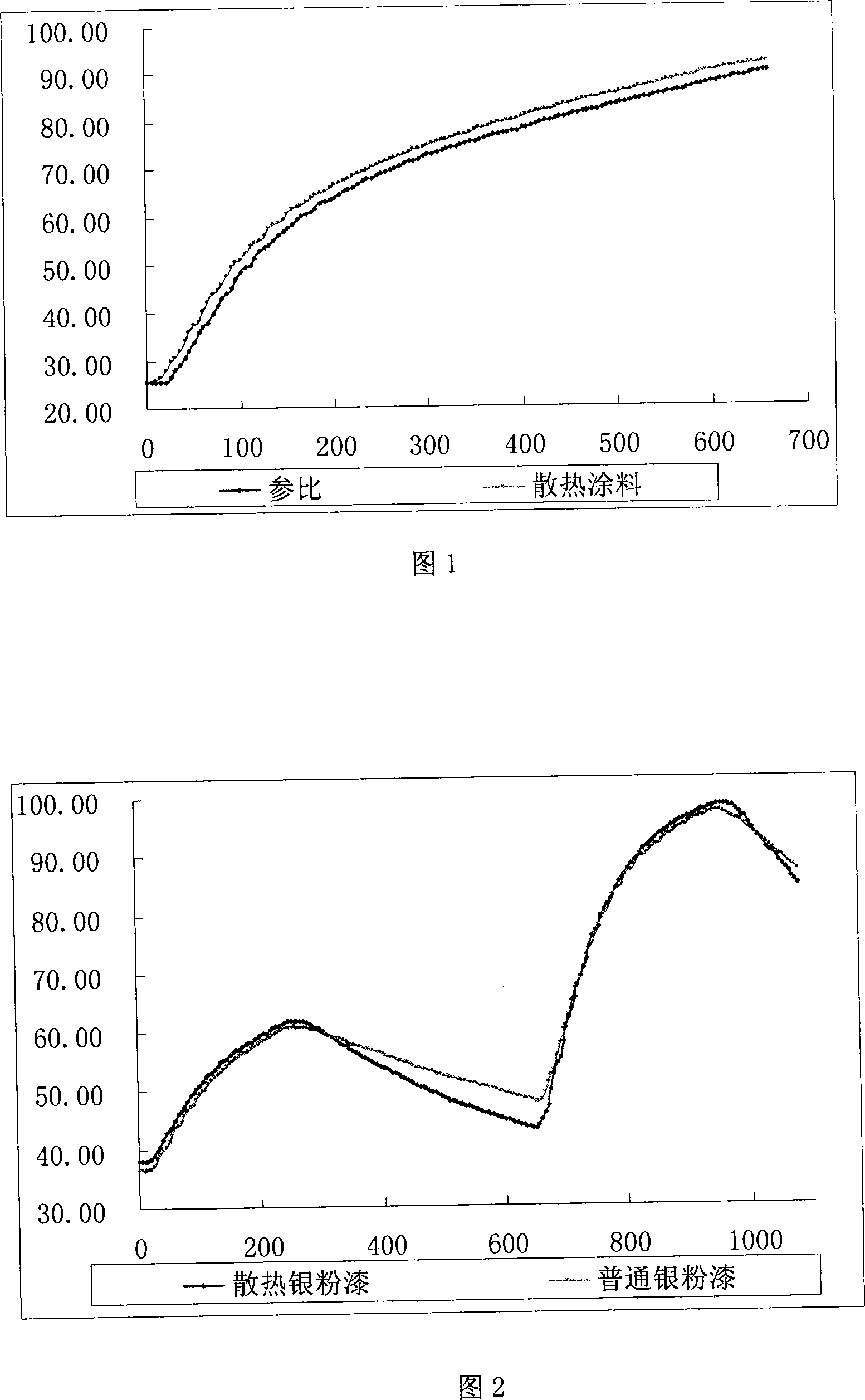

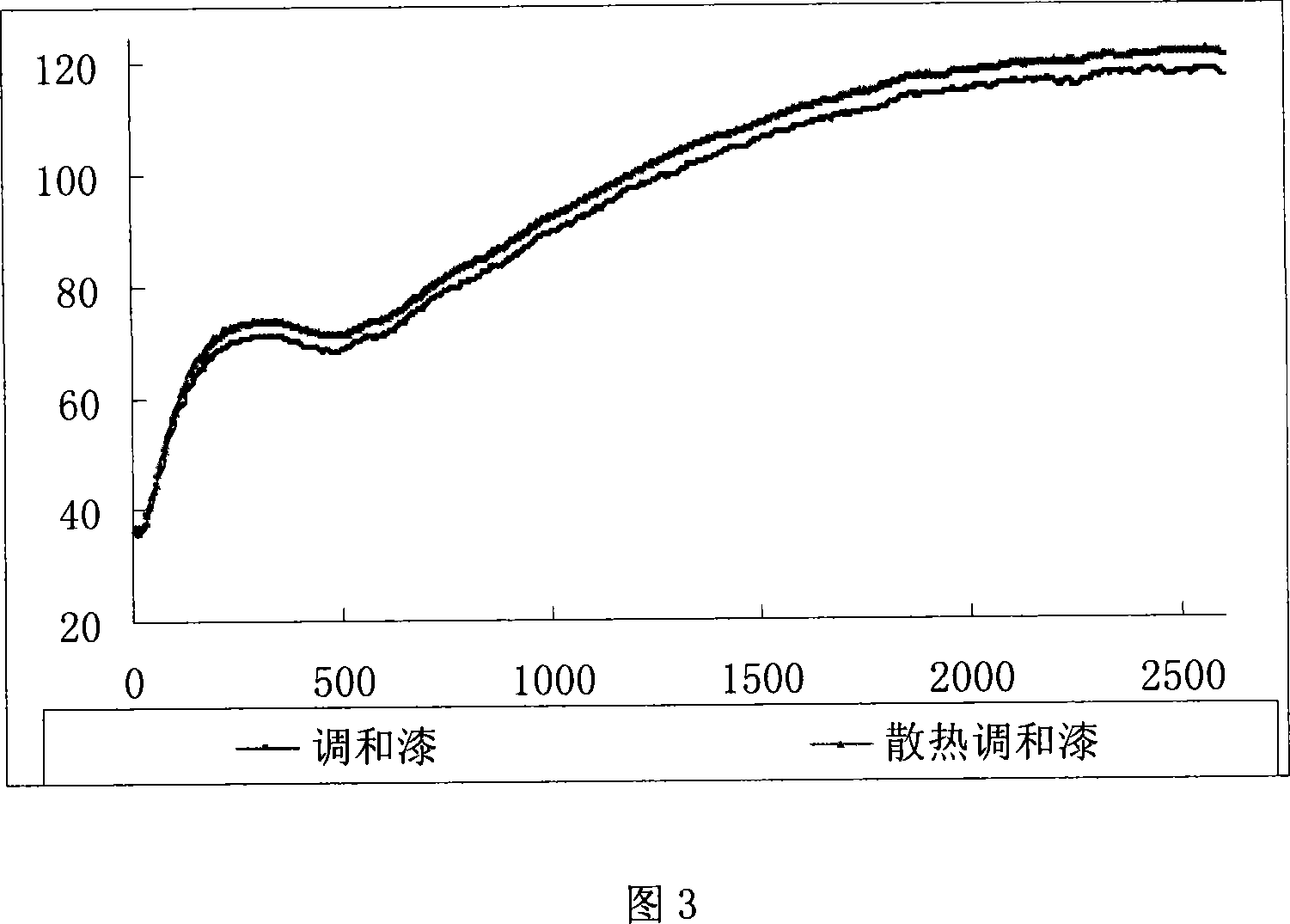

Infrared radiation filling material and applied method for the same in coating

InactiveCN101125969AImprove thermal conductivityEfficient radiationInorganic pigment treatmentCoatingsInfraredRare earth

The invention provides a filler which can radiate infrared and an application method in coating, relating to coating additive technical field. The preparation method of the filler is divided into the steps: 1. preparing metal oxide mother liquid doped with rare earth; 2. preparing gel; 3. preparing tourmaline metal oxide powder doped with rare earth; 4. preparing tourmaline metal oxide powder doped with secondary baked rare earth; 5. preparing filler product which can radiate infrared. The infrared radiation filler which is synthesized and mixed with the normal coating, can generate the infrared radiation coating, with the intensified radiation function. After renovation the filler can effectively radiate infrared in low temperature ranging from 50-200 DEG C and thermal conductive capacity thereof is evidently increased and the temperature of thermal pipe surface is increased when the thermal pipe surface is coated with the coating.

Owner:HEBEI UNIV OF TECH

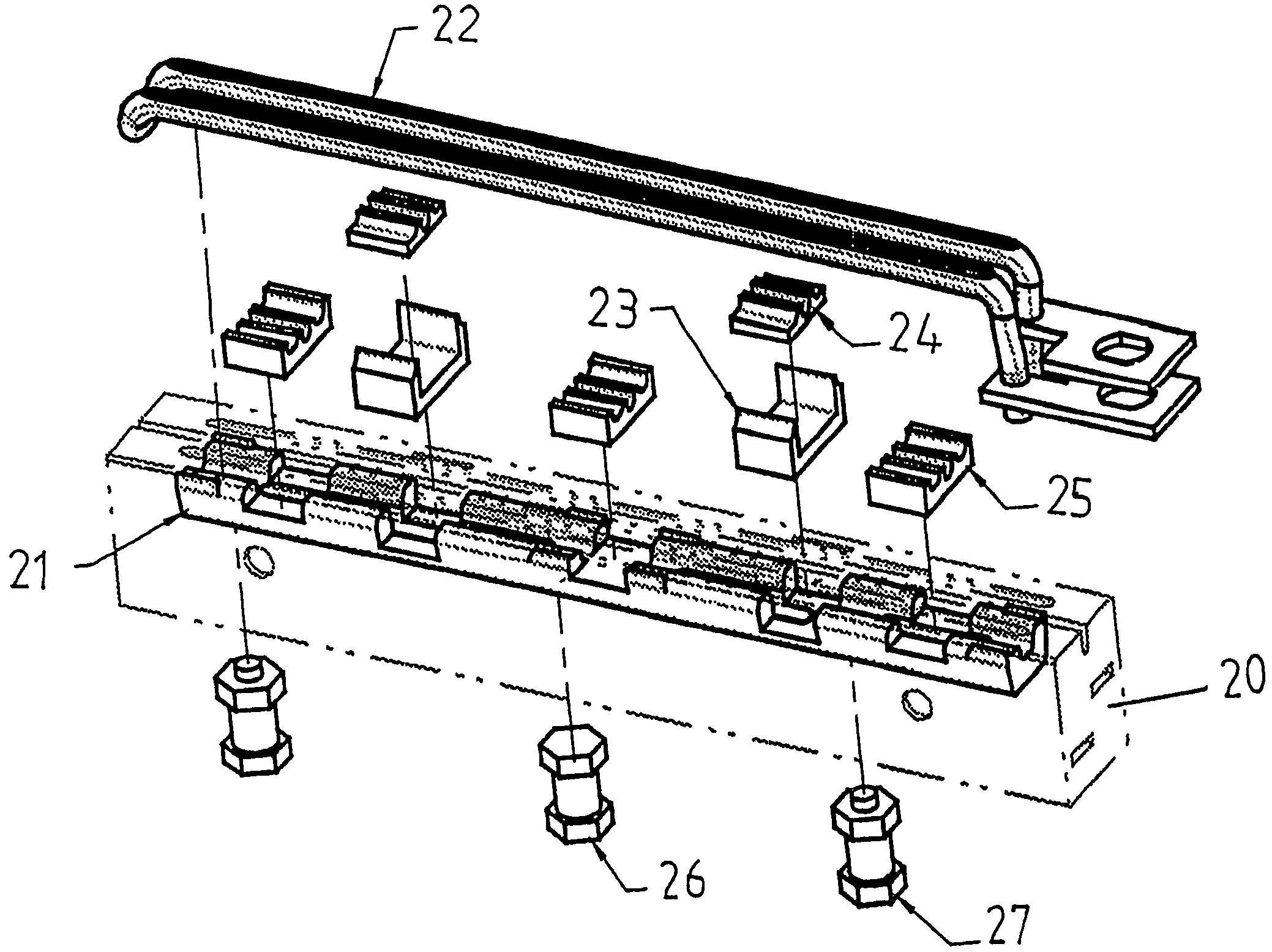

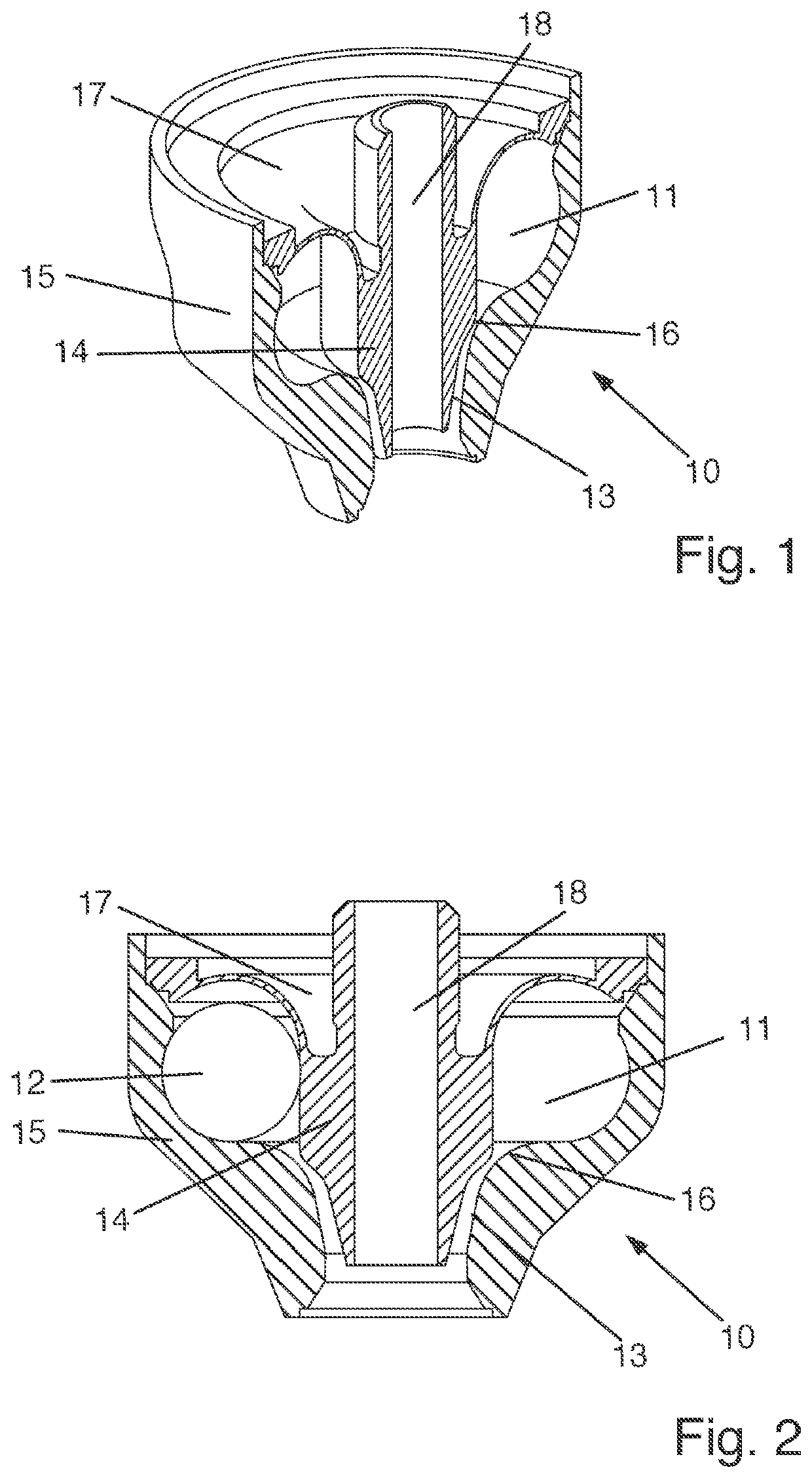

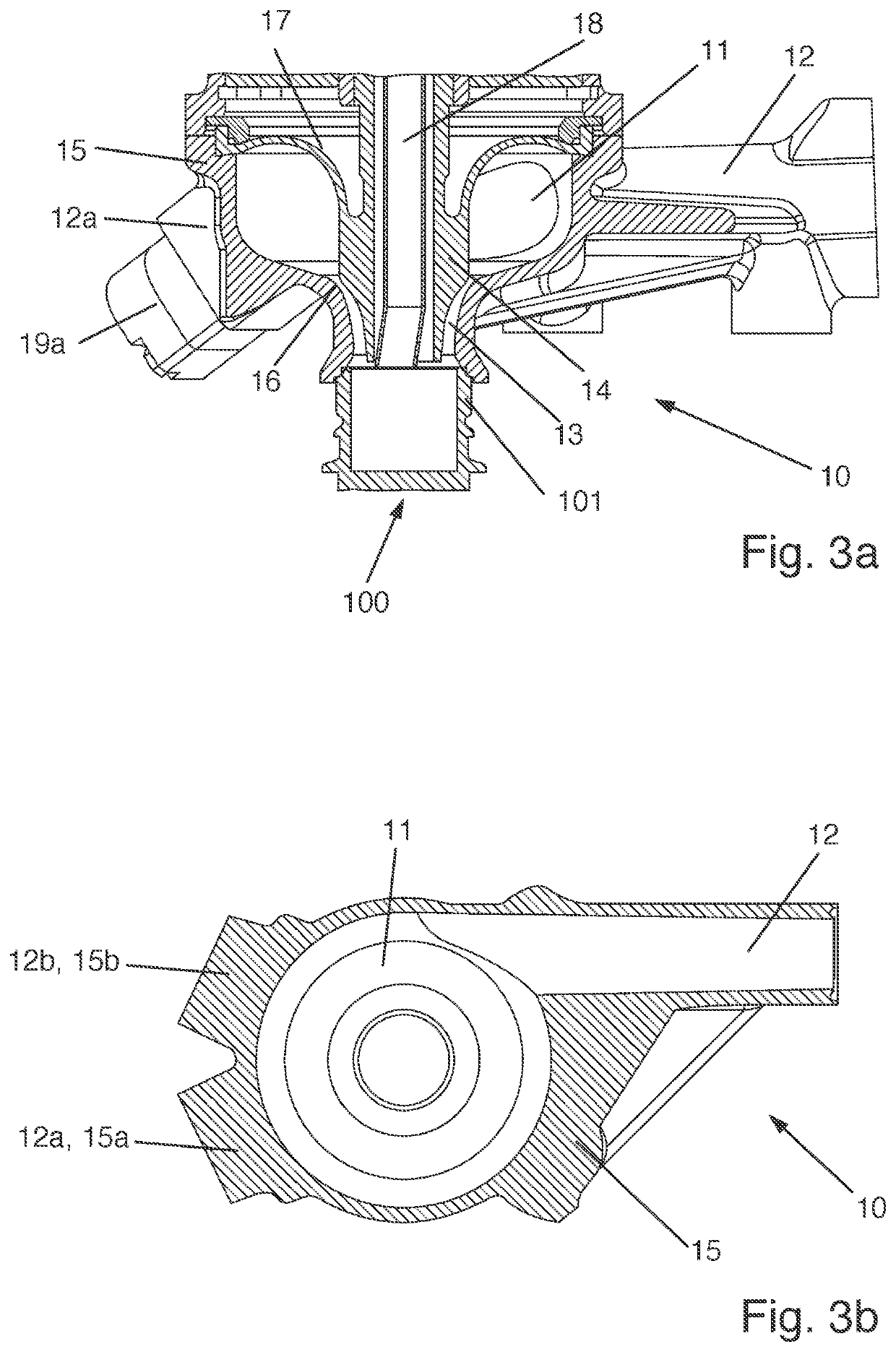

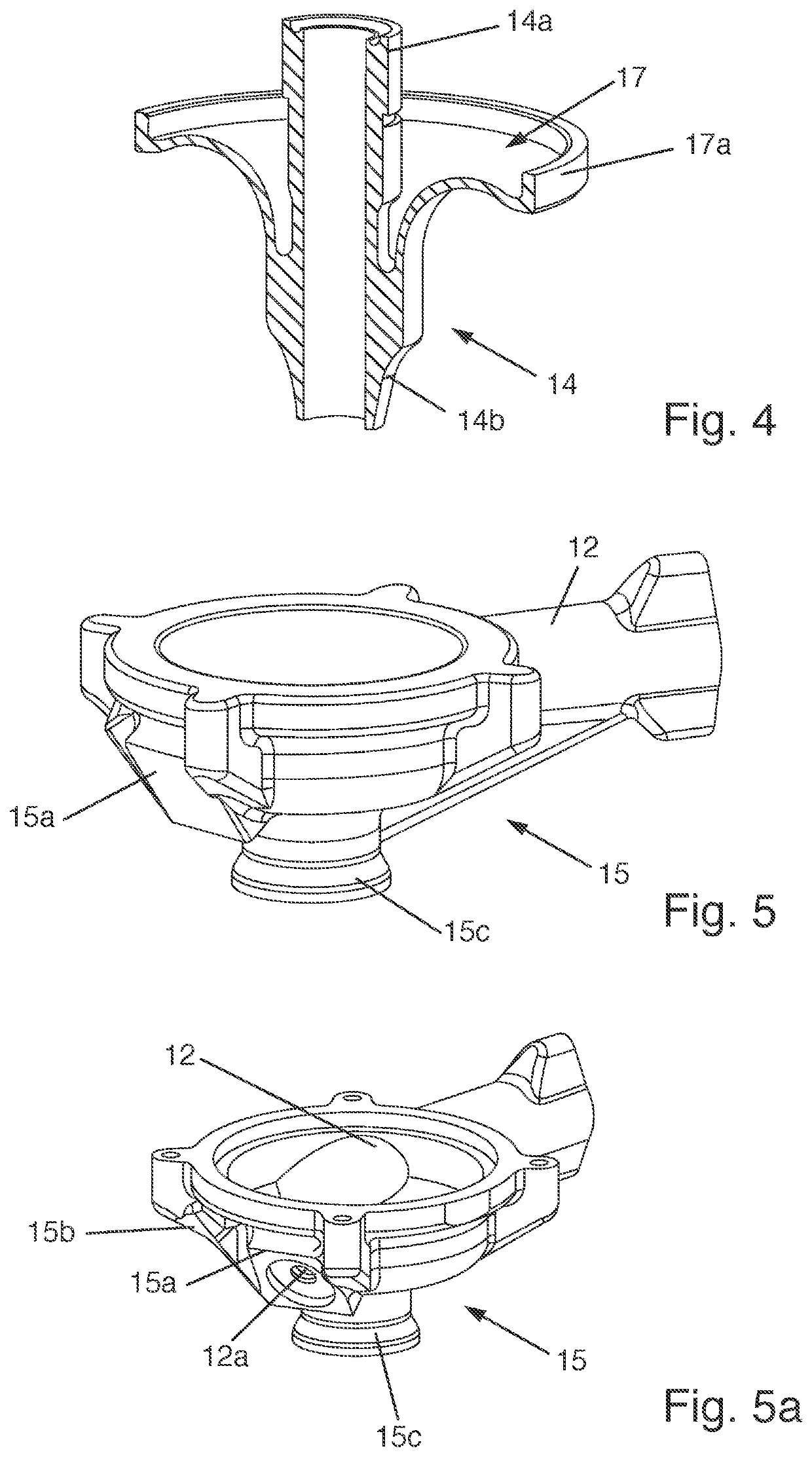

Sealing jaw

A sealing jaw for manufacturing a sealing seam in a heat-sealable packaging material. The invention furthermore relates to an induction sealing device with a sealing jaw and to a packaging machine with induction sealing device. In order to provide a sealing jaw with which a sealed and durable sealing seam can be produced, even when solid components of the in-filled product are trapped between the jaws that have to be moved towards one another, a sealing jaw is proposed with means of a sealing jaw with a sealing surface that is provided in order to come into contact with the heat-sealable material, and a rod or bar-shaped heating device that is provided in order to heat up the heat-sealable material, wherein a pressure element is provided on the sealing surface, projecting above said sealing surface, and distanced from the heating device.

Owner:TETRA LAVAL HLDG & FINANCE SA

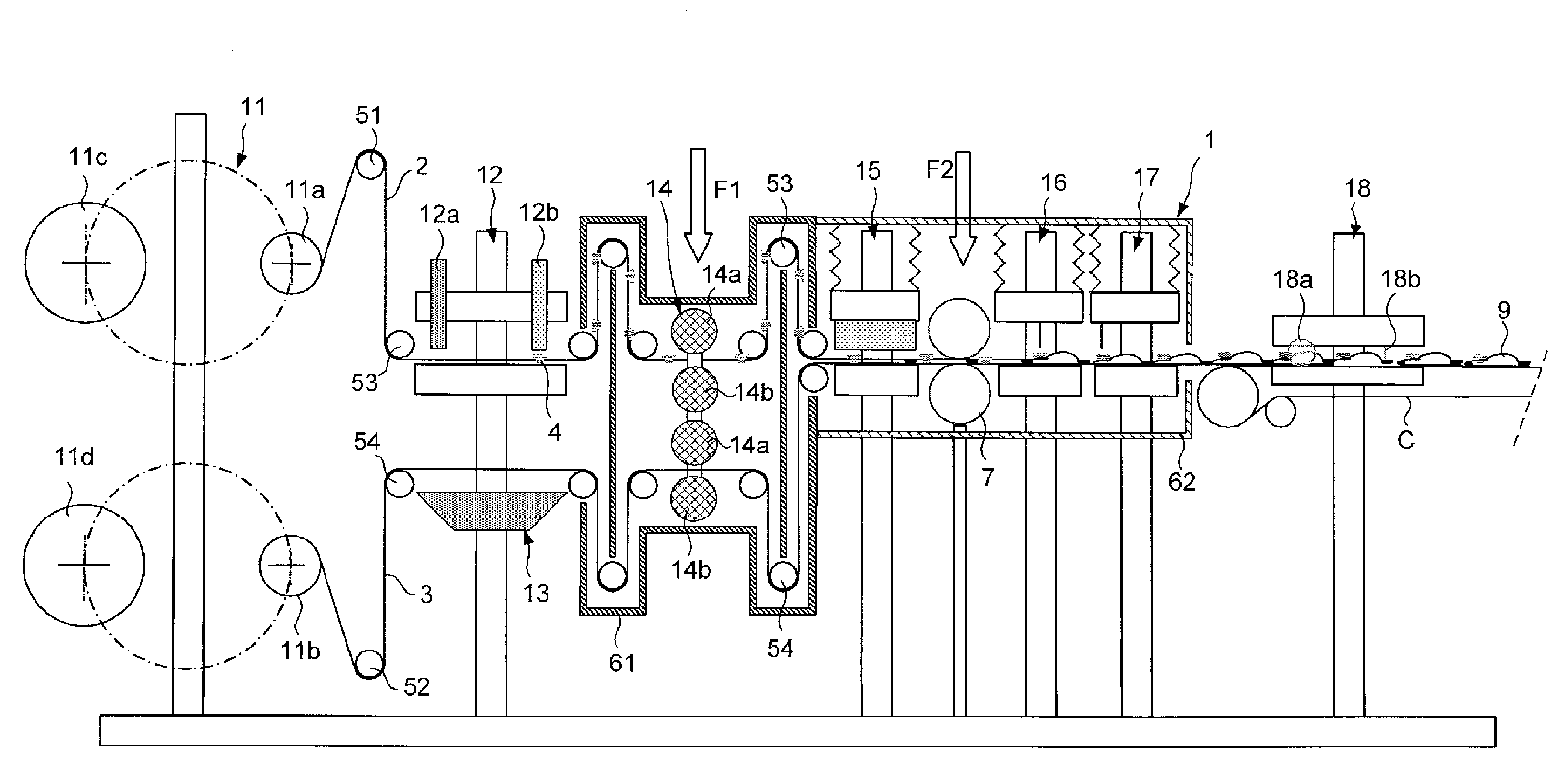

Method for Manufacturing Sterile Flexible Bags Filled with a Product, Particularly with a Therapeutic Liquid, and Corresponding Bags

InactiveUS20130108189A1Effective and fast sterilizationSimple designEnvelopes/bags making machineryBag making operationsVALVE PORTEngineering

A method for manufacturing sterile flexible bags filled with a filling product and provided with a valve, including a) a step of placing valves on a first flexible film and sterilizing at least one of the two surfaces of the first film, b) a step of forming bags by heat welding from at least the first film, and filling the bags with a filling product. The valves each include a base applied directly onto the first film, and a tube assembled via an open end onto base in order to cover a tapping area of the base, the tube having a removable portion intended to be removed to uncover the tapping area and allow the product to be withdrawn by poking a needle into the area.

Owner:HEMA

Manufacturing method of light, adsorbent and autoclaved aerated type environment-friendly filler

InactiveCN104437347AImprove waterproof performanceImprove crack resistanceOther chemical processesSustainable biological treatmentEnvironmental resistanceSlag

The invention discloses a manufacturing method of light, adsorbent and autoclaved aerated type environment-friendly filler, wherein the manufacturing method comprises preparation of raw materials, green body staying and autoclaved aeration; the preparation of raw materials comprises the following steps: (1) selecting raw materials, feeding coal gangues, furnace clinkers and coal ash into a ball mill for stirring and crushing into a mixture with the grain size of 30-50mm, which is used as a main material, feeding fine limestone into the ball mill, smashing into grains with the grain sizes of 30-50mm, adding 20-30 in parts by weight of cement into the particles, stirring to form auxiliary materials; and (2) preparing raw materials, namely simultaneously feeding the main material and the auxiliary materials into a double-shaft squeezing granulator to obtain pre-finished products with the grain sizes of 10-25mm. The manufacturing method of the light, adsorbent and autoclaved aerated type environment-friendly filler has the beneficial effects that the environment-friendly filler is prepared from the coal gangues, the furnace clinkers and the coal ash as the main materials, so that the waste utilization of the coal system is solved and the environment is protected. Moreover, compared with conventional filler, the prepared environment-friendly filler product has the relatively good water resistance, crazing resistance and ageing resistance.

Owner:颜松柏 +1

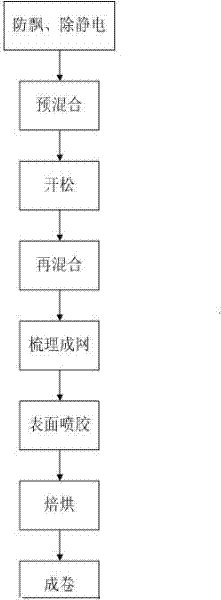

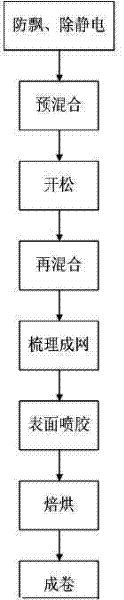

Down filler processing method

InactiveCN102342604AEasy to handleThere will be no gang phenomenonOvergarmentsClothes making applicancesProcess engineeringFiller - product

The invention discloses a down filler processing method which comprises the steps of preventing flying and removing static, premixing, loosening, mixing again, carding for web, spraying glue on surface, baking, and coiling. The processing method disclosed by the invention is simple, and the processing technology is reasonable; the prepared down filler product not only maintains the original looseness and warm keeping features of down, but also is easy to tailor and does not clot or penetrate.

Owner:CHANGSHU YIXIN NONWOVEN PROD

Plastic filler produced by using ceramic waste and production method thereof

The invention relates to a plastic filler produced by using ceramic waste and a production method thereof. The production method is characterized by producing the plastic filler product by using ceramic waste powder, marble waste slag powder, granite waste slag powder, quick lime powder, calcium sulfate, magnesium oxide, chlorinated paraffin, PEG400 monooleate, ferroferric oxide, KH-560 aminopropyltrimethoxysilane, A-78 leveler and ND-50 antiager as raw materials and by mixing with a double-axis paddle mixer uniformly. The product has the advantages of comprehensive utilization of solid waste, conversion of waste into valuable materials, no pollution, low cost and good benefit and meets national requirements for energy conservation, emission reduction, environmental protection and low-carbon economy development.

Owner:清远绿由环保科技有限公司

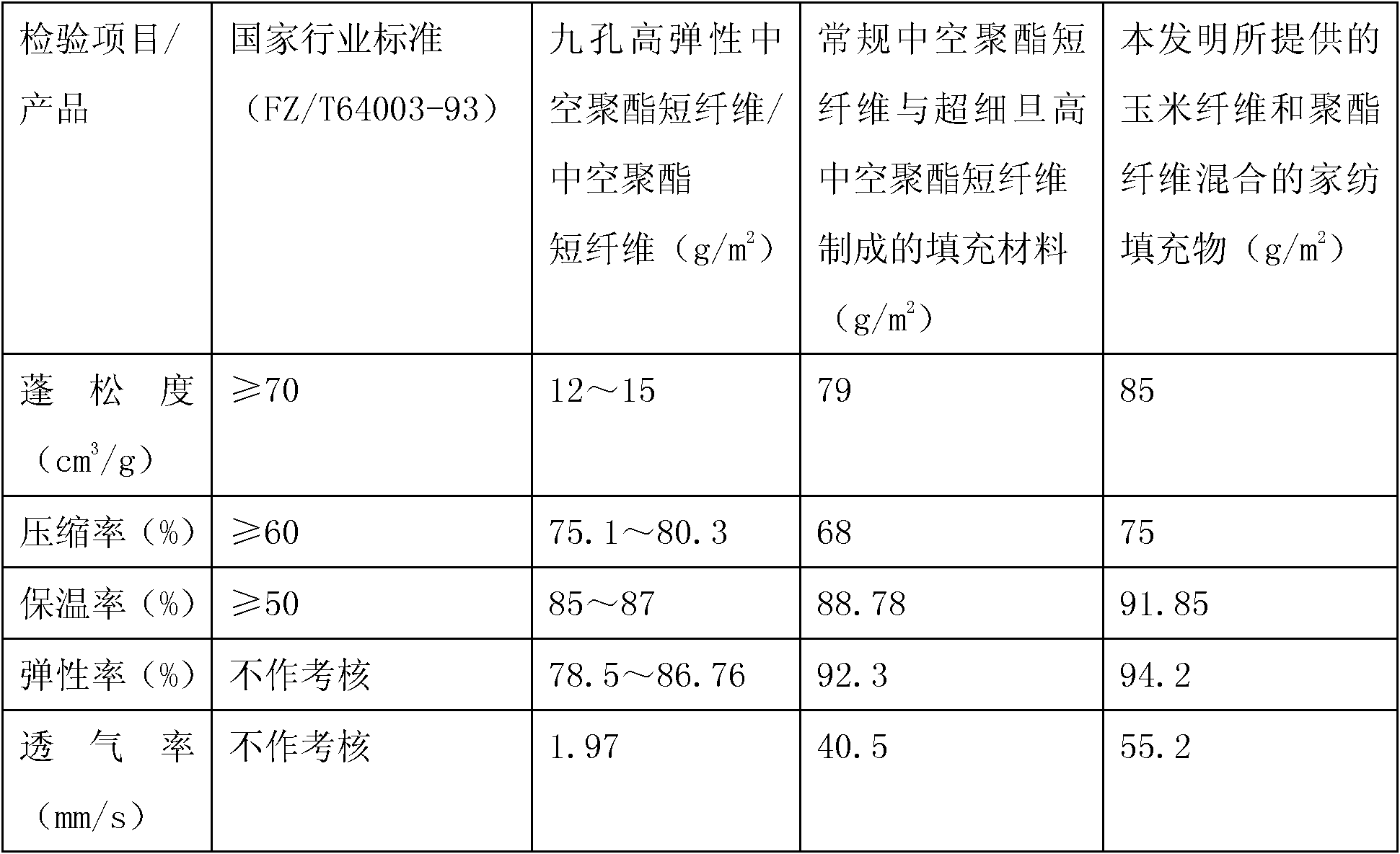

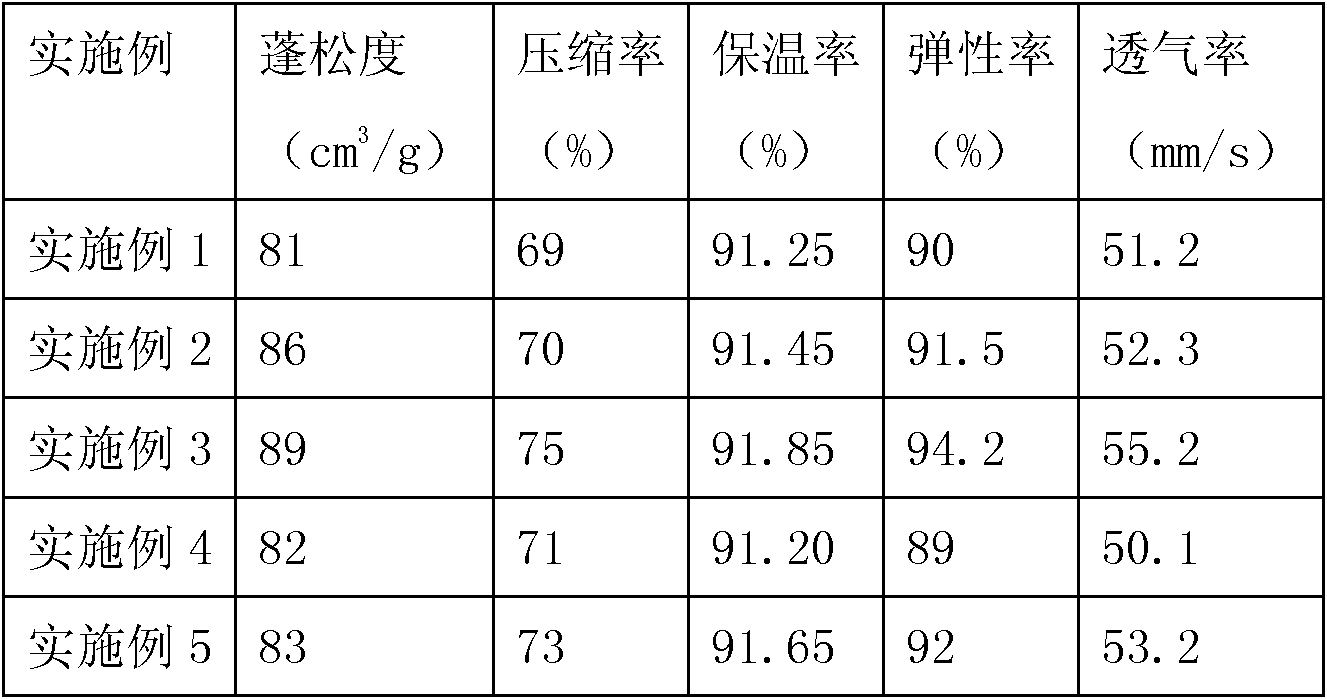

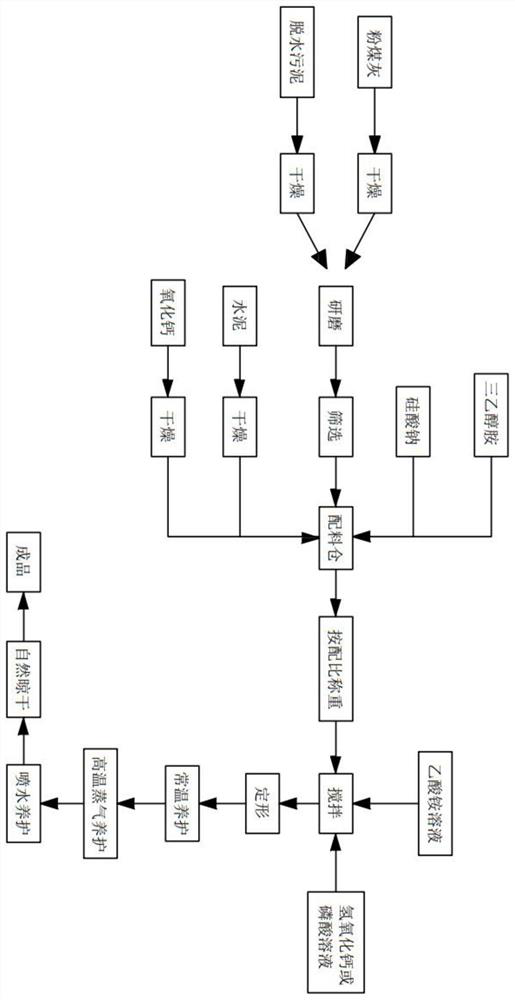

Textile filler formed by mixing corn fibers and polyester fibers and preparation method thereof

InactiveCN103030091ASolve the problem that it is difficult to form a cotton webWell mixedUpholstery manufactureUpholstery fillingPolyesterQuality of life

The invention discloses a textile filler formed by mixing corn fibers and polyester fibers, which is characterized in that the textile filler is formed by mixing conventional hollow polyester staple fibers and corn fibers, and the hollow polyester staple fiber has a fineness of 6. 67DTEX, a hollow degree of 10%, and a length of 38mm; the corn fiber has a fineness of 1.5 to 3.0 dtex, and is a crimped fiber with a length of 50 to 90mm, and the weight percentage of the hollow polyester staple fibers is 25% to 75%; and the weight percentage of the corn fiber is 25% to 75%. The invention also provides a preparation method of the textile filler formed by mixing the corn fibers and the polyester fibers. Various filler products prepared by the textile filler formed by mixing corn fibers and polyester fibers have the advantages of uniform and smooth appearance, lightweight sense, higher filling power, lasting elastic restoring force, excellent warmth and soft hand feel, and makes people feel comfortable, thereby improving sleep and quality of life.

Owner:SOUTH BEDDING TECH

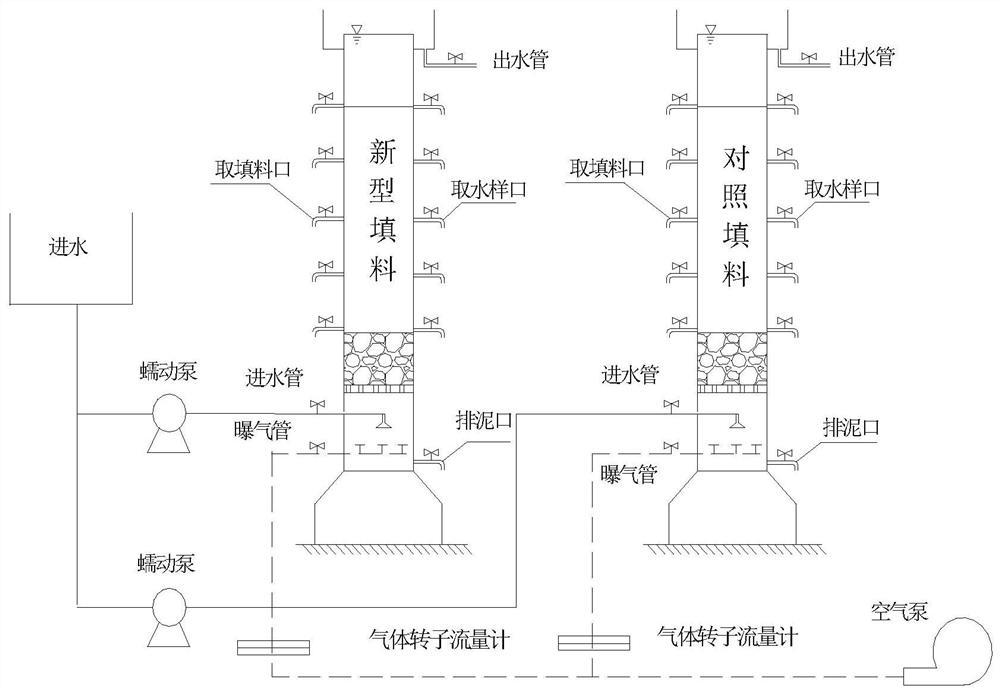

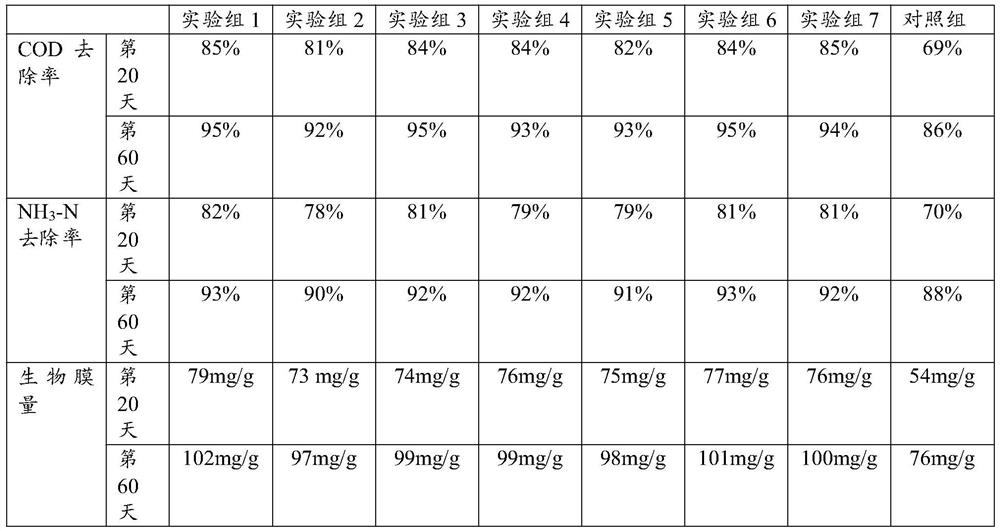

Sintering-free raw material ball filler for rural sewage treatment system, and preparation and maintenance method of sintering-free raw material ball filler

ActiveCN114163176AReduce packing weightHigh specific surface areaSolid waste managementSustainable biological treatmentWater treatment systemFiller - product

The invention discloses a sintering-free raw material ball filler for a rural sewage treatment system as well as a preparation method, a maintenance method and application of the sintering-free raw material ball filler. Comprising 50-60% of fly ash, 10-20% of dewatered sludge, 20-30% of cement, 5-8% of calcium oxide, 1-2% of ammonium acetate, 3-5% of sodium silicate and 0.04-0.06% of triethanolamine. Preparing a raw material ball filler by adopting a sintering-free process; the obtained raw material ball filler is sequentially subjected to normal-temperature curing, high-temperature steam curing and water spraying curing, a filler product with excellent ineffective efficiency is prepared from a finished product, the filler product is applied to a BAF system, and the removal rates of COD and NH3-N in the stable period can be stabilized at 84% and 71% respectively. In a word, the fly ash is used as a main raw material, the cement and the dewatered sludge are added, the calcium oxide is used as an auxiliary exciting agent, the ammonium acetate is used as a pore increasing agent, the specific surface area of the filler is increased, and the raw material ball filler has high porosity, large specific surface area, moderate strength and excellent performance.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

New Functional Additive in Polymers

InactiveUS20090029171A1Easy millingIncrease ratingsAlkaline-earth metal silicatesSynthetic resin layered productsPlastic filmFiller - product

New functional additive in polymers comprised of micronized diatomite filler product, methods of producing the new functional additive in polymers, and methods of use thereof are provided. The new functional additive in polymers has, for example, a small median particle size (for example, less than 10 microns) and a small top particle size (for example, less than 20 microns), and a high blue light brightness (for example, higher than 84). The new functional additive in polymers may be used in a variety of applications such as reinforcement filler in polymers and anti-block filler in plastic films.

Owner:ADVANCED MINERALS

All metal leave N place armor joint form with joint fill retention

InactiveUS20120117892A1Eliminates wooden forming laborEliminates materialCeilingsWallsNeopreneFiller - product

The objective of this invention is to provide ease of application for steel armored joints used in industrial concrete floor construction. It provides one step simple and precise installation. Provides a substrate for joint filler compression. Eliminates the need for wood forms and field welding that produces waste.Elevation adjustment and the ease thereof are achieved by vertical slots cut in the upright. The neoprene bolts are to be tightened when the steel is at the desired elevation. Two part armored joints separate as the concrete contracts during the curing process. Then the joint filler product is applied and retained in a permanent encased condition.

Owner:SMITH PATRICK MICHAEL

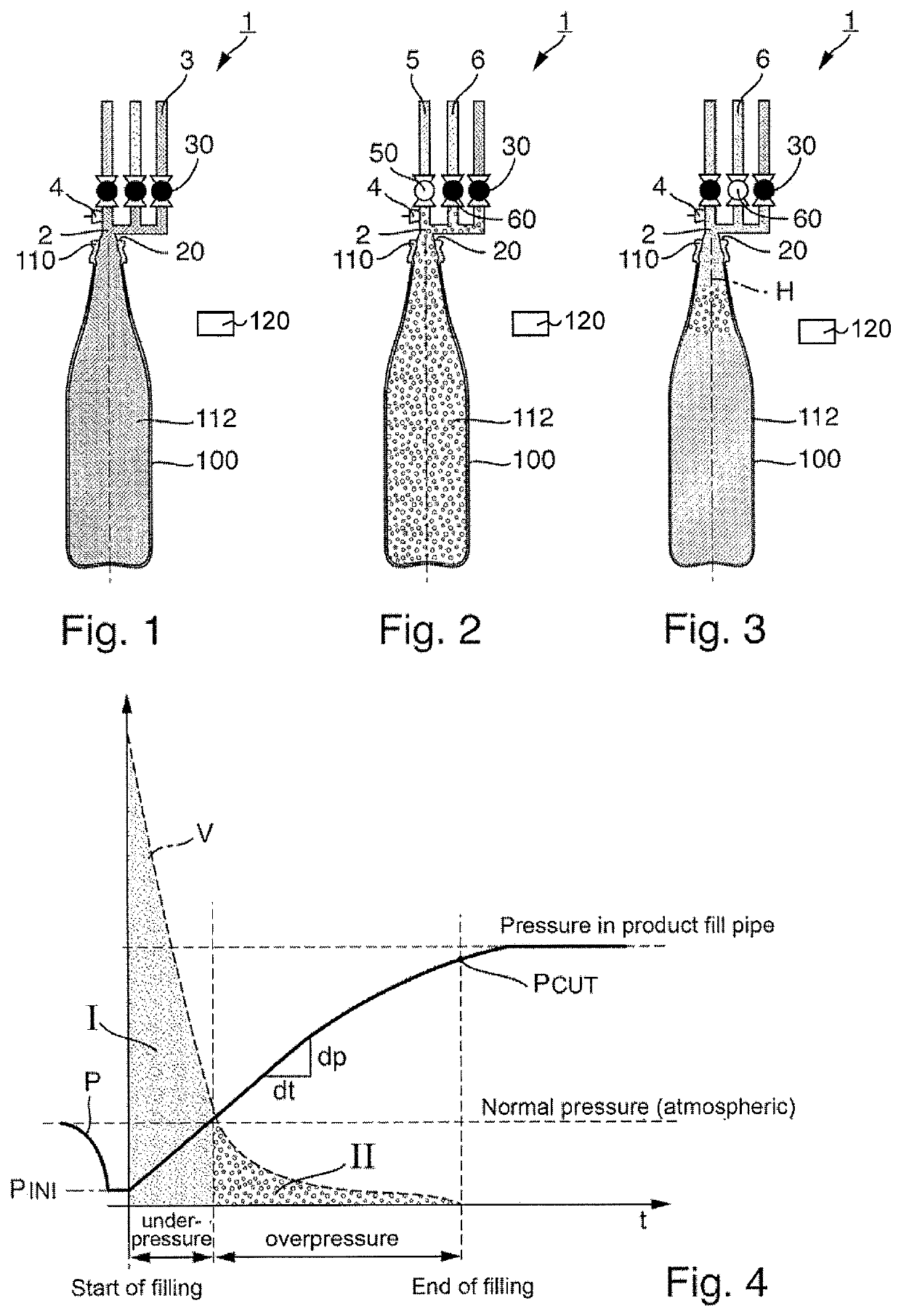

Method and device for filling a container to be filled with a filling product

ActiveUS10836621B2Reduce complexityFast fillFilling using suctionFilling using counterpressureFiller - productMechanical engineering

Owner:KRONES AG

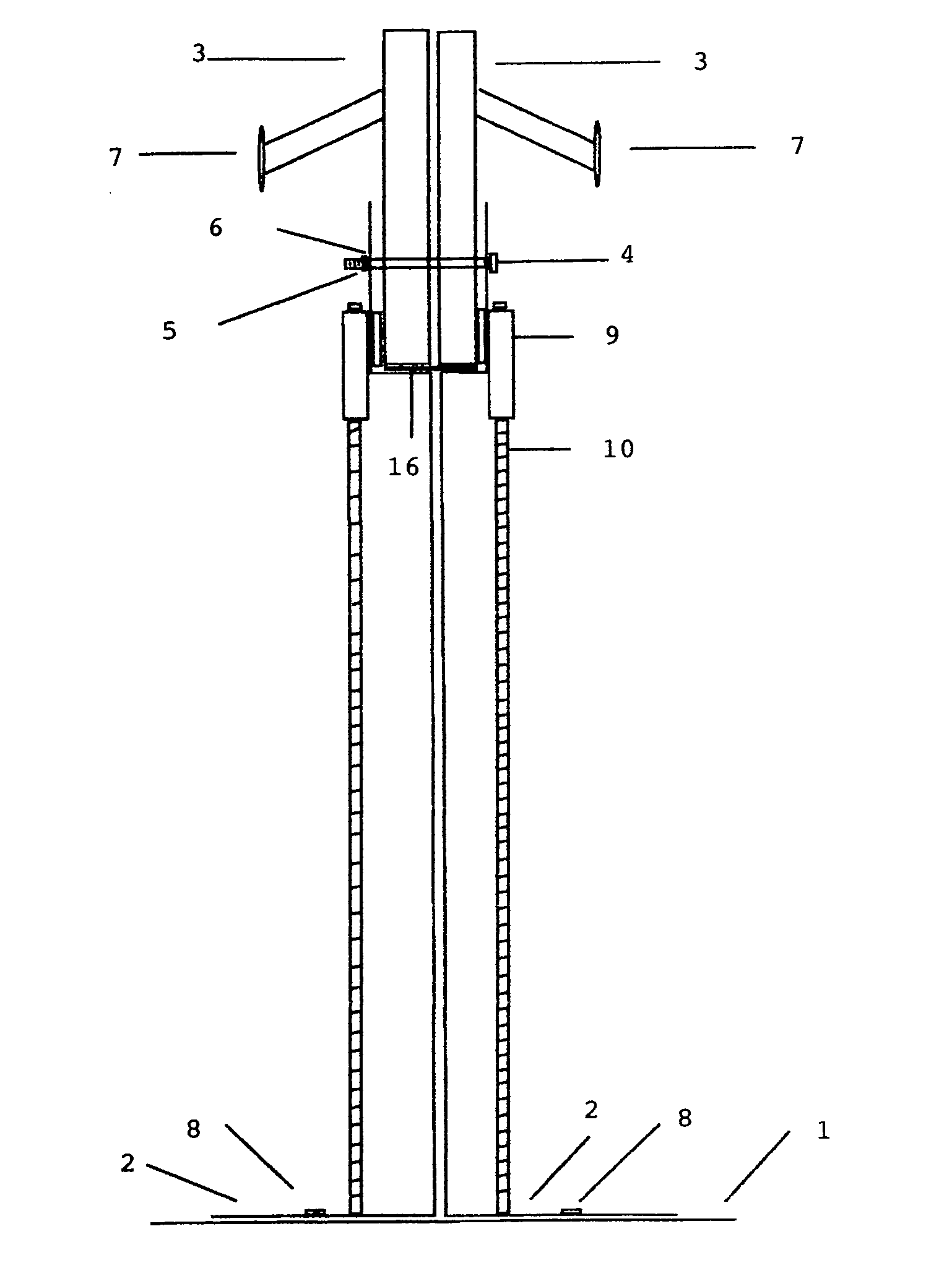

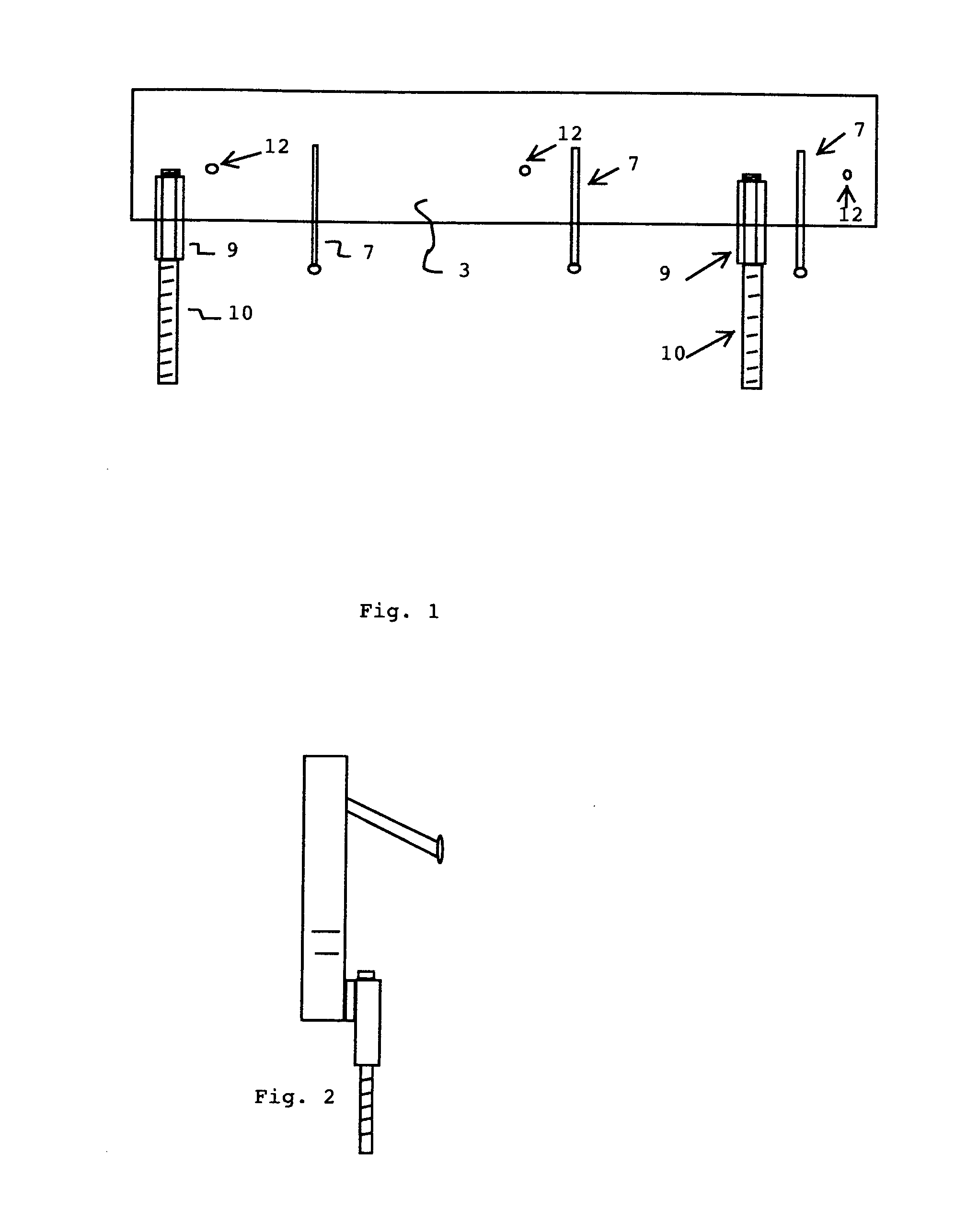

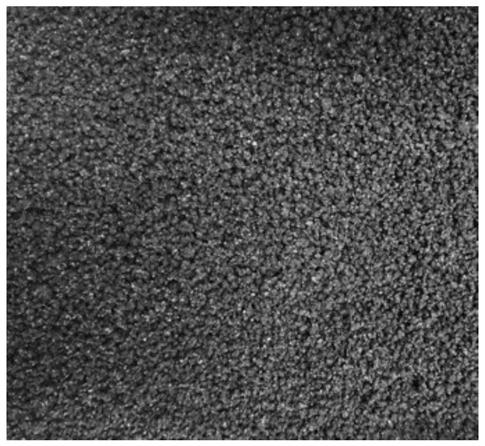

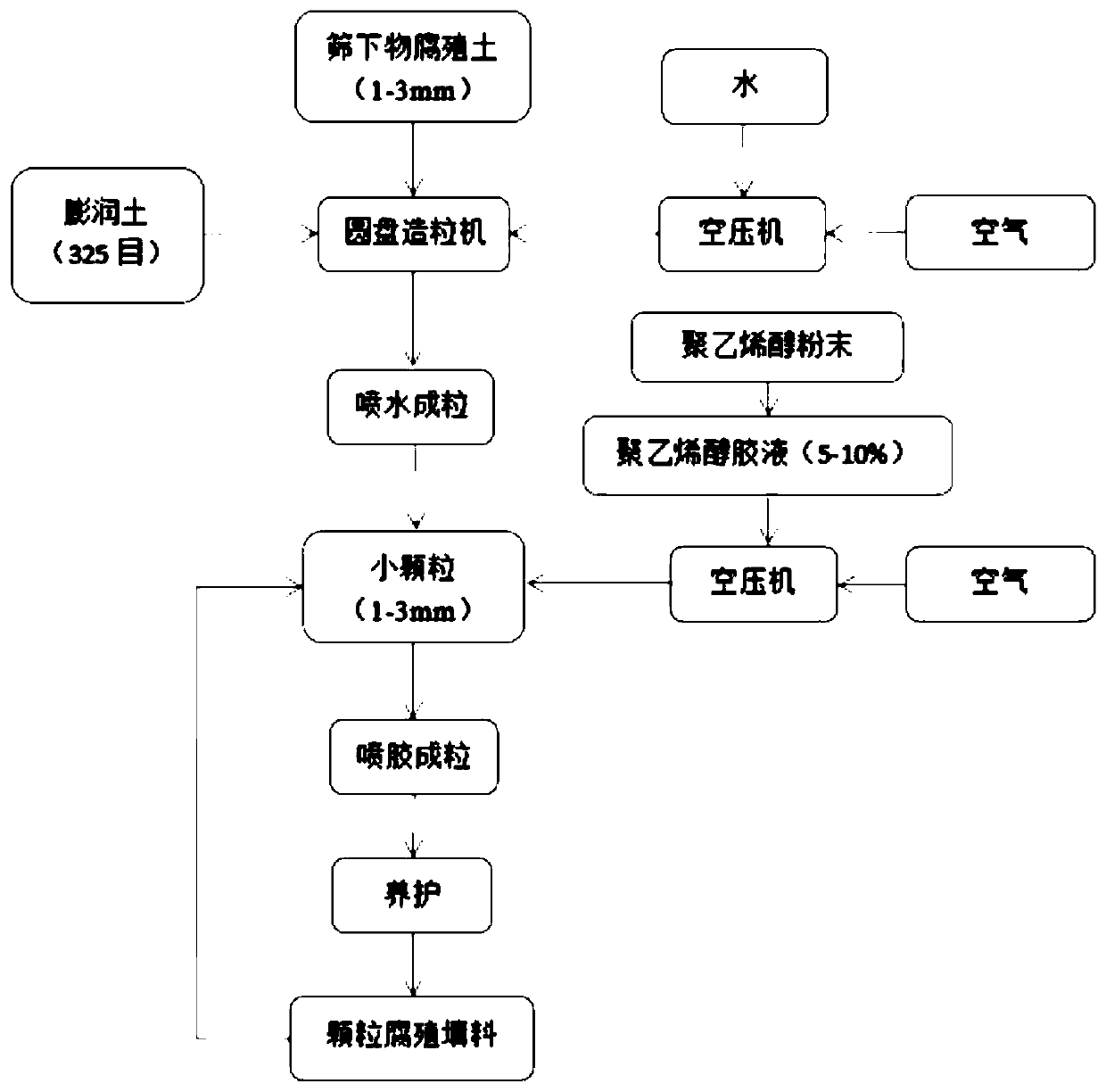

Granular humic biological filler and production method and application thereof

ActiveCN111533243AEffective adhesionRelieve blockageGranulation in rotating dishes/pansSustainable biological treatmentPolyvinyl alcoholFiller - product

The invention belongs to the technical field of environmental engineering water treatment, and particularly relates to a granular humic biological filler and a production method and application thereof. The production method comprises the following steps: (1) mixing undersize humus soil and bentonite in a disc granulator according to a certain mass ratio, and adding a proper amount of water by utilizing an atomized water spray head to form mixture particles, (2) adding hot water into polyvinyl alcohol powder to dissolve the polyvinyl alcohol powder to prepare a polyvinyl alcohol glue solution,and (3) spraying the polyvinyl alcohol glue solution to the mixture particles in the disc granulator in an atomizing and spraying manner under a certain air pressure condition, so that the mixture particles fully absorb the polyvinyl alcohol glue solution, and air-drying to obtain the granular humic biological filler. The finally formed humic filler is uniform in particle size, high in mechanicalstrength and good in water resistance, standardization of humic biological filler products is achieved, and a new way for large-scale resource utilization of undersize humus soil is achieved.

Owner:NANJING UNIV +1

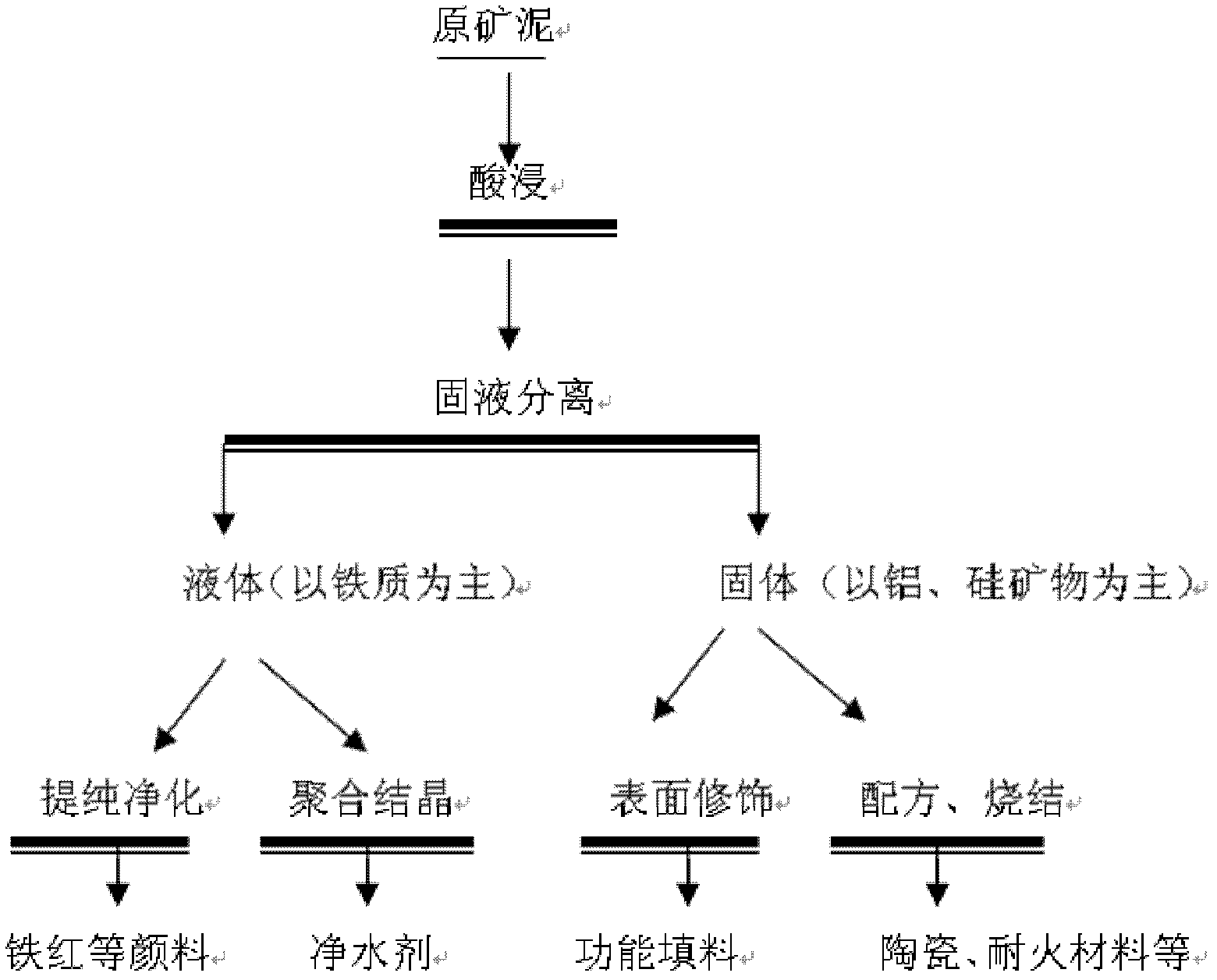

Method for carrying out comprehensive treatment on alumyte ore washing fine slit

InactiveCN102247976AEliminate stockpilingAchieve recyclingIron oxides/hydroxidesSolid waste disposalSludgeFiller - product

The invention discloses a method for carrying out comprehensive treatment on alumyte ore washing fine slit, comprising the following steps of: separating irony minerals from silica-alumina minerals by adopting acid leaching, polymerizing the irony minerals into a poly iron water purifying agent or carrying out purifying, dust removing, oxidizing and roasting on the irony minerals to obtain an iron oxide red pigment; and processing the silica-alumina minerals into filler products. By adopting the method disclosed by the invention, the traditional thinking that the alumyte ore washing fine slitis restricted to stockpiling and can obtain single recycled components is changed, and ore sludge full-component recycling is realized, thus the aims of completely eliminating stockpiling of the ore sludge and utilizing a mined resource to the utmost extent are achieved.

Owner:GUANGZHOU UNIVERSITY

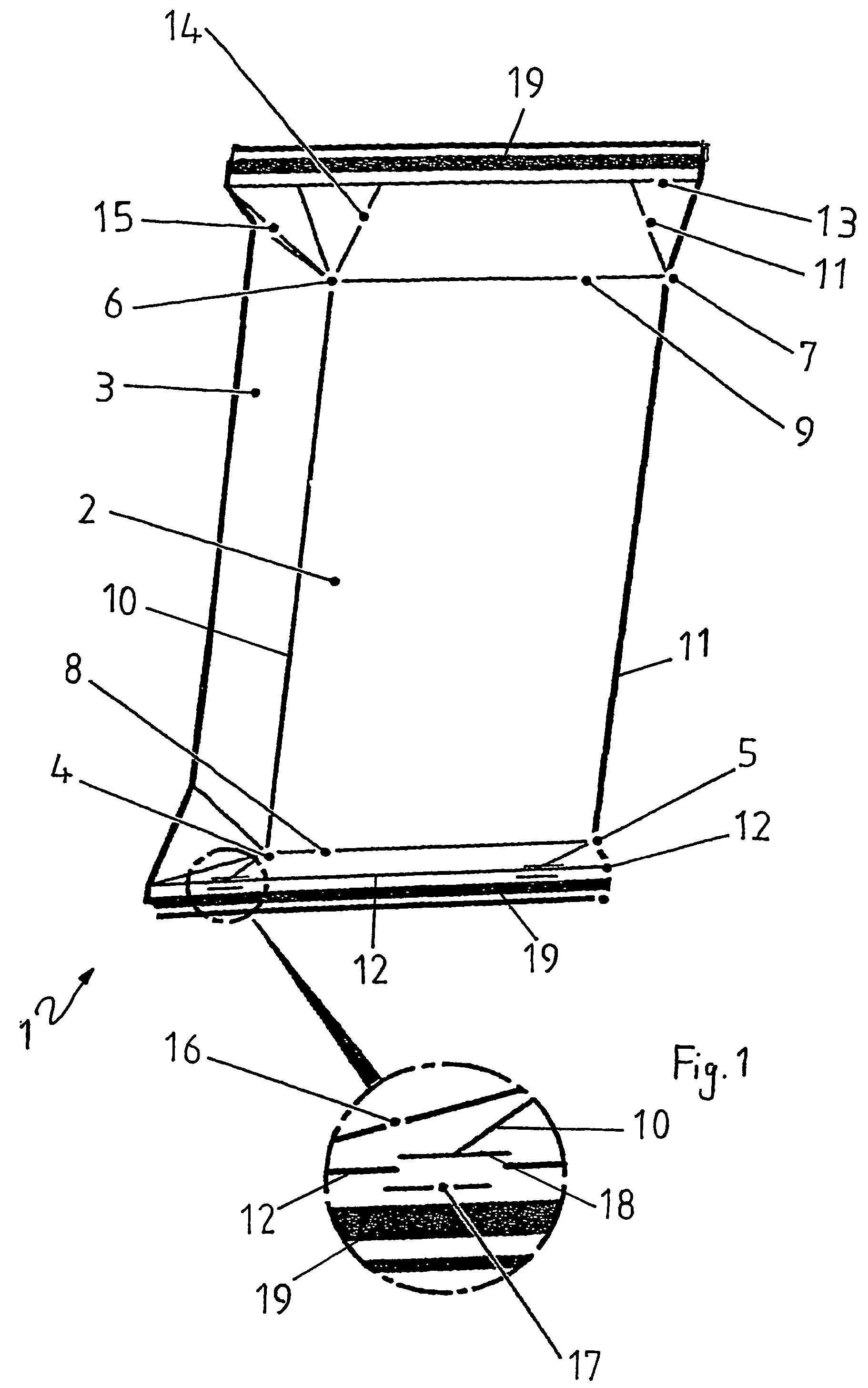

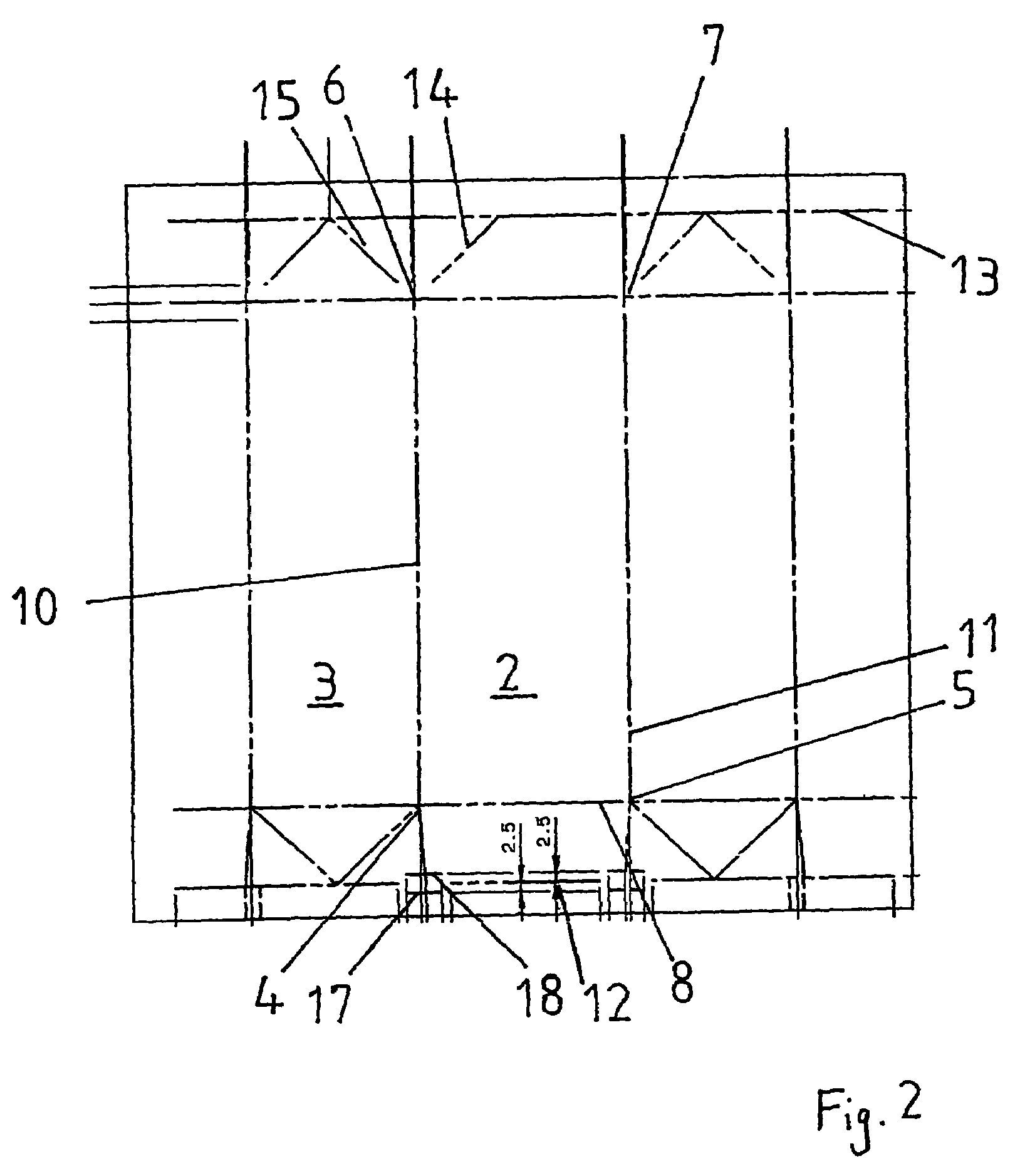

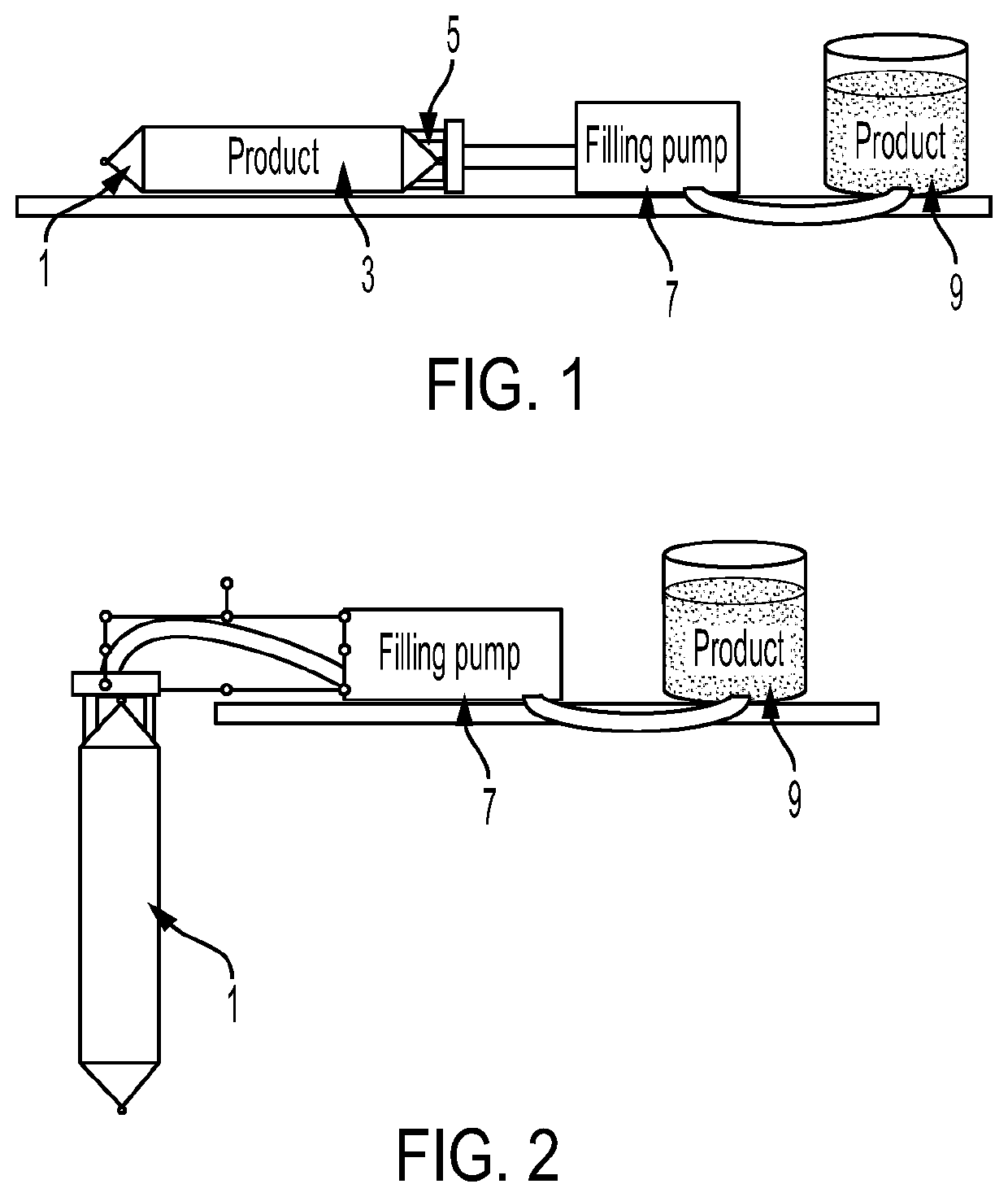

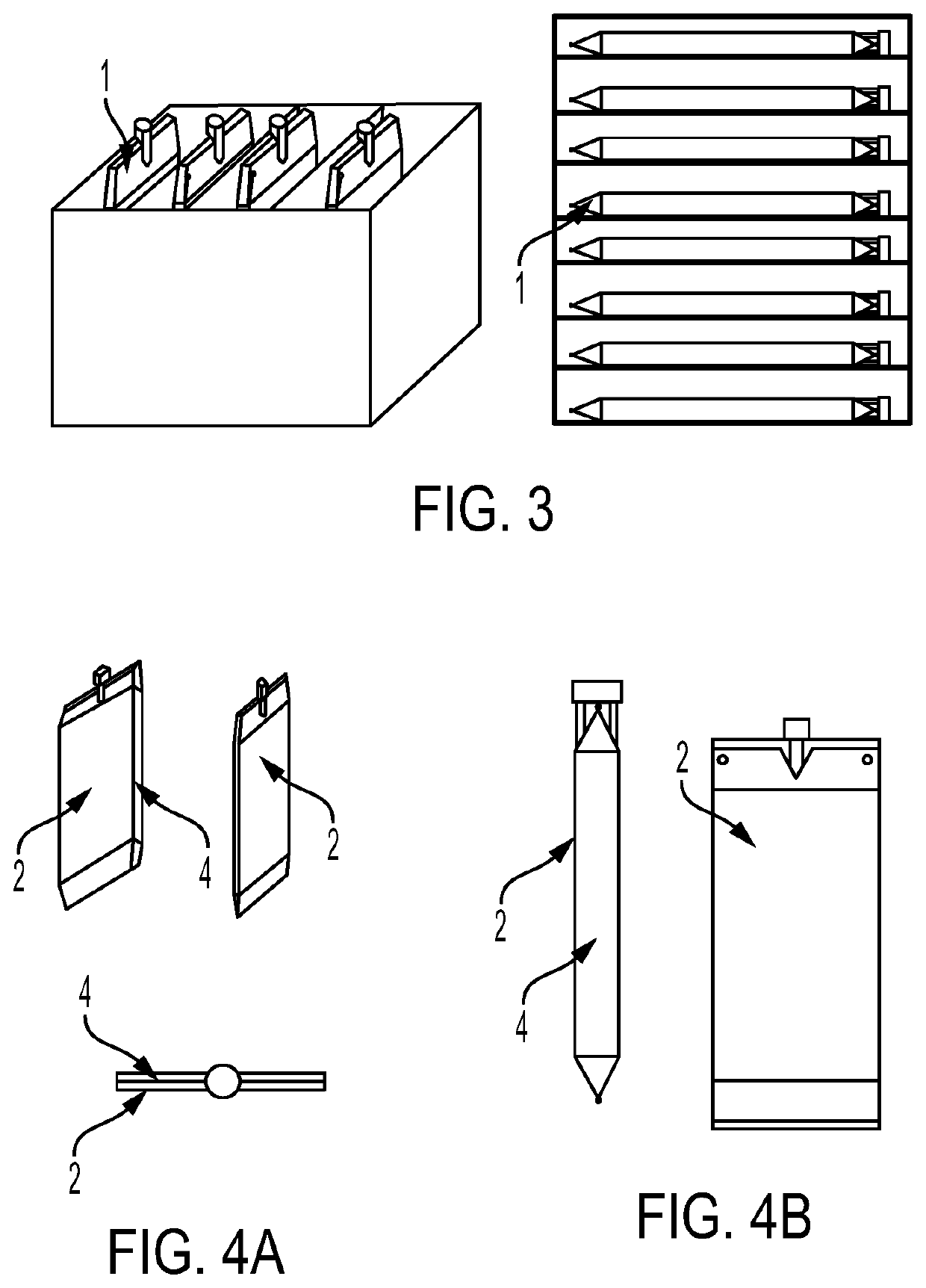

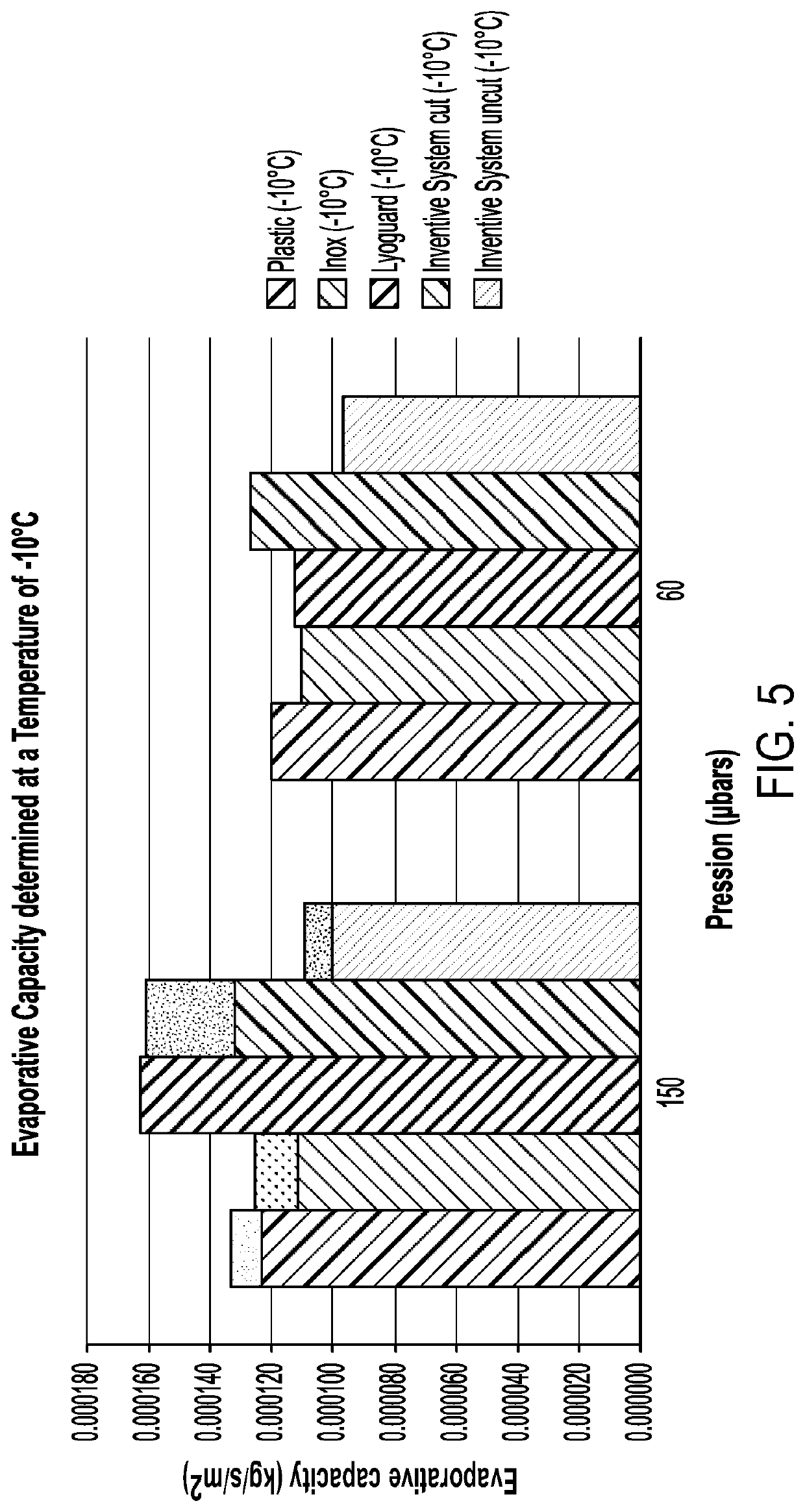

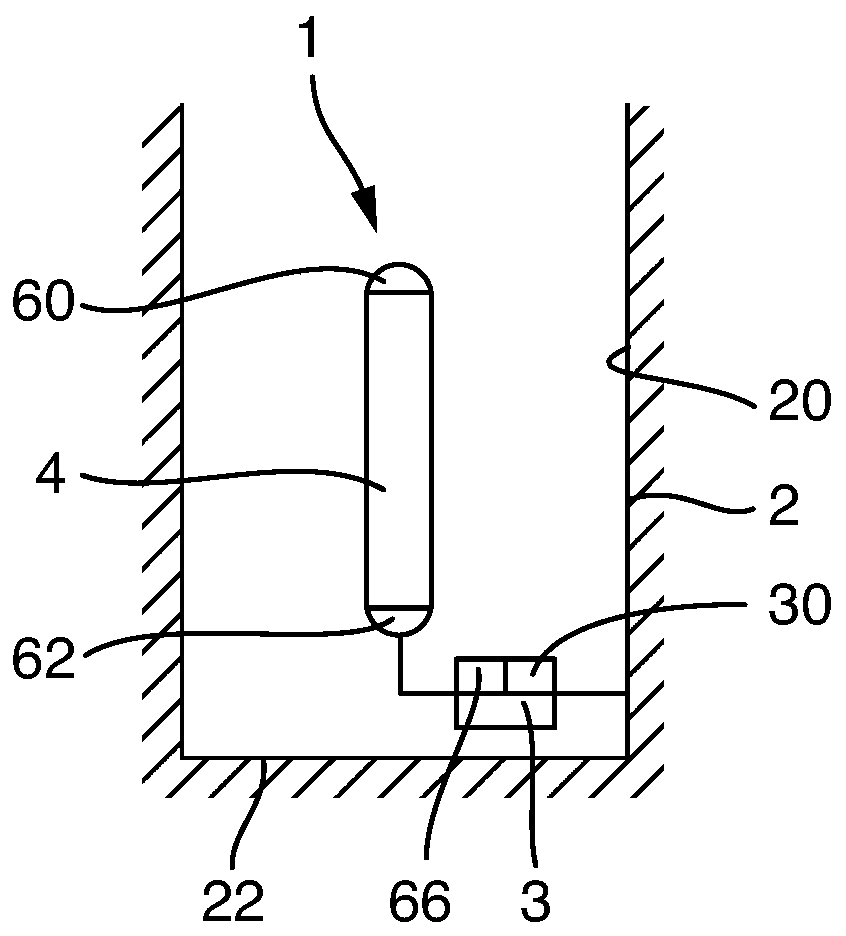

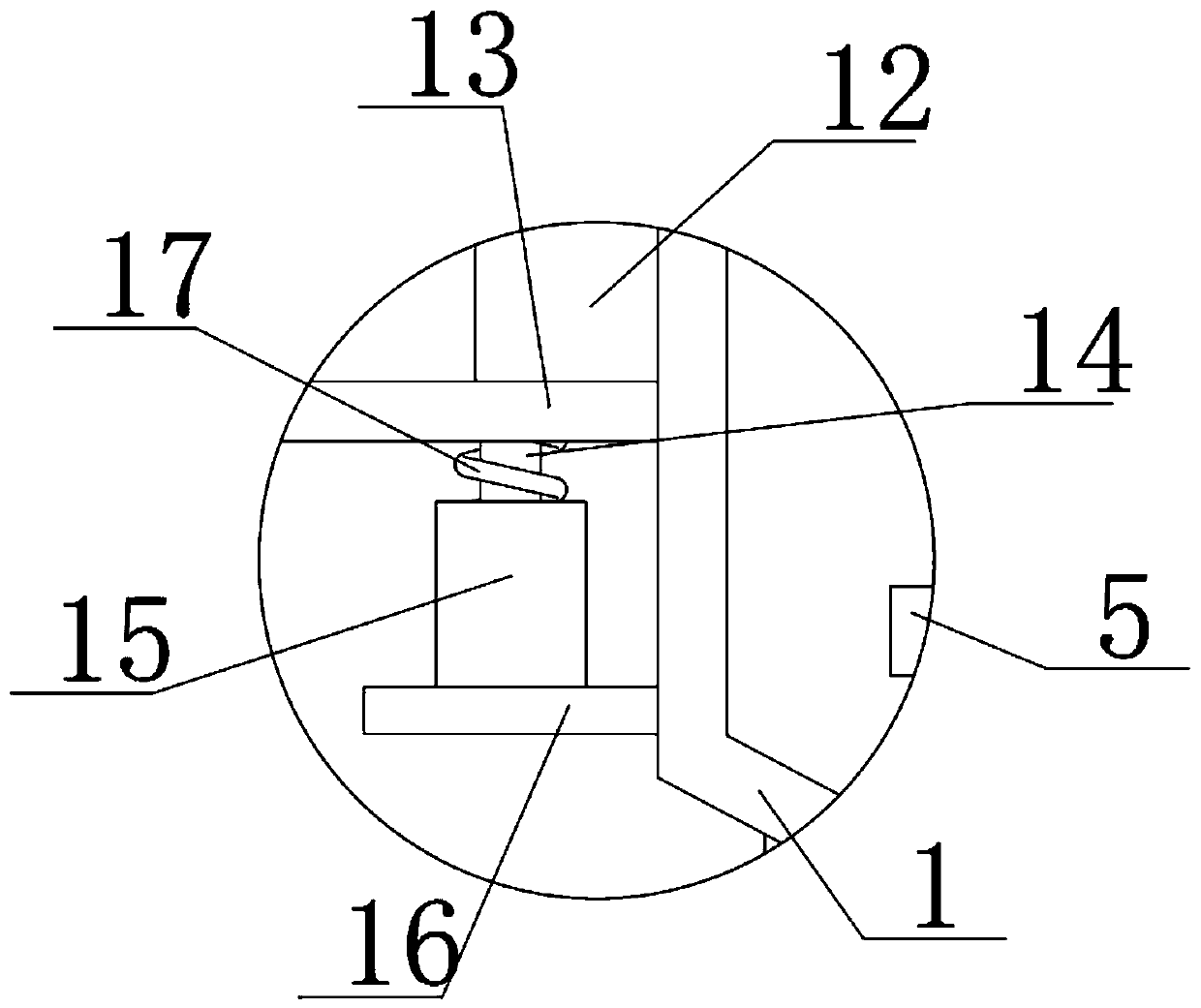

Process for lyophilising a product

ActiveUS11135168B2Maximise dryingUniform thicknessPowder deliveryBacteria material medical ingredientsFiller - productMechanical engineering

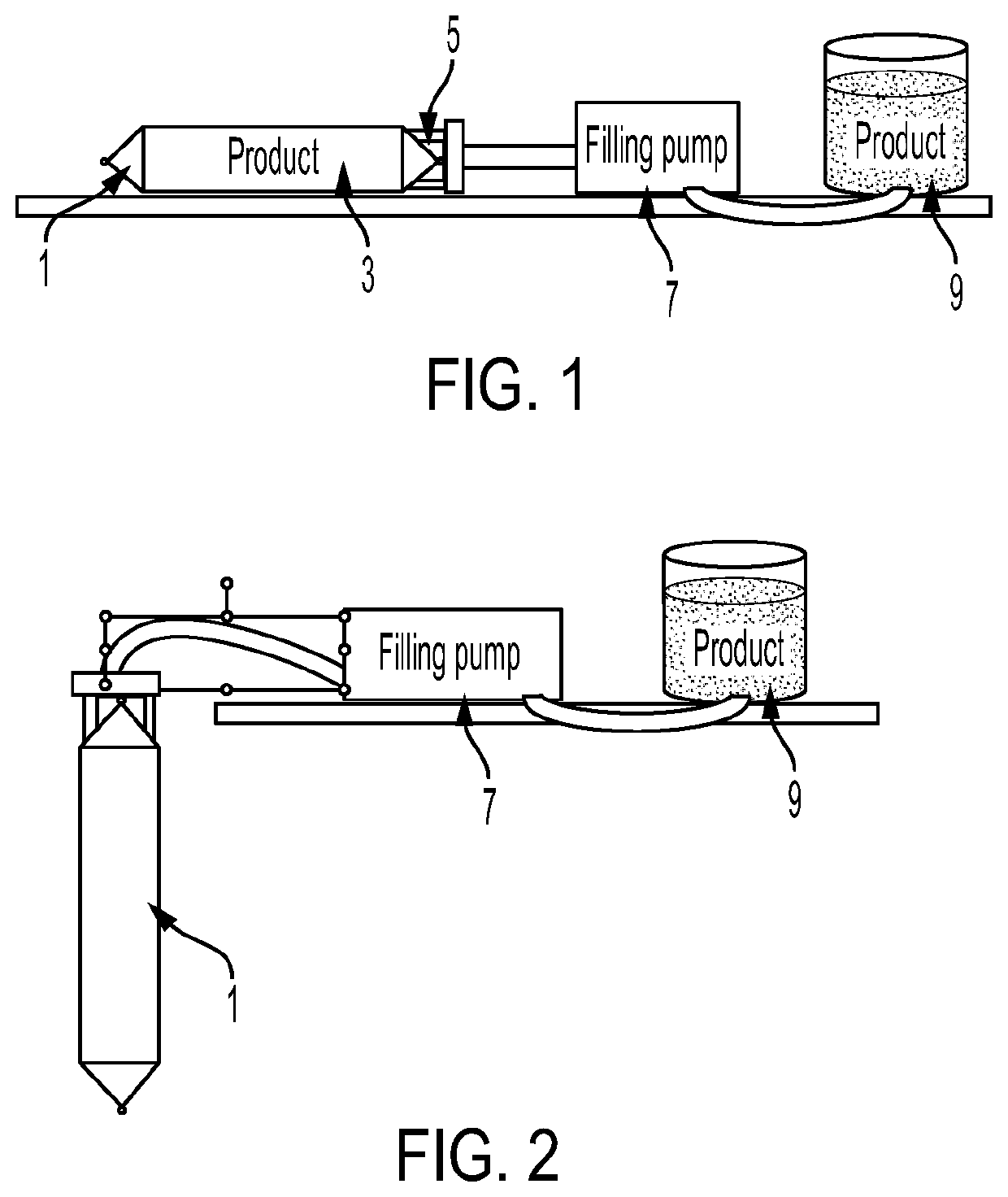

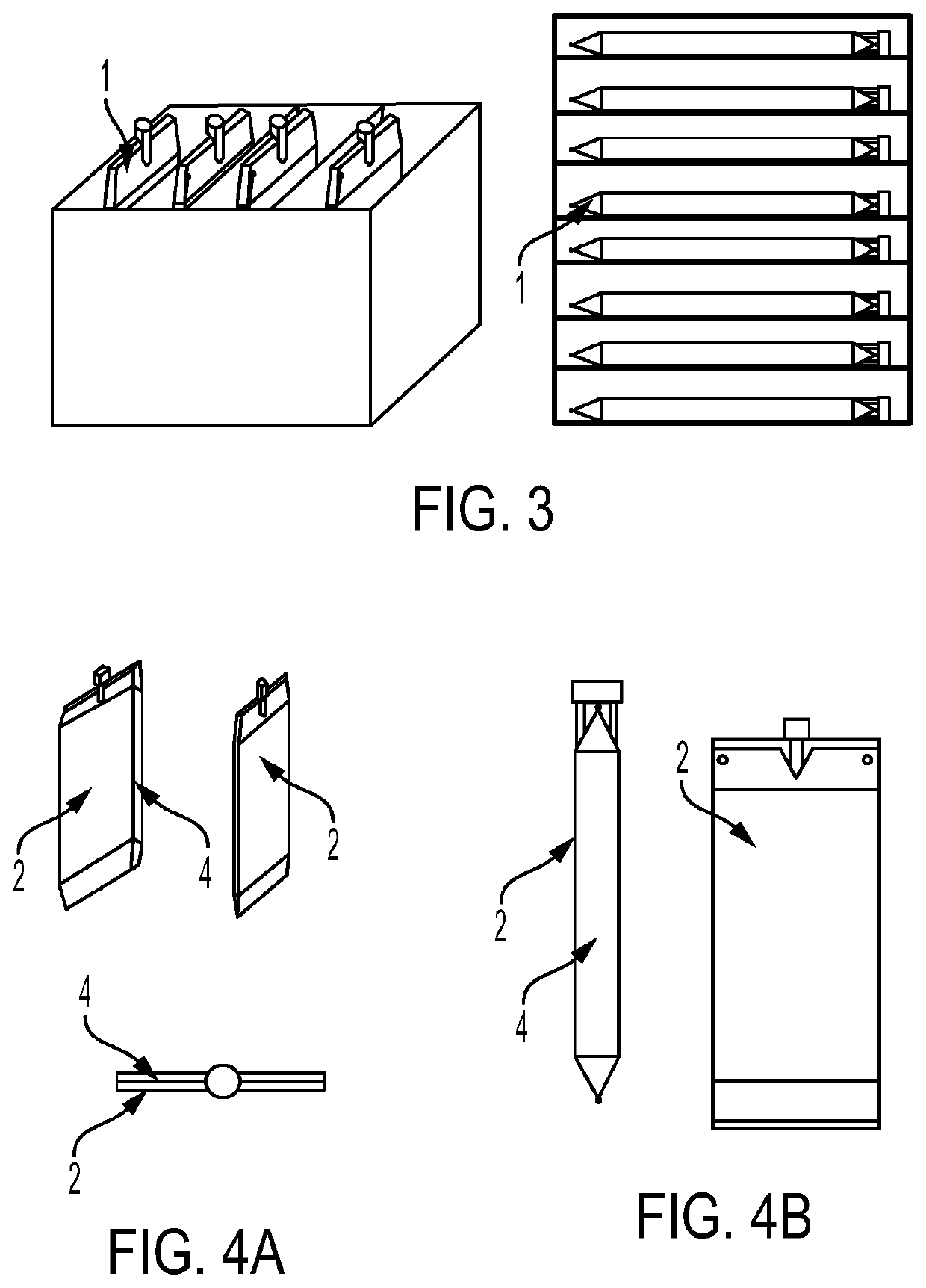

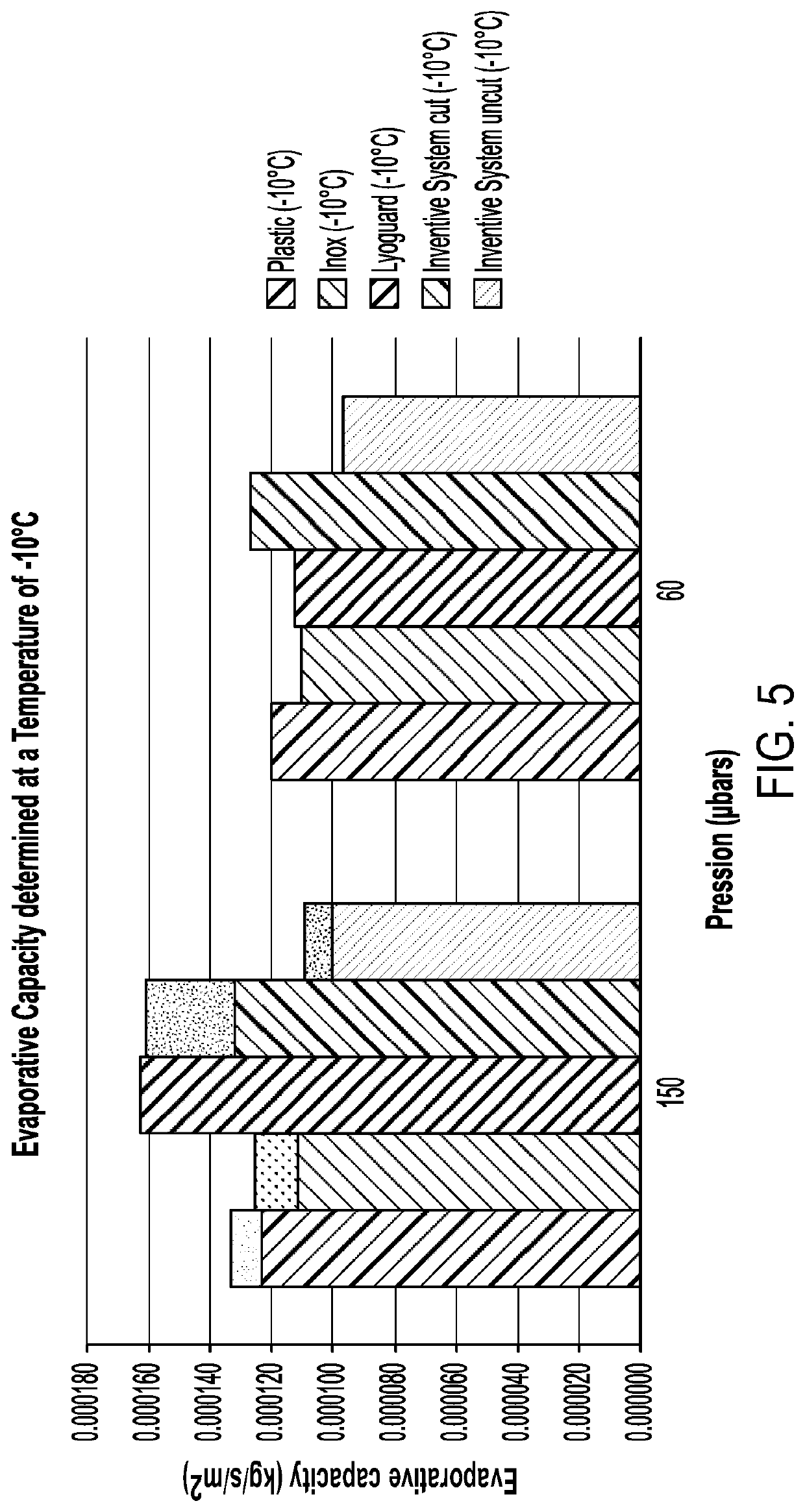

The present invention relates to a process for lyophilising a product (3), comprising the steps of providing a bulk product (3) loading system in the form of a bag (1), the bag (1) having an interior and an exterior defined by a flexible wall, the bag (1) further comprising a filling port (5) providing access to the interior of the bag (1), filling a product (3) having a first moisture content into the interior of the bag (1) via the filling port (5), and exposing the product (3) in the interior of the bag (1) to a lyophilisation cycle such that the moisture content of the product (3) is reduced from the first moisture content to a second, lower, moisture content.

Owner:4D PHARMA LEON S L U

Low rolling resistance all steel radial tire tread rubber composition

InactiveCN110305374ALow priceImprove mobilitySpecial tyresRolling resistance optimizationRolling resistanceFiller - product

Owner:TRIANGLE TIRE

Process for lyophilising a product

ActiveUS20200179289A1Maximise dryingUniform thicknessPowder deliveryBacteria material medical ingredientsFiller - productMechanical engineering

The present invention relates to a process for lyophilising a product (3), comprising the steps of providing a bulk product (3) loading system in the form of a bag (1), the bag (1) having an interior and an exterior defined by a flexible wall, the bag (1) further comprising a filling port (5) providing access to the interior of the bag (1), filling a product (3) having a first moisture content into the interior of the bag (1) via the filling port (5), and exposing the product (3) in the interior of the bag (1) to a lyophilisation cycle such that the moisture content of the product (3) is reduced from the first moisture content to a second, lower, moisture content.

Owner:4D PHARMA LEON S L U

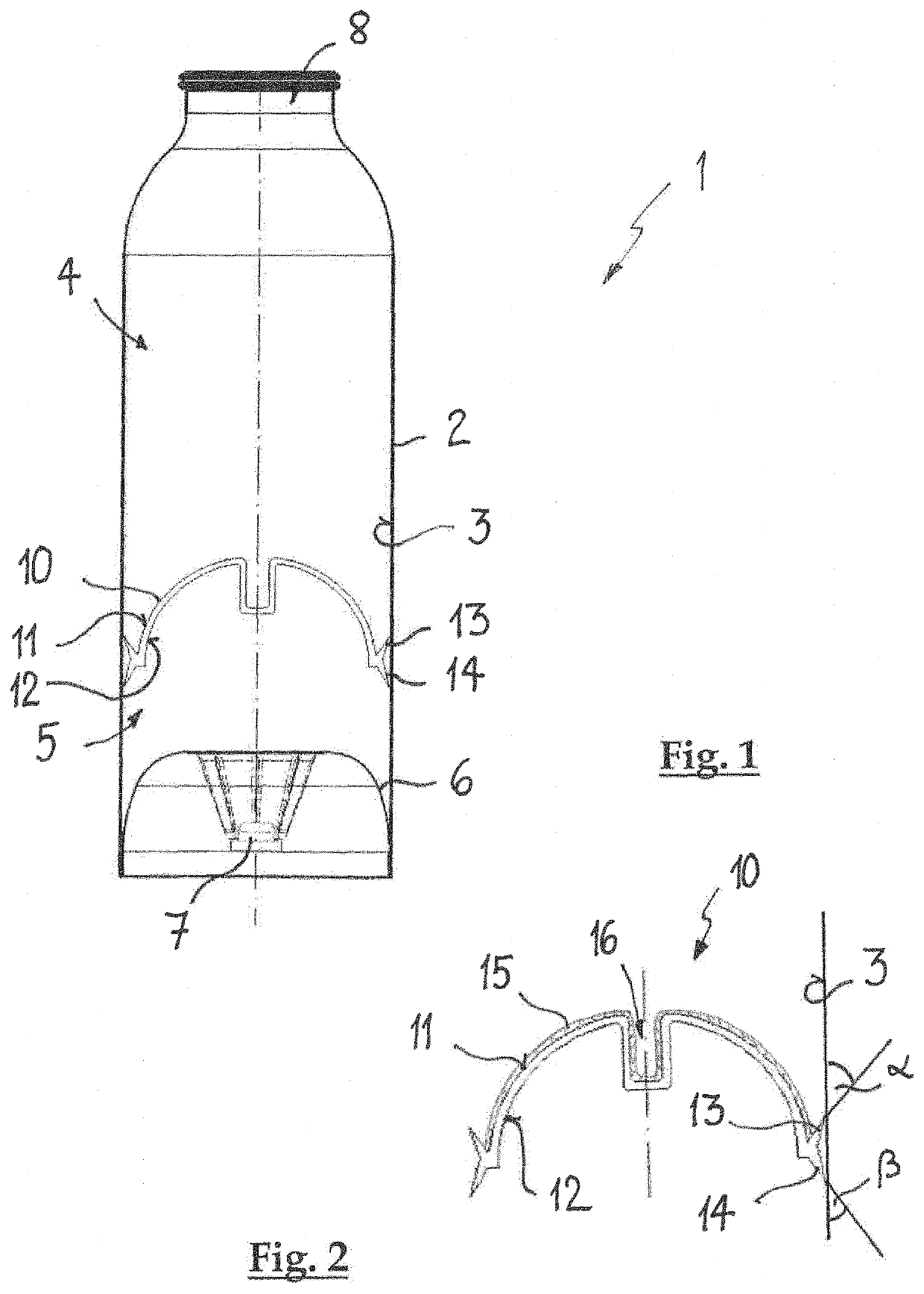

Pressure container of plastic

A plastic pressure container has an essentially cylindrical container body with an opening closable in a pressure-tight manner by a valve attachment for dispensing a filling product. An interior plunger is arranged in a longitudinally displaceable manner along a longitudinal axis to subdivide the container body into a receiving chamber adjacent to the opening for the filling product and into a separated reservoir in a pressure tight manner, for a pressure medium. The plunger includes two circumferential sealing lips separated in the axial direction. An upper sealing lip extends into the receiving chamber and a lower sealing lip extends into the reservoir, and these are pressed in a fluid-tight manner onto an inner wall which delimits the interior of the container body, by pressure in the receiving chamber and reservoir.

Owner:ALPLA WERKE ALWIN LEHNER

Preparation method of highly carbonized fiber woven filler

The invention relates to a preparation method of highly carbonized fiber woven fillers, relating to a preparation method of woven fillers. A polyacrylonitrile fiber wire bundle is processed sequentially through constant-temperature wire discharging, multi-section pre-oxidation, medium-temperature carbonization and high-temperature carbonization in a microaerobic carbon corrosion method; wherein the temperature of the low-temperature section pre-oxidation is 238-280 DEG C, and the temperature of the medium-temperature carbonization is 900-550 DEG C; and nitrogen is adopted as a carbon wire protection gas in the microaerobic carbon corrosion method, and the temperature of the high-temperature carbonization is 1450-1700 DEG C. The prepared highly carbonized fiber woven fillers has good self-lubricating performance, high strength, high modulus, good resistance against high temperature, low temperature and corrosion and good thermal conductivity, can be used for a long time in mediums with particle fluid and in rotation of high linear speed, and can also be used to replace the existing filler products of all materials.

Owner:张孟福

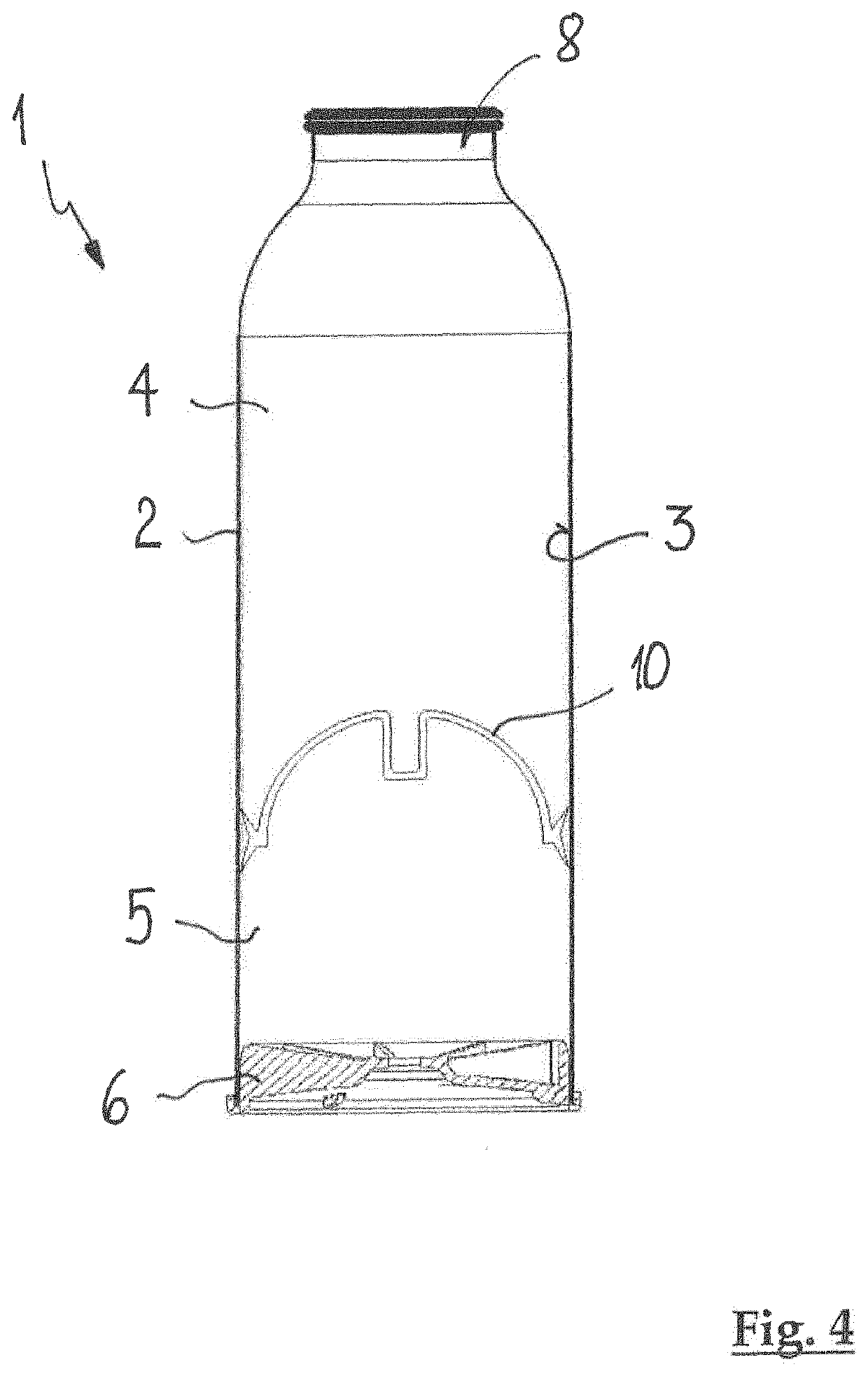

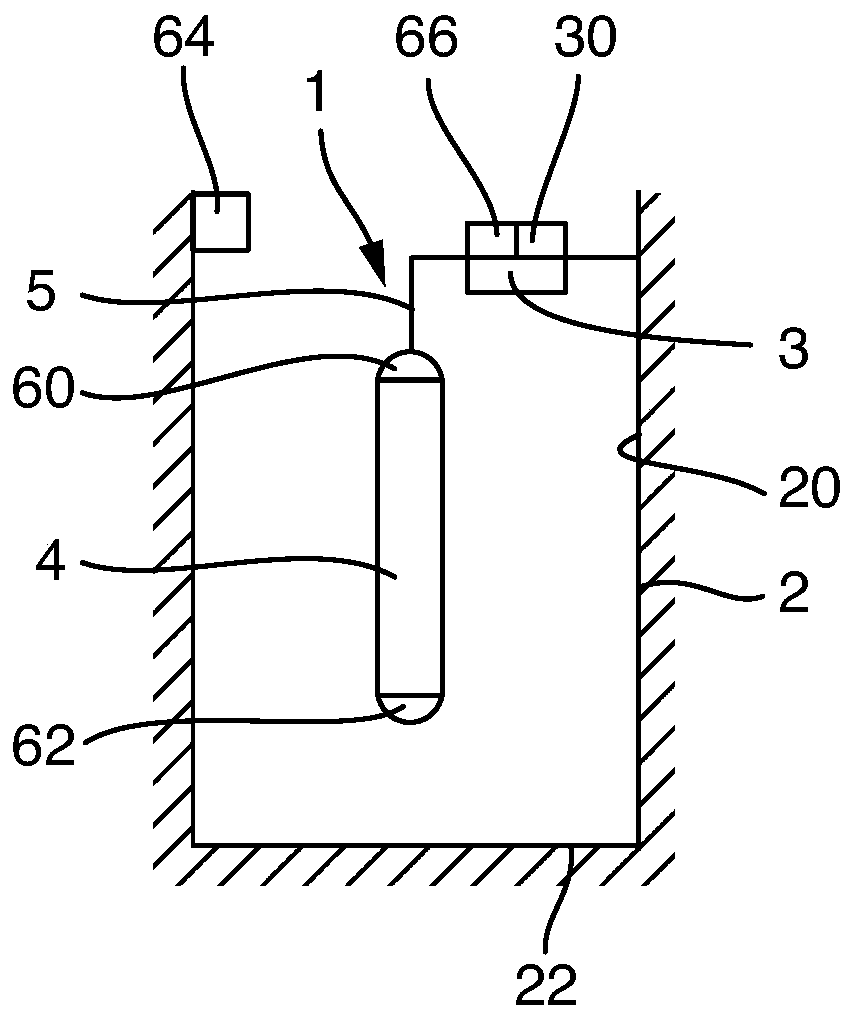

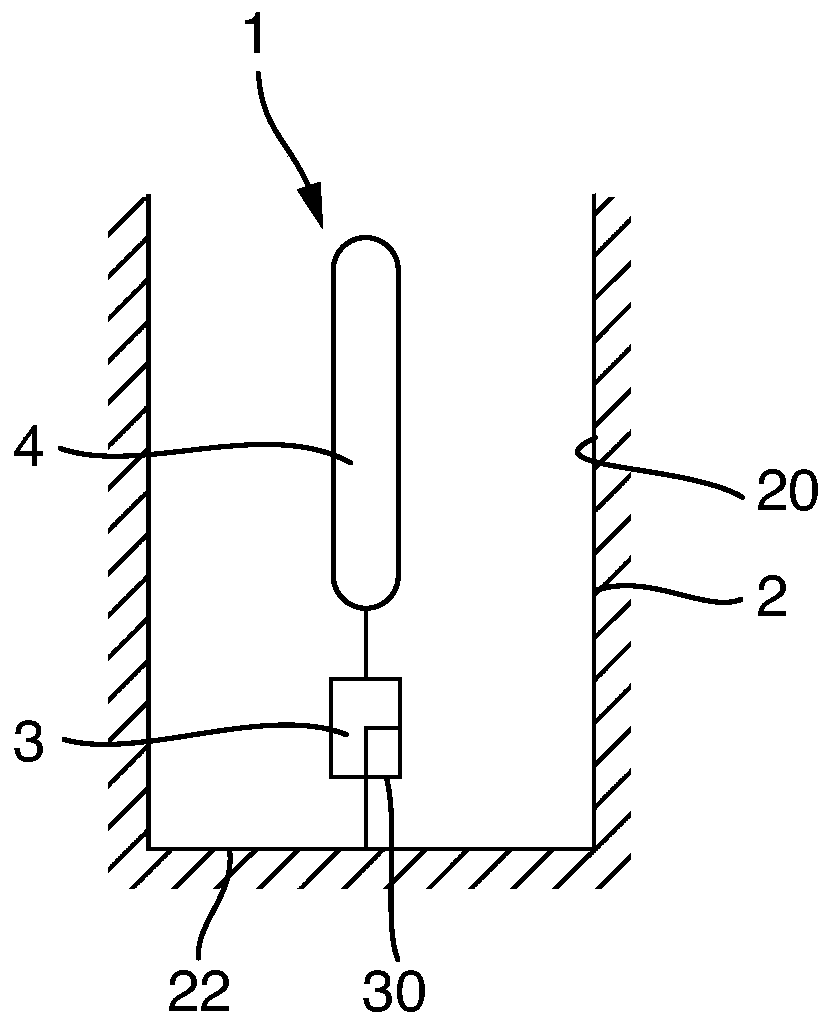

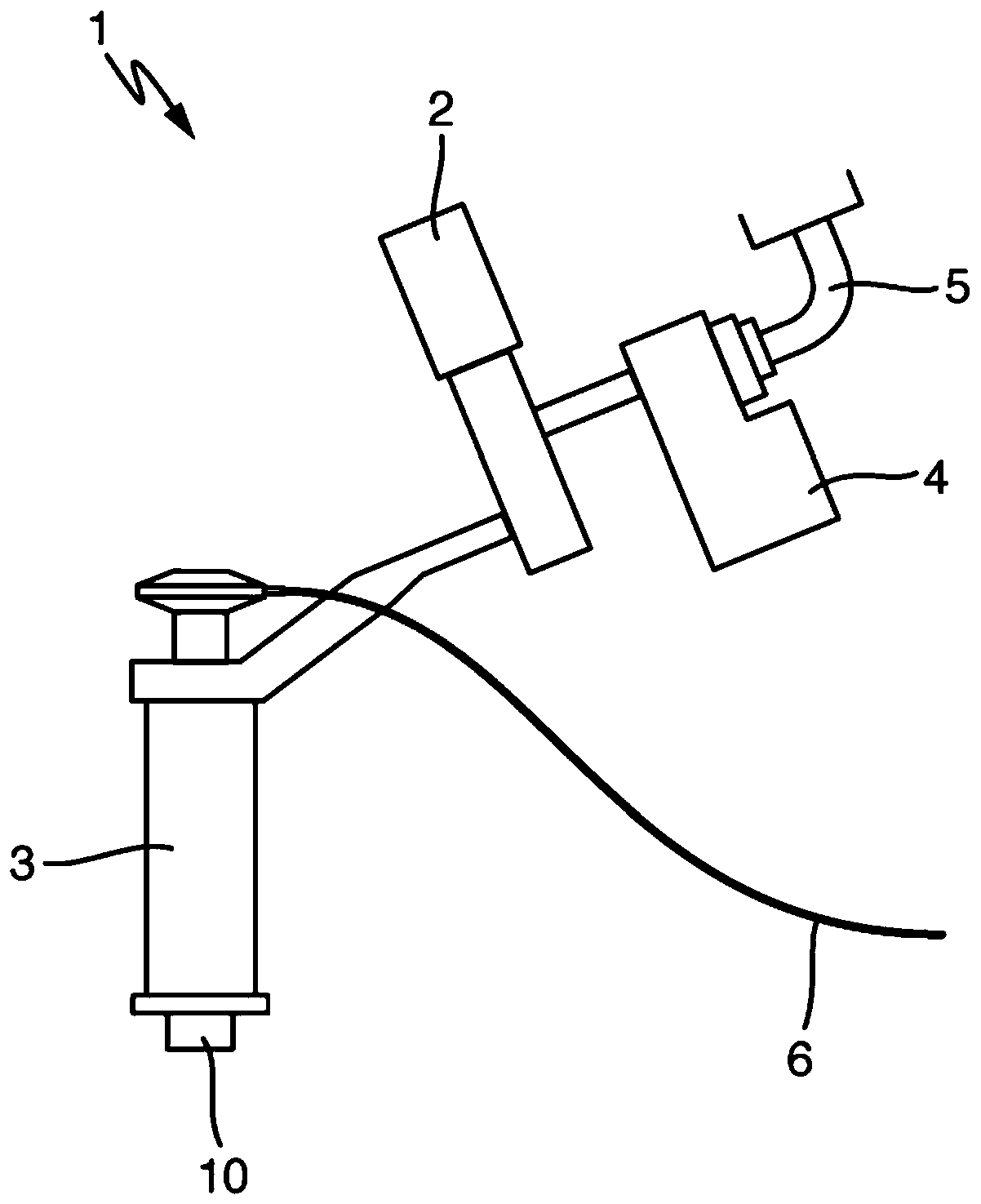

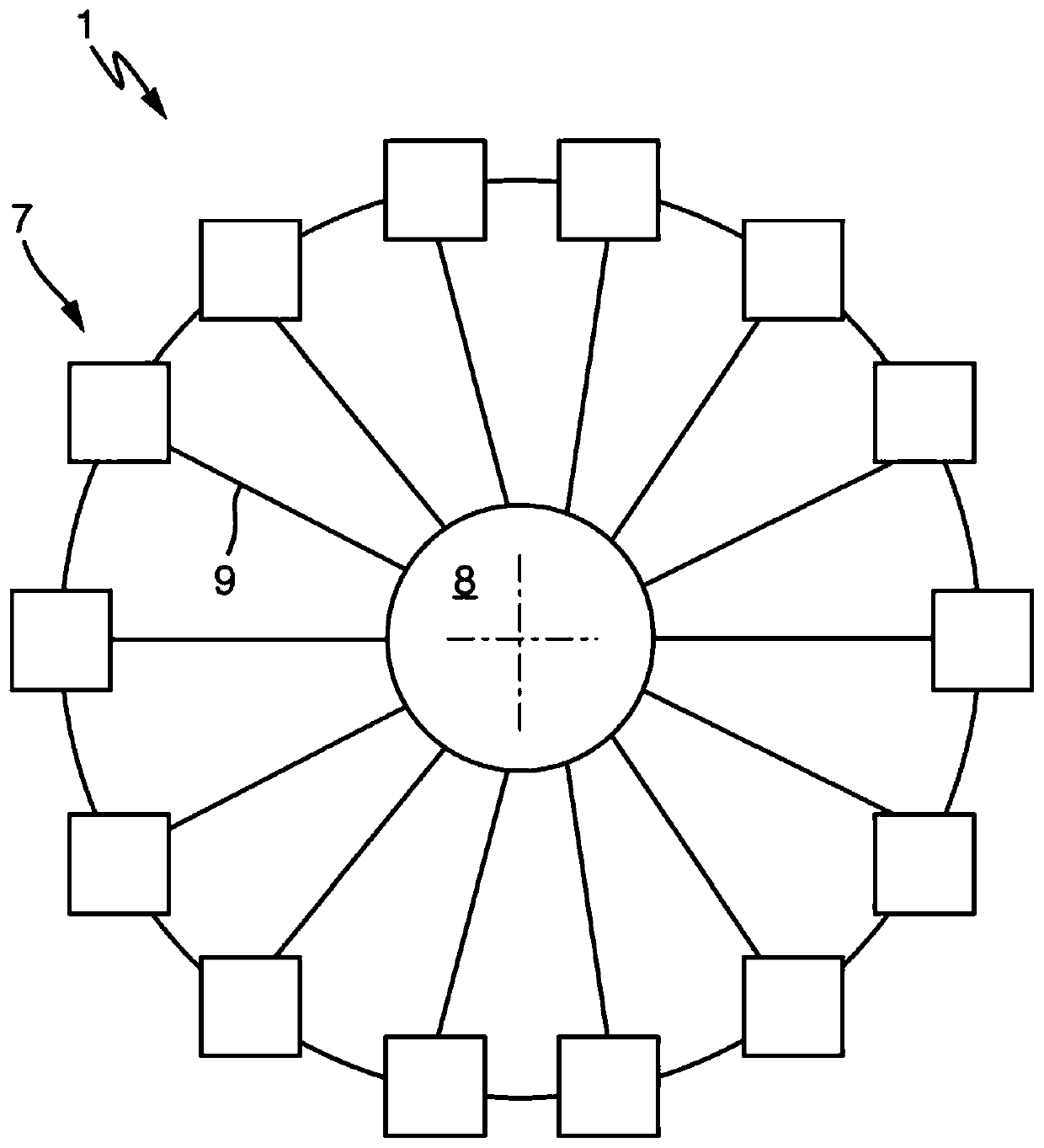

Device for determining the filling level of a filling product in a filling product reservoir

PendingCN110383017AAvoid accumulationReliable handlingLevel indicator with buoyant probesMachines/enginesFiller - productMechanical engineering

The present invention relates to a device (1) for determining the filling level of a filling product in a filling product reservoir (2) of a filling product filling system, preferably a beverage reservoir in a beverage filling system, comprising an immersible body (4) arranged in the filling product reservoir (2) for immersion into the filling product and a force-measuring cell (3) connected to the immersible body (4) for determining the weight force acting on the immersible body (4), the immersible body (4) being completely formed from a full material.

Owner:KRONES AG

Natural amorphous silica filler products

ActiveUS9834684B2Increase brightnessReduce absorptionPigmenting treatmentSpecial tyresSilicon dioxideSealant

Natural amorphous silica filler products featuring high brightness, low oil absorption, fine particle size, and low crystalline silica content are described. Methods for making, using, and measuring the properties of the natural amorphous silica filler products are also described. The natural amorphous silica filler products described herein may be useful in a variety of products including, but not limited to, polymers, sealants, paints, caulks, latex, architectural coatings, industrial coatings, pozzolan, glass catalysts, ceramic glazes, and anti-blocking applications.

Owner:IMERYS USA INC

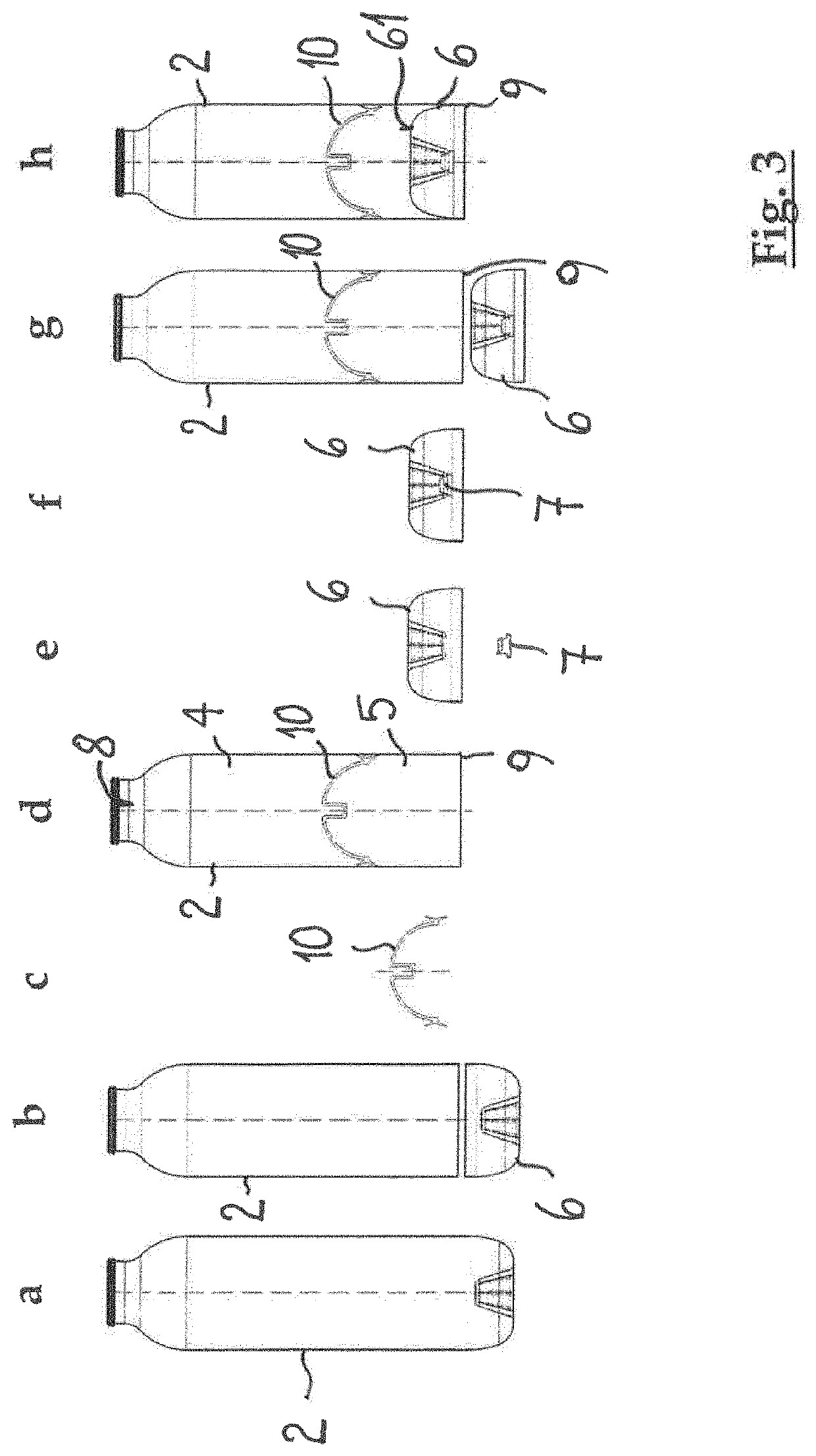

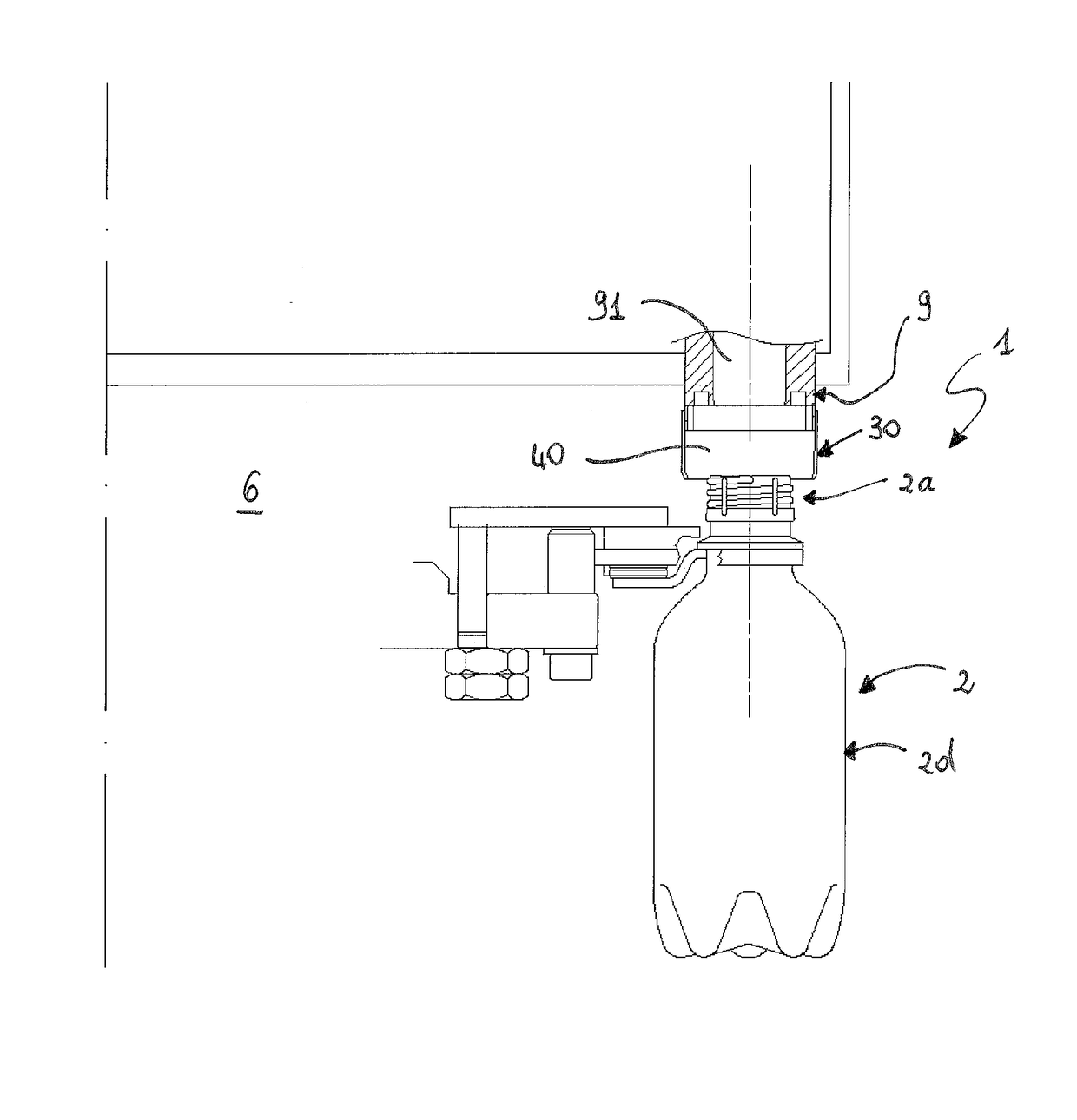

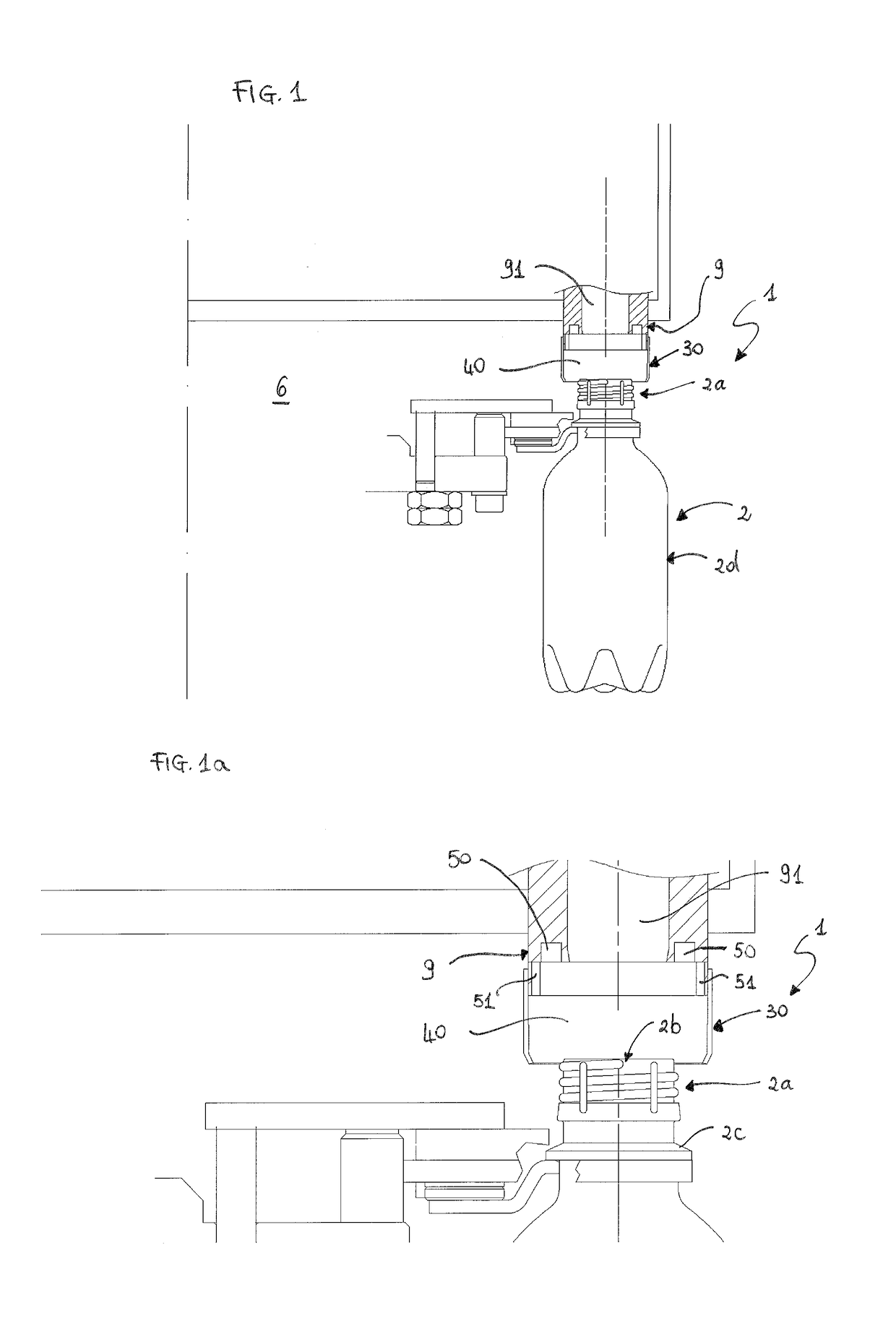

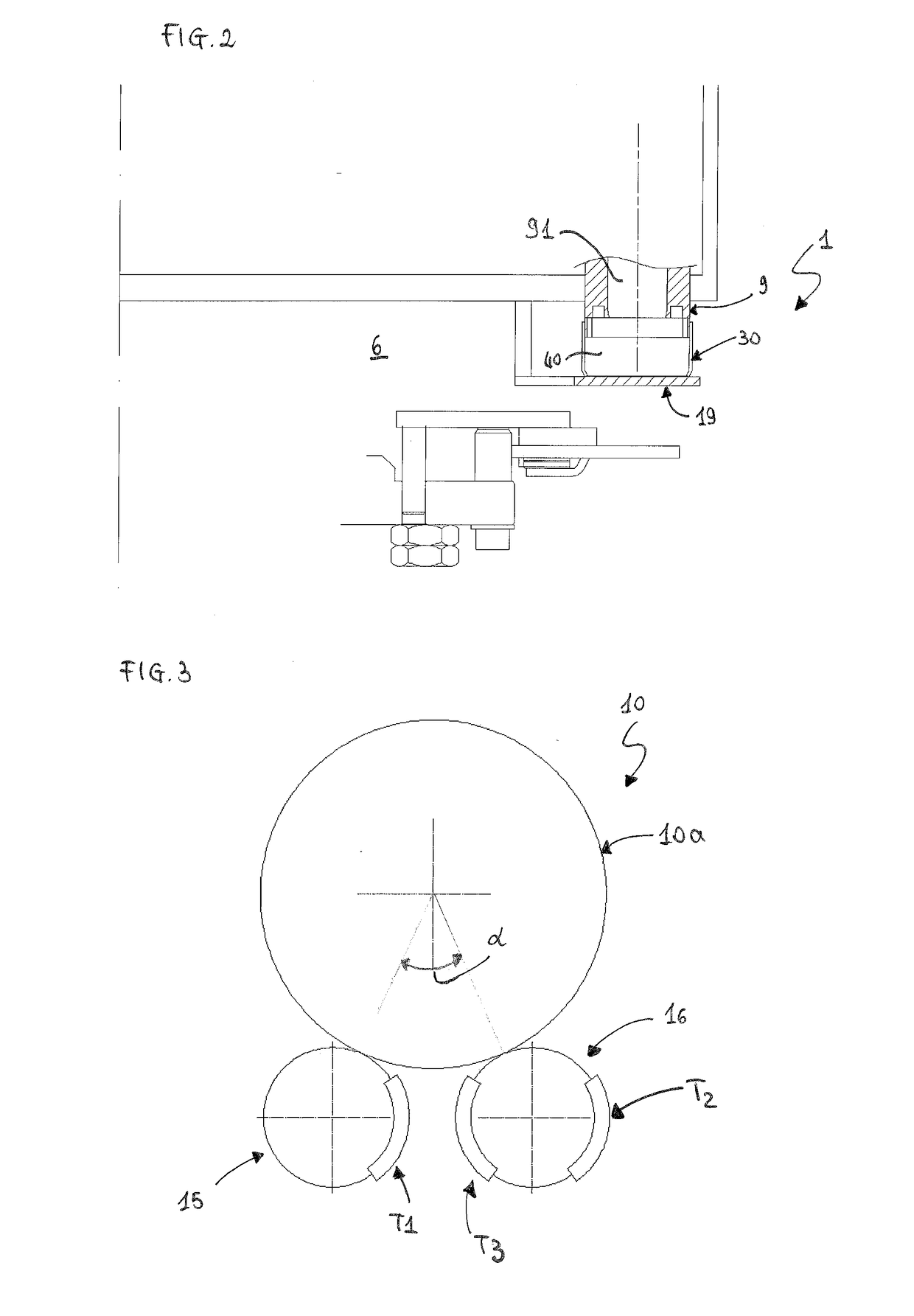

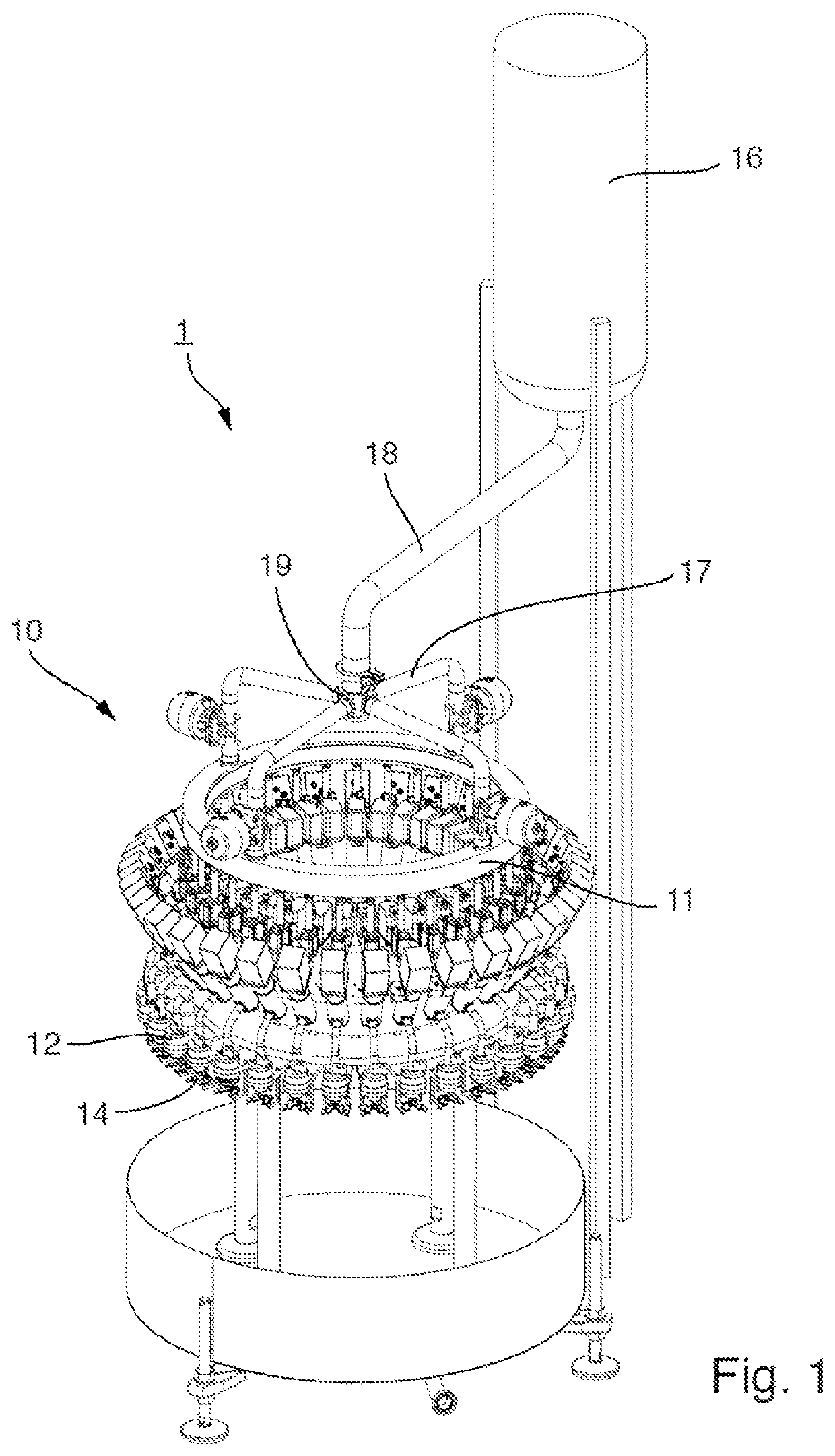

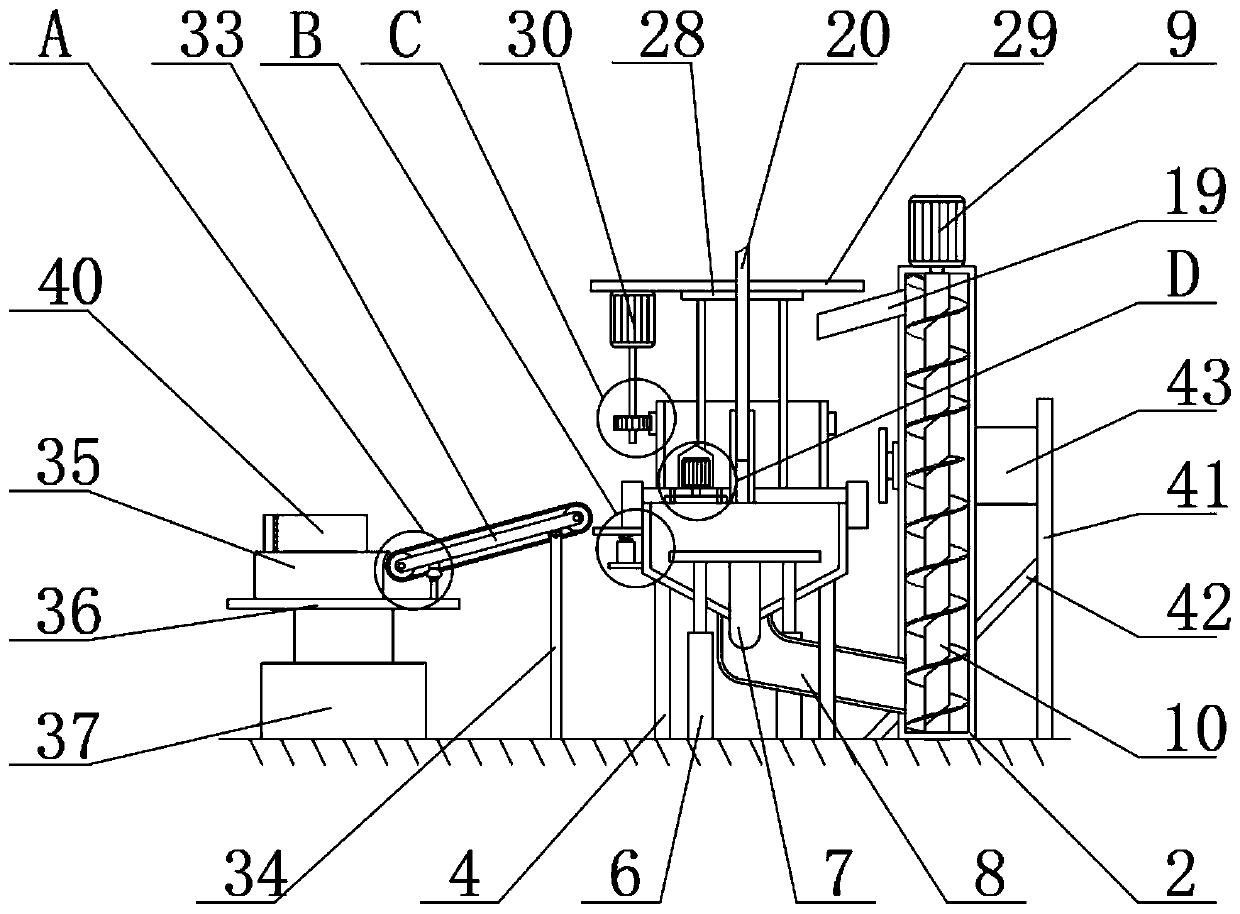

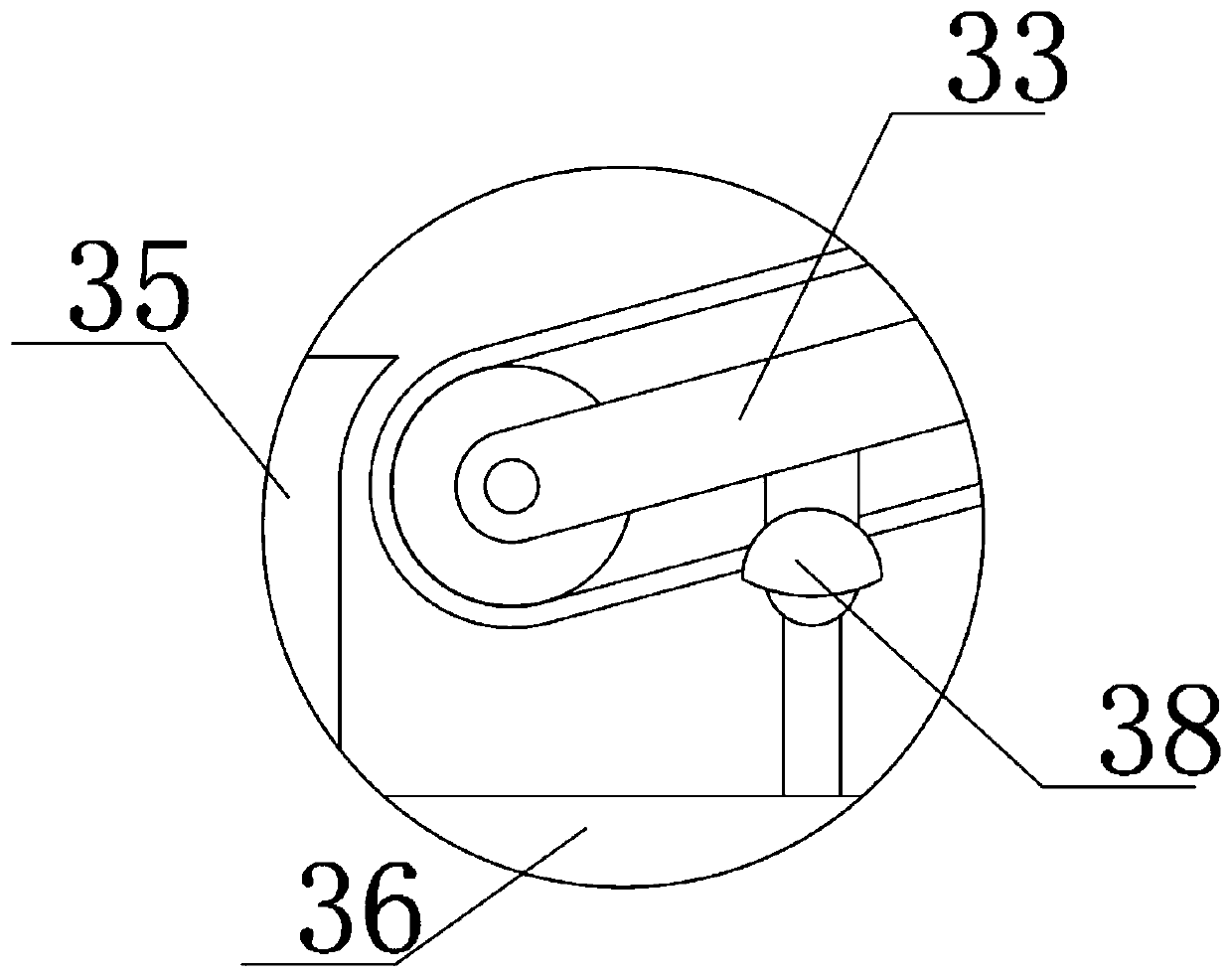

Apparatus and method for filling containers

ActiveUS20170327365A1Shorten the timeQuicker and more practicalClosing machinesSynchronising machinesMechanical engineeringBlood plasma

A method for filling a container (2) with a filling product, comprising the steps of: positioning the container (2) in a filling station (1) so that its mouth (2b) is below the filling valve (9); separating a treatment volume (40) of the neck (2a) comprised between the filling valve (9) and at least one part of the neck (2a) of the container (2) from an external environment (6) containing the body (2d) of the container (2); dispensing plasma into the treatment volume (40) so that it flows over the neck (2a) of the container (2); enabling the filling valve (9) to dispense the filling product into the container (2).

Owner:GEA PROCOMAC

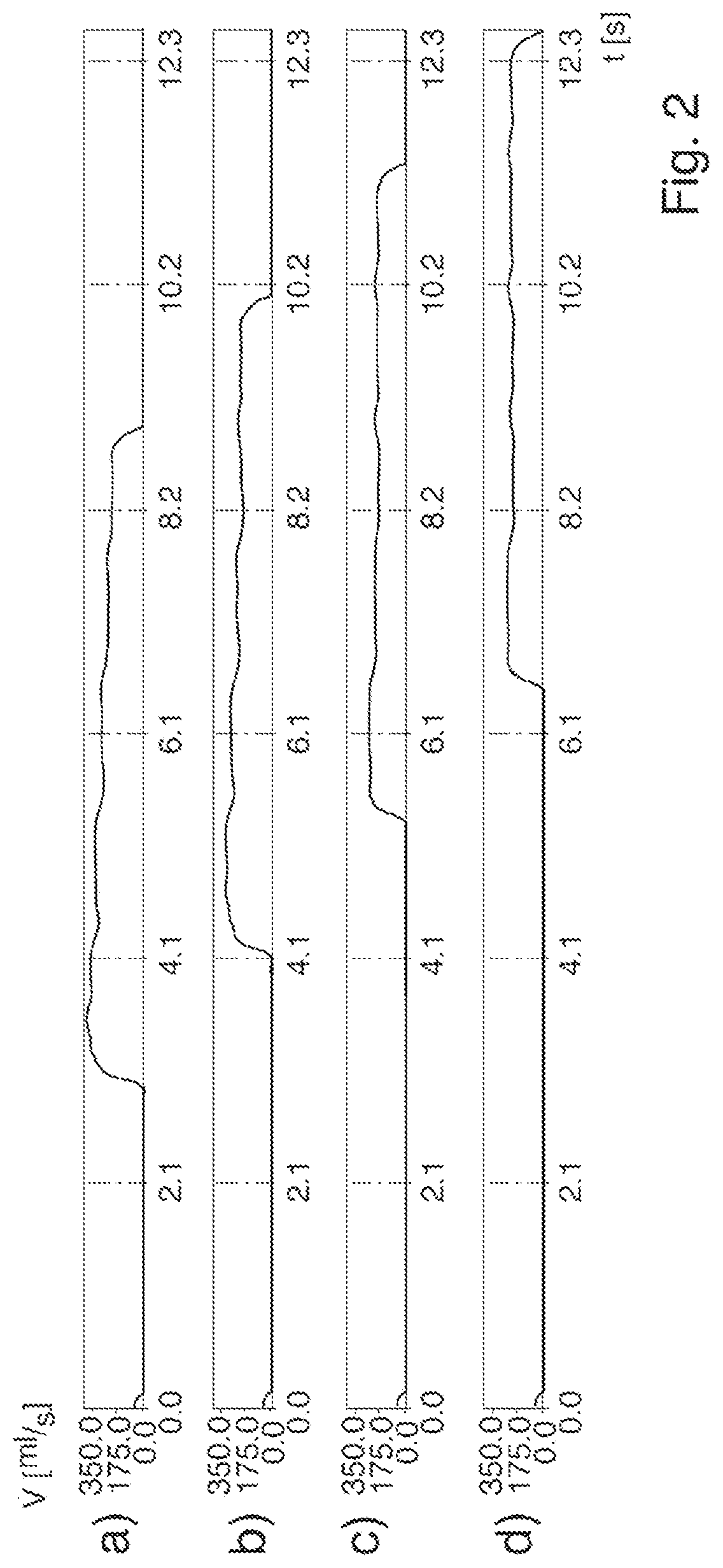

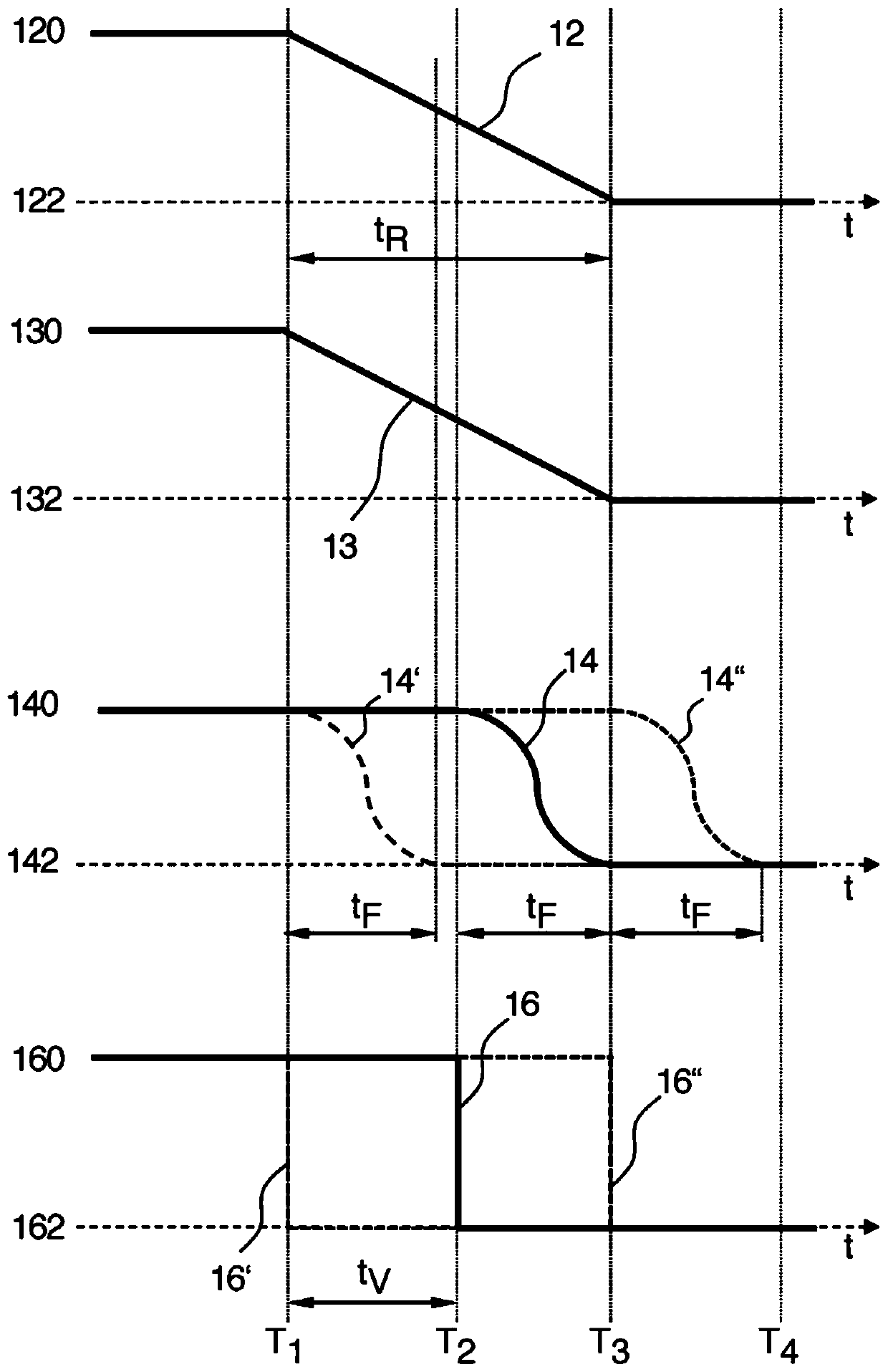

Method for filling containers with a filling product

ActiveUS20200198954A1Accurate calculationEasy to fillSafety device in filling machineryFluid handling accessoriesProcess engineeringControl valves

A method for filling a container with a filling product in a filling-product filling system having a control valve, having the steps:a differential pressure Δpv decreasing across the control valve; andregulating and / or controlling the control valve as a function of the differential pressure Δpv which has been determined.

Owner:KRONES AG

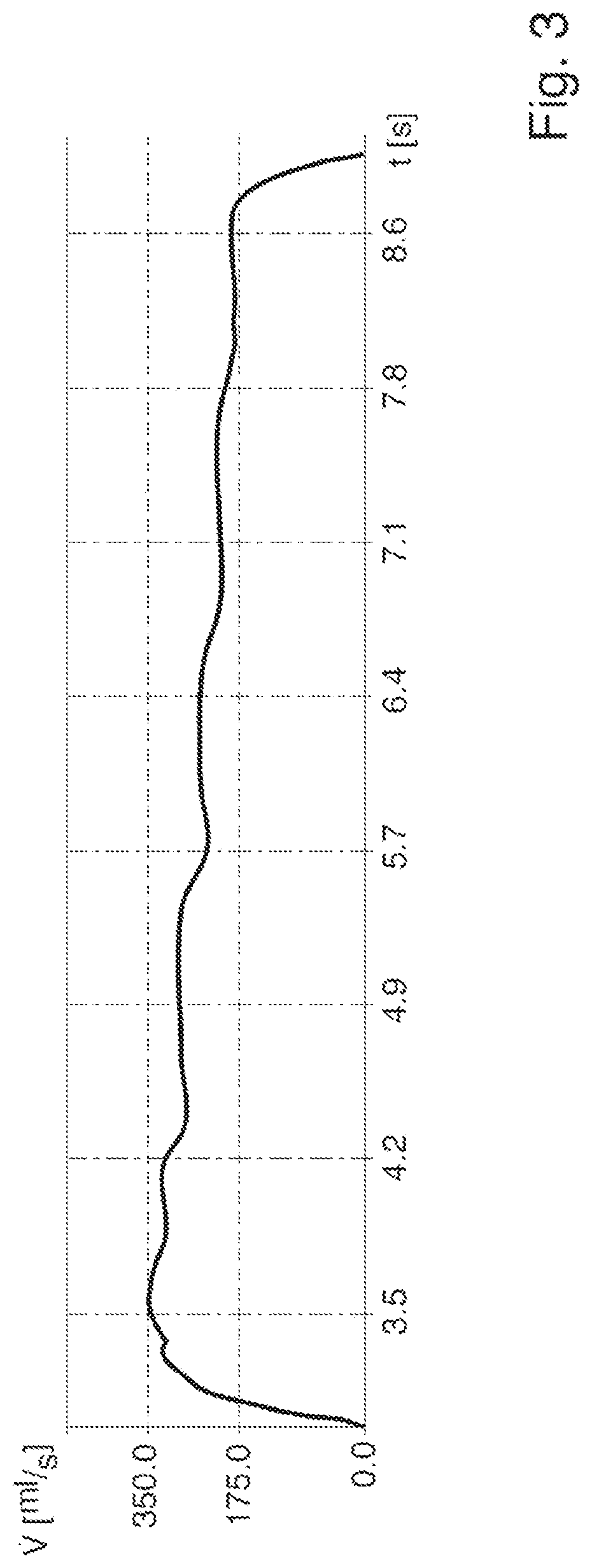

Method and device for filling a fill product

ActiveCN109956068AAccurate deviation timeSure easyLiquid materialLiquid bottlingFiller - productMechanical engineering

A method for filling with a filling product, for example for filling with a beverage in a beverage filling plant by the free jet method, includes supplying a flow of filling product through a fillingproduct supply line by opening a filling valve disposed in the filling product supply line and opening an associated regulating valve for regulating a volume flow, and closing the regulating valve andthe filling valve in order to end the flow of filling product at the end of filling. The closing of the regulating valve and the filling valve are synchronized. A corresponding device is also described.

Owner:KRONES AG

Guide plate molding machining device and using method thereof

InactiveCN110918888AFlat surfaceSufficient machining allowanceFoundry mouldsMould handling/dressing devicesFiller - productMachining

The invention relates to the technical field of continuous mills, in particular to a guide plate molding machining device and a using method thereof. The guide plate molding machining device comprisesa forming box, a material return barrel and a collecting plate; supporting legs are fixedly connected to the bottom end surface of the forming box, and the bottom ends of the supporting legs are fixedly connected with the ground; the inner side of the forming box is provided with a placement plate, and the bottom end surface of the placement plate is fixedly connected with a first hydraulic rod;the first hydraulic rod penetrates through the forming box and is slidably connected with the forming box, and the bottom end surface of the first hydraulic rod is fixedly connected with the ground; the bottom end surface of the placement plate is fixedly connected with a plugging block, and the plugging block is slidably connected with the forming box; and the bottom end surface of the forming box communicates with a recycling pipe, and the recycling pipe communicates with the material return barrel. According to the guide plate molding machining device and the using method thereof, only resin sand is adopted for filling, after being subjected to pouring and taken out of the box, a product is smooth in surface and free of sintering, sand burning, shrinkage depression and other defects, inaddition, the machining allowance is enough, the working efficiency is greatly improved, and the accessory cost and the manpower cost are reduced.

Owner:HENGYANG HONGYU MACHINERY MANFUACTURING CO LTD

Multifunctional filling valve

ActiveUS20210009403A1Improve hygieneCompact and reliable designLiquid transferring devicesLiquid bottlingEngineeringFiller - product

A filling valve for filling a container with a filling product, e.g., a beverage in a beverage filling system, includes a valve base body. The valve base body includes an outlet configured to discharge the filling product into the container; a swirl chamber configured to receive the filling product and is able to be brought into a fluidic connection with the outlet; and a main inlet, which feeds into the swirl chamber and is configured to introduce at least one main component of the filling product into the swirl chamber such that the filling product is swirled in the swirl chamber, whereby after exiting from the outlet the filling product flows downwardly in a spiral movement in the container. The swirl chamber has an annular shape, the cross-sectional contour thereof having a rounded shape, substantially without corner points, in the direction of extent and perpendicular to the direction of extent.

Owner:KRONES AG

Process for the preparation of surface treated mineral filler products and uses of same

ActiveUS20150141565A1Pigment treatment with non-polymer organic compoundsPolymer scienceApplication areas

The present invention relates to a process for preparing a surface treated mineral filler product, and to its preferred use in the field of plastic applications, and in particular polypropylene (PP)- or polyethylene (PE)-based breathable or extrusion coating film applications.

Owner:OMYA INT AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com