Patents

Literature

70 results about "Carbon corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Corrosion of carbon steel occurs when the relative humidity of the air is 70% to 80% and the air temperature is above 32 F. Corrosion rates may be accelerated by air impurities that dissolve in condensed water or rain water and by dust and dirt settling on the metal surface.

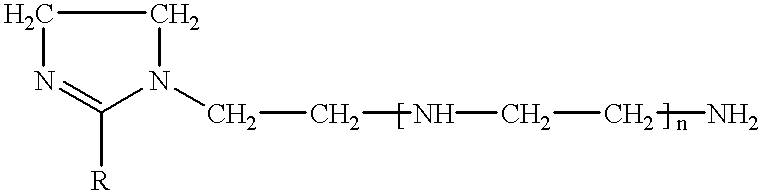

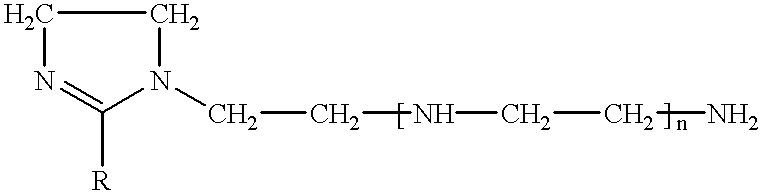

Sulphydryl acid and imidazoline salts as inhibitors of carbon corrosion of iron and ferrous metals

InactiveUS6395225B1Inhibit static corrosionHigh salinityDrilling compositionBorehole/well accessoriesCarbon corrosionFerric

The invention concerns inhibitor compositions based on fatty sulphydryl acid and poly(ethyleneamino)imidazoline salts for considerably reducing the corrosive effect of carbon brine on iron and ferrous metals. These compositions are as efficient when the corrosive medium is driven with a high flowrate and in biphasic brine / oil medium.

Owner:CECA SA

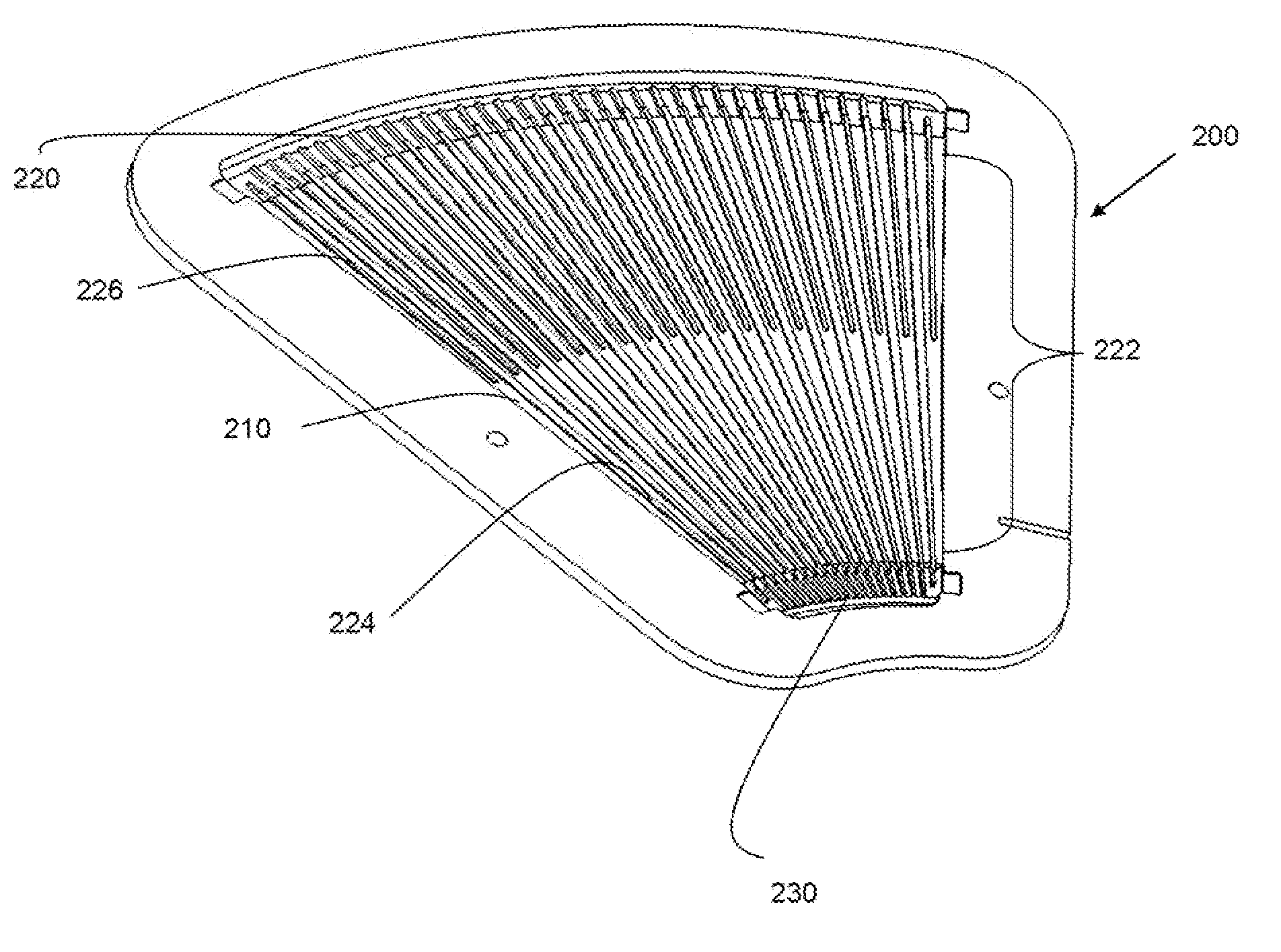

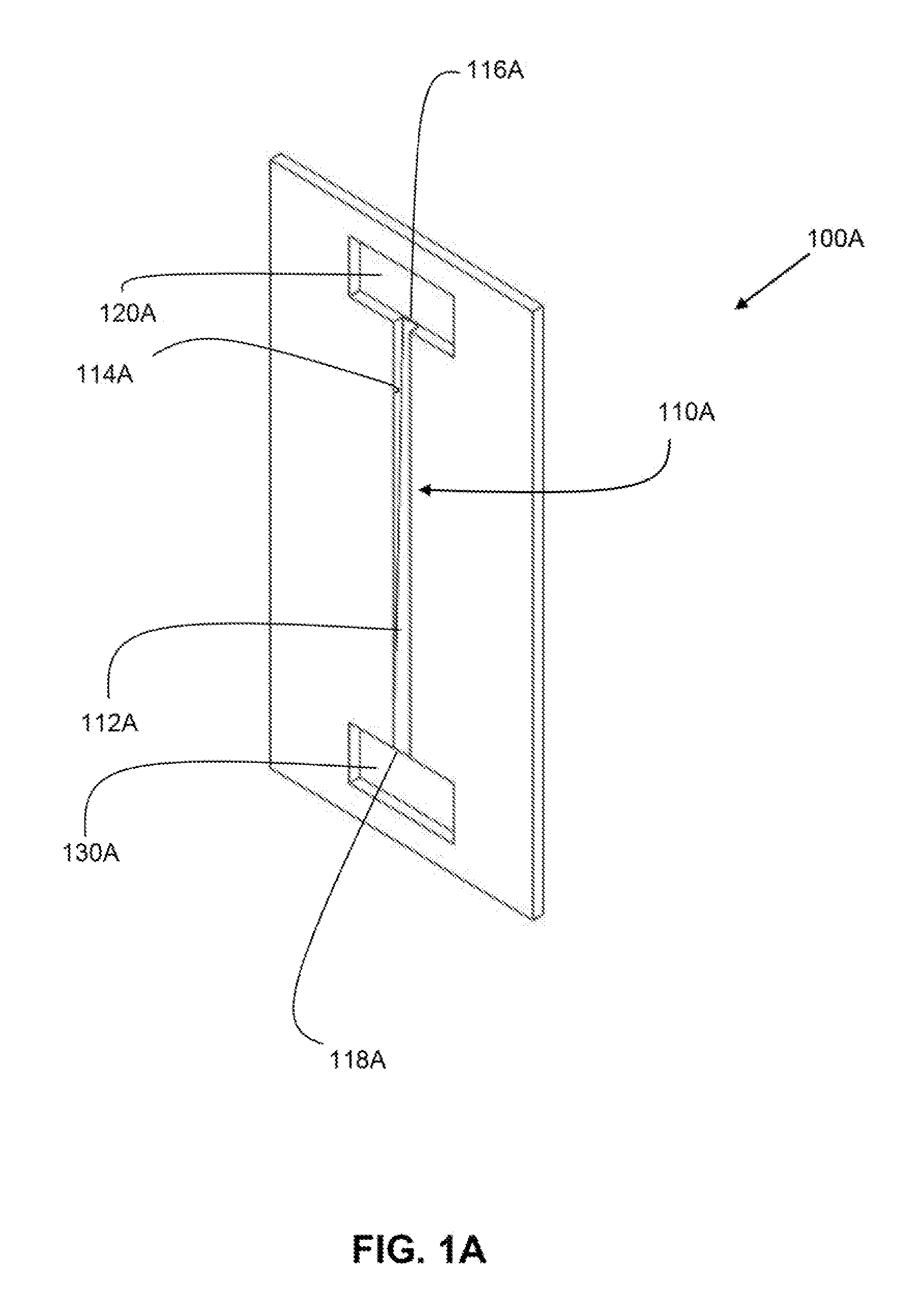

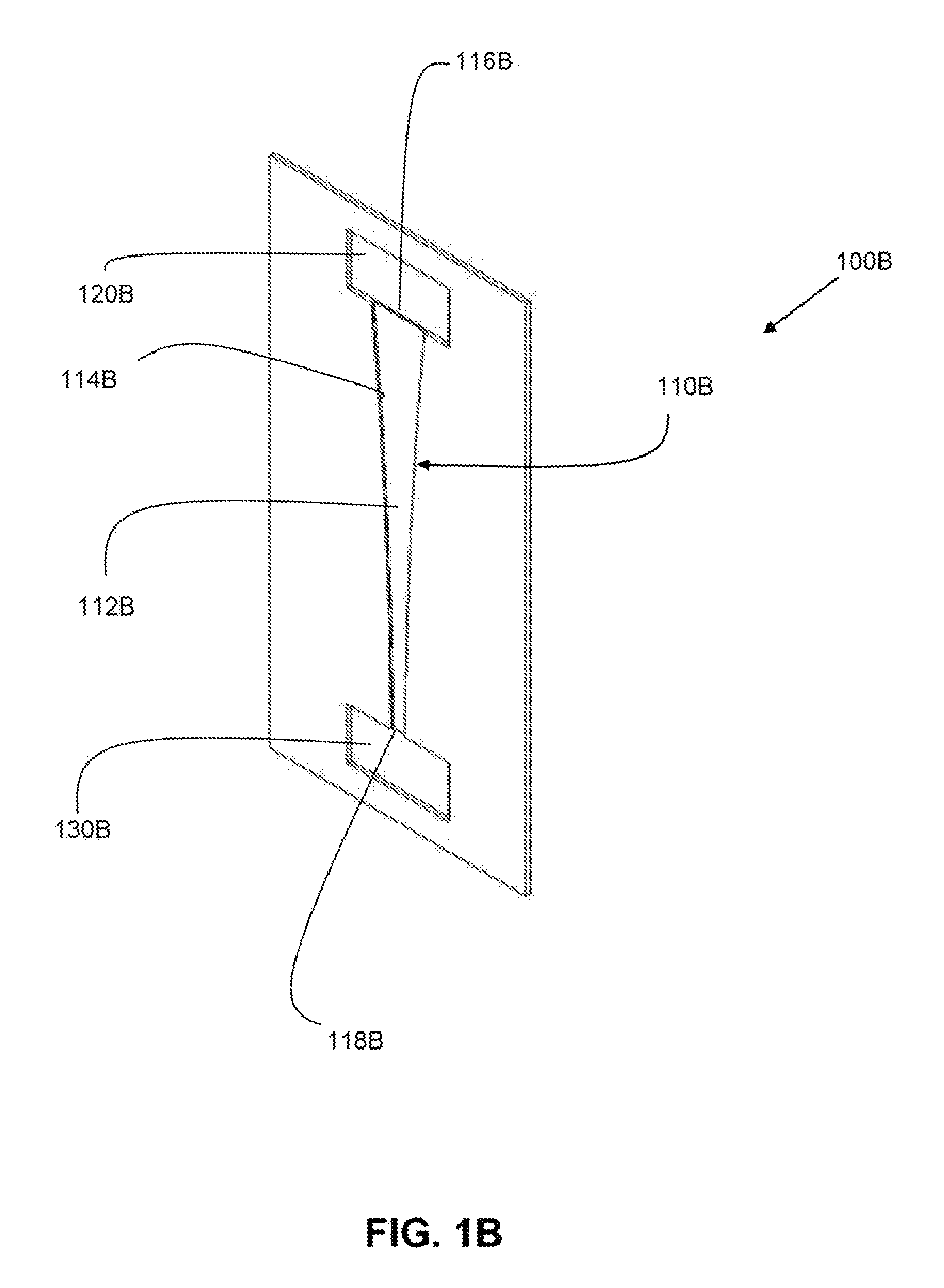

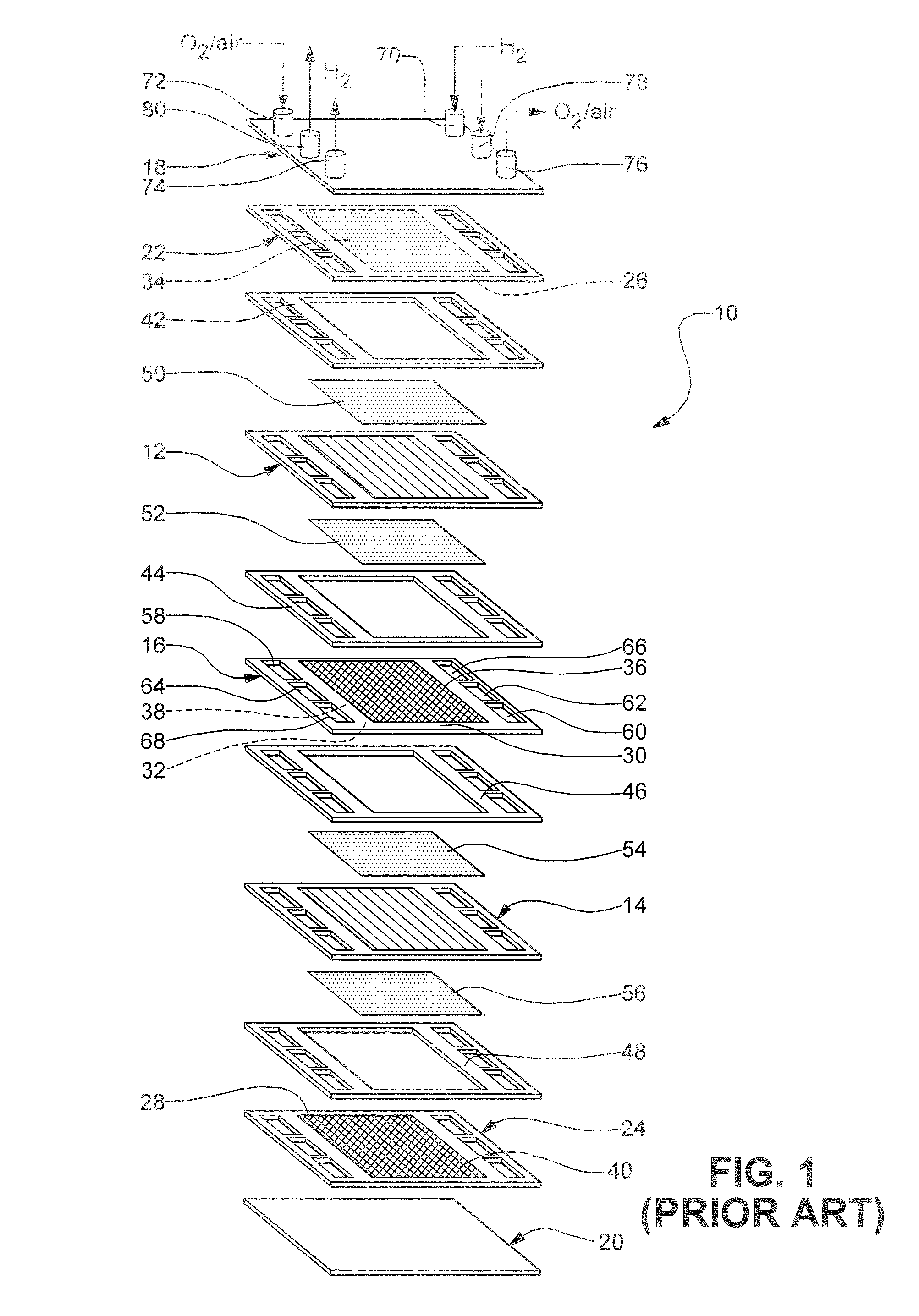

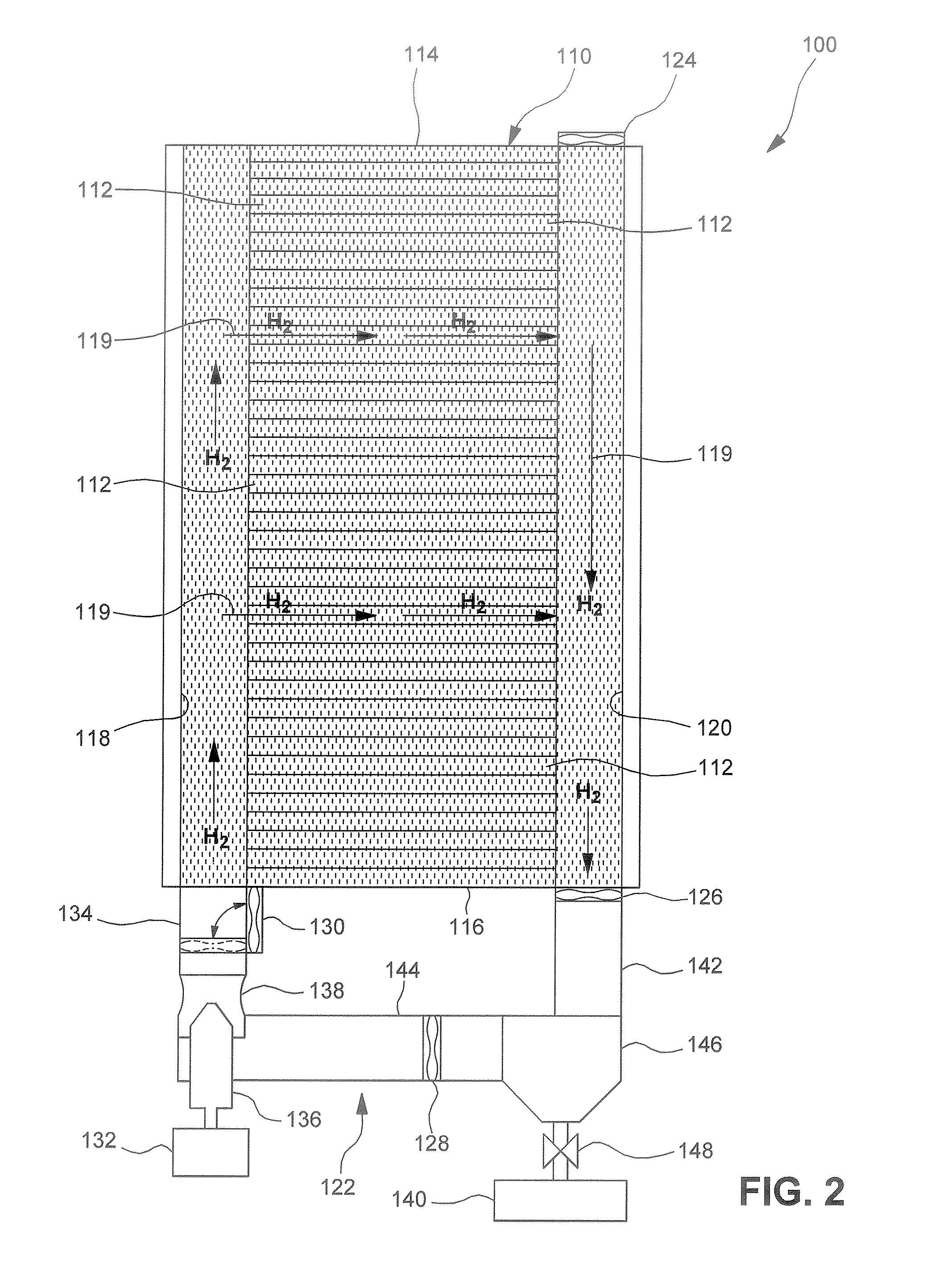

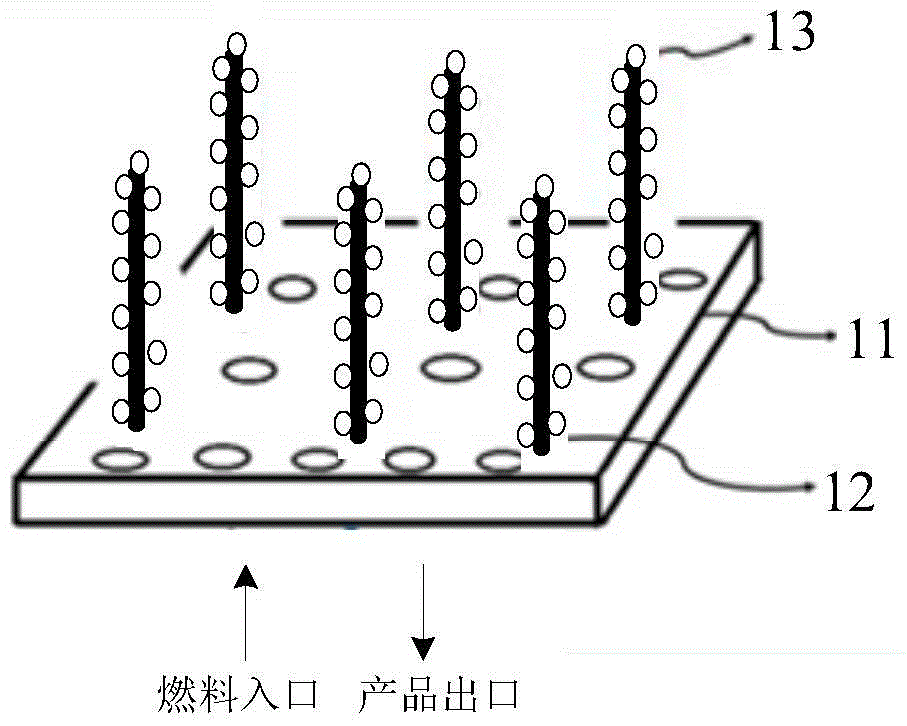

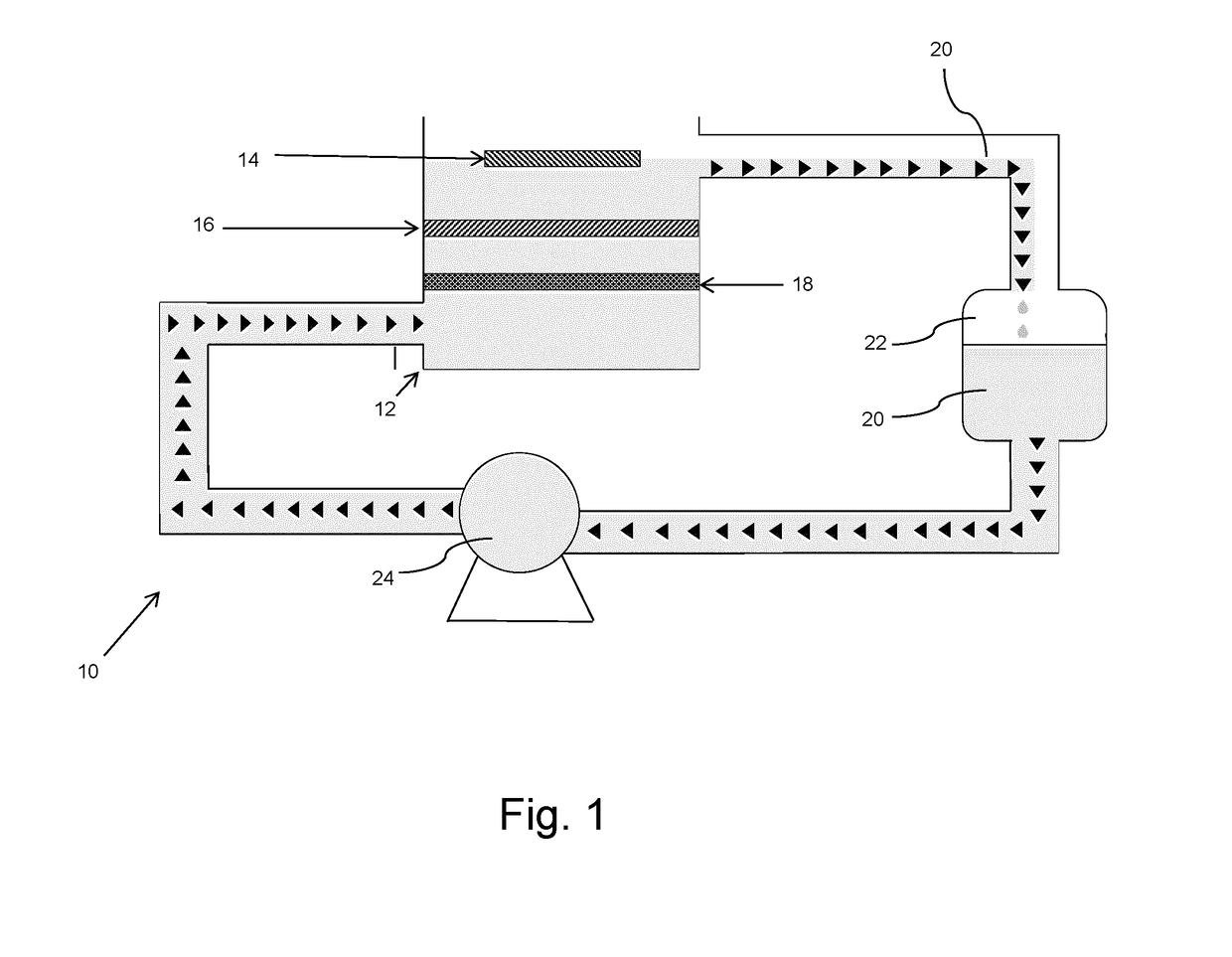

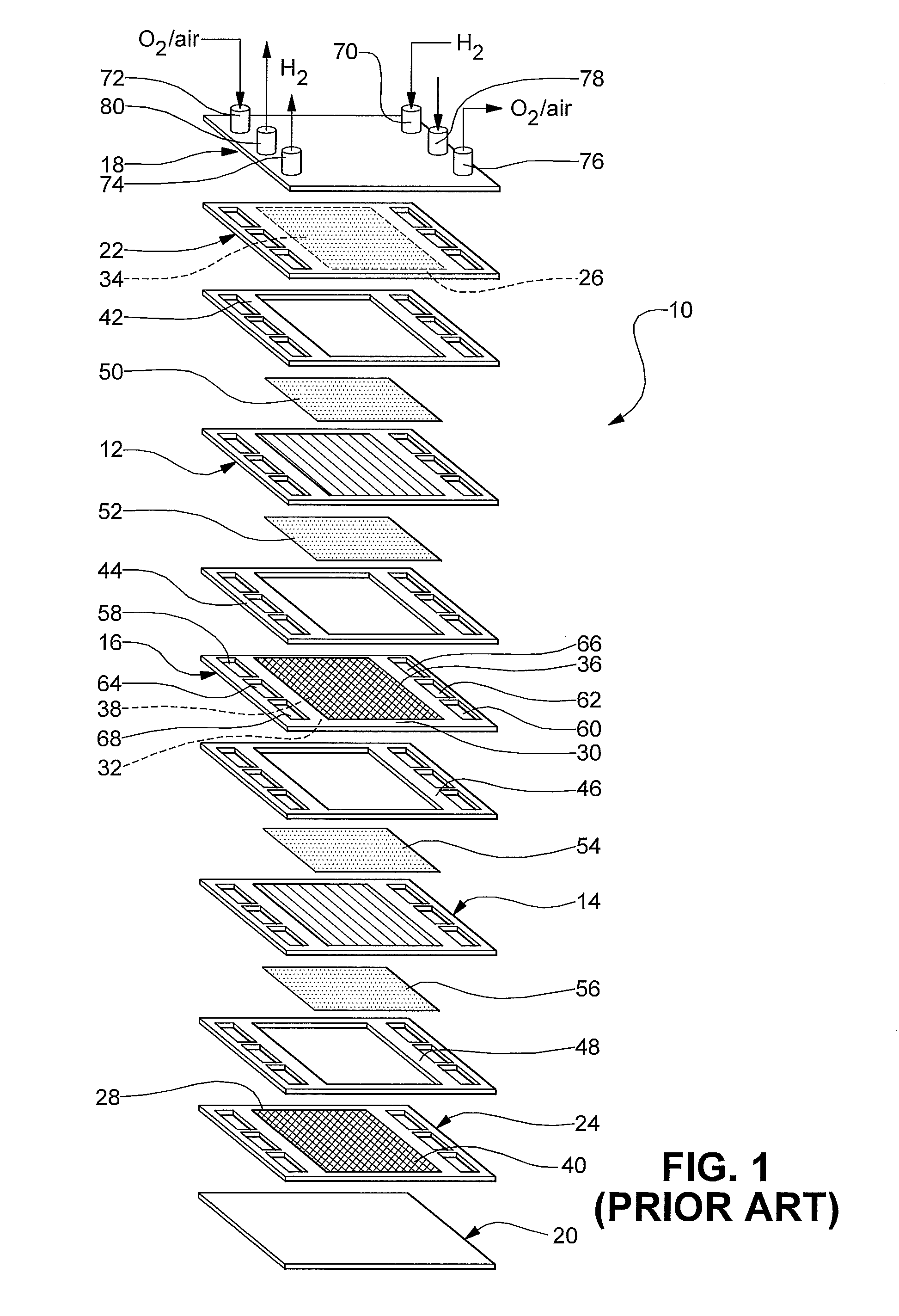

Fuel Cell Flow Channels and Flow Fields

ActiveUS20150180052A1Uniform current densityReduce the cross-sectional areaFuel cells groupingFuel cell auxillariesCarbon corrosionCatalyst degradation

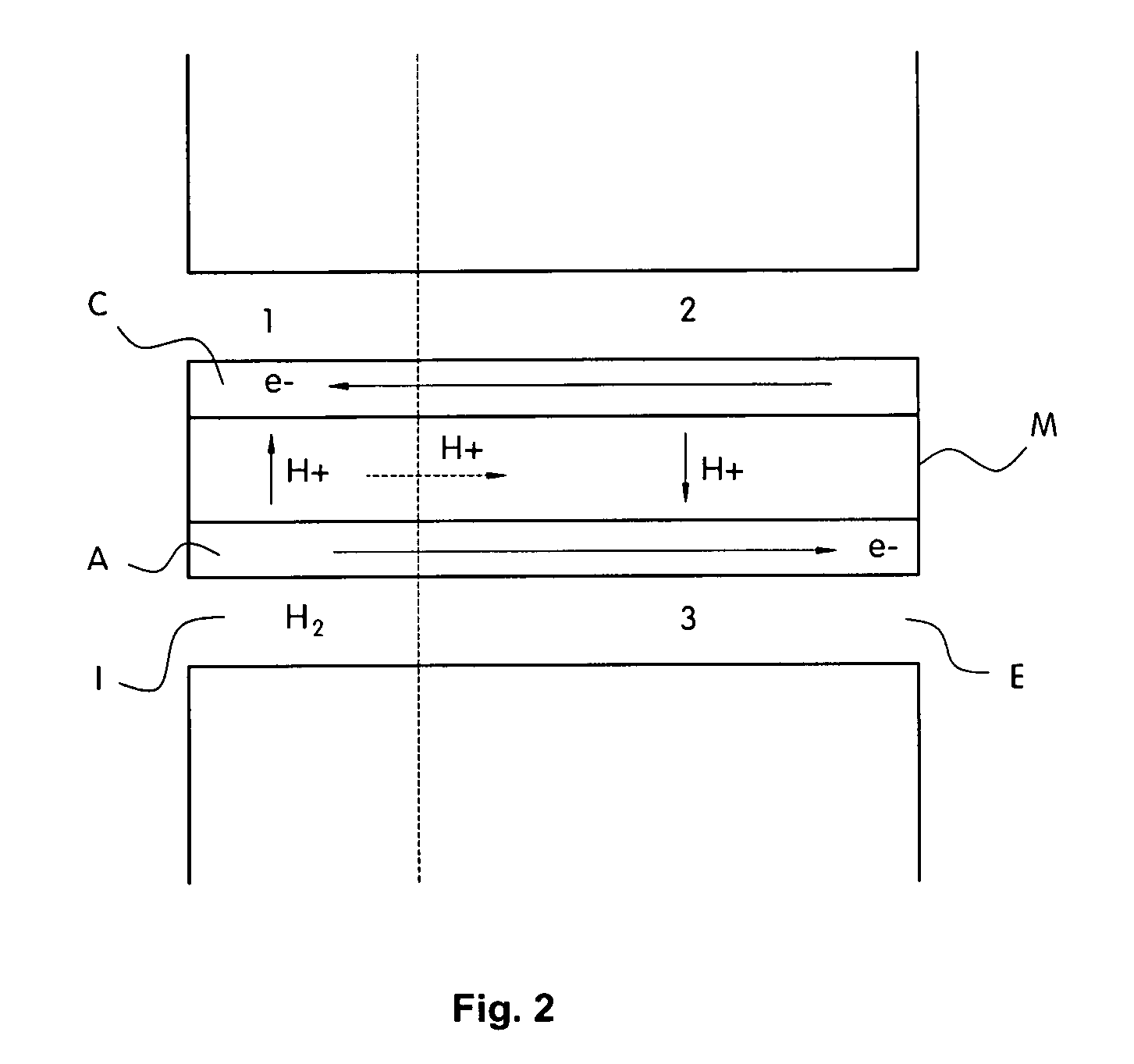

A fuel cell anode flow field includes at least one flow channel with a cross-sectional area that varies along at least a portion of its length. In some embodiments, the channel width decreases along at least a portion of the channel length according to a natural exponential function. This type of anode flow field can improve performance, reduce fuel consumption and / or reduce detrimental effects such as carbon corrosion and catalyst degradation, thereby improving fuel cell longevity and durability. When operating the fuel cell on either a substantially pure or a dilute fuel stream, this type of anode flow field can provide more uniform current density. These flow channels can be incorporated into reactant flow field plates, fuel cells and fuel cell stacks.

Owner:LOOP ENERGY INC

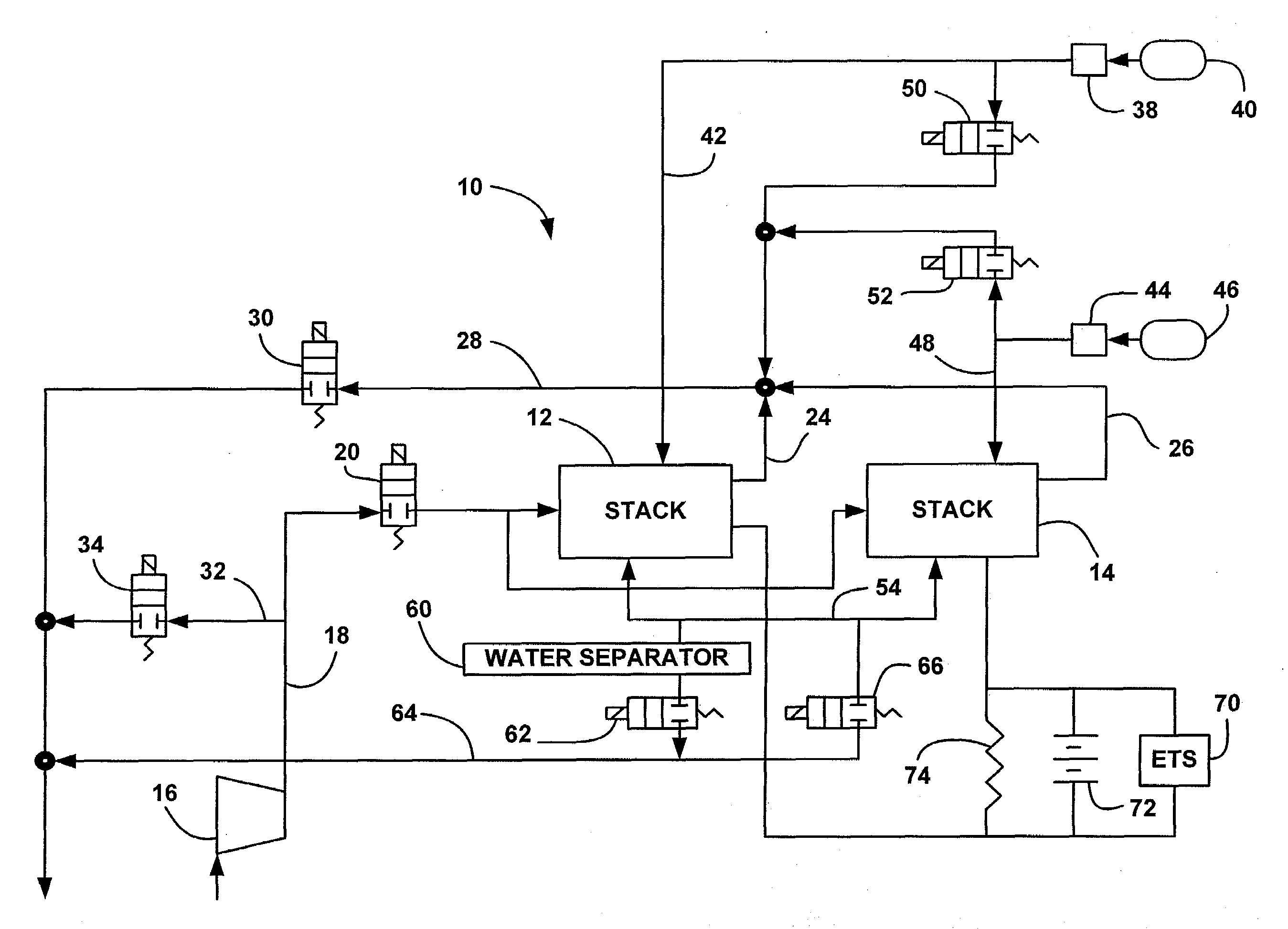

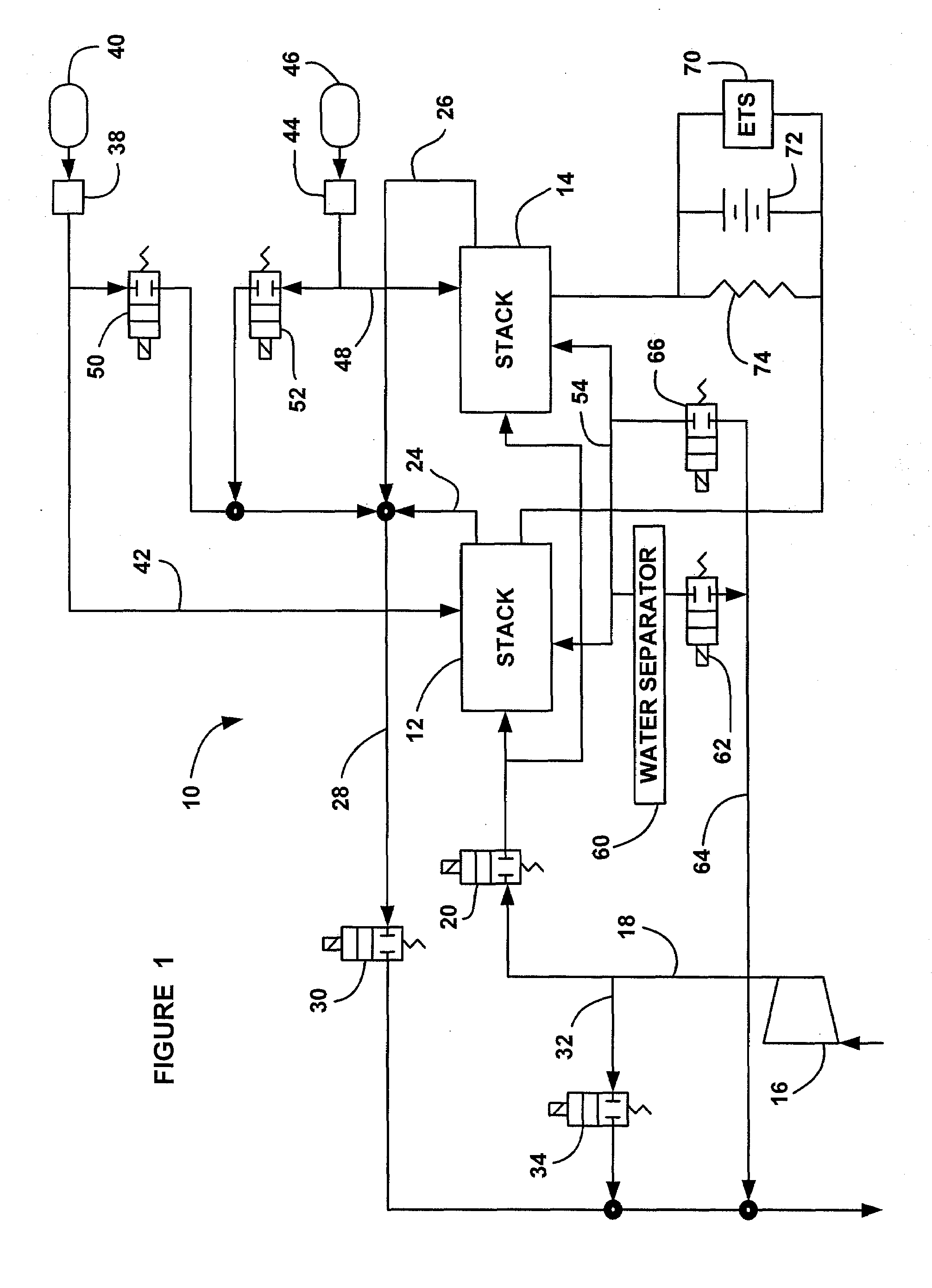

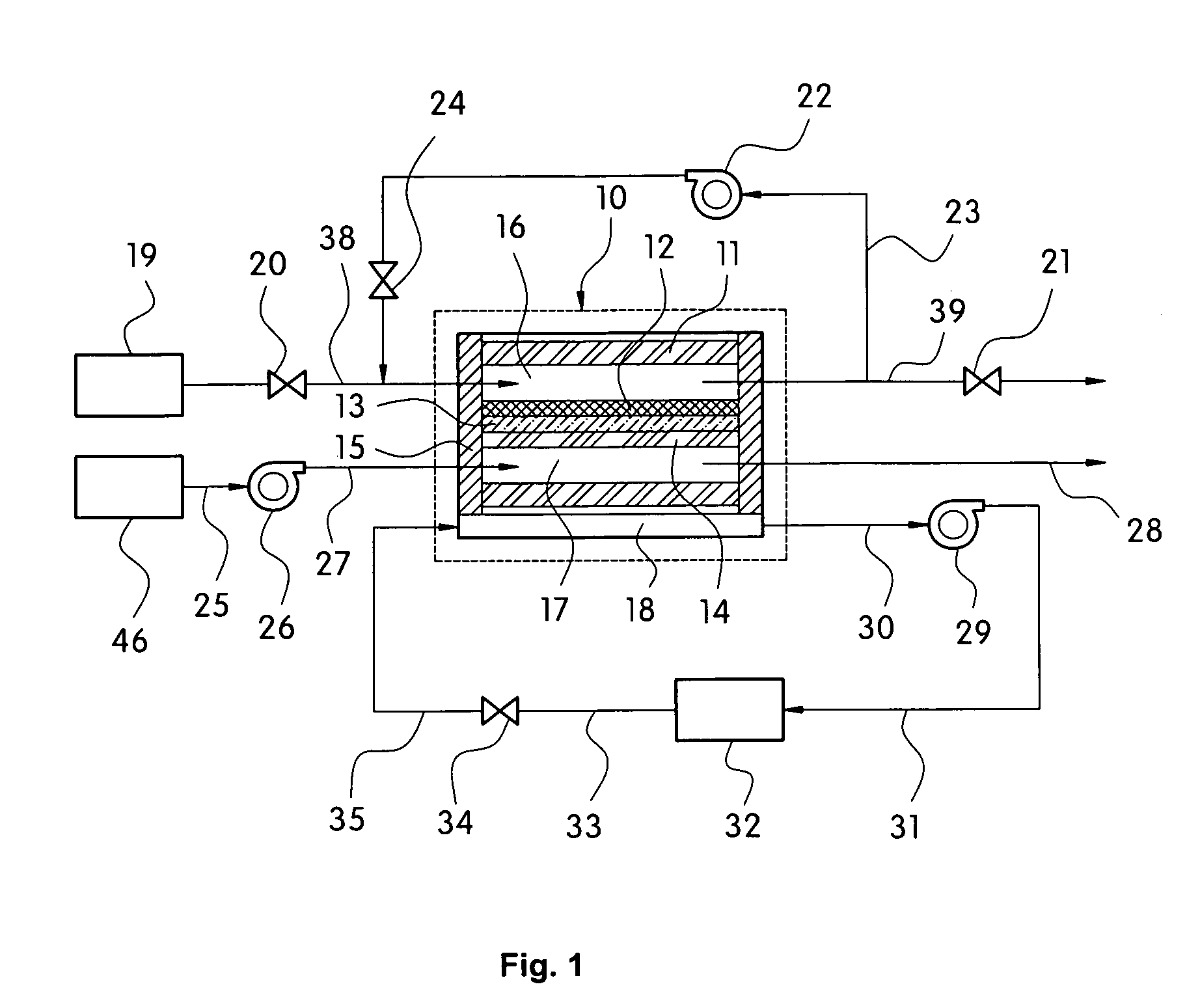

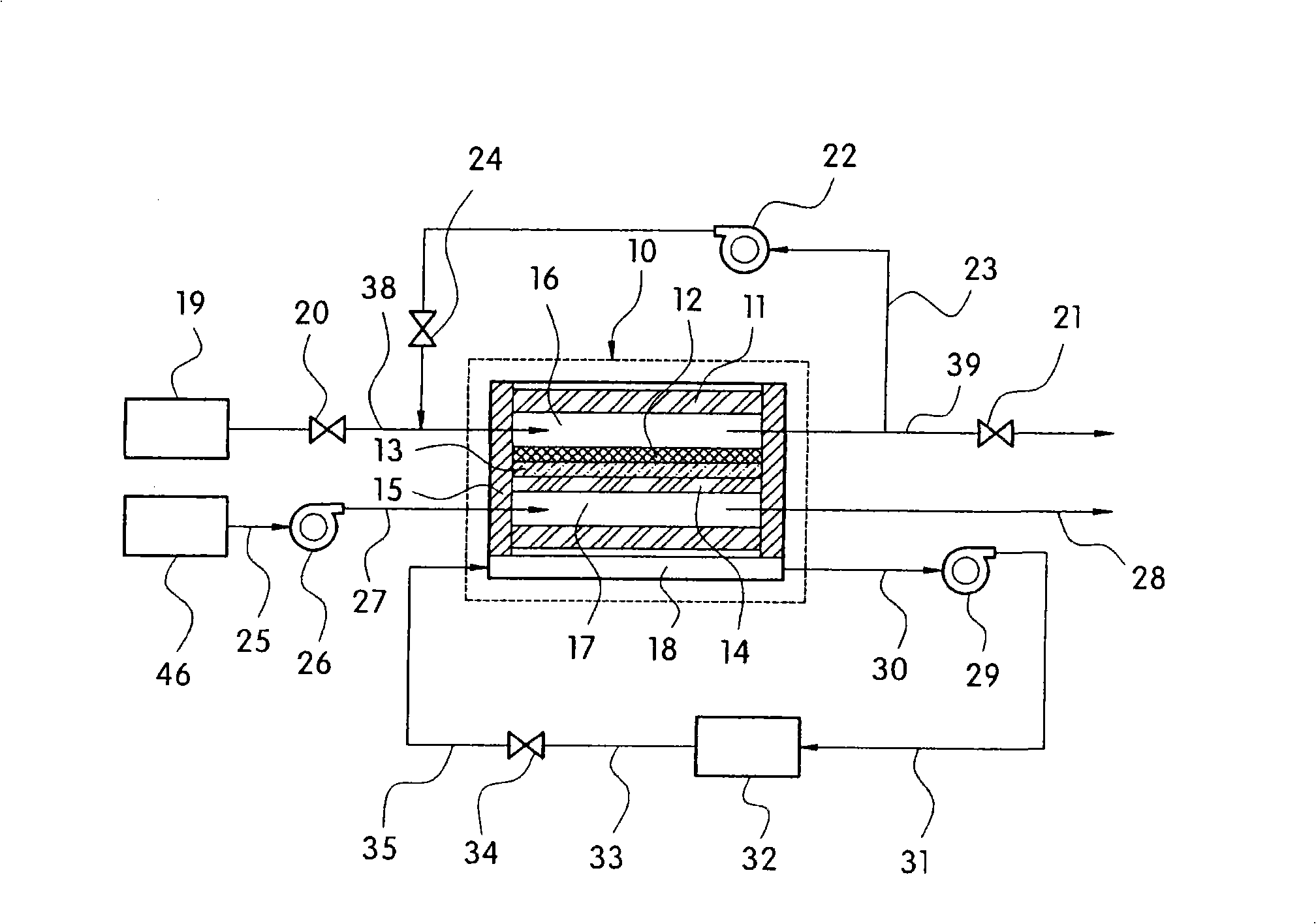

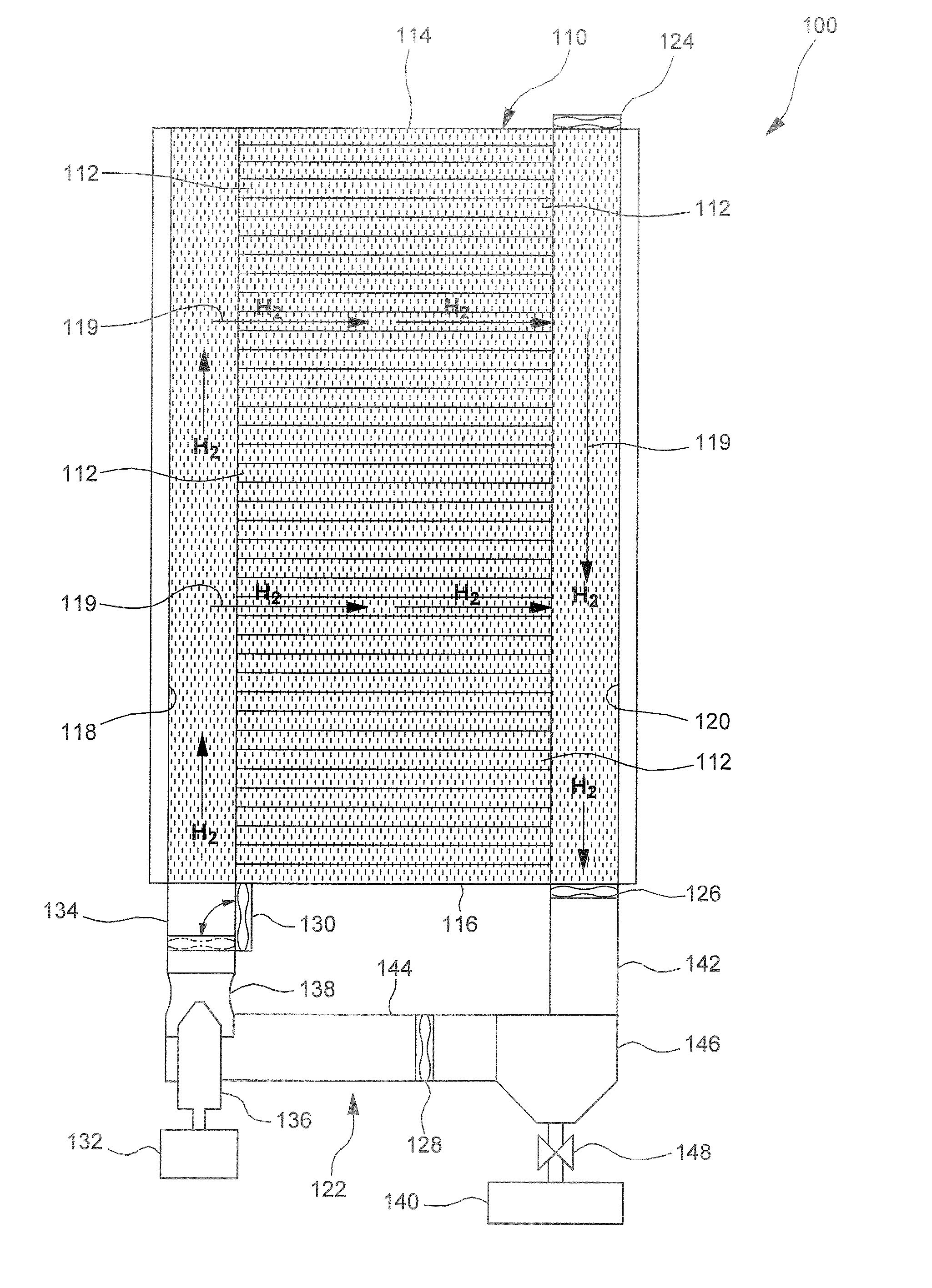

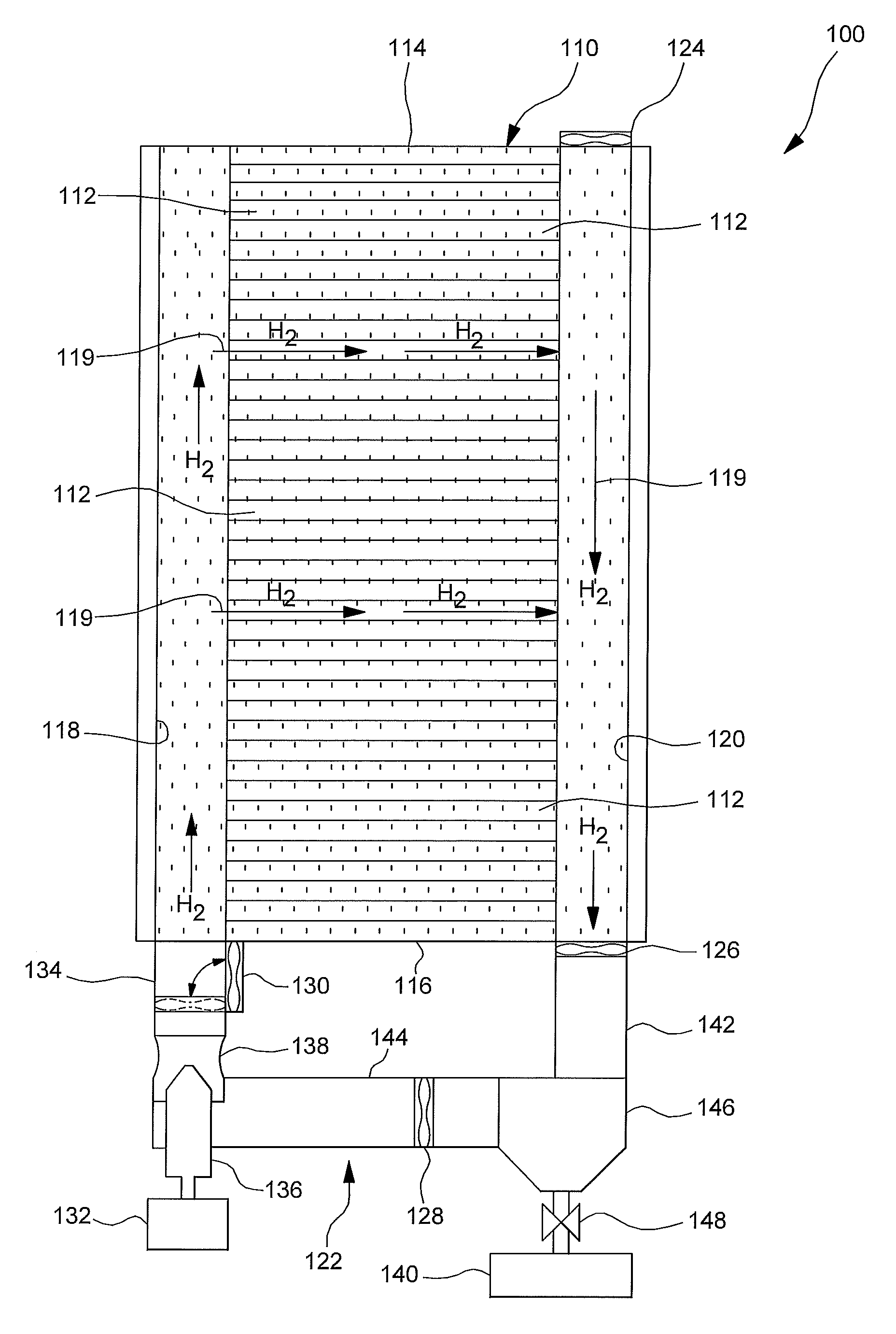

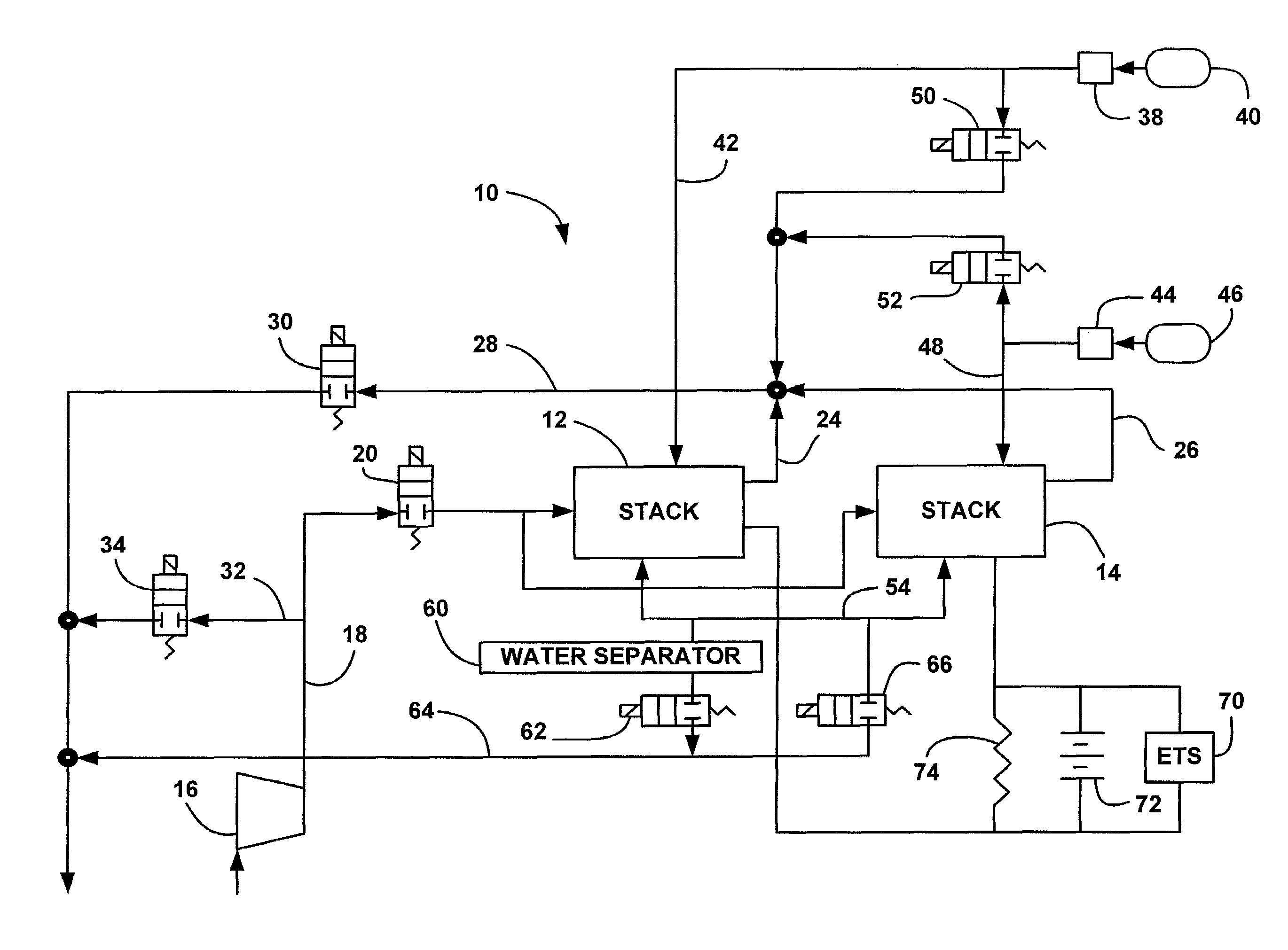

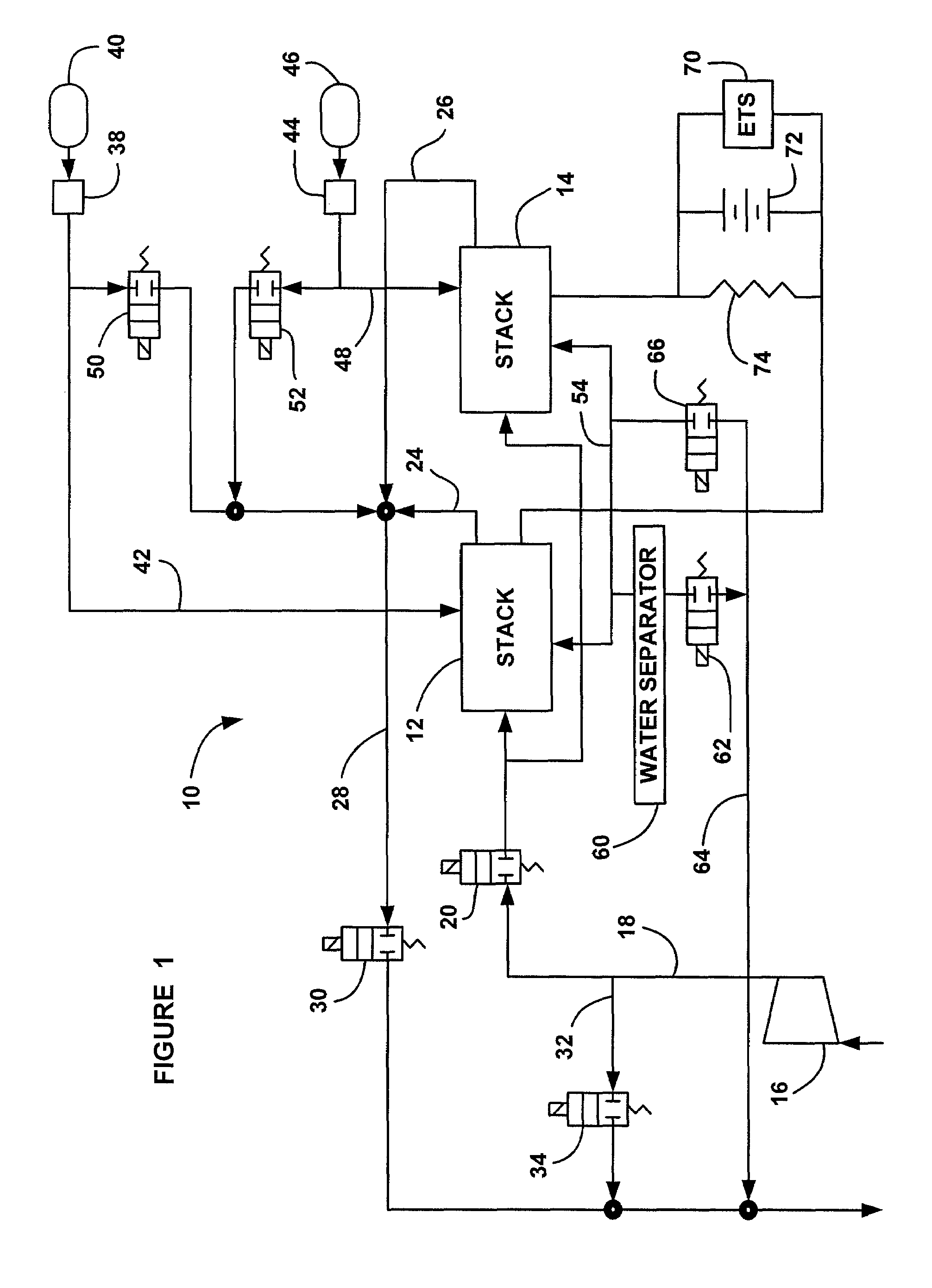

Strategies for Mitigating Cell Degradation During Start-Up and Shutdown with H2/N2 Storage

ActiveUS20080182138A1Reduce corrosionMinimize timeFuel cells groupingFuel cell auxillariesEngineeringCarbon corrosion

A system and method for reducing cathode carbon corrosion during start-up of a fuel cell stack. If a long enough period of time has gone by since the last system shutdown, then both the anode side and the cathode side of the stack will be filled with air. If the system includes split sub-stacks, then a start-up sequence uses a fast hydrogen purge through each sub-stack separately so as to minimize the time of the hydrogen / air front flowing through the anode side of the stacks. The start-up sequence then employs a slow hydrogen purge through the sub-stacks at the same time. If the time from the last shutdown is short enough where a significant amount of hydrogen still exists in the cathode side and the anode side of the sub-stacks, then the fast hydrogen purge can be eliminated, and the start-up sequence proceeds directly to the slow hydrogen purge.

Owner:GM GLOBAL TECH OPERATIONS LLC

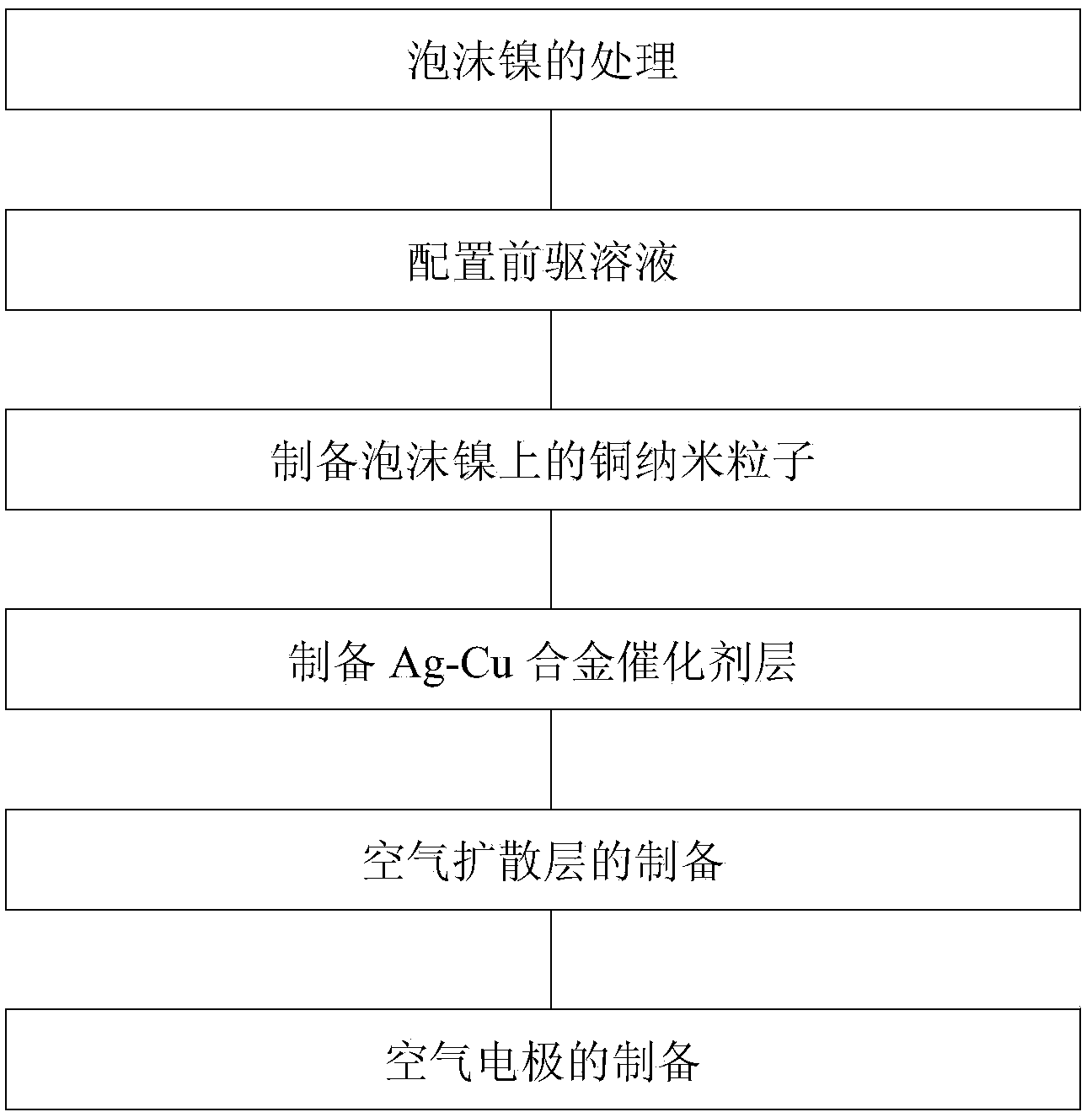

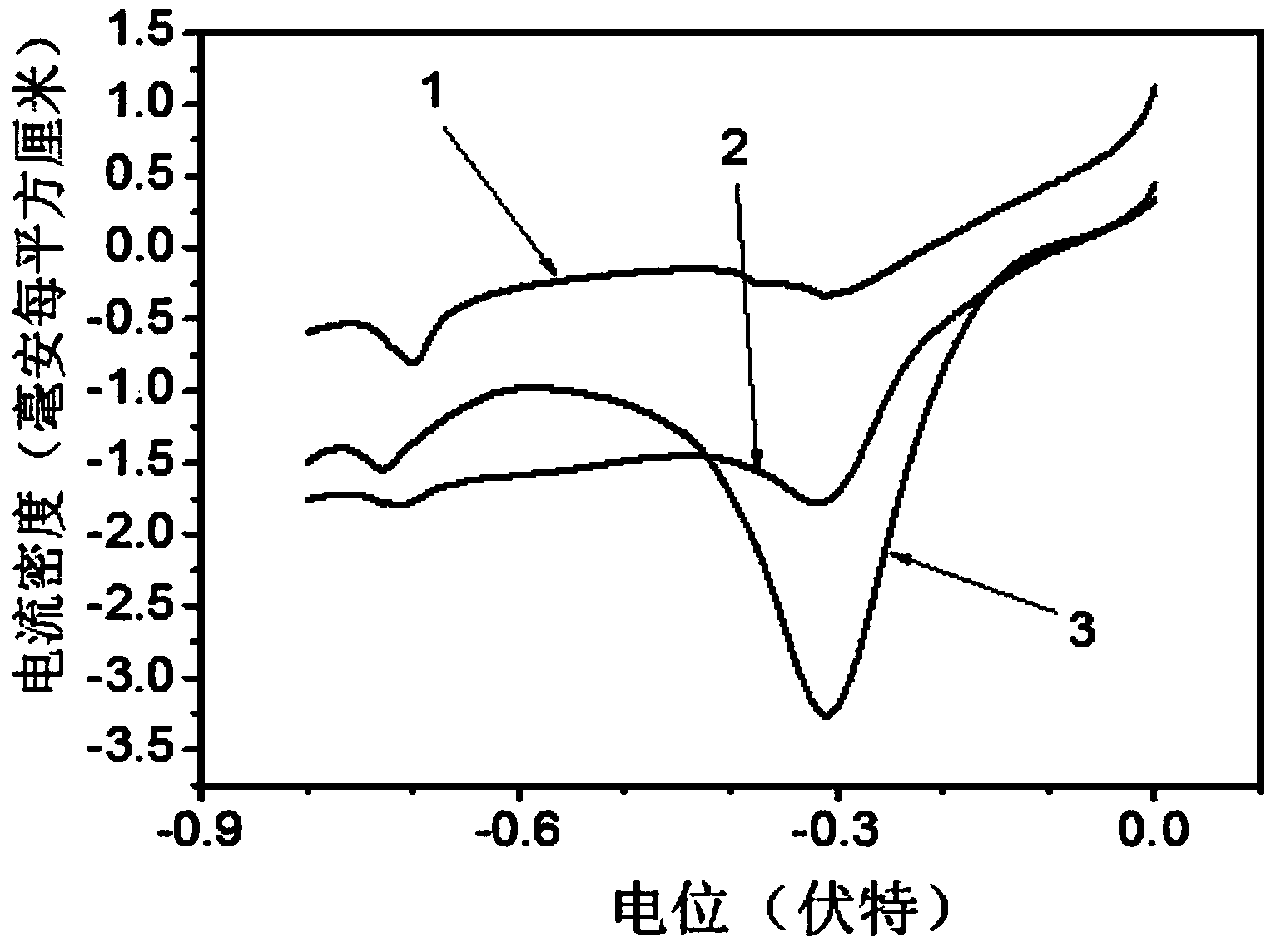

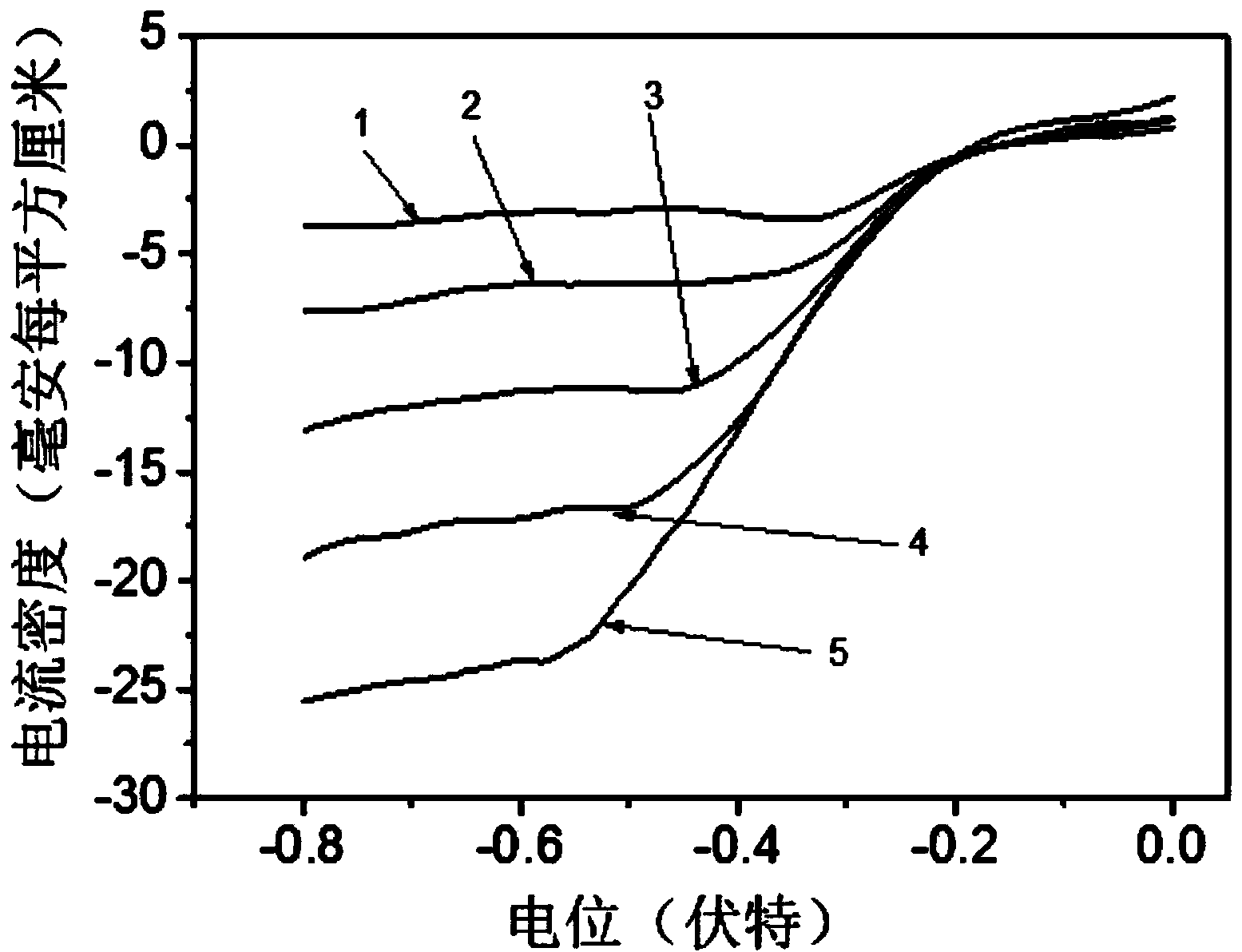

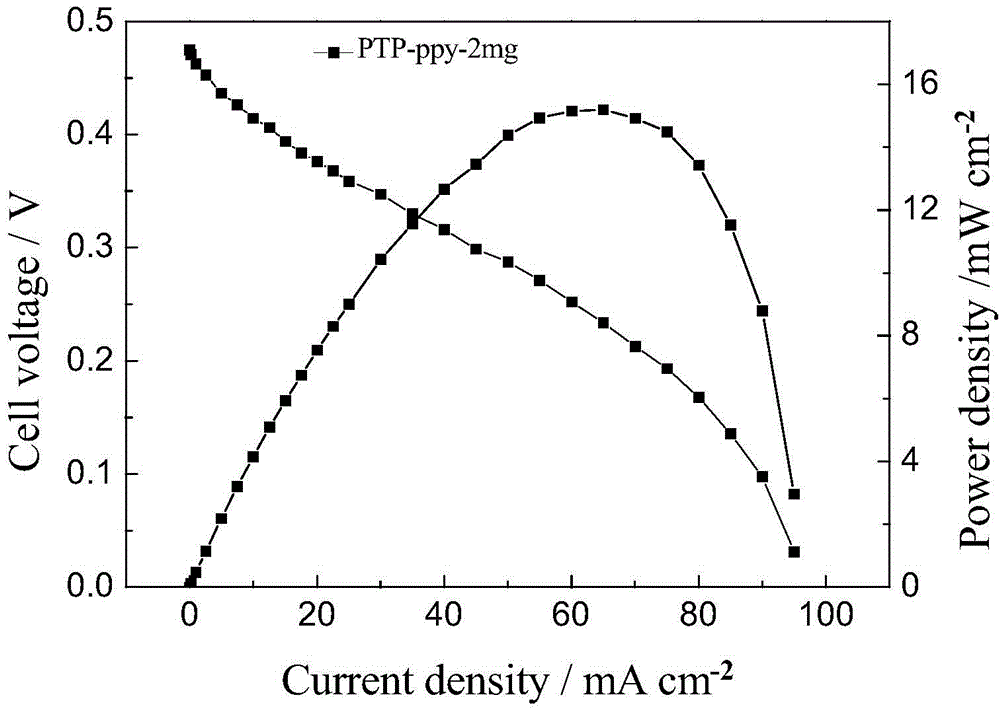

Carbon-free Ag-Cu catalyst layer-based air electrode and its making method

ActiveCN104393307AImprove electrocatalytic activityEnhanced electrocatalytic reduction propertiesCell electrodesCarbon corrosionCopper oxide

The invention relates to a carbon-free Ag-Cu catalyst layer-based air electrode and its making method. The carbon-free Ag-Cu catalyst layer-based air electrode is obtained by depositing Ag-Cu alloy on foamed nickel; the microstructure of the Ag-Cu alloy is dendrite or spherocrystal or lamella crystal; and a Ag, Cu and Cu2O phase exists in the Ag-Cu alloy and is composed of Ag in zero valence state and Cu, and a copper oxide layer is arranged on the surface of the Ag-Cu alloy. The discharge power of the primary zinc air battery of the Ag-Cu catalyst air electrode under 100mA / cm<2> is 79.9-85.8mW.cm<-2>, and the charge and discharge reciprocating efficiency of the secondary zinc air battery of the Ag-Cu catalyst air electrode is greater than 51.8%. The catalyst layer has a very good oxygen reduction electrocatalysis property and overcomes the disadvantages of carbon corrosion and low electrocatalytic activity in the prior art.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Pipeline steel with resistance against carbon dioxide and hydrogen sulfide corrosion and preparation method thereof

ActiveCN103334055AAccelerated corrosionImproved resistance to hydrogen sulfide stress corrosion cracking (SCC)Carbon corrosionChemical composition

The invention relates to a pipeline steel, especially to a pipeline steel with resistance against carbon dioxide and hydrogen sulfide corrosion, and also relates to a preparation method thereof, and belongs to the field of pipeline steel manufacturing technology. The pipeline steel with resistance against carbon dioxide and hydrogen sulfide corrosion comprises following chemical compositions in mass percent, C 0.02 to 0.08%, Si 0.10 to 0.50%, Mn 0.10 to 0.50%, V 0.01 to 0.20%, Al 0.01 to 0.05%, Cu 0.10 to 0.50%, Cr 2.0 to 6.0%, Ni 0.3% or less, Nb 0.3% or less, Ti 0.3% or less, P 0.02% or less, and S 0.005% or less, with the balance being Fe or impurity elements which are unavoidable. The pipeline steel is resistant against both carbon dioxide and hydrogen sulfide corrosion, and can be used in an environment with both of the two corrosive gases, and the resistance against carbon dioxide and hydrogen sulfide corrosion of the pipeline steel is 2 times or more of that of currently used carbon steel.

Owner:NANJING IRON & STEEL CO LTD

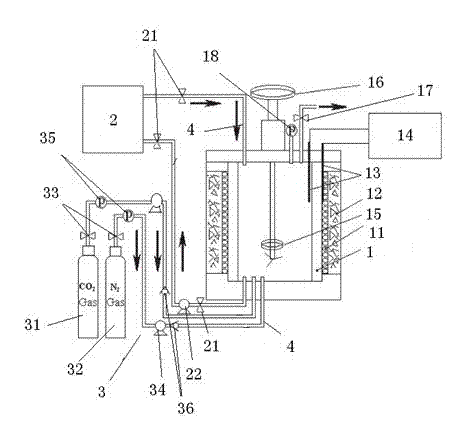

Contrast simulation testing device for carbon dioxide corrosion resistant performance of steel and testing method thereof

InactiveCN102854127ASatisfy Comparative Corrosion TestSimple structureWeather/light/corrosion resistancePreparing sample for investigationCarbon corrosionCarbon dioxide corrosion

The invention discloses a contrast simulation testing device for carbon dioxide corrosion resistant performance of steel and a testing method thereof. The device comprises a reaction kettle, a solution pond and a pressure adjusting device, wherein the solution tank is connected with the reaction kettle by a liquid control valve; a heating rod and a heat insulation material are wound on the outer wall of the reaction kettle; a thermal couple and a temperature adjuster are arranged in the reaction kettle; a sample clamp connected with a stirring device is arranged in the reaction kettle; and a pressure adjusting device comprises a CO2 gas tank and an N2 gas tank which are connected with the bottom of the reaction kettle. The method is used for contrasting and simulating a condition that a pipeline steel material is corroded by CO2 in crude oil so as to evaluate corrosion velocity of the steel material of which the temperature is between 90 and 120 DEG C, CO2 partial pressure is between 1 and 2.4MPa in the solution. The CO2 corrosion resistant performance of the steel with different materials, steel levels and thicknesses can be tested at the same time, and the test is convenient and easy. Corrosion simulation test of various oil fields is performed by adjusting the temperature, partial pressure and solution components.

Owner:NANJING IRON & STEEL CO LTD

Method for preparing carbon fibre braided packing

The invention relates to a method for preparing braided packing, in particular to a method for preparing carbon fiber braided packing, which mainly aims to solve problems of causing equipment to be frequently shutdown for inspection and affecting the normal operation of the production due to low tensile strength, easy scouring during the use, short service life, and the need of frequent replacement existing in the prior art. The method also solves the technical problems that certain materials with better strength have no electric conductivity and heat conductivity and can be overheated and burnt when the materials are used under working conditions of high pressure, high temperature and high speed, thereby easily producing dielectric leakage, frequently causing process shutdown, bringing great loss to the production and economy and so on. The method comprises the steps: the adoption of a polyacrylonitrile fiber, constant-temperature filament unwinding, multi-stage pre-oxidation, middle-temperature carbonization, the protection of high temperature carbonization by a micro-oxygen carbon corrosion method, sizing, filament winding, one-step carbon filament pretreatment, pipe inversion, the adjustment of spindle tension, fixed temperature constant control braiding, negative pressure filling and soaking, drying, shaping, inspection, packing and warehouse entry.

Owner:浙江国泰密封材料股份有限公司

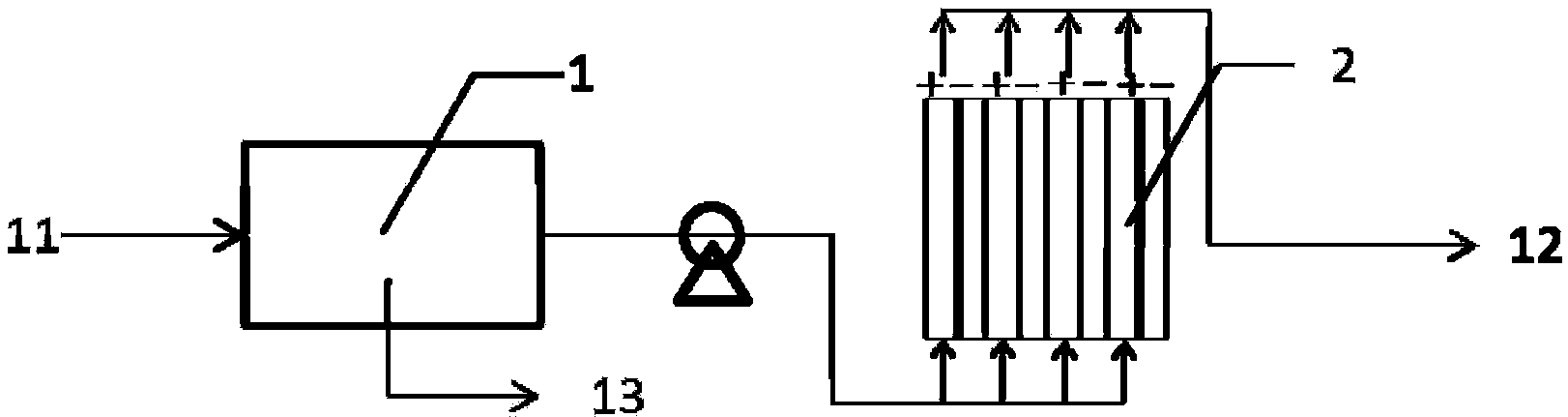

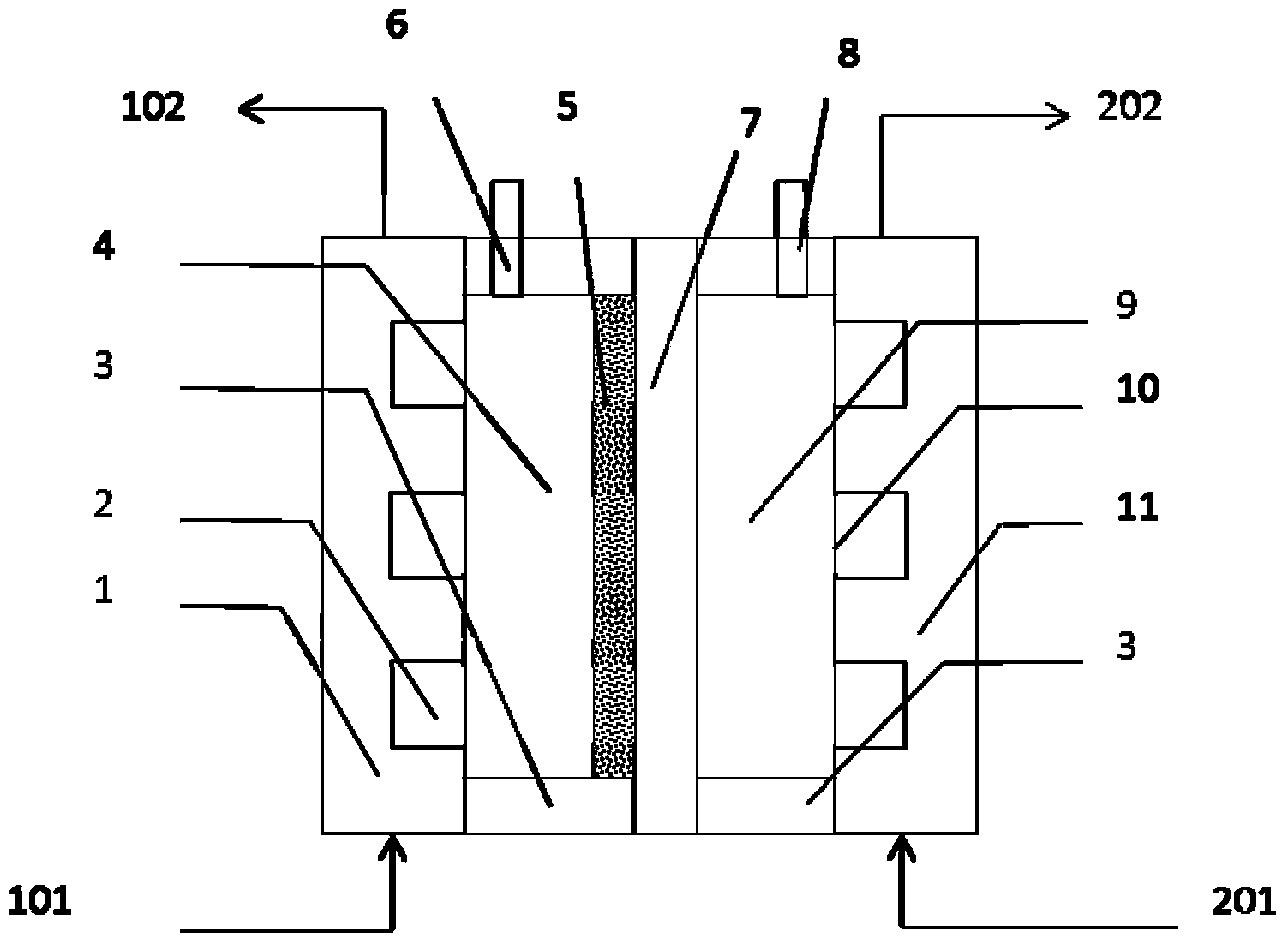

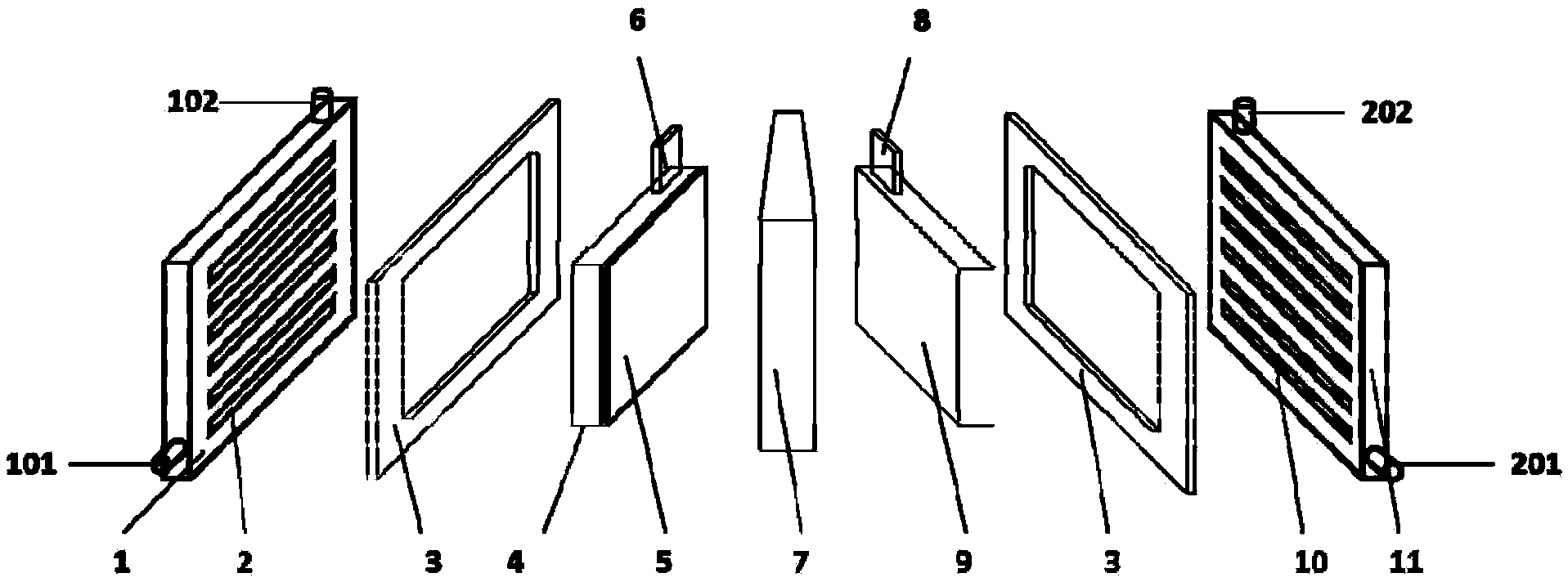

Low-energy-consumption electrochemical treatment device and method for degradation-resistant organic wastewater

ActiveCN104176797AReduce processing efficiencyReduced current efficiencyMultistage water/sewage treatmentWater/sewage treatment using germicide/oligodynamic-processSupporting electrolyteChemical treatment

The invention relates to an electrochemical treatment device and method for degradation-resistant organic wastewater, and designs a'zero polar distance' SPE (Solid Polymer Electrolysis) electrooxidation sewage treatment electrolytic bath like a solid polymer electrolyte fuel cell technology. According to the device, an anode chamber and a cathode chamber are separated by utilizing an ion exchange membrane, the anode with stable titanium-based size, the ion exchange membrane and the nickel cathode are pressed by utilizing an end plate, and a'zero polar distance' SPE electrooxidation sewage treatment electrolytic bath is formed. When the device is subjected to electrolytic operation, the wastewater is electrically oxidized at the anode, so that organic matters and ammonia nitrogen in the water are mineralized and degraded; and running water or the wastewater is introduced into the cathode chamber, and hydrogen separated out due to electrolysis at the cathode is recovered. The device has the advantages that extra supporting electrolyte is not needed to be added, the bath pressure and energy consumption of electrooxidation can be greatly reduced due to the'zero polar distance', and the problem that oxygen (chlorine) and hydrogen separated out in the electrolysis process is solved. In addition, a carbon material is not used, reduction of current efficiency caused by carbon corrosion is avoided, and the reliability and stability of the sewage treatment device are improved. Moreover, continuous water flow is utilized at the cathode, and the scaling and plugging possibility on the cathode side of the ion exchange membrane can be greatly reduced.

Owner:BEIJING JINDAYU ENVIRONMENT TECH CO LTD

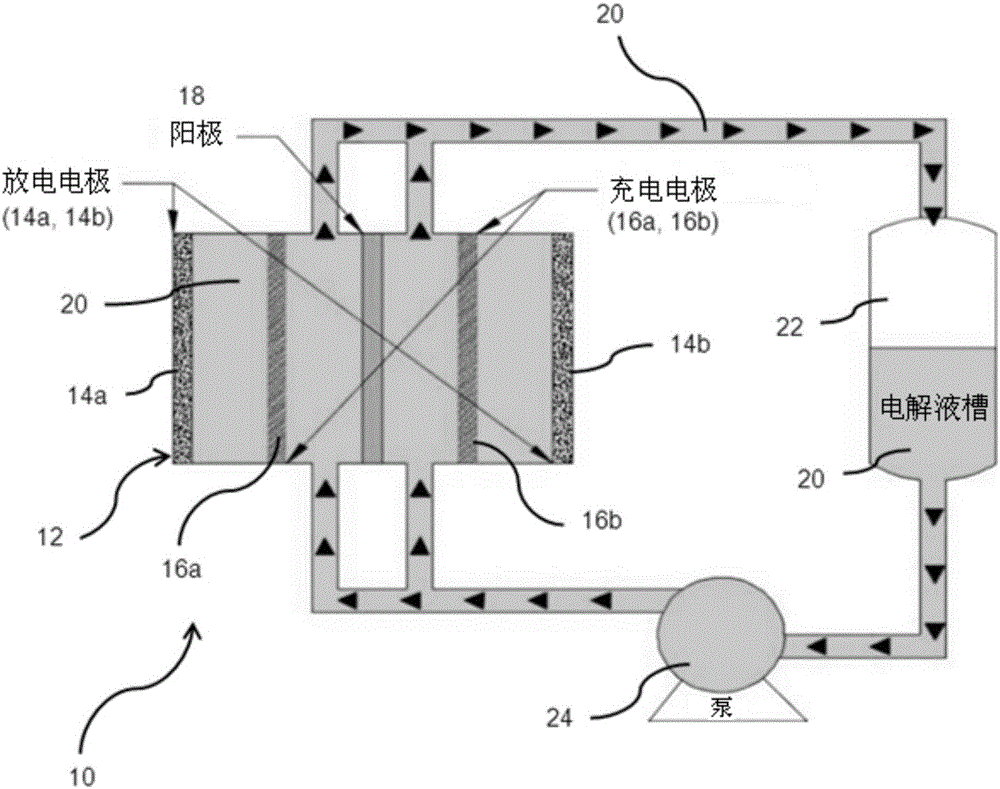

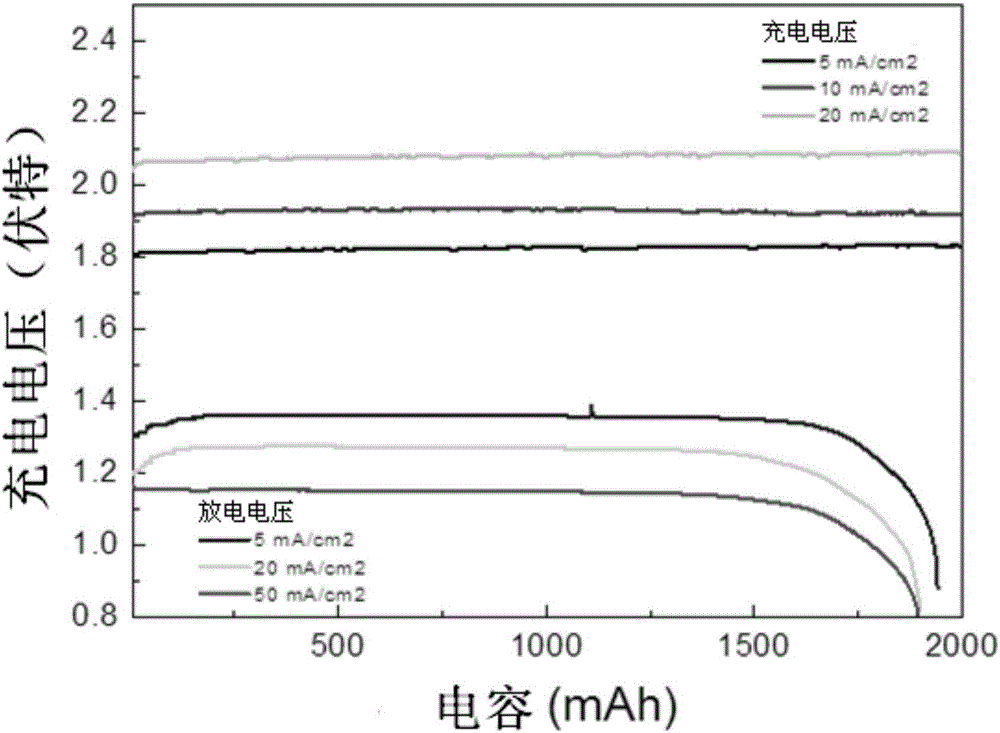

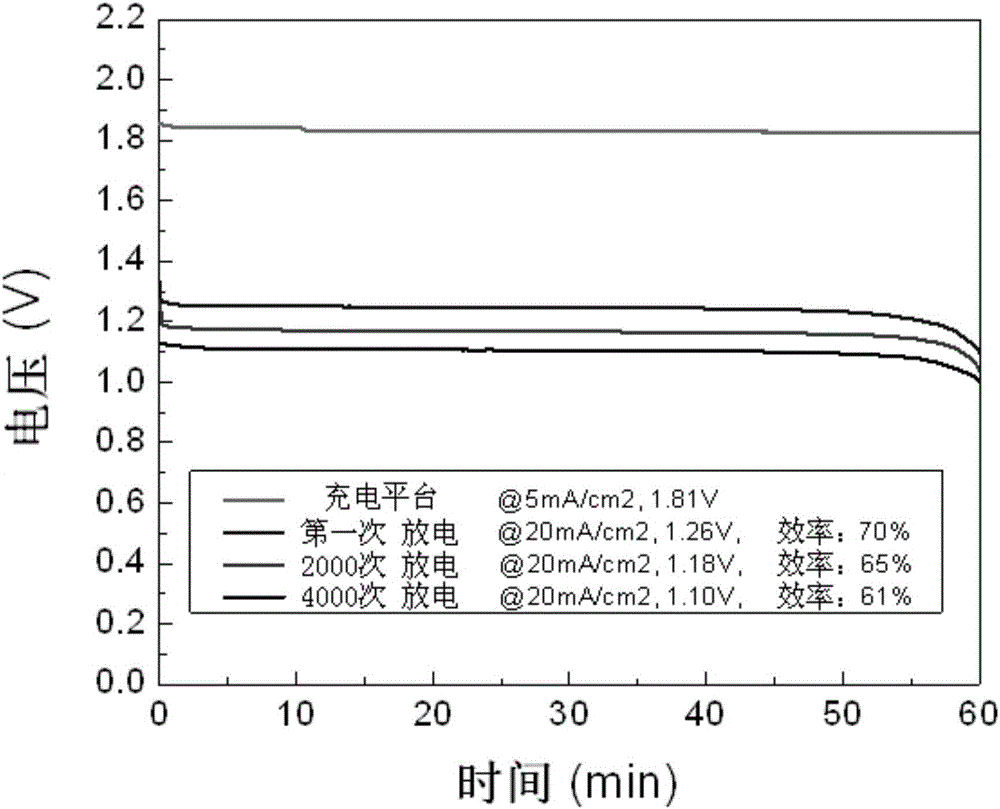

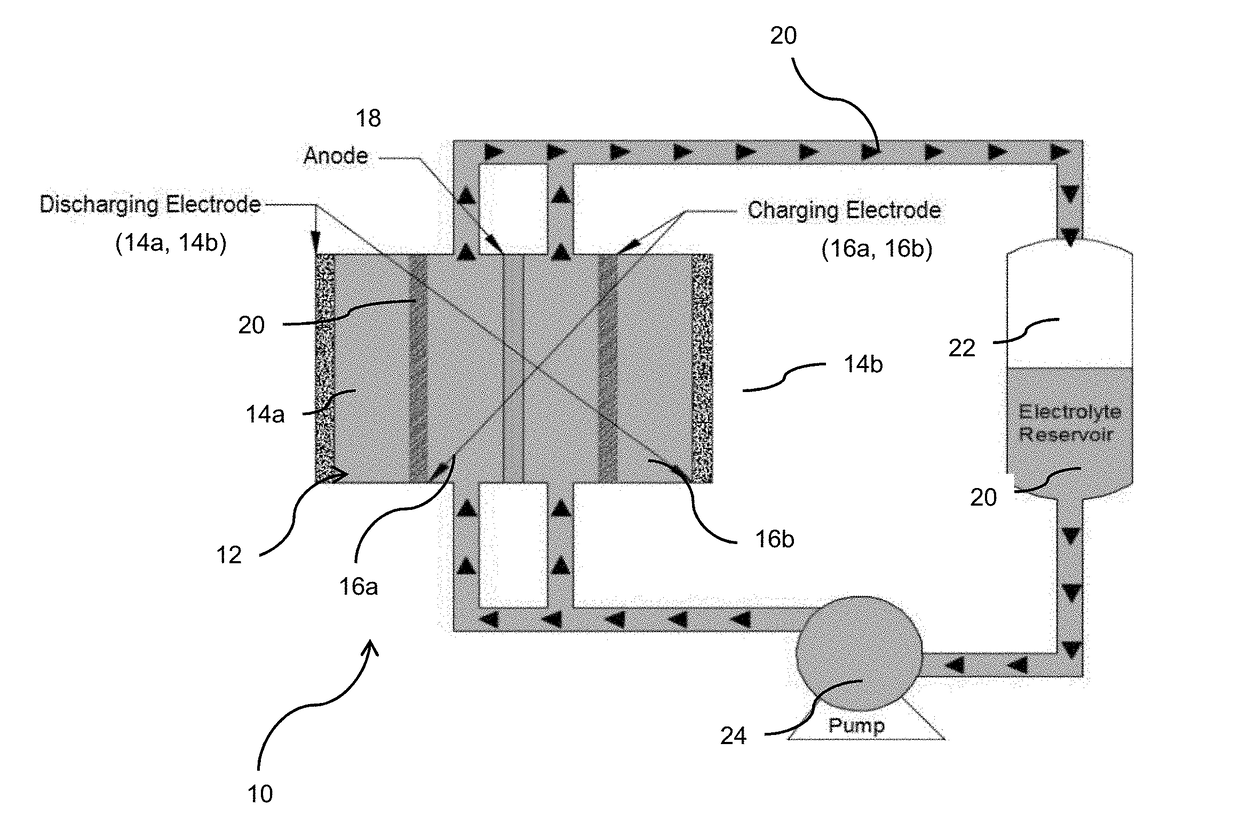

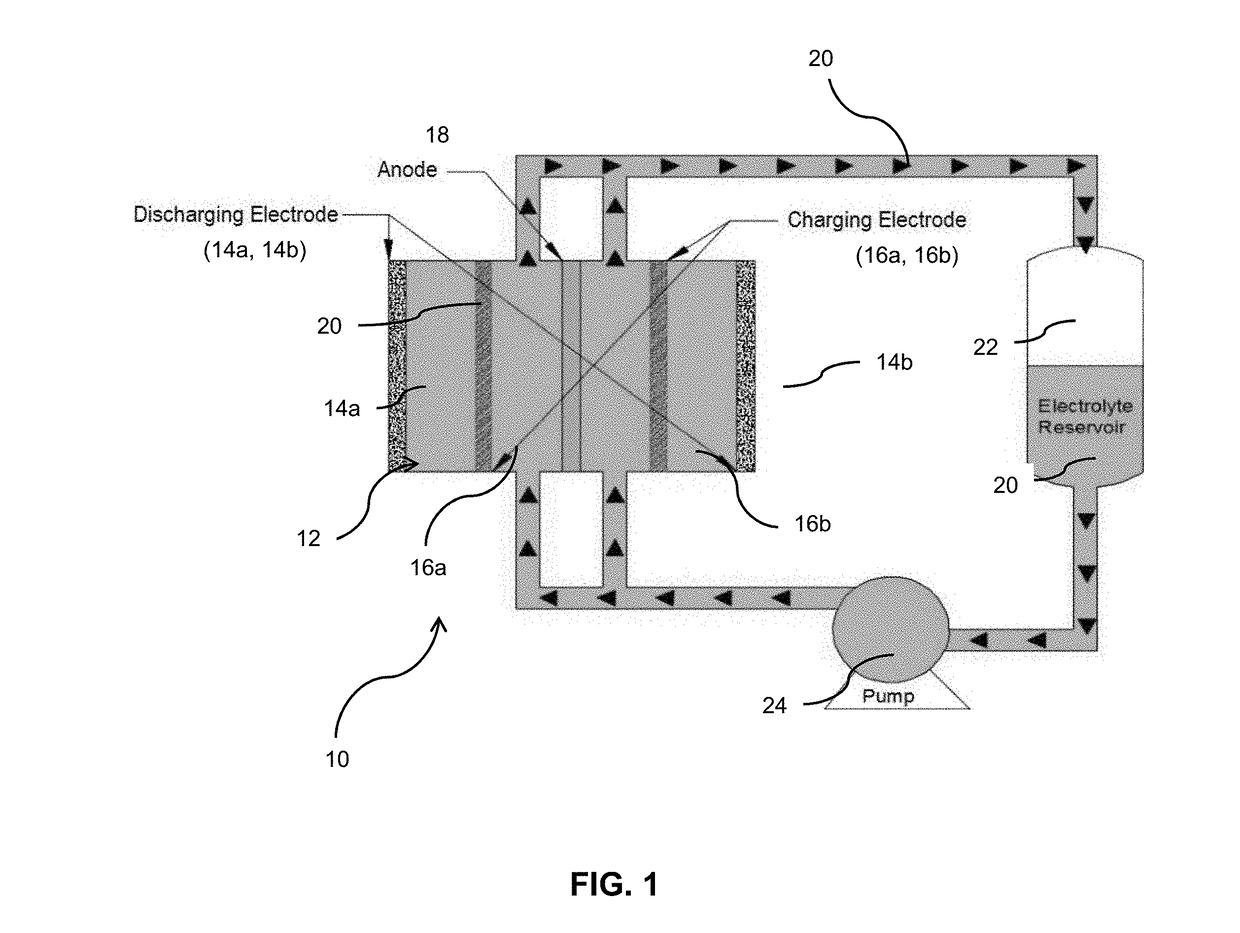

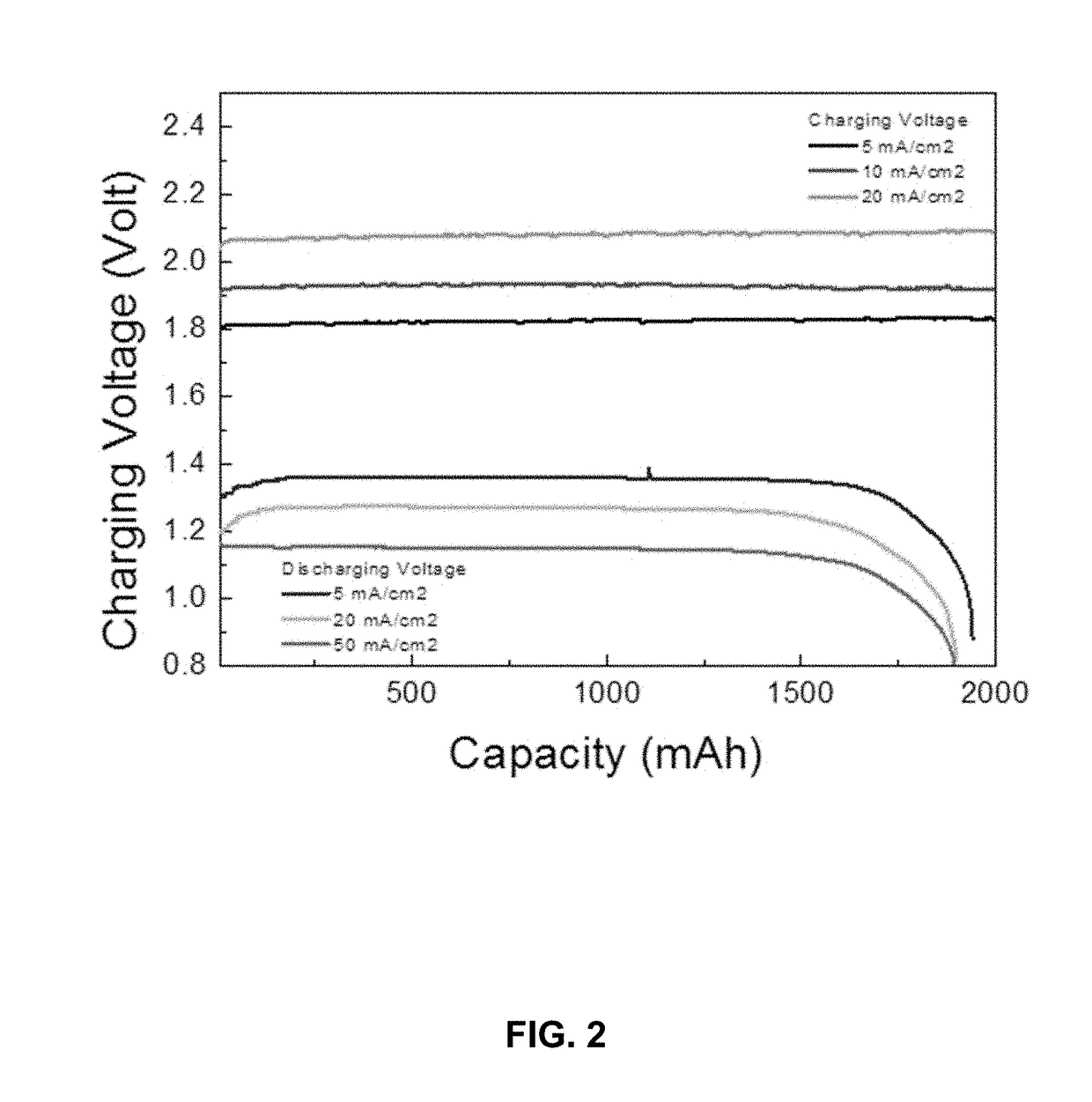

Tri-electrode zinc-air battery with flowing electrolyte

InactiveCN106030899AIncreased operating lifeAvoid lostFuel and secondary cellsHybrid cell detailsCarbon corrosionZinc ion

A rechargeable tri-electrode single flow zinc air battery which is capable of providing theoretically unlimited cycle life is provided. The tri-electrode configuration consists of one anode and two cathodes, one for charging and another for discharging. The charge cathode may comprise a water-permeable metal mesh and / or metal foam, which avoids carbon corrosion. The discharge cathode is a catalytic oxygen reduction electrode. The anode comprises an inert, conductive electrode allowing for zinc deposition during battery charging, and zinc dissolving during battery discharging. The flowing electrolyte removes zinc ions from the anode preventing or minimizing the formation of zinc oxides during discharging, and clean the anode after each full discharge.

Owner:陈忠伟 +1

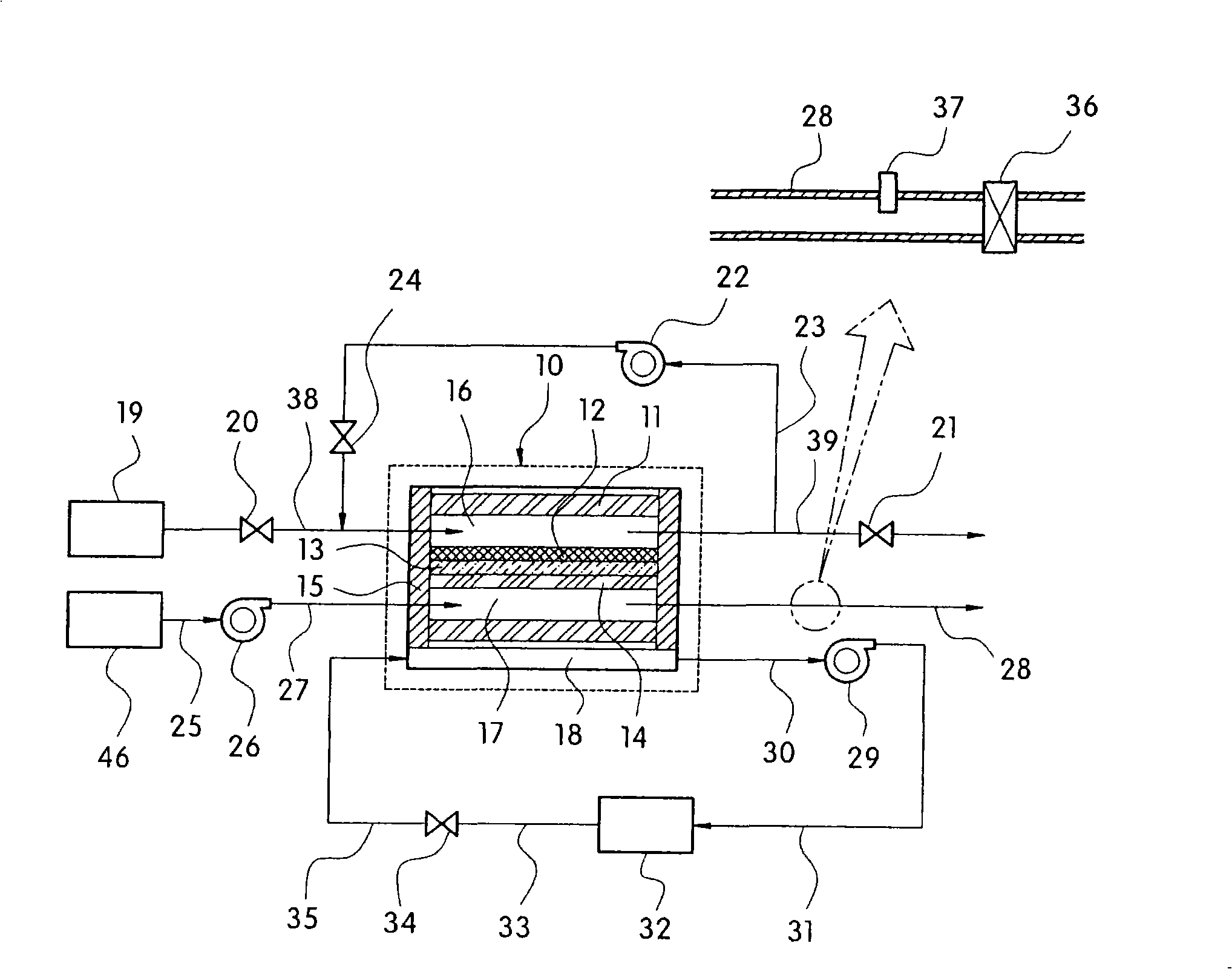

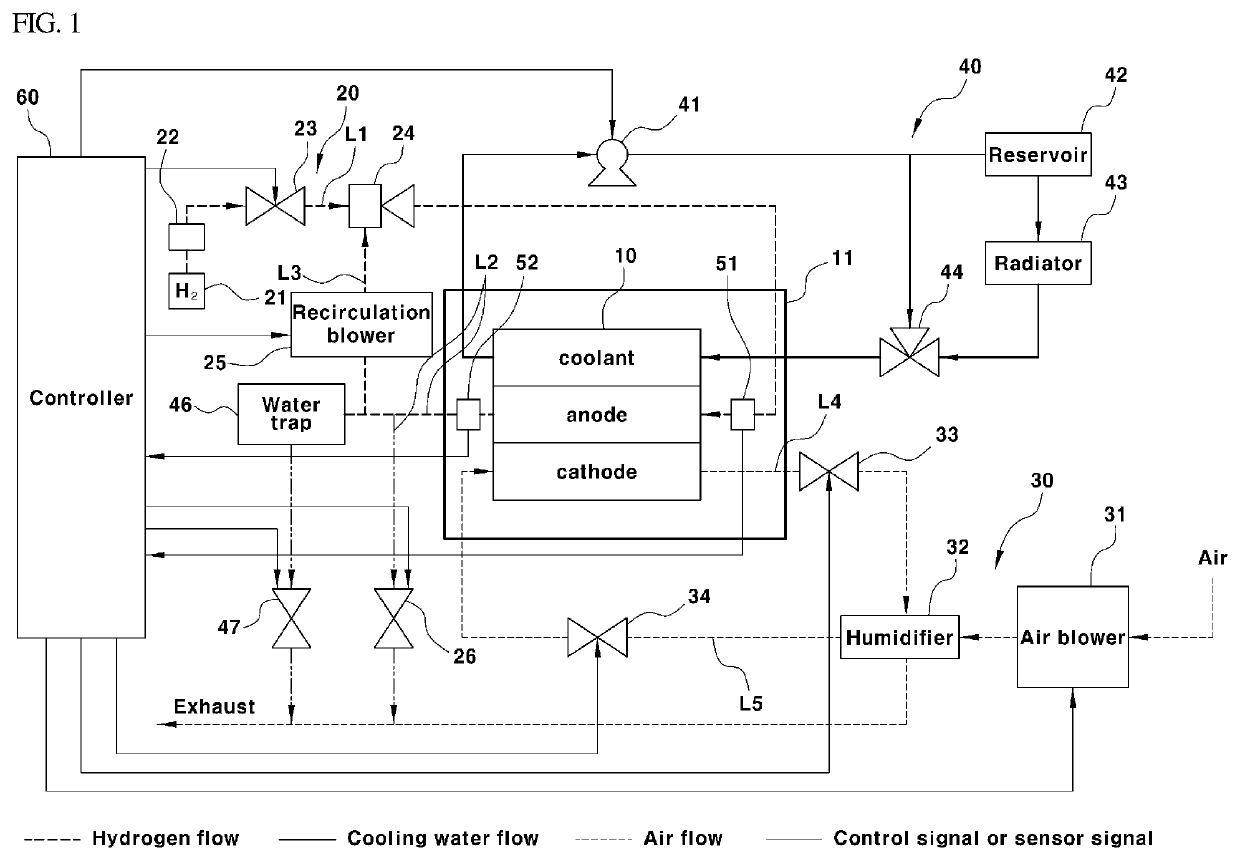

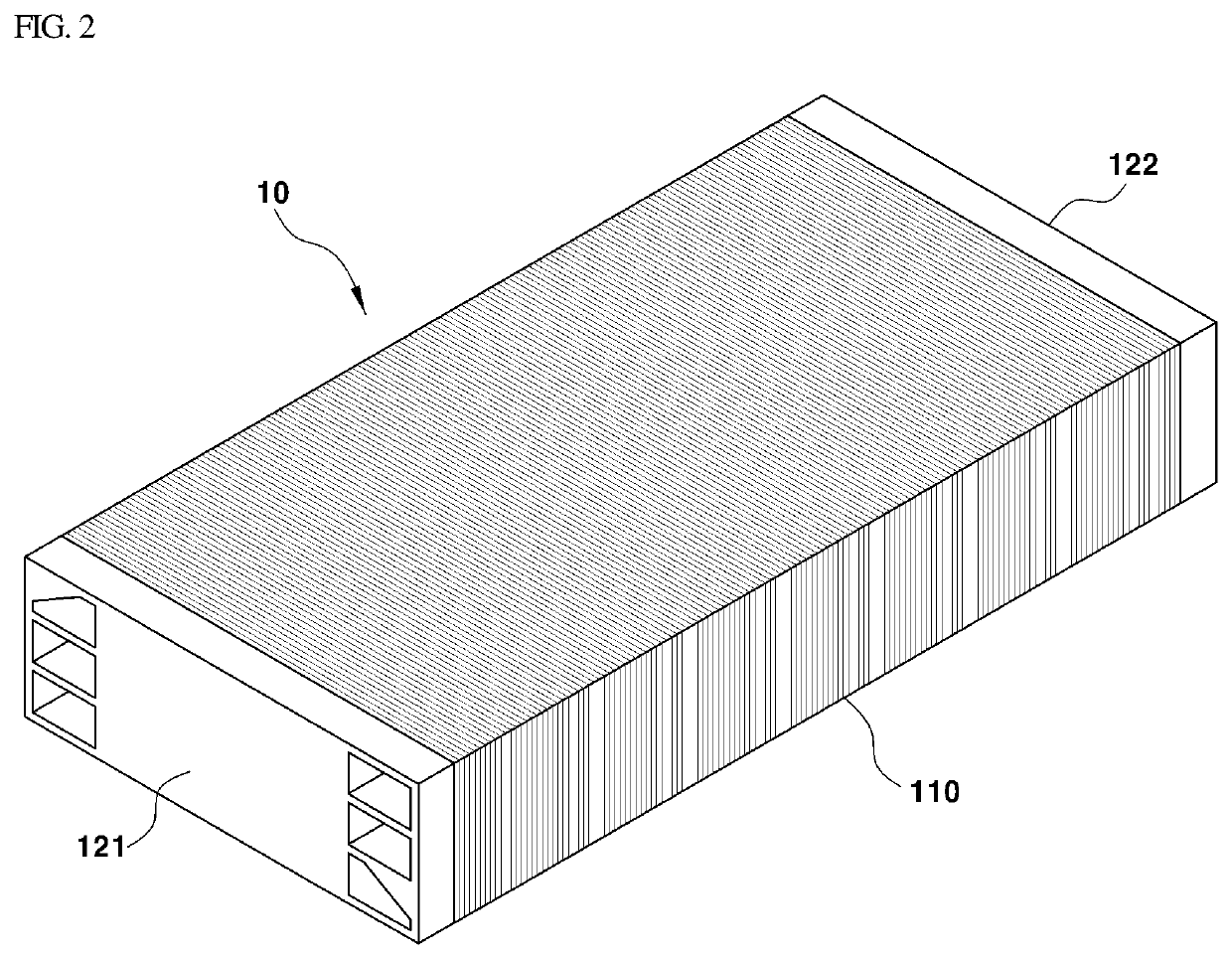

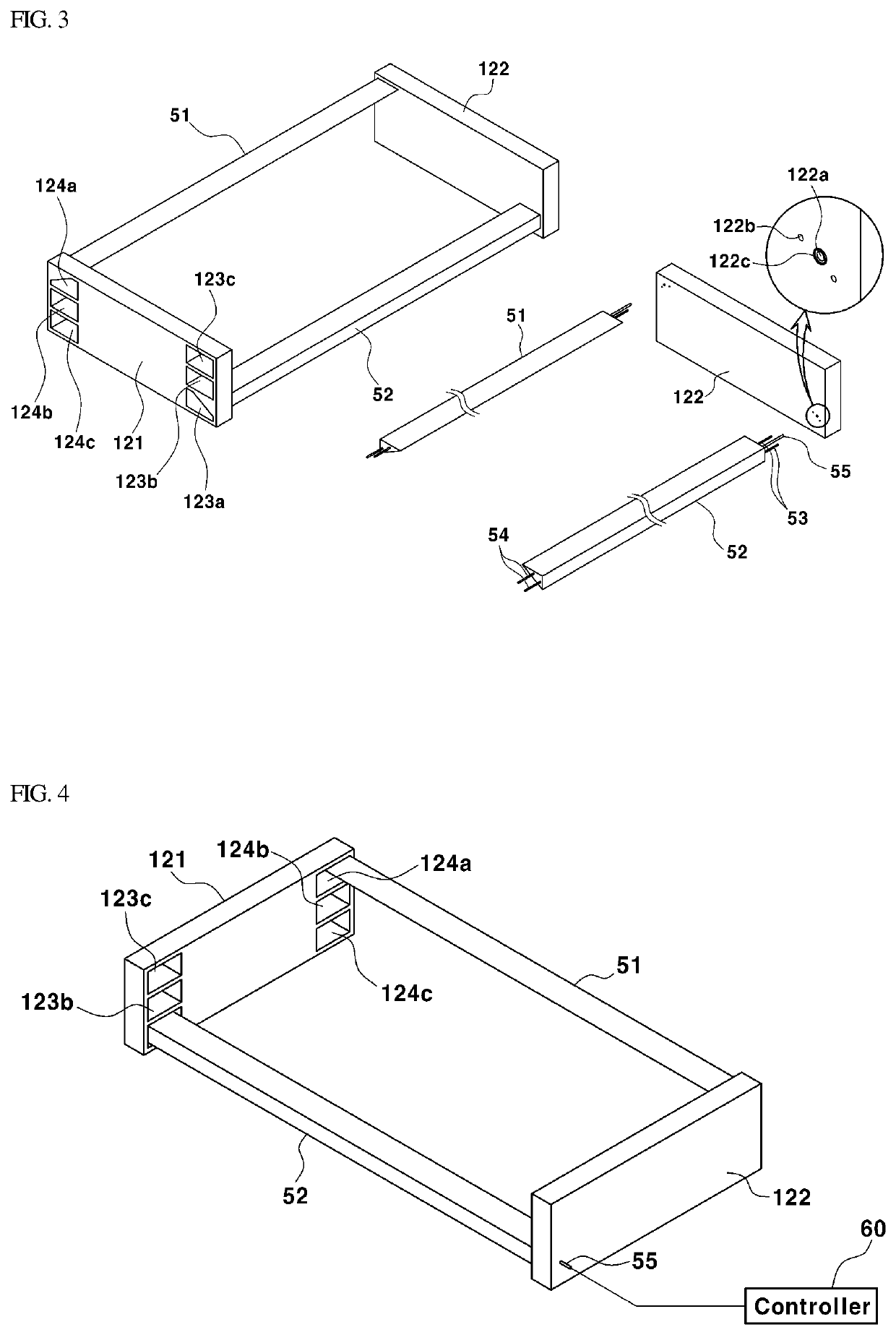

Apparatus for preventing carbon corrosion at cathod in fuel cell

InactiveUS20080318099A1Prevent materialPreventing carbon corrosionFuel cell auxillariesCheck valvesCarbon corrosionElectricity

The present invention provides an apparatus for effectively preventing carbon corrosion from occurring at the cathode of a fuel cell. The present apparatuses include an air blower supplying air from an air supply source to a fuel cell; a fuel cell receiving air from the air blower to generate electricity by a chemical reaction; an air discharge pipe through which residual air remaining after oxygen of the air is consumed for chemical reaction in the fuel cell is discharged; a pressure sensor provided in the air discharge pipe for detecting air pressure in the fuel cell; an air discharge solenoid valve provided in the air discharge pipe for controlling air flow of the air discharge pipe; and a controller controlling operation of the air blower and the air discharge solenoid valve by receiving a signal detected by the pressure sensor wherein the controller detects the air pressure through the pressure sensor to allow the air blower to supply air to the fuel cell until the air pressure reaches a predetermined pressure and then closes the air discharge solenoid valve until the oxygen in the fuel cell is completely exhausted, thereby preventing the formation of hydrogen / oxygen interface at the anode of the fuel cell.

Owner:HYUNDAI MOTOR CO LTD +1

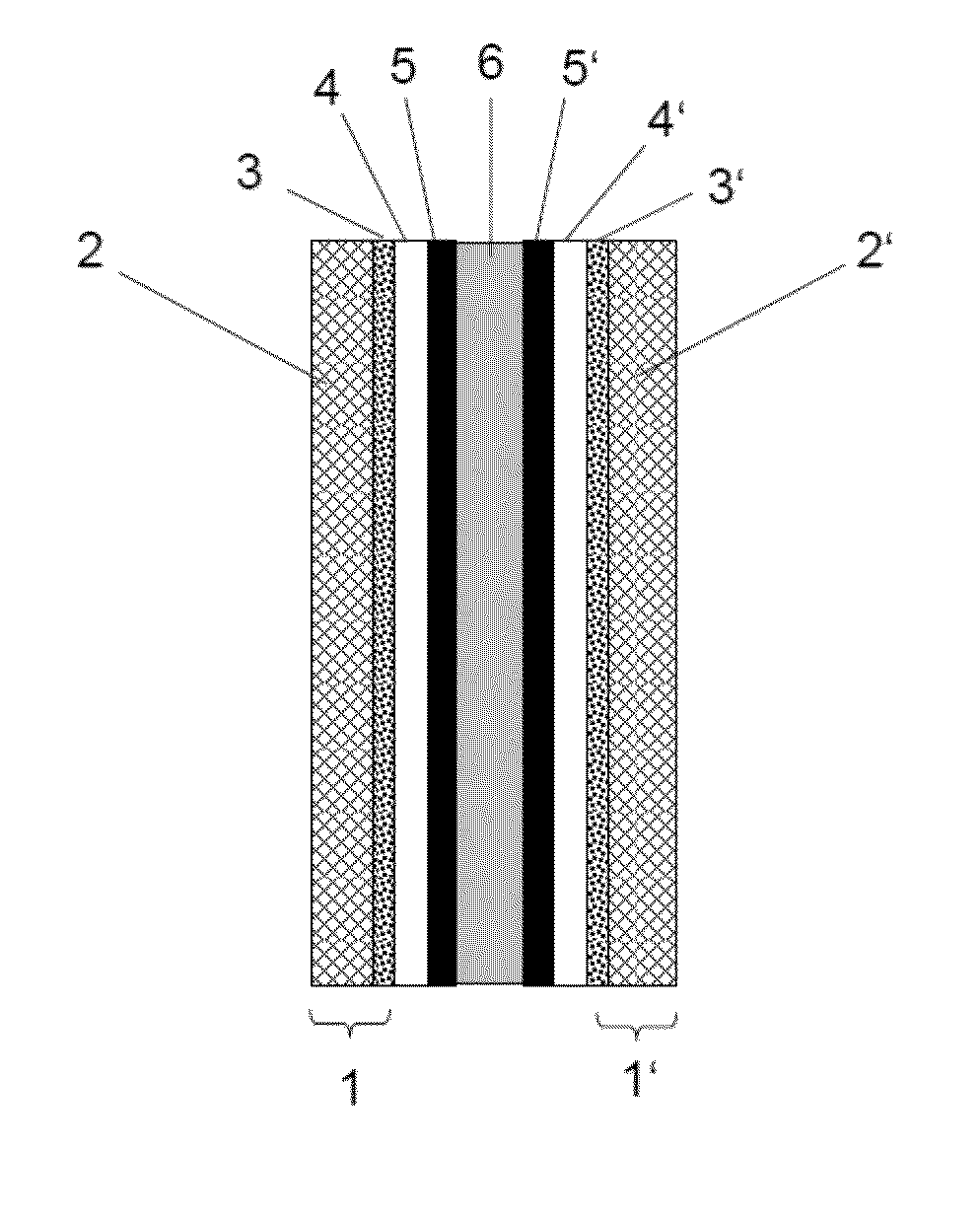

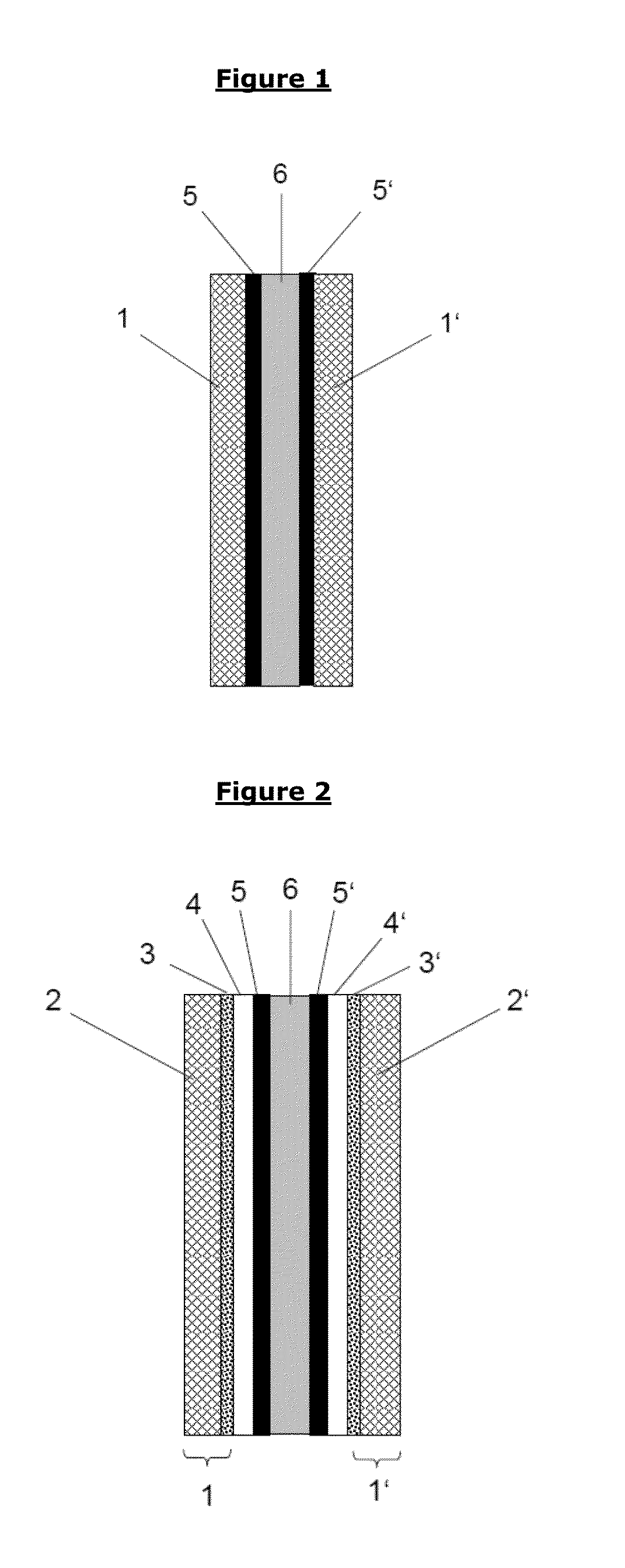

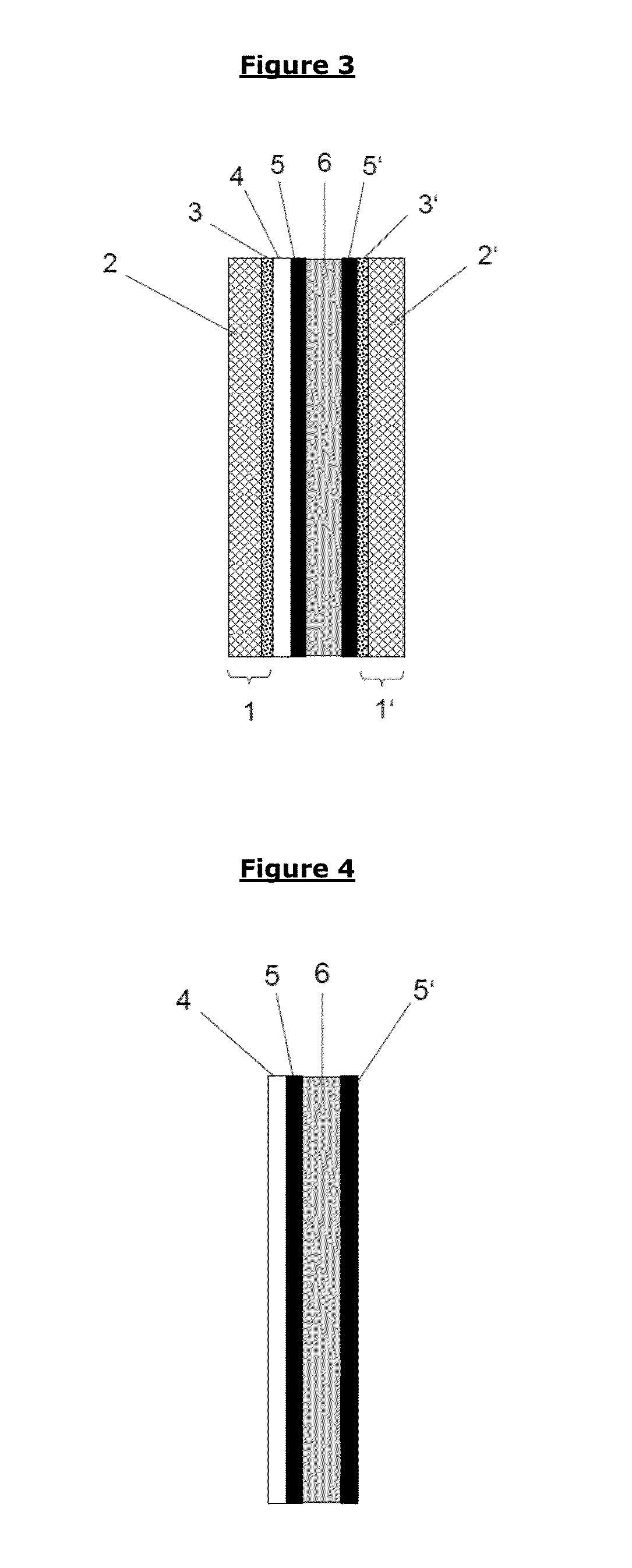

Barrier layer for corrosion protection in electrochemical devices

ActiveUS20150354072A1Corrosion protection is enhancedImprove stabilityCellsMachining electrodesAir atmosphereCarbon corrosion

The invention is directed to a barrier layer for corrosion protection in electrochemical devices, e.g. carbon based gas diffusion layers (GDLs) in electrochemical devices, comprising electrically conductive ceramic material and a non-ionomeric polymer binder. The electrically conductive ceramic material has an electrical conductivity of >0.1 S / cm, preferably >1 S / cm in air atmosphere (as detected by the powder method) and is selected from the group of precious metal and / or base metal containing oxides, carbides, nitrides, borides and mixtures and combinations thereof. Membrane-electrode assemblies (MEAs), catalyst-coated membranes (CCMs), gas diffusion electrodes (GDEs) and gas diffusion layers (GDLs) comprising the barrier layer of the invention show improved corrosion resistance, preferably against carbon corrosion; particularly in start-up / shut-down cycles and fuel starvation situations of PEM fuel cells.

Owner:GREENERITY GMBH

Apparatus for preventing carbon corrosion at cathod in fuel cell

InactiveCN101330153AAvoid corrosionFuel cell auxillariesSolid electrolyte fuel cellsCarbon corrosionElectricity

The present invention provides an apparatus for effectively preventing carbon corrosion from occurring at the cathode of a fuel cell. The present apparatuses include an air blower supplying air from an air supply source to a fuel cell; a fuel cell receiving air from the air blower to generate electricity by a chemical reaction; an air discharge pipe through which residual air remaining after oxygen of the air is consumed for chemical reaction in the fuel cell is discharged; a pressure sensor provided in the air discharge pipe for detecting air pressure in the fuel cell; an air discharge solenoid valve provided in the air discharge pipe for controlling air flow of the air discharge pipe; and a controller controlling operation of the air blower and the air discharge solenoid valve by receiving a signal detected by the pressure sensor wherein the controller detects the air pressure through the pressure sensor to allow the air blower to supply air to the fuel cell until the air pressure reaches a predetermined pressure and then closes the air discharge solenoid valve until the oxygen in the fuel cell is completely exhausted, thereby preventing the formation of hydrogen / oxygen interface at the anode of the fuel cell.

Owner:HYUNDAI MOTOR CO LTD +1

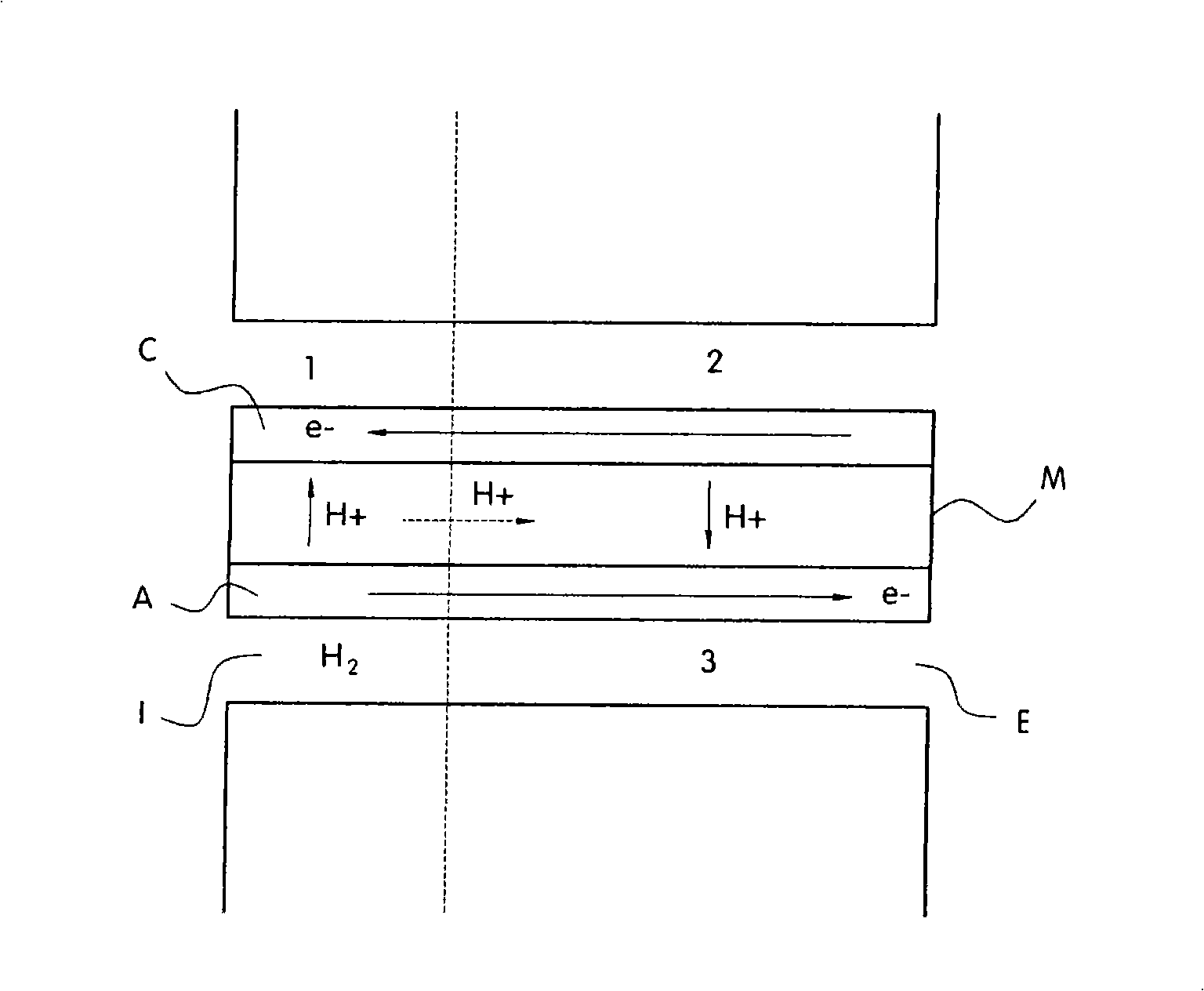

Shutdown strategy to avoid carbon corrosion due to slow hydrogen/air intrusion rates

ActiveUS20100143754A1Minimizing carbon corrosionMaximize durabilityFuel cells groupingFuel cell auxillariesCarbon corrosionHydrogen

A fuel cell system including a fuel cell stack having a plurality of fuel cells, each of the fuel cells including an electrolyte membrane disposed between an anode and a cathode, an anode supply manifold in fluid communication with the anodes of the fuel cells, the anode supply manifold providing fluid communication between a source of hydrogen and the anodes, an anode exhaust manifold in fluid communication with the anodes of the fuel cells, and a fan in fluid communication with the anodes of the fuel cells, wherein the fan controls a flow of fluid through the anodes of the fuel cells after the fuel cell system is shutdown.

Owner:GM GLOBAL TECH OPERATIONS LLC

Submerged arc welding wire used for pipeline steel of carbon dioxide corrosion resistant 65 ksi strength grade

InactiveCN103121149AGuaranteed StrengthAvoid generatingWelding/cutting media/materialsSoldering mediaCarbon corrosionCarbon dioxide corrosion

The invention relates to a submerged arc welding wire used for pipeline steel of a carbon dioxide corrosion resistant 65 ksi strength grade. The technical scheme of the submerged arc welding wire used for the pipeline steel of the carbon dioxide corrosion resistant 65 ksi strength grade is that chemical constituents of the submerged arc welding wire is: carbon (C) is 0.001-0.05 wt%, manganese (Mn) is 0.40-0.80 wt%, silicon (Si) is 0.10-0.30 wt%, chromium (Cr) is 3.00-6.00 wt%, copper (Cu) is 0.20-0.40 wt%, (vanadium+ niobium+ titanium) is 0.04-0.10 wt%, sulphur (S) is less than or equal to -0.001 wt%, phosphorus (P) is less than or equal to 0.002 wt%, and the balance are ferrum (Fe) and inevitable impurities. Elements of an alloy are simple, the prepared submerged arc welding wire is matched with welding flux SJ 101, mechanical property and corrosion resistant property of formed welding metal are matched with the property of the pipeline steel of the carbon dioxide corrosion resistant 65 ksi strength grade, and the technical requirement of welding prepared oil and gas pipelines can be met, and the submerged arc welding wire used for the pipeline steel of the carbon dioxide corrosion resistant 65 ksi strength grade has good corrosion resistant property.

Owner:WUHAN UNIV OF SCI & TECH

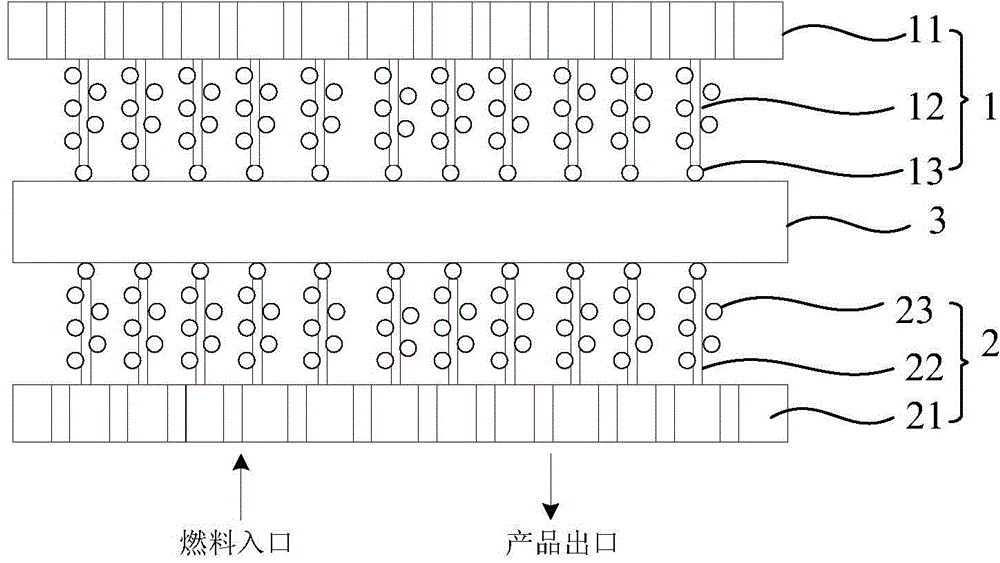

A carbon-free membrane electrode assembly

ActiveCN104701549AEfficient use ofImprove performanceCell electrodesSolid electrolyte fuel cellsCarbon corrosionPolymer electrolytes

A carbon-free membrane electrode assembly is provided. The carbon-free membrane electrode assembly at least comprises a cathode membrane electrode, an anode membrane electrode and a solid polymer electrolyte membrane used for conducting protons, wherein the cathode membrane electrode at least comprises a porous and electrically-conducting cathode collector plate, a cathode nano-ordered array grown on the surface of the cathode collector plate and a cathode catalytic layer combined on the surface of the cathode nano-ordered array; and the anode membrane electrode at least comprises a porous and electrically-conducting anode collector plate, an anode nano-ordered array grown on the surface of the anode collector plate and an anode catalytic layer combined on the surface of the anode nano-ordered array. The assembly adopts the nano-ordered arrays as carriers for the catalytic layers so that the utilization rate of a catalyst is close to 100%, thus largely improving performance of the catalytic layers. The membrane electrodes are carbon-free, thus facilitating complete solving of a carbon corrosion problem in a fuel cell, thereby largely improving running stability and prolonging the service lifetime of the cell.

Owner:SHANGHAI ADVANCED RES INST CHINESE ACADEMY OF SCI

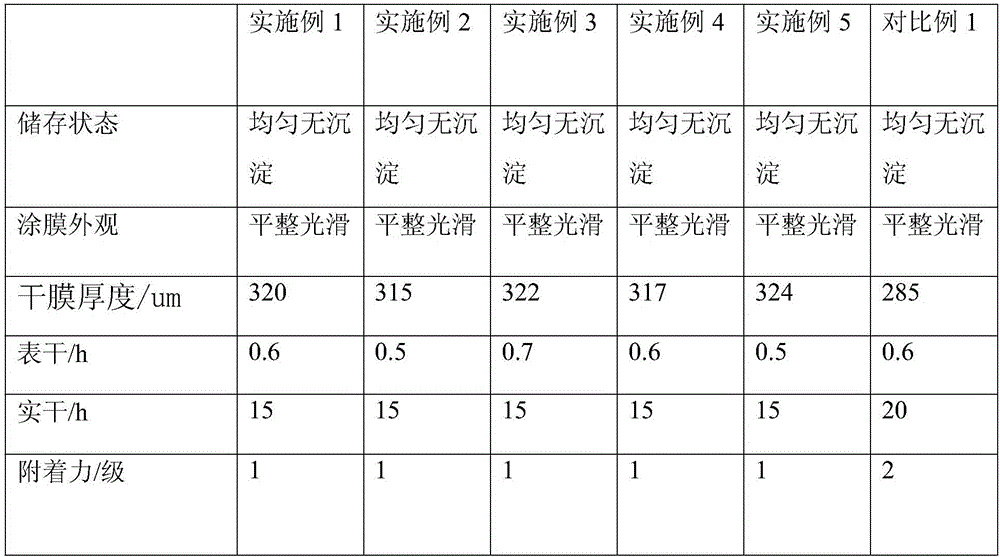

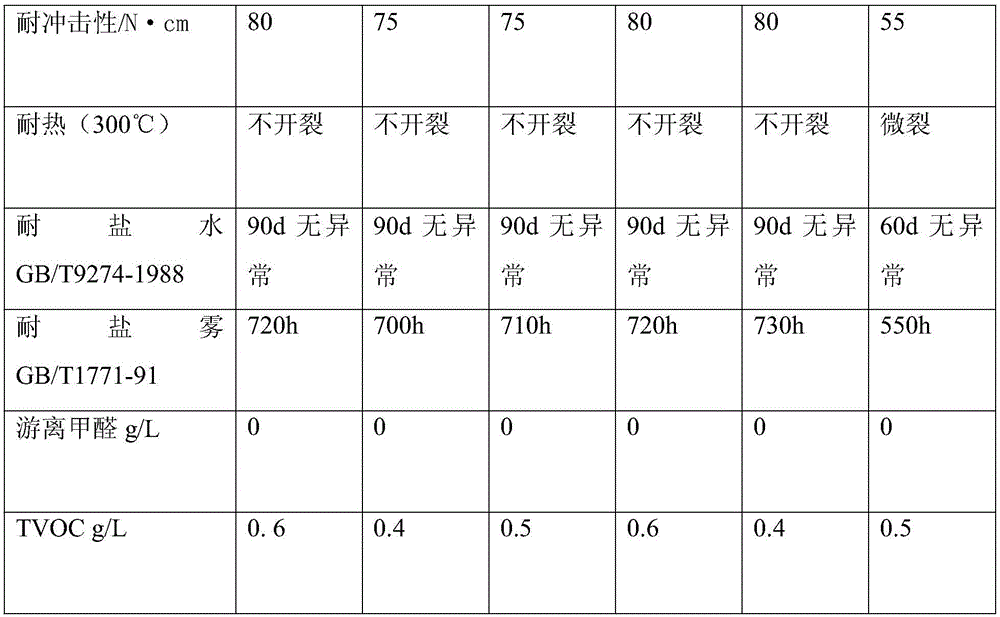

Environment-friendly fluorine-carbon corrosion-prevention coating and preparation method thereof

The invention provides environment-friendly fluorine-carbon corrosion-prevention coating. The environment-friendly fluorine-carbon corrosion-prevention coating is prepared from the following components in parts by weight: 80-100 parts of acrylic modified fluorine-carbon resin emulsion, 2-4 parts of an alkynol auxiliary agent, 3-6 parts of graphene oxide powder, 6-10 parts of nano silicon dioxide powder, 10-15 parts of a film forming auxiliary agent, 3-7 parts of a salt mist resisting agent, 6-12 parts of a pigment, 5-15 parts of talcum powder and 50-80 parts of de-ionized water. The product provided by the invention has extremely high adhesive force; the binding force between a coating layer and a matrix is high; in a coating composition, a dense interface transition layer is formed by the coating layer with the help of a metal oxide nano material and graphene powder, so that the comprehensive thermodynamic property of the coating is matched with the matrix; and the coating can be sprayed and molded on any curve surface, any inclined surface and any vertical plane and does not have a sagging phenomenon.

Owner:GUANGZHOU JULAN HEALTH IND RES INST CO LTD

Steel for high-frequency resistance welding petroleum casing pipe, casing pipe and manufacturing method thereof

ActiveCN102839324AGood resistance to carbon dioxide corrosionIncrease the equivalentDrilling rodsDrilling casingsCarbon corrosionButt welding

The invention relates to steel for a petroleum casing pipe. The steel for the petroleum casing pipe comprises the components in percentage by mass: 0.05 to 0.10 percent of C, 0.10 to 0.30 percent of Si, less than 0.015 percent of P, less than 0.003 percent of S, 0.1 to 0.3 percent of Mn, 2 to 2.5 percent of Cr, 0.01 to 0.04 percent of Al and the balance of Fe and unavoidable impurities, wherein the total amount of impurity elements is less than 0.05 weight percent; and the carbon equivalent is not greater than 0.6. The invention also relates to the petroleum casing pipe made of the steel. The manufacturing method for the steel comprises the following processes of: a hot rolling process of the steel for the petroleum casing pipe: the finish rolling temperature is 850 to 890 DEG C, and the coiling temperature is 620 to 660 DEG C; a carbon dioxide gas protection welding process for coiled plate butt welding: the wire feeding speed is 12 to 14 m / min, the current is 557 to 561 A, the welding speed is 52 to 54 cm / min, and the gas flow is 23 to 25 L / min; and overall pipe heat treatment: heating and keeping the temperature of 900 to 950 DEG C for 40 to 70 minutes, tempering at the temperature of 620 to 650 DEG C after water quenching, and keeping the temperature for 60 to 80 minutes. The high-frequency resistance welding petroleum casing pipe provided by the invention has the steel grade of 80 ksi and high carbon dioxide corrosion resistance; and the annual average corrosion rate of a finished pipe is below 1 / 3 of that of a conventional N80 oil well pipe.

Owner:BAOSHAN IRON & STEEL CO LTD

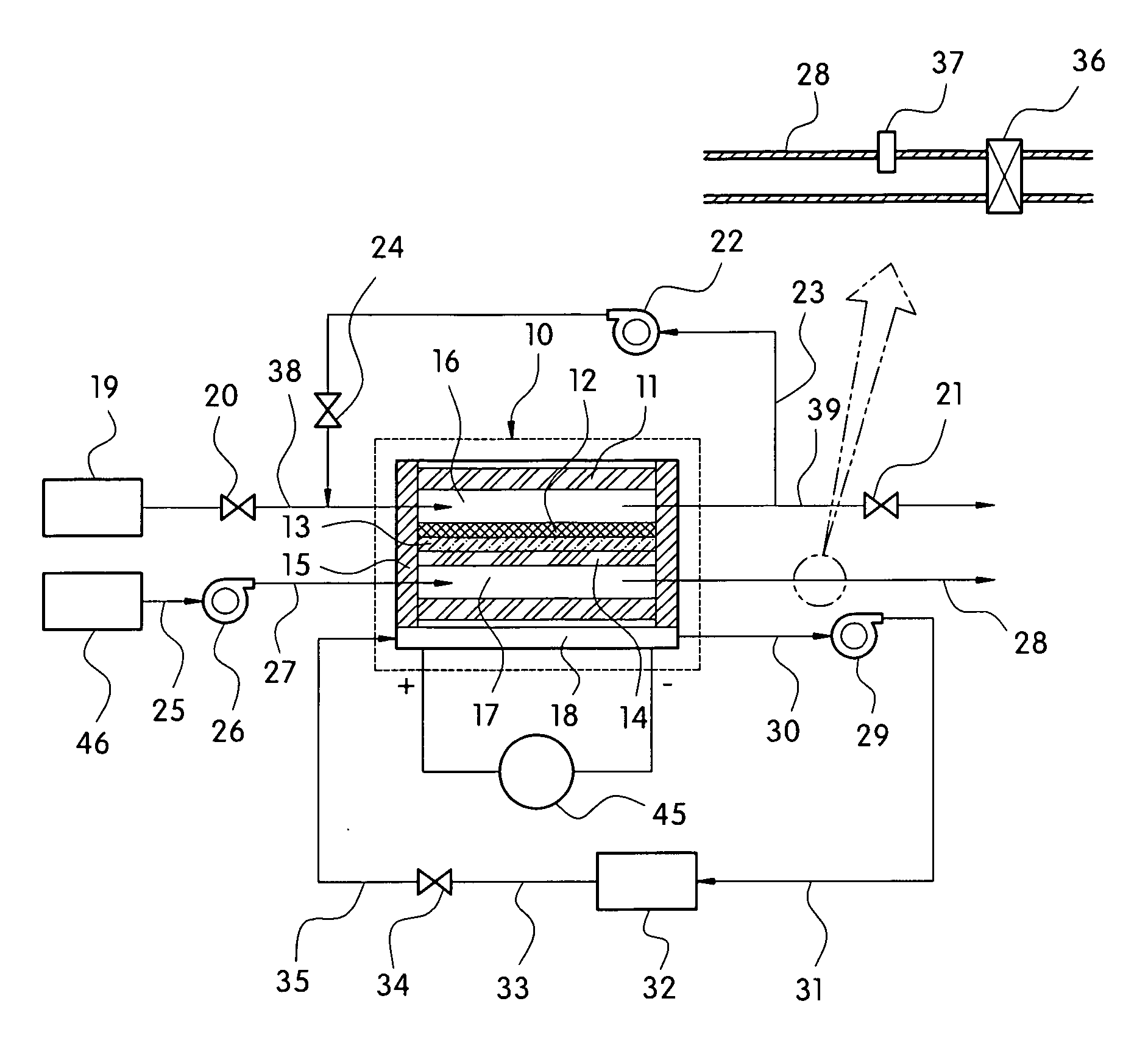

Horizontal tri-electrode single flow zinc-air battery with a floating cathode

InactiveUS20190051908A1Inhibition formationFuel and primary cellsFuel and secondary cellsCarbon corrosionElectrolyte leakage

A rechargeable horizontally configured tri-electrode single flow zinc-air battery with a floating cathode, which is theoretically capable of providing unlimited cycle life is provided. The tri-electrode configuration consists of one anode and two cathodes, one for charging and one for discharging. The charge cathode may comprise a water permeable alkaline resisting metal / mesh foam, which avoids carbon corrosion. The floating discharge cathode comprises an air permeable and water permeable catalytic oxygen reduction electrode, which eliminates or reduces the blockage of air tunnels. The anode comprises an inert, conductive electrode allowing for zinc deposition during battery charging and zinc dissolving during battery discharging. The flowing electrolyte removes zinc ions from the anode preventing or minimizing the formation of zinc oxides during discharging and cleans the anode after each full discharge. The horizontal configuration further eliminates or reduces electrolyte leakage.

Owner:CHEN ZHONGWEI +1

Shutdown strategy to avoid carbon corrosion due to slow hydrogen/air intrusion rates

ActiveUS20140038073A1Minimizing carbon corrosionNot sacrificing a hydrogen-hydrogen shutdown strategyFuel cell auxillariesCarbon corrosionHydrogen

A fuel cell system including a fuel cell stack having a plurality of fuel cells, each of the fuel cells including an electrolyte membrane disposed between an anode and a cathode, an anode supply manifold in fluid communication with the anodes of the fuel cells, the anode supply manifold providing fluid communication between a source of hydrogen and the anodes, an anode exhaust manifold in fluid communication with the anodes of the fuel cells, and a fan in fluid communication with the anodes of the fuel cells, wherein the fan controls a flow of fluid through the anodes of the fuel cells after the fuel cell system is shutdown.

Owner:GM GLOBAL TECH OPERATIONS LLC

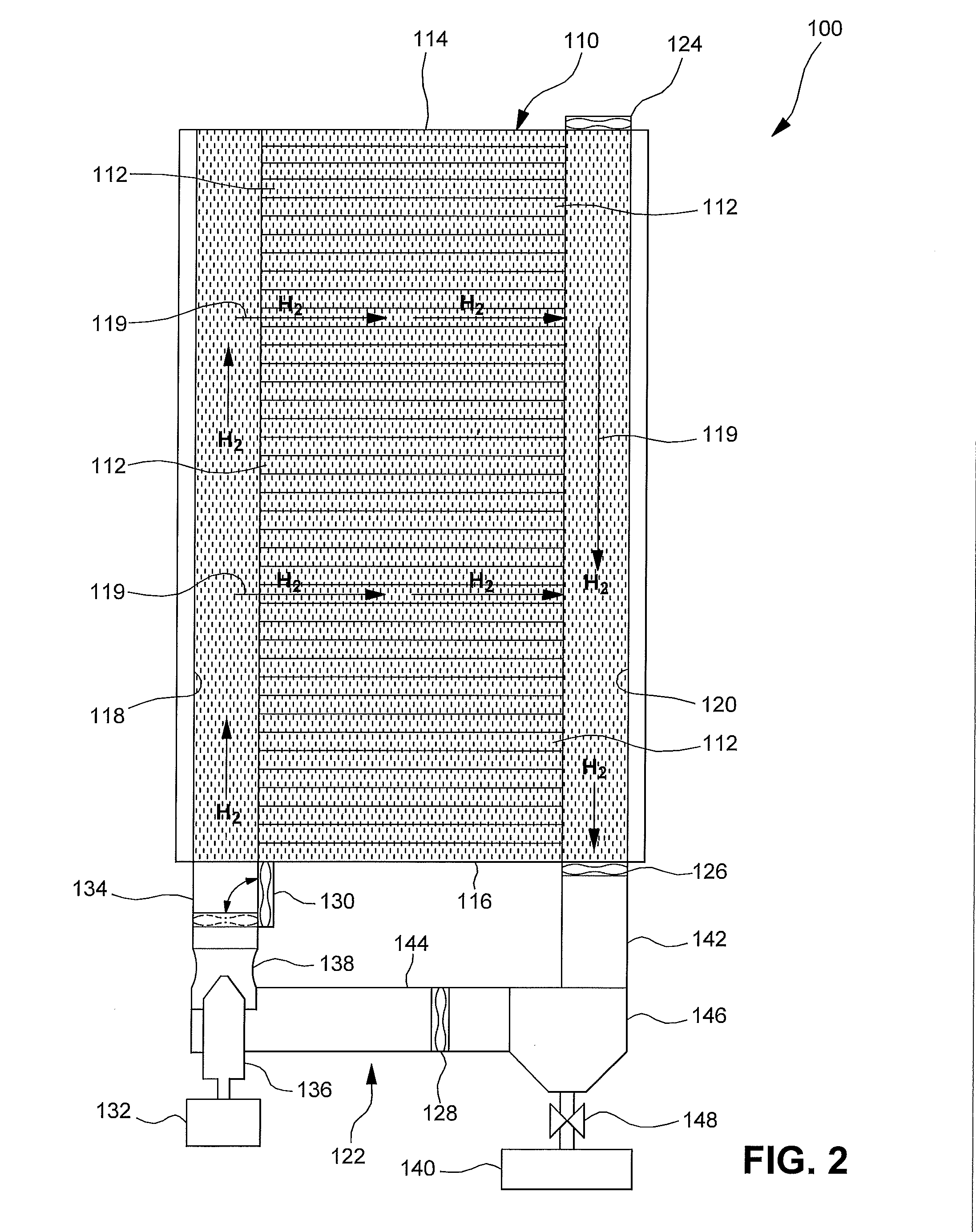

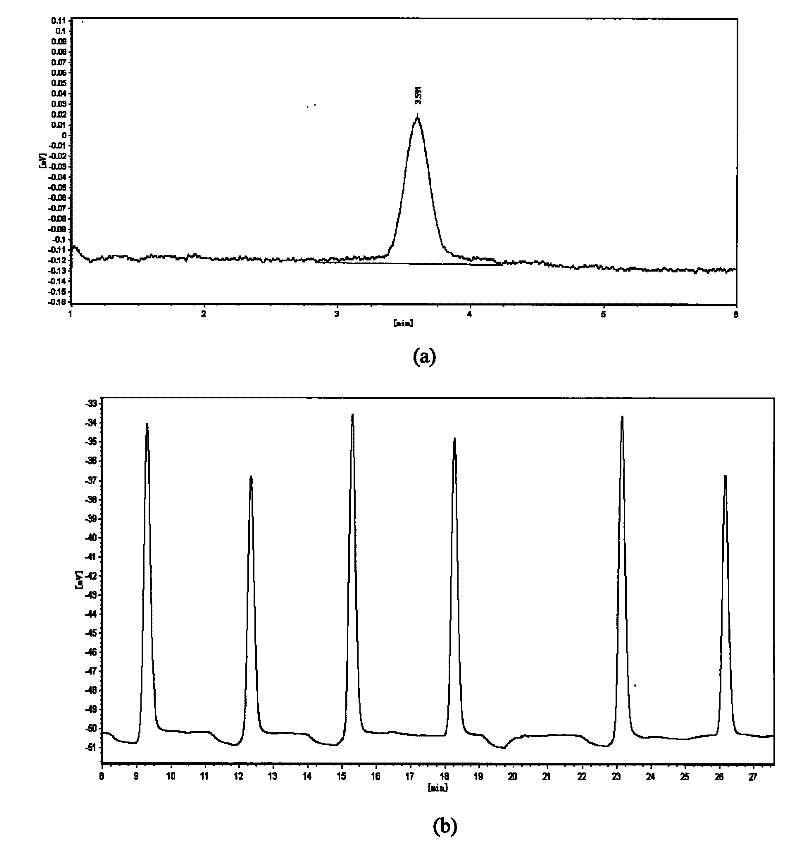

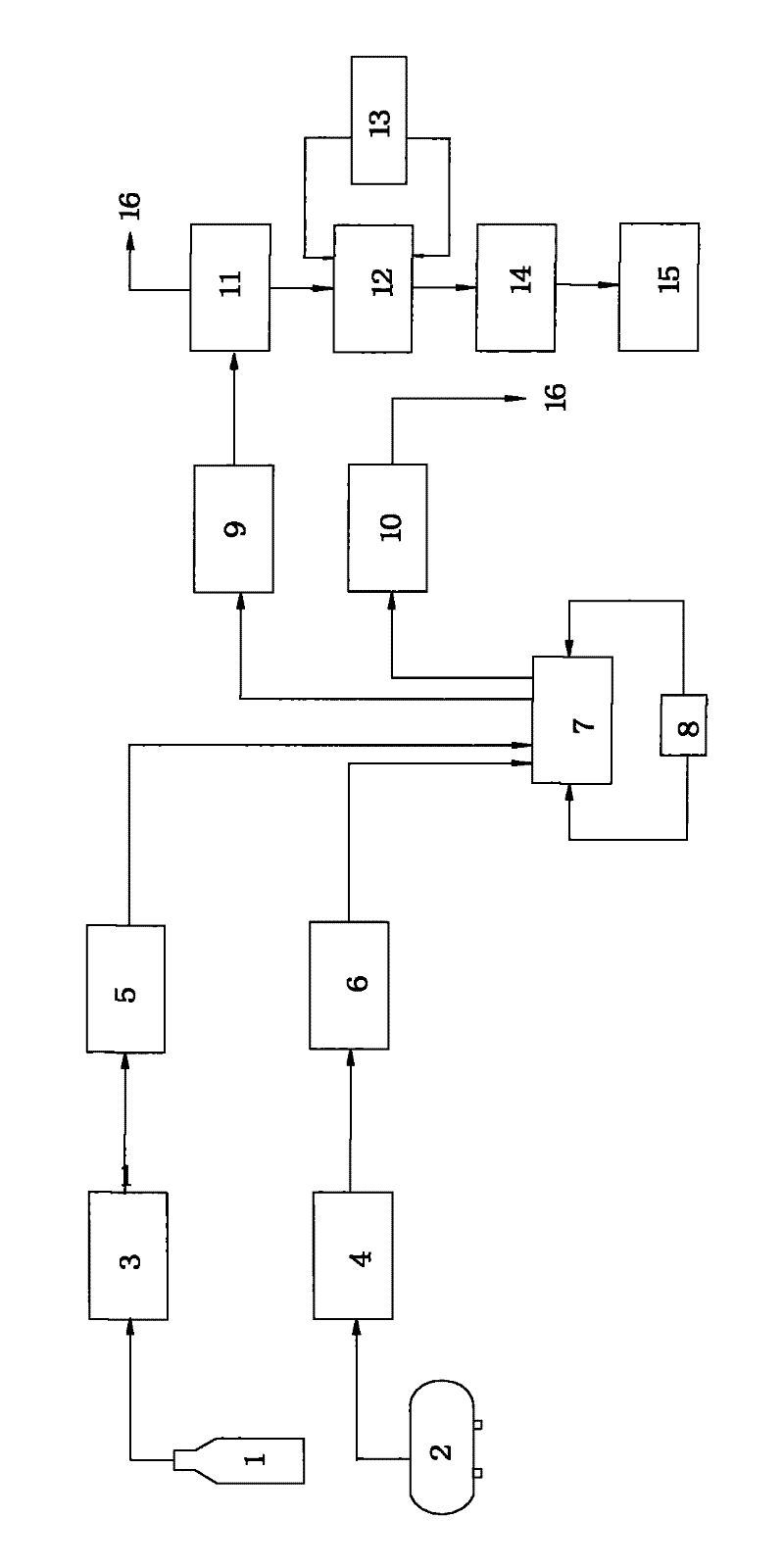

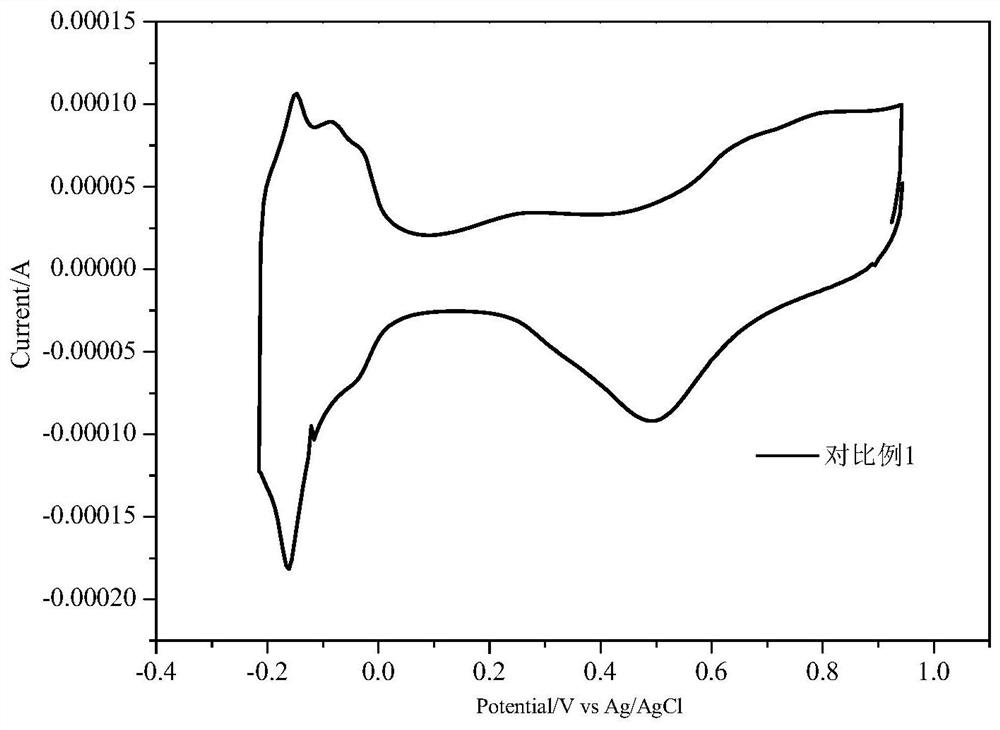

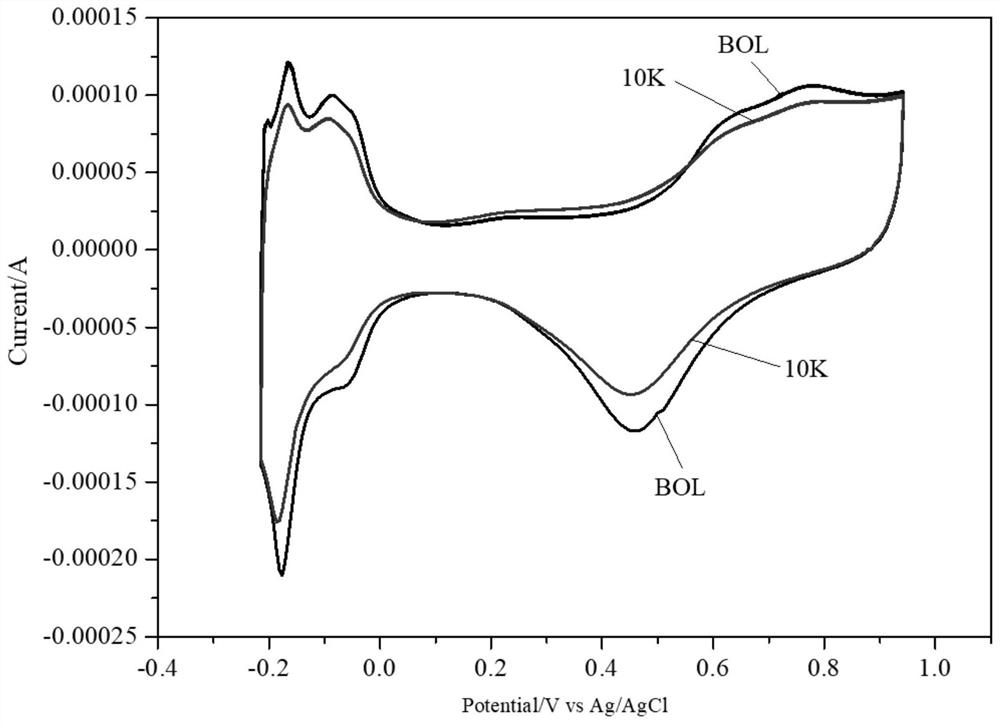

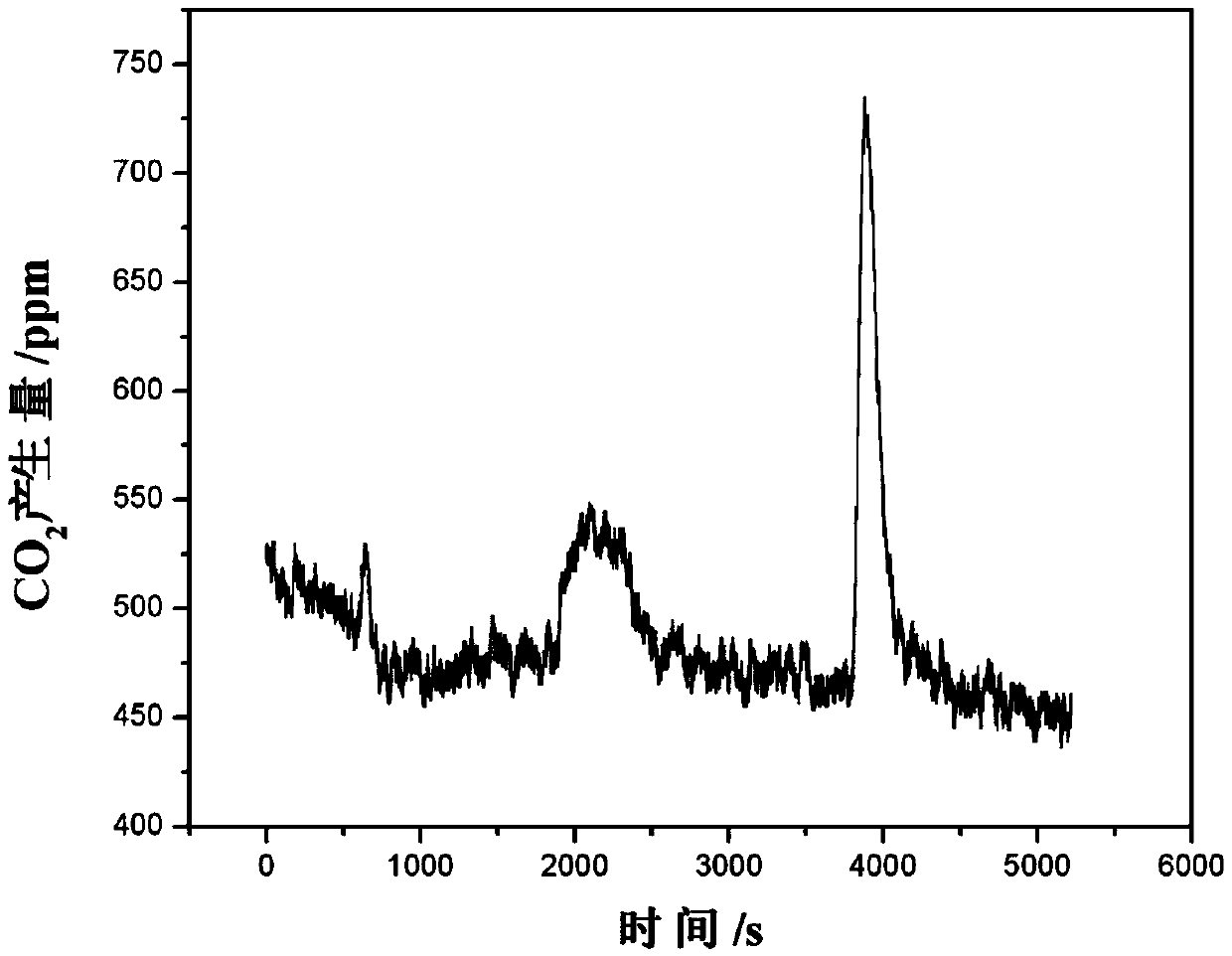

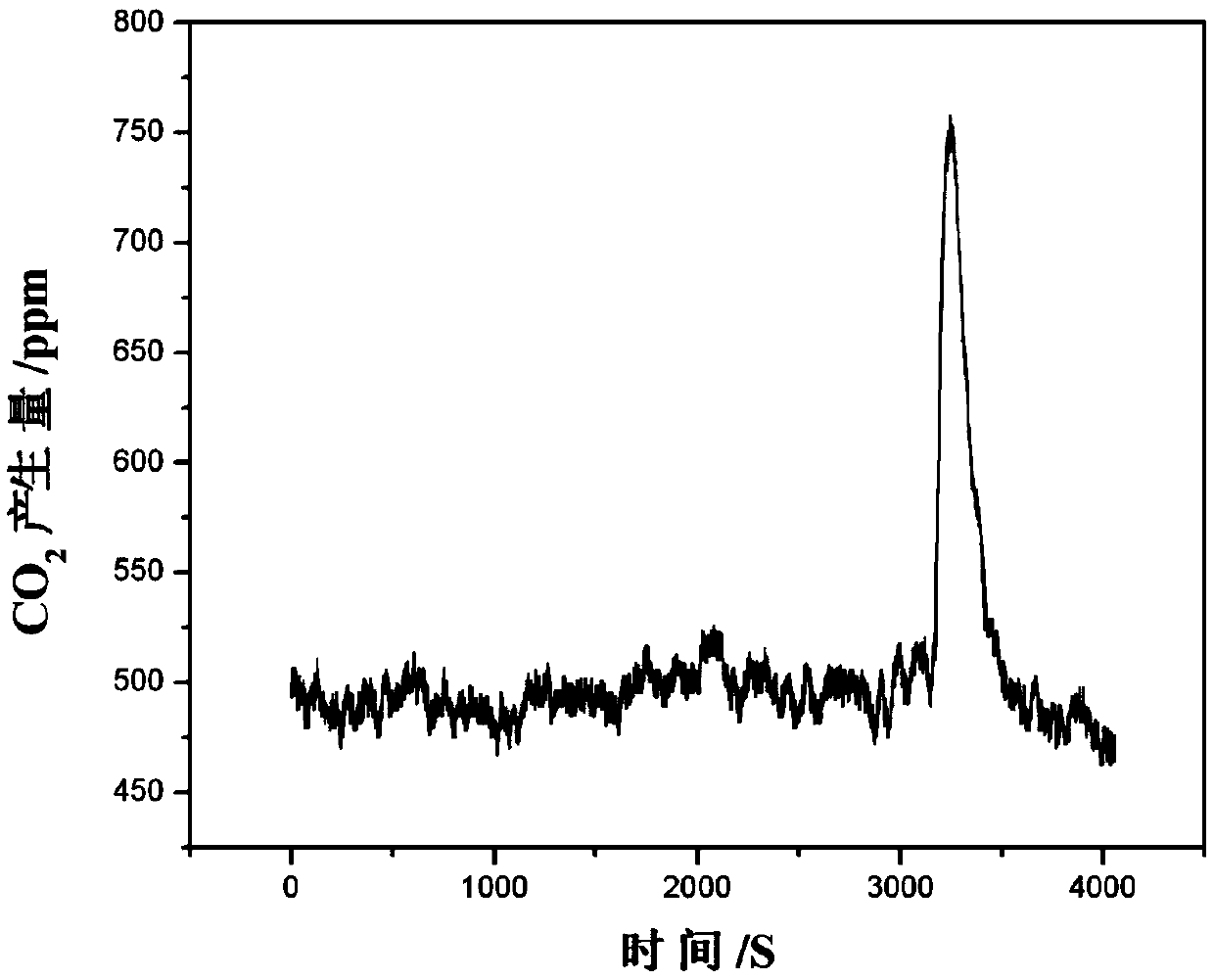

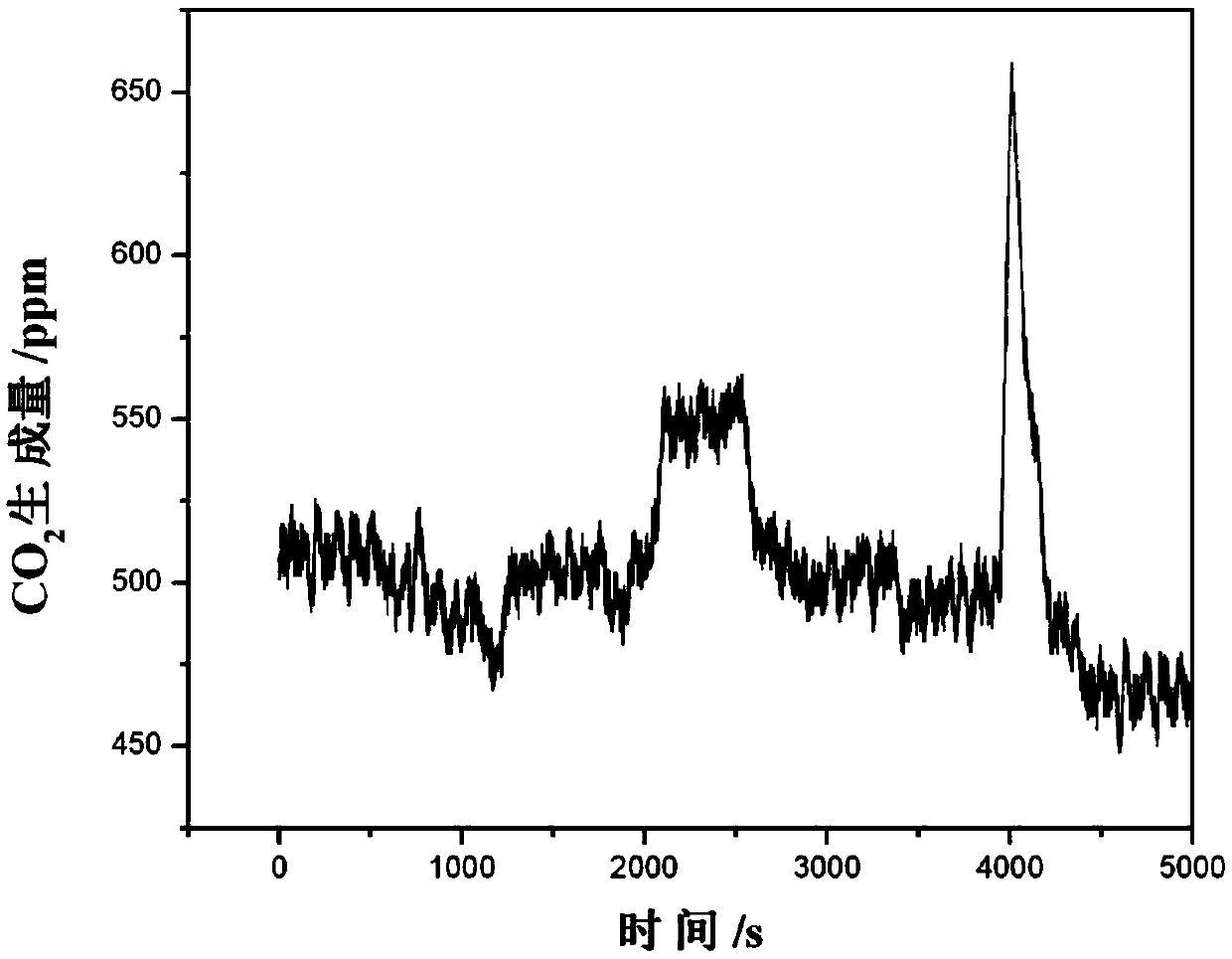

An online detection method for carbon corrosion in membrane electrodes

InactiveCN102297906AIntuitive test methodImprove accuracyComponent separationCarbon corrosionMethod test

The invention discloses an online detection method of carbon corrosion condition in proton exchange membrane fuel cell membrane electrode (MEA). The method tests the carbon corrosion condition of MEA in actual running process using Cox reformer and gad detection equipment. Tail gas of anode outlet or tail gas of cathode outlet of a fuel cell in normal running is fed into the Cox reformer through a gas controller; the tail gas converted by the reformer is fed into the gas detection equipment to obtain the condition of carbon corrosion. The test method comprises a tail gas controller, a gas reformer, catalyst, a temperature controller, a sampling system, the gas detection equipment and a gas pipeline. Through the detection method, the concentration of carbon corrosion product in MEA can be automatically detected on line, and the corrosion condition of carbon accurately can be reflected in time; and furthermore, the detection method is featured by simple test process, easy control and good repeatability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

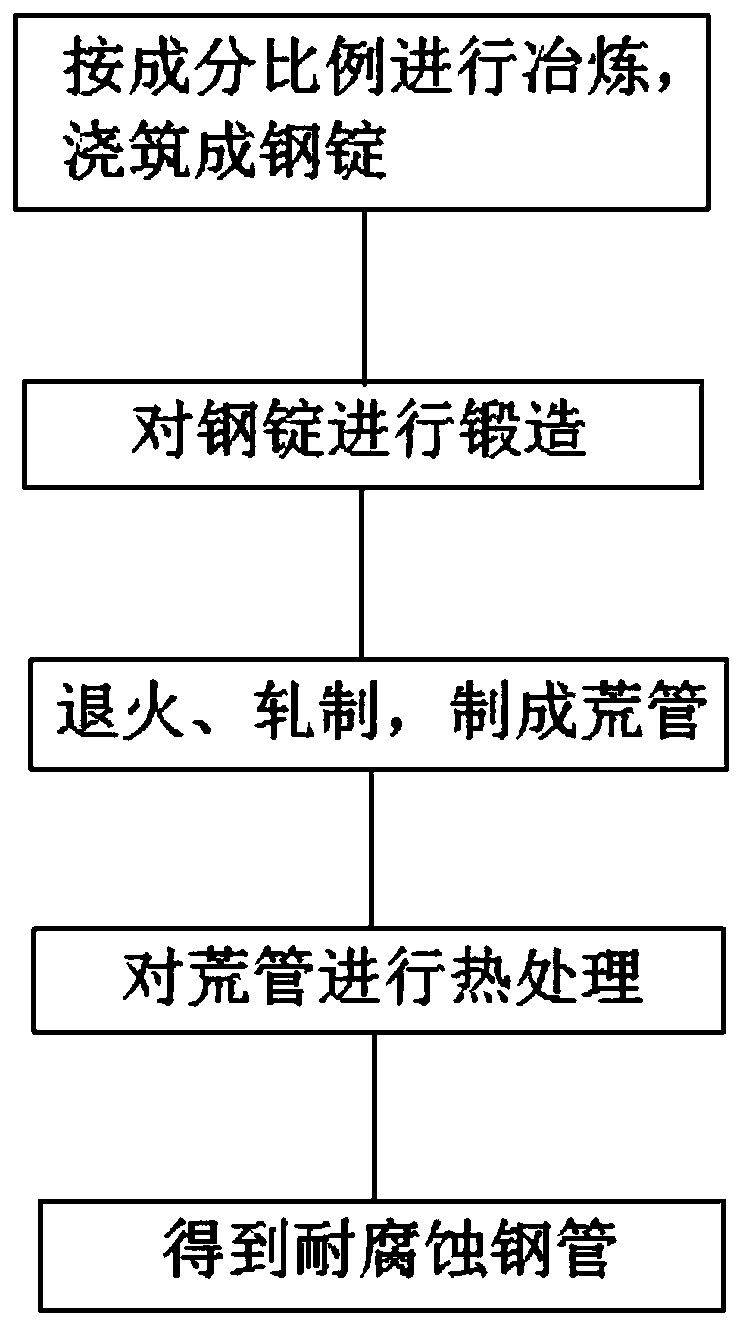

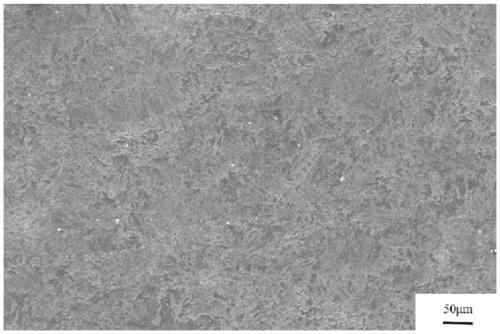

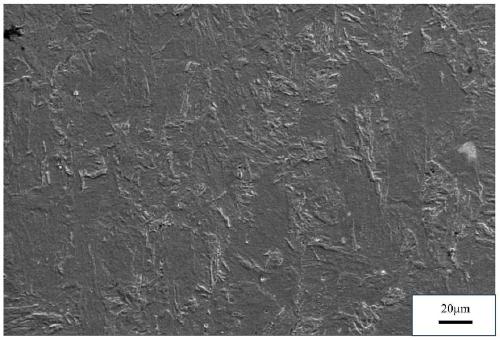

Carbon dioxide corrosion resistant seamless steel pipe and preparation method thereof

ActiveCN111218624AExcellent resistance to carbon dioxide corrosionReduce corrosion rateCarbon corrosionCarbon dioxide corrosion

The invention provides a carbon dioxide corrosion resistant seamless steel pipe and a preparation method thereof, and relates to the technical field of pipeline steel manufacturing. A prepared steel pipe has excellent carbon dioxide corrosion resistant performance, the corrosion rate of the steel pipe is lower than 0.06 mm / a, and the manufacturing cost is low. The steel pipe comprises the components of 0.03-0.08% of C, 5.50-8.5% of Cr, 0.1-2% of Ni, 0.010-0.055% of Nb, 0-0.012% of P, 0-0.006% of S, 0-0.010% of N and the balance Fe and inevitable impurities. The method comprises the steps of S1, conducting smelting and pouring to obtain a steel ingot according to the mass ratio of the components; S2, conducting forging and primary annealing; S3, conducting secondary annealing; S4, rolling apipe to obtain a pipe blank; and S5, conducting heat treatment. The technical scheme provided by the invention is suitable for the seamless steel pipe preparation process.

Owner:UNIV OF SCI & TECH BEIJING

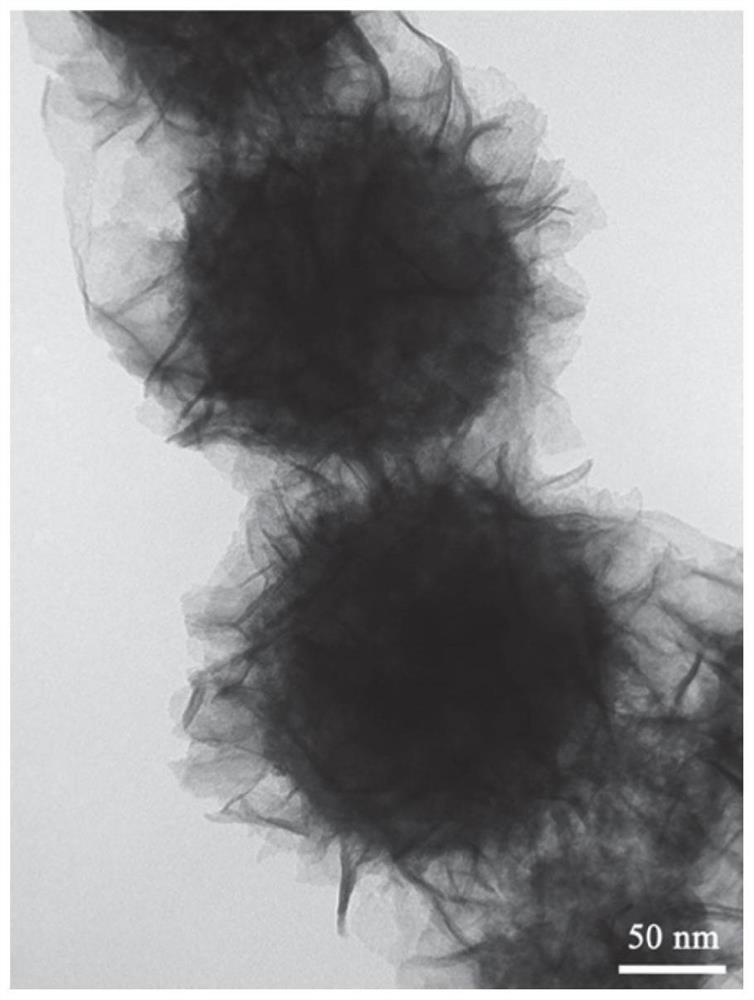

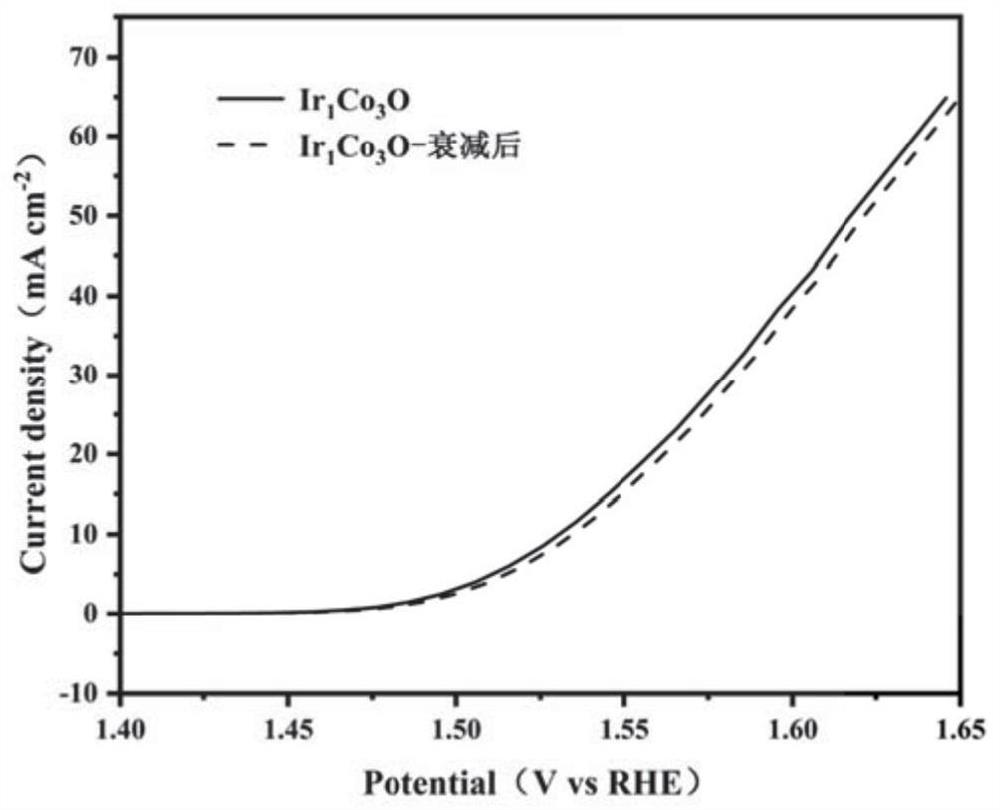

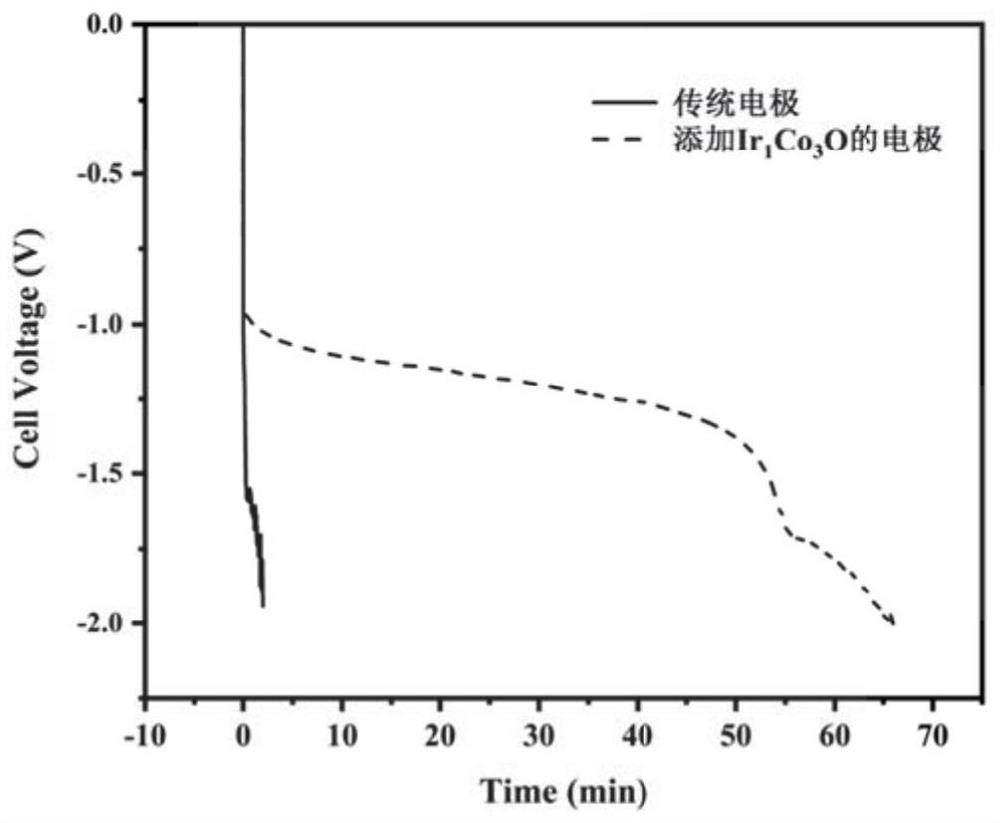

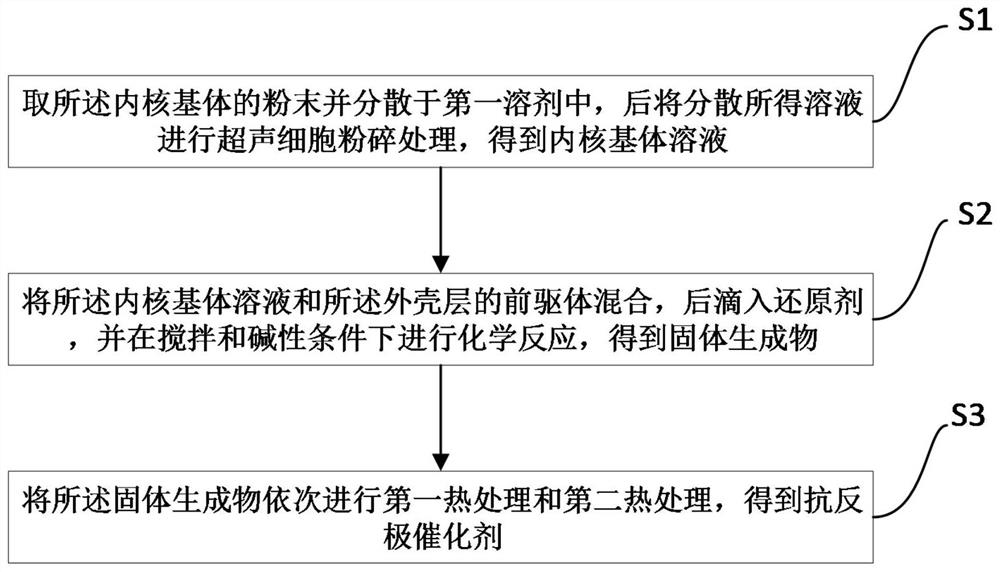

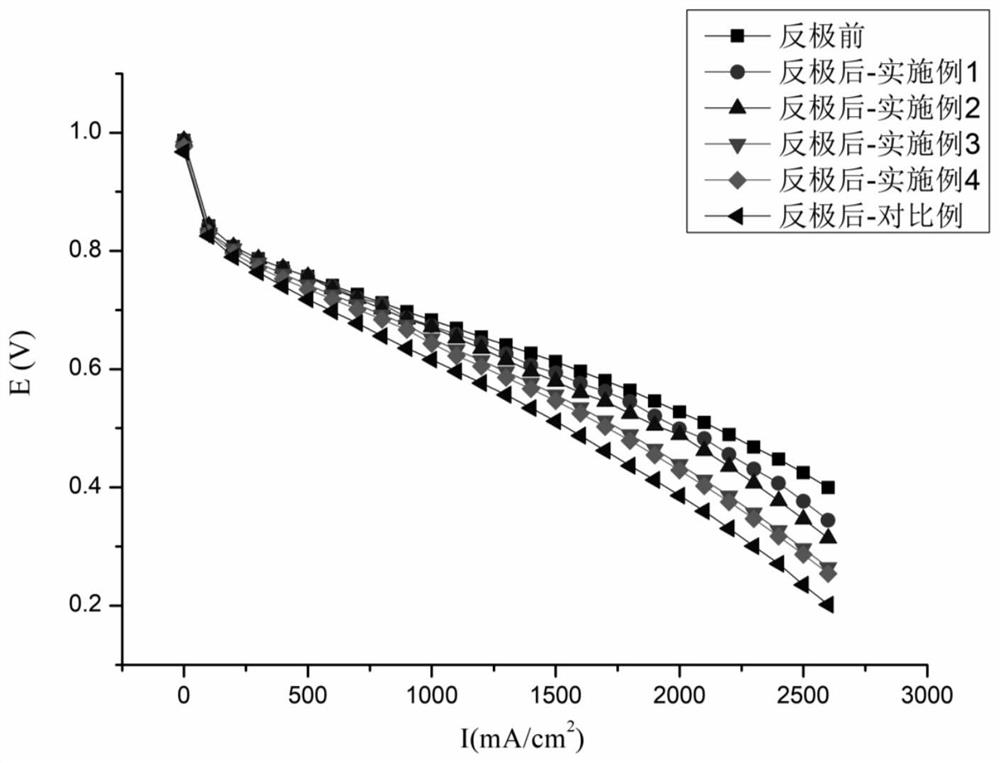

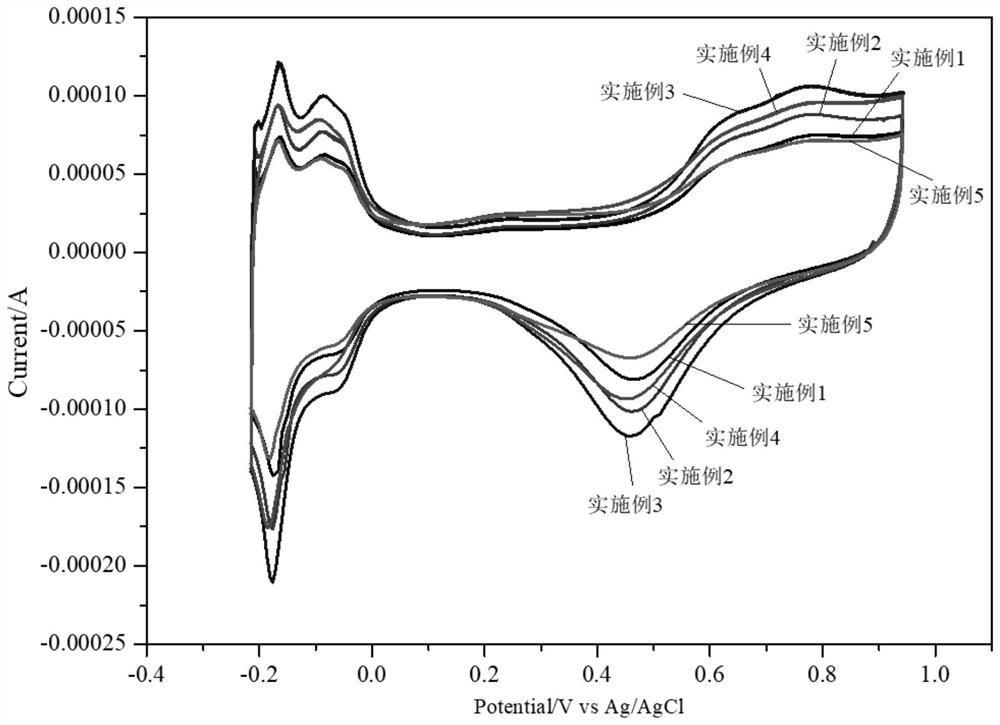

Fuel cell membrane electrode anti-reverse electrode additive and preparation method thereof

ActiveCN112838224AImproved anti-reverse abilityIncreased durabilityCell electrodesCarbon corrosionIridium

The invention discloses a fuel cell membrane electrode anti-reverse electrode additive and a preparation method thereof. The additive comprises a self-supporting iridium-cobalt alloy catalyst prepared by using a sodium borohydride reduction method, the antipole resistance of the cell prepared by the additive provided by the invention is remarkably improved, carbon corrosion of an anode catalyst layer and agglomeration of platinum particles caused by antipole can be effectively relieved, and the durability of the fuel cell under complex working conditions is improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Strategies for mitigating cell degradation during start-up and shutdown with H2/N2 storage

Owner:GM GLOBAL TECH OPERATIONS LLC

Preparation method of highly carbonized fiber woven filler

The invention relates to a preparation method of highly carbonized fiber woven fillers, relating to a preparation method of woven fillers. A polyacrylonitrile fiber wire bundle is processed sequentially through constant-temperature wire discharging, multi-section pre-oxidation, medium-temperature carbonization and high-temperature carbonization in a microaerobic carbon corrosion method; wherein the temperature of the low-temperature section pre-oxidation is 238-280 DEG C, and the temperature of the medium-temperature carbonization is 900-550 DEG C; and nitrogen is adopted as a carbon wire protection gas in the microaerobic carbon corrosion method, and the temperature of the high-temperature carbonization is 1450-1700 DEG C. The prepared highly carbonized fiber woven fillers has good self-lubricating performance, high strength, high modulus, good resistance against high temperature, low temperature and corrosion and good thermal conductivity, can be used for a long time in mediums with particle fluid and in rotation of high linear speed, and can also be used to replace the existing filler products of all materials.

Owner:张孟福

Anti-reverse-pole catalyst for battery and preparation method and application thereof

ActiveCN113629255AEnhanced anti-reverse polarity performanceImprove stabilityCell electrodesCarbon corrosionPtru catalyst

The invention relates to an anti-reverse-pole catalyst for a battery and a preparation method and application thereof, which belong to the field of batteries. The anti-reverse-pole catalyst provided by the invention is of a core-shell structure, the core-shell structure comprises an inner core matrix and a coating layer, and the coating layer is compactly loaded on the surface of the inner core matrix to form a wrapping form; and the stability of the particles of the inner core matrix under high potential is greater than that of the particles of the coating laye. The inner core matrix particles with high ORE activity are wrapped by the coating layer particles with better stability to form the core-shell structure, the core-shell structure can inhibit the inner core matrix with high ORE activity from participating in the reaction and inhibit the rate of water electrolysis reaction (OER) in the battery reaction energy supply process, so that the rate of water electrolysis reaction (OER) and the rate of carbon corrosion reaction (COR) are balanced, and meanwhile, the coating layer with higher stability can protect the inner core matrix, so that the anti-reverse-pole performance of the catalyst is enhanced.

Owner:DONGFENG MOTOR GRP

Catalyst carrier for fuel cell, catalyst and preparation method of catalyst carrier

InactiveCN112850787AIncreased durabilityEasy to operateCell electrodesCarbon preparation/purificationOXALIC ACID DIHYDRATECarbon corrosion

The invention relates to a catalyst carrier for a fuel cell, a catalyst and a preparation method thereof, and the catalyst carrier is prepared by the following steps: adding a carbon carrier into a mixed solution, and then sequentially carrying out ultrasonic dispersion, stirring, sedimentation, suction filtration, drying and roasting to obtain the catalyst carrier for the fuel cell, wherein the mixed solution is a mixture of an oxalic acid solution containing a vanadium precursor and an ethanol water solution. According to the prepared composite carrier, the vanadium oxide with the advantage of acid and alkali resistance is adopted, conversion among vanadium ions with different valence states is preferentially carried out at high potential, carbon corrosion is slowed down, and the durability of the catalyst is improved.

Owner:浙江高成绿能科技有限公司

Fuel cell system having oxygen sensor, and control method thereof

ActiveUS20200091530A1Inhibit deteriorationReduce oxygen concentrationReactant parameters controlCell electrodesCarbon corrosionThermodynamics

A fuel cell system and a control method thereof are provided. In the system, an oxygen sensor is mounted on the anode inlet side and the anode outlet side of a fuel cell stack to measure an oxygen concentration. Based on the measured oxygen concentration, a control operation is performed on the fuel cell system to reduce the oxygen concentration on the anode side. Accordingly, the irreversible deterioration of the fuel cell occurring due to the reverse voltage of the cell during driving of the fuel cell vehicle and the cathode carbon corrosion occurring due to the inflow of air during parking are effectively reduced, thereby increasing the durability of the fuel cell and the fuel cell vehicle.

Owner:HYUNDAI MOTOR CO LTD +1

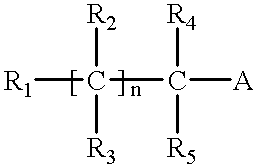

Polymethylenepolyamine dipropionamides as environmentally safe inhibitors of the carbon corrosion of iron

Owner:CECA SA

Start-stop method of high-temperature proton exchange membrane fuel cell

The mixed gas of CO and H2 is used for feeding in the start-stop process, and the competitive adsorption characteristic of CO and H2 on the surface of Pt is utilized to lower the anode hydrogen oxidation amount in the start-stop process, thereby lowering the cathode carbon corrosion amount in the start-stop process. The start-stop strategy provided by the invention is more suitable for a high-temperature proton exchange membrane fuel cell, and by utilizing the strategy, the problem of cathode carbon corrosion in the start-stop process can be effectively relieved, the service life of the fuel cell is prolonged to a greater extent, and the durability of the fuel cell is improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Tri-Electrode Zinc-Air Battery with Flowing Electrolyte

InactiveUS20180048041A1Avoid formingLong lastingFuel and secondary cellsHybrid cell detailsCarbon corrosionElectrolytic agent

A rechargeable tri-electrode single flow zinc air battery which is capable of providing theoretically unlimited cycle life is provided. The tri-electrode configuration consists of one anode and two cathodes, one for charging and another for discharging. The charge cathode may comprise a water-permeable metal mesh and / or metal foam, which avoids carbon corrosion. The discharge cathode is a catalytic oxygen reduction electrode. The anode comprises an inert, conductive electrode allowing for zinc deposition during battery charging, and zinc dissolving during battery discharging. The flowing electrolyte removes zinc ions from the anode preventing or minimizing the formation of zinc oxides during discharging, and clean the anode after each full discharge.

Owner:CHEN ZHONGWEI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com