Fuel cell membrane electrode anti-reverse electrode additive and preparation method thereof

A fuel cell membrane and proton exchange membrane technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of cumbersome catalyst preparation process, poor conductivity of titanium oxide, etc., and achieve favorable gas transport, good conductivity, and preparation methods simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Take 10mL CoCl 2 (10mmol / L) solution, 3mL H 2 Add IrCl (10mmol / L) solution into 50mL ethylene glycol solution, stir well at 25°C, then add 1g NaBH 4 , and continued stirring at 25°C for 3h, the reaction product was washed with a large amount of deionized water, and then placed in a 60°C oven for vacuum drying overnight. After the dried powder was carefully ground, it was annealed in a tube furnace at 400°C for 2h at a heating rate of 2°C / min, and cooled naturally to room temperature to obtain the prepared sea urchin-like iridium-cobalt alloy catalyst.

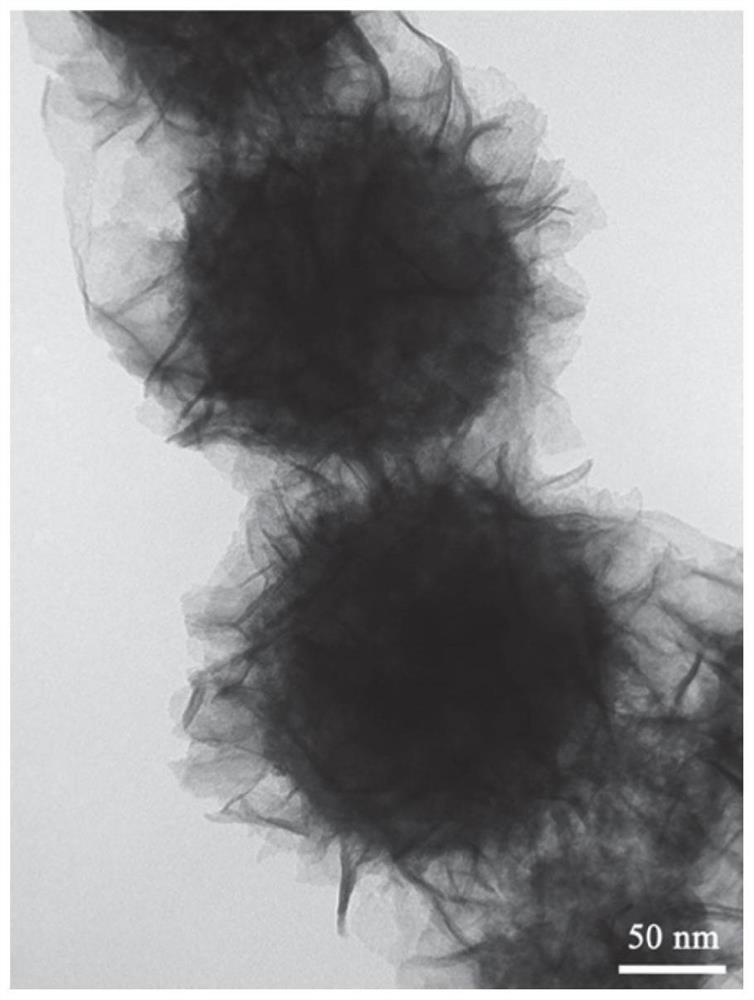

[0034] Taking Example 1 as an example, figure 1 The morphology of the anti-reversal additive provided in Example 1 of the present invention has a particle size of about 100 nm, which is slightly larger than carbon black, so it can be added to the anode catalytic layer as a catalyst.

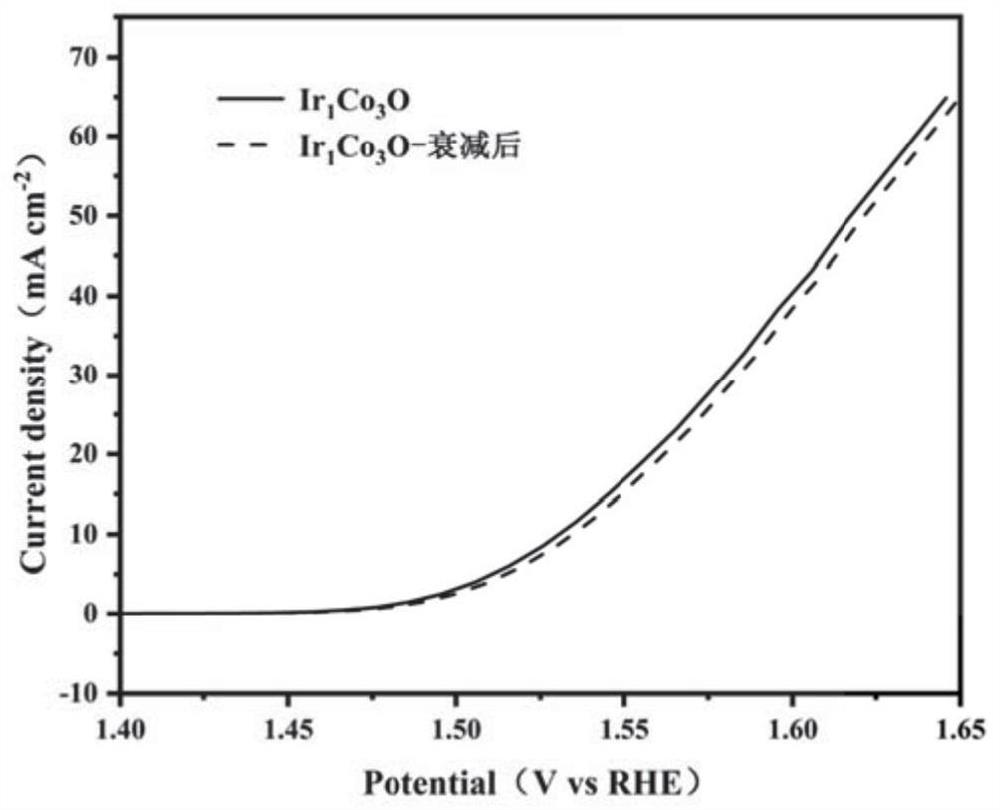

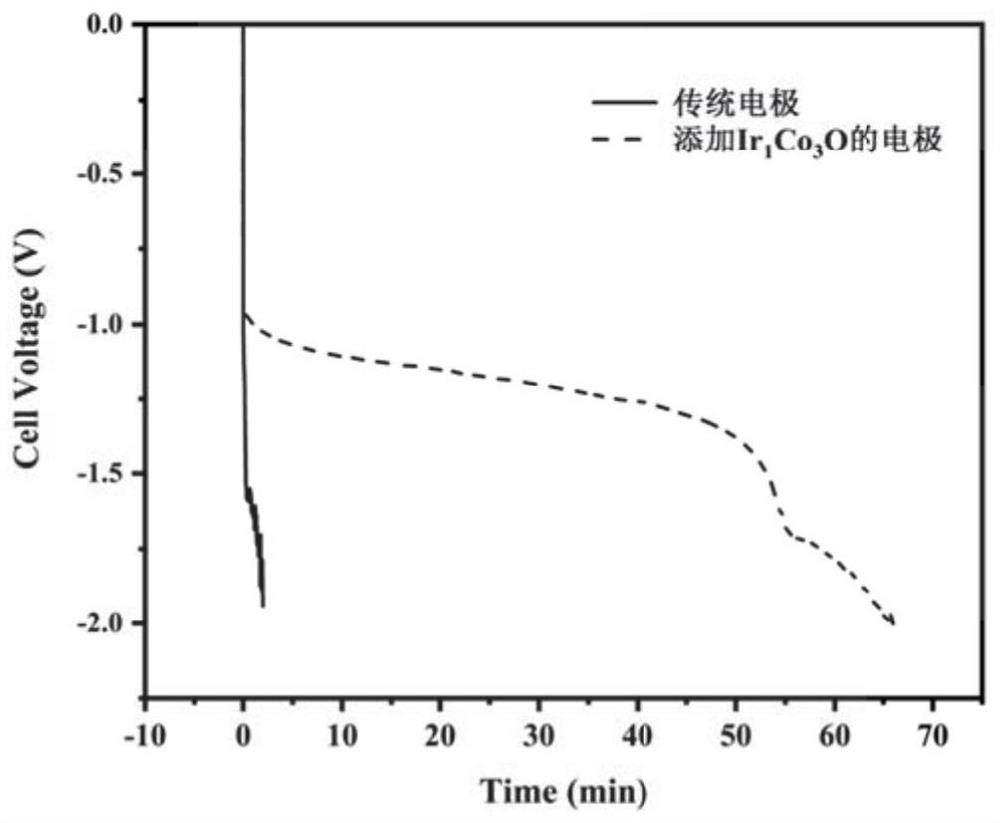

[0035] figure 2 The OER performance diagram of the prepared iridium-cobalt alloy catalyst and its performance diagram after the stabi...

Embodiment 2

[0038] Take 10mL CoCl 2 (10mmol / L) solution, 3mL H 2 Add IrCl (10mmol / L) solution into 50mL ethylene glycol solution, stir well at 25°C, then add 1g NaBH 4 , and continued stirring at 25°C for 3h, the reaction product was washed with a large amount of deionized water, and then placed in a 60°C oven for vacuum drying overnight. After the dried powder was carefully ground, it was annealed in a tube furnace at 500°C for 2h at a heating rate of 2°C / min, and cooled naturally to room temperature to obtain the prepared sea urchin-like iridium-cobalt alloy catalyst.

[0039] Taking Example 2 as an example, the catalyst prepared in Example 2 is at 10mA cm -2The overpotential is 295mV, and the performance is good. The anti-reversal additive prepared in Example 2 is introduced into the fuel cell anode catalyst layer in a physically mixed manner, and the anode catalyst layer includes a Pt / C catalyst and an anti-reversal additive IrCo alloy, wherein Pt / C and IrCo are in the catalyst lay...

Embodiment 3

[0041] Take 10mL CoCl 2 (10mmol / L) solution, 3mL H 2 Add IrCl (10mmol / L) solution into 50mL ethylene glycol solution, stir well at 25°C, then add 1g NaBH 4 , and continued stirring at 25°C for 3h, the reaction product was washed with a large amount of deionized water, and then placed in a 60°C oven for vacuum drying overnight. After the dried powder was carefully ground, it was annealed in a tube furnace at 300°C for 2h at a heating rate of 2°C / min, and cooled naturally to room temperature to obtain the prepared sea urchin-like iridium-cobalt alloy catalyst.

[0042] Taking Example 3 as an example, the catalyst prepared in Example 3 is at 10mA cm -2 The overpotential is 299mV, and the performance is good. The anti-reversal additive prepared in Example 3 is introduced into the fuel cell anode catalyst layer in a physically mixed manner, and the anode catalyst layer includes a Pt / C catalyst and an anti-reversal additive IrCo alloy, wherein Pt / C and IrCo are in the catalyst la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com