Anti-reverse-pole catalyst for fuel cell and preparation method of anti-reverse-pole catalyst

A fuel cell and catalyst technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as membrane electrode damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

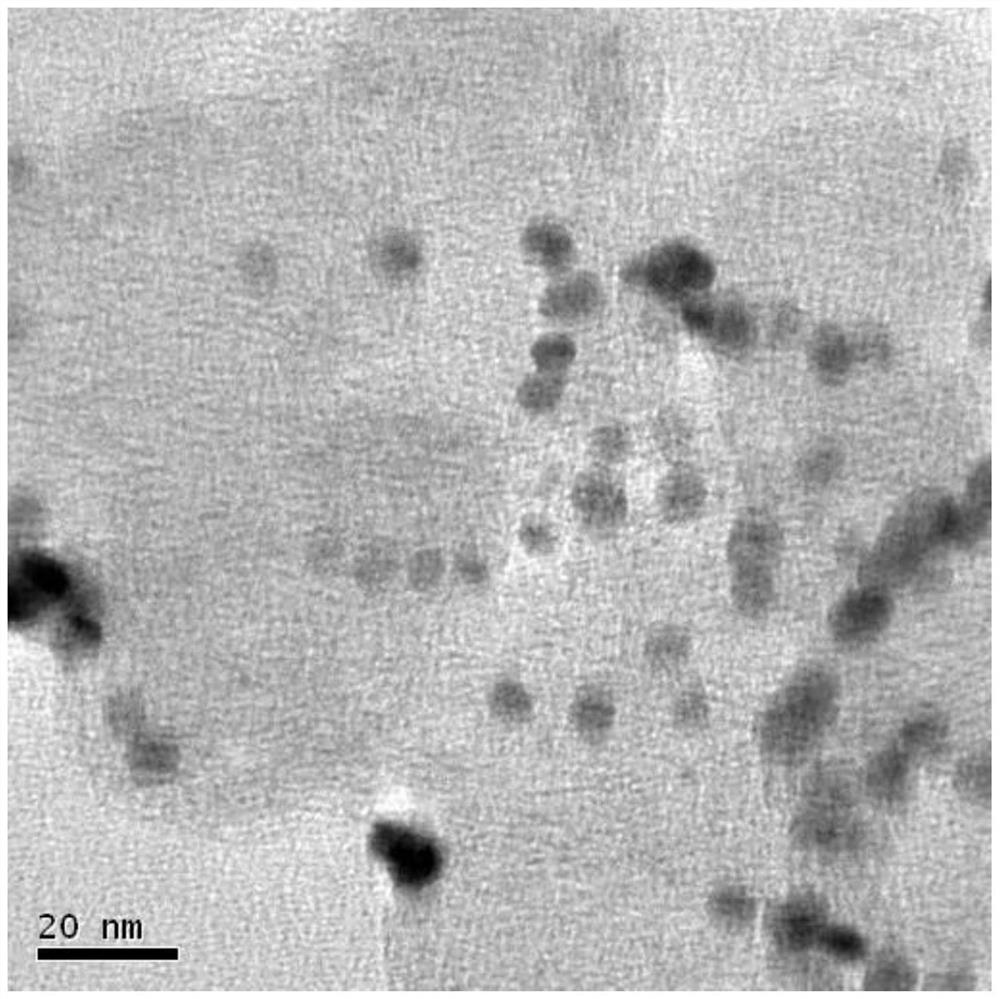

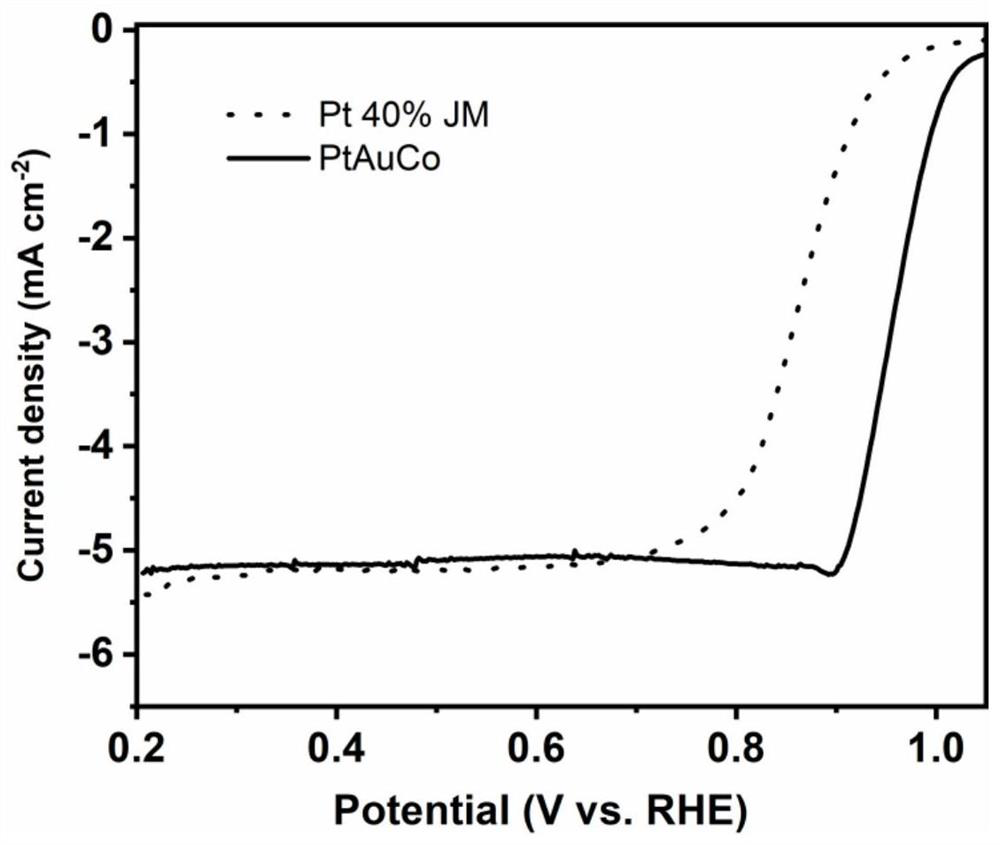

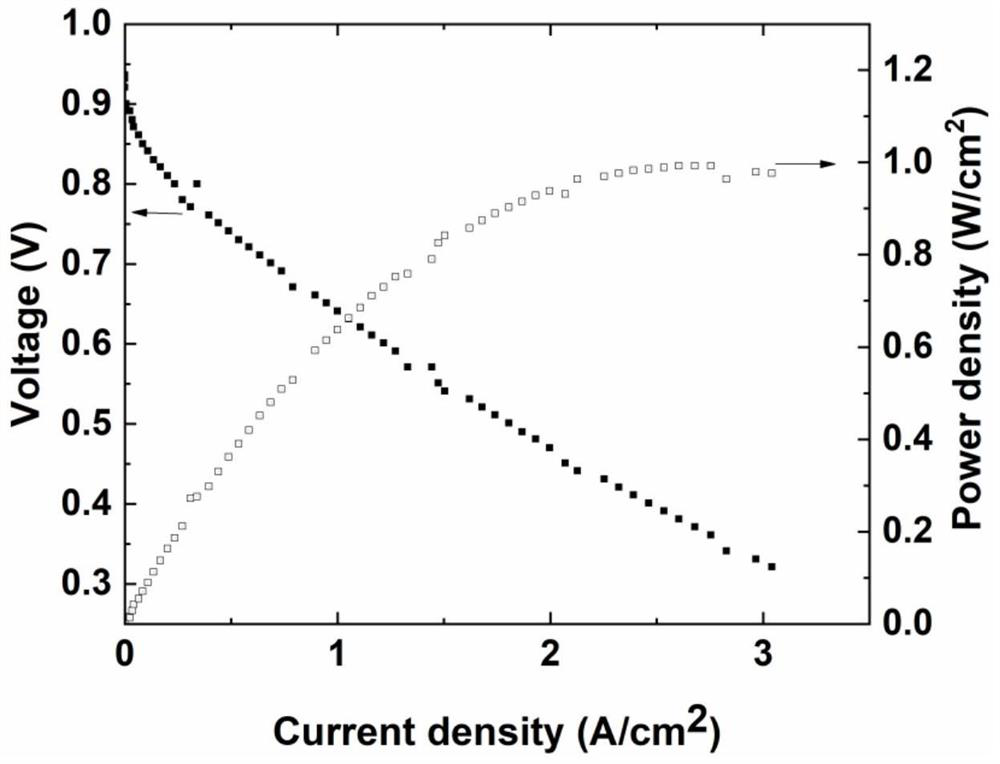

[0025] Weigh 1g of porous carbon black and place it in a tube furnace, and heat it from normal temperature to 950°C at a heating rate of 2°C / min, and keep it warm for 3 hours. After natural cooling, replace with nitrogen gas and seal for use. Disperse the ammonia-treated carrier material in 800 ml of ethylene glycol solution, and then fully disperse it by means of a high-speed cutting machine and ultrasonic charging. Thereafter 2.5 g of nickel acetate, 10 g of polyvinylpyrrolidone and 10 g of ammonium citrate were added, after which the pH was adjusted to 12 with sodium hydroxide. After thorough cutting and sonication, heating was carried out by microwave at 180 degrees for 10 minutes. After the reaction, the temperature was lowered to 80 degrees for later use. For product-related test results, see figure 1 , figure 2 and image 3 .

[0026] In addition, weigh 1 gram of chloroplatinic acid and 200 mg of ruthenium chloride, disperse it in 500 mL of ethylene glycol, add 5 ...

Embodiment 2

[0028] Weigh 1g of porous carbon black and place it in a tube furnace, and heat it from normal temperature to 950°C at a heating rate of 2°C / min, and keep it warm for 3 hours. After natural cooling, replace with nitrogen gas and seal for use. Disperse the ammonia-treated carrier material in 800 ml of nitrogen, nitrogen-dimethylformamide solution, and then fully disperse it by means of a high-speed cutting machine and ultrasonic charging. Thereafter 2.5 g of nickel acetate, 15 g of polyvinylpyrrolidone were added, and then the pH was adjusted to 12 with sodium hydroxide. After thorough cutting and sonication, heating was carried out by microwave at 180° C. for 10 minutes. After the reaction, the temperature was lowered to 80 degrees for later use.

[0029] In addition, 1 gram of chloroplatinic acid was weighed and dispersed in 500 mL of ethylene glycol. After fully dispersed by adding 5 grams of ammonium citrate and 5 grams of potassium iodide, it was added dropwise to the abo...

Embodiment 3

[0031] Weigh 1g of porous carbon black and place it in a tube furnace, and heat it from normal temperature to 950°C at a heating rate of 2°C / min, and keep it warm for 3 hours. After natural cooling, replace with nitrogen gas and seal for use. Disperse the ammonia-treated carrier material in 400 ml of ethylene glycol solution, and then fully disperse it by means of a high-speed cutting machine and ultrasonic charging. Thereafter, 1.82 g of cobalt nitrate and 10 g of ammonium citrate were added, and then the pH was adjusted to 12 with sodium hydroxide. After sufficient cutting and sonication, the reaction kettle was heated at 180 degrees to maintain a constant temperature, and 50 ml of 3 % formaldehyde solution. After 3 hours of reaction, the temperature was lowered to 80°C for use.

[0032] In addition, 1 gram of platinum acetylacetonate and 100 mg of chloroauric acid were weighed, dispersed in 100 mL of ethylene glycol, 10 potassium iodide was added, and after being fully disp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com