Catalyst carrier for fuel cell, catalyst and preparation method of catalyst carrier

A catalyst carrier and fuel cell technology, applied in battery electrodes, carbon preparation/purification, circuits, etc., can solve problems such as high concentration polarization and ohmic polarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

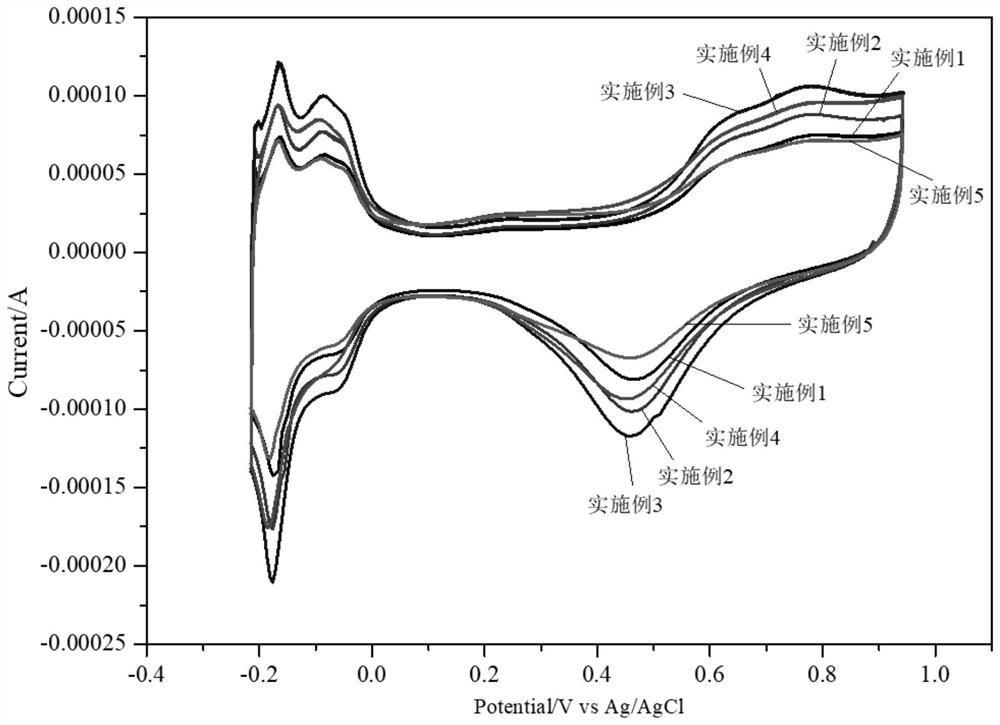

Embodiment 1

[0038] Weigh 0.5g of carbon carrier Vulcan XC72R into a beaker, add 0.4g of 5wt% metavanadate ammooxalic acid solution, 30g of 10wt% ethanol aqueous solution, sonicate for 20min, and stir with a glass rod; after the end, stir the beaker on a magnetic stirrer for 90min at room temperature , and finally settled overnight, filtered with suction, air-dried at 80°C for 60 minutes, and calcined at 300°C for 60 minutes to finally obtain the desired composite carrier.

[0039] Preparation of composite oxide supported platinum catalyst by liquid phase reduction method: 0.3g of composite carrier, 2.7g of 20wt% chloroplatinic acid aqueous solution, and 18g of ethylene glycol were placed in a three-necked flask, ultrasonically dispersed for 20min, and then 2.7g of sodium hydroxide was added, 0.3 g formaldehyde, stirred and reacted at 80°C for 300min in a water bath, cooled and settled after the reaction, filtered, dried at 100°C for 120min, and finally obtained the desired 40% Pt / VOx-C cat...

Embodiment 2

[0041] Weigh 0.5g of carbon carrier Vulcan XC72R into a beaker, add 0.6g of 5wt% metavanadate ammooxalic acid solution, 30g of 10wt% ethanol aqueous solution, sonicate for 20min, and stir with a glass rod; after the end, stir the beaker on a magnetic stirrer for 90min at room temperature , and finally settled overnight, filtered with suction, air-dried at 80°C for 60 minutes, and calcined at 300°C for 60 minutes to finally obtain the desired composite carrier.

[0042] Preparation of composite oxide supported platinum catalyst by liquid phase reduction method: 0.3g of composite carrier, 2.7g of 20wt% chloroplatinic acid aqueous solution, and 18g of ethylene glycol were placed in a three-necked flask, ultrasonically dispersed for 20min, and then 2.7g of sodium hydroxide was added, 0.3 g formaldehyde, stirred and reacted at 80°C for 300min in a water bath, cooled and settled after the reaction, filtered, dried at 100°C for 120min, and finally obtained the desired 40% Pt / VOx-C cat...

Embodiment 3

[0044] Weigh 0.5g of carbon carrier BP2000 into a beaker, add 0.9g of 5wt% metavanadate ammooxalic acid solution, 30g of 10wt% ethanol aqueous solution, ultrasonicate for 20min, and stir with a glass rod; after the end, stir the beaker on a magnetic stirrer for 90min at room temperature, Finally, settle overnight, filter with suction, air-dry at 80°C for 60 minutes, and bake at 300°C for 60 minutes to obtain the desired composite carrier.

[0045] Preparation of composite oxide supported platinum catalyst by liquid phase reduction method: 0.3g of composite carrier, 2.7g of 20wt% chloroplatinic acid aqueous solution, and 18g of ethylene glycol were placed in a three-necked flask, ultrasonically dispersed for 20min, and then 2.7g of sodium hydroxide was added, 0.3 g formaldehyde, stirred and reacted at 80°C for 300min in a water bath, cooled and settled after the reaction, filtered, dried at 100°C for 120min, and finally obtained the desired 40% Pt / VOx-C catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com