A carbon-free membrane electrode assembly

A technology of carbon film electrodes and components, applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems of reducing the electrochemical performance and stability of batteries, not nano-ordered structures, etc., to solve the problem of carbon corrosion and improve operation stability Sexuality and longevity, performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

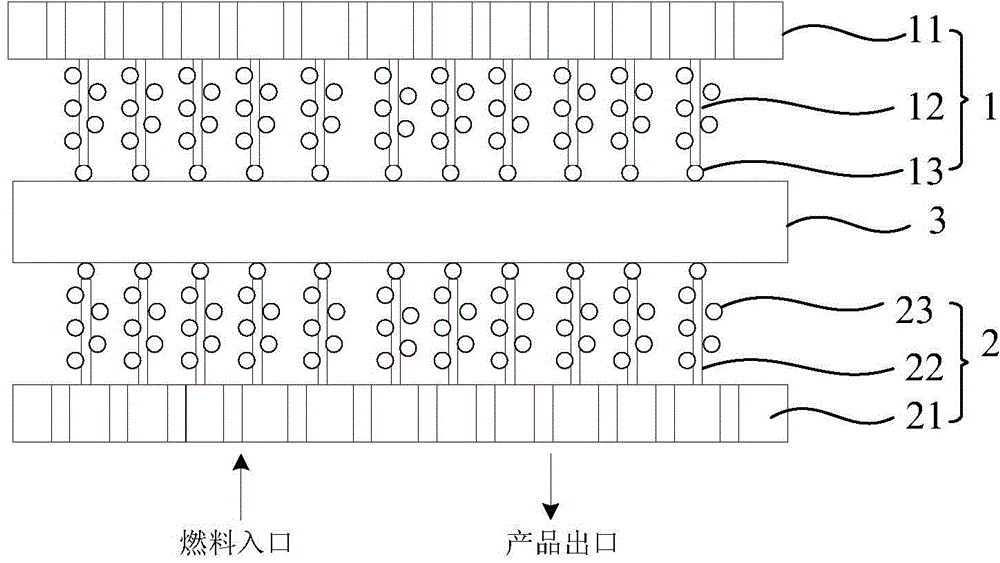

[0049] The present invention provides a carbon-free membrane electrode assembly, which at least includes: a cathode membrane electrode 1 , an anode membrane electrode 2 and a solid polymer dielectric membrane 3 .

[0050] Wherein, the cathode membrane electrode 1 includes a porous and conductive cathode current collecting plate 11, a cathode ordered nano-array 12 grown on the surface of the cathode current collecting plate 11, and a cathode combined on the upper surface of the cathode ordered nano-array 12. Catalyst layer 13.

[0051] In an application example, the cathode current collector 11 is made of a porous conductive material. Porous, for the transport of reactants, products, and electrons, can be used as fuel inlet and product outlet; conductive, for the output of current. The cathode current collector 11 is one of porous titanium, porous stainless steel, aluminum oxide, and conductive polymer, or a composite material of at least two of the above. In this embodiment,...

Embodiment 2

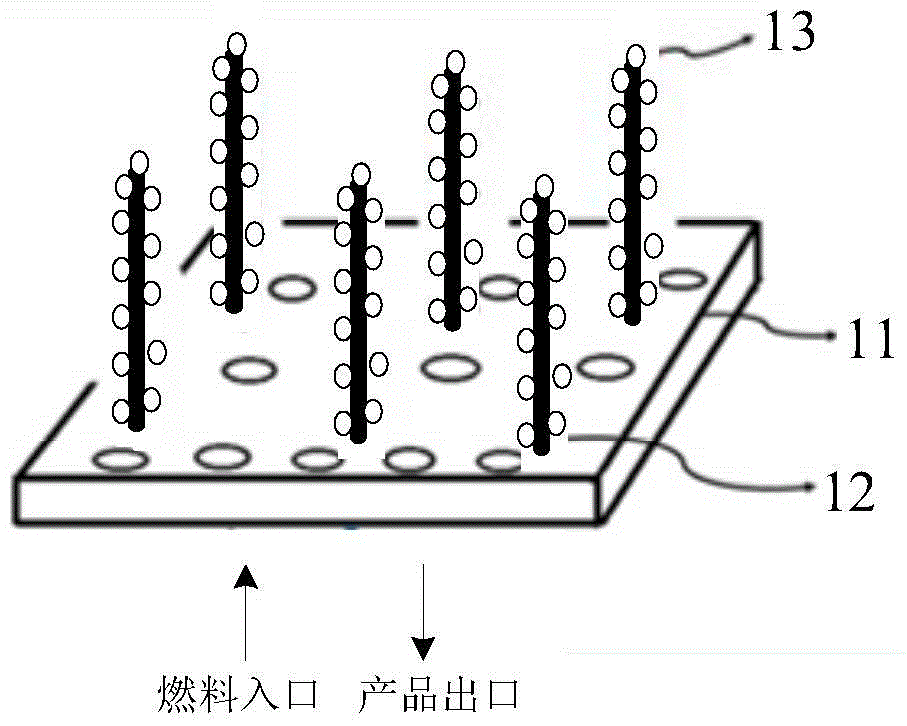

[0061] see figure 2 , is shown as a simplified structural schematic diagram of an embodiment of the carbon-free membrane electrode assembly of the present invention. For the sake of simplicity, the anode membrane electrode and the cathode membrane electrode have the same structure, which is not shown in the figure; the anode membrane electrode and the cathode membrane electrode have the same structure. The solid polymer electrolyte membrane between the membrane electrode structures is also omitted, and only the cathode membrane electrode assembly is shown.

[0062] In this embodiment, the cathode current collecting plate 11 is a porous titanium plate; the nano-ordered array 12 is an ordered array of polypyrrole nanowires.

[0063] The specific process steps are as follows:

[0064] (1) Pretreatment of porous titanium plate:

[0065] In order to provide enough nucleation sites, activate the core center, reduce the interfacial energy resistance, and facilitate the vertical gr...

Embodiment 3

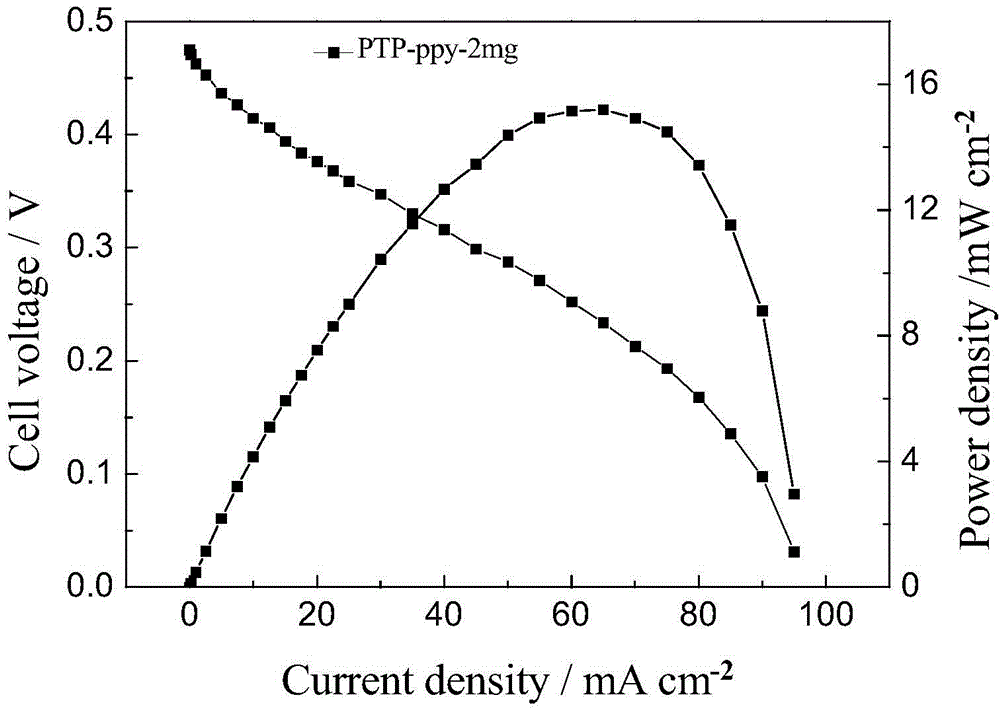

[0075] The preparation method of this example is the same as that of Example 2. The porous titanium plate is used as the substrate, that is, the cathode current collecting plate 11, and nanometer-ordered polypyrrole nanometers are grown on the surface of the porous titanium plate by electropolymerization. Tube array 12, then use the porous titanium plate as an electrode, the electrolyte is a mixed solution of chloroplatinic acid and ruthenium chloride, and -0.25Vvs saturated calomel is a reference electrode, in the polypyrrole ordered nanotube array In-situ deposition on the surface generates a load of 0.2 mg.cm -2 The PtRu alloy catalyst, that is, the cathode catalytic layer 13, the ratio of Pt atoms and Ru atoms is 3:1.

[0076] It should be noted that, for the sake of simplicity, the structure of the anode membrane electrode and the cathode membrane electrode is the same, which is not shown in the figure; the solid polymer electrolyte membrane between the structure of the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com