Patents

Literature

30results about How to "Intuitive test method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for testing grade of adhesive residue of pressure-sensitive adhesive product

ActiveCN106290150ATest Method SpecificationTest method can be replicatedUsing mechanical meansMaterial analysisEngineeringThermostat

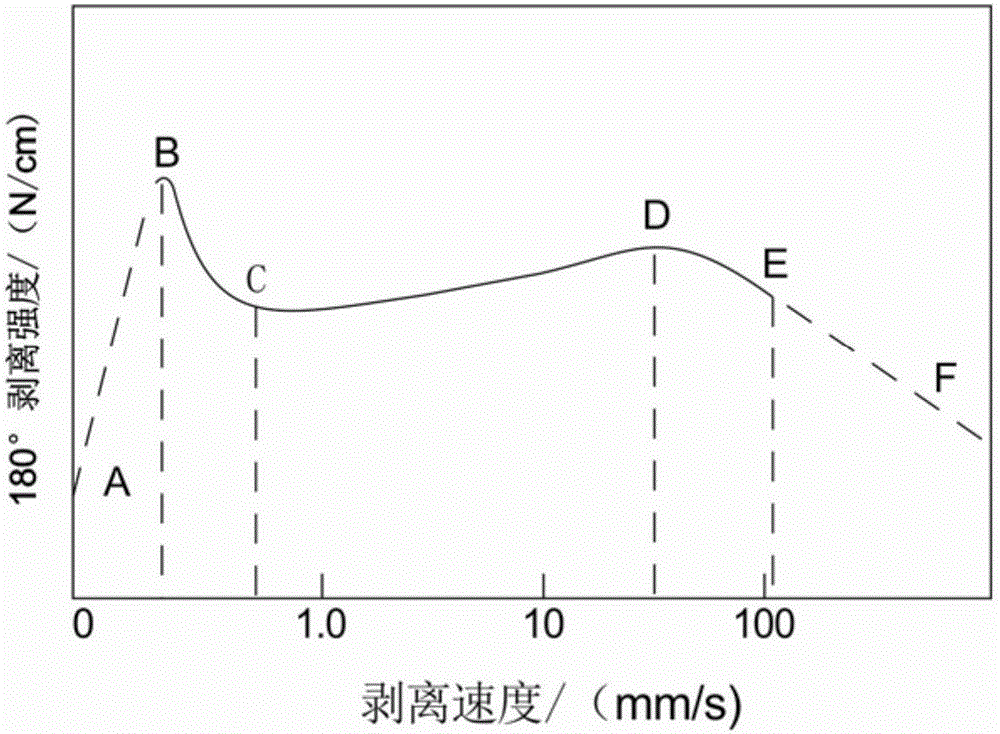

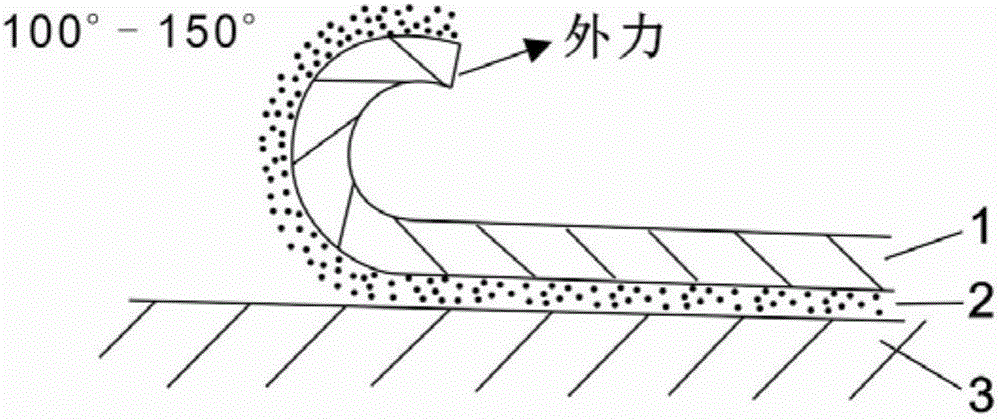

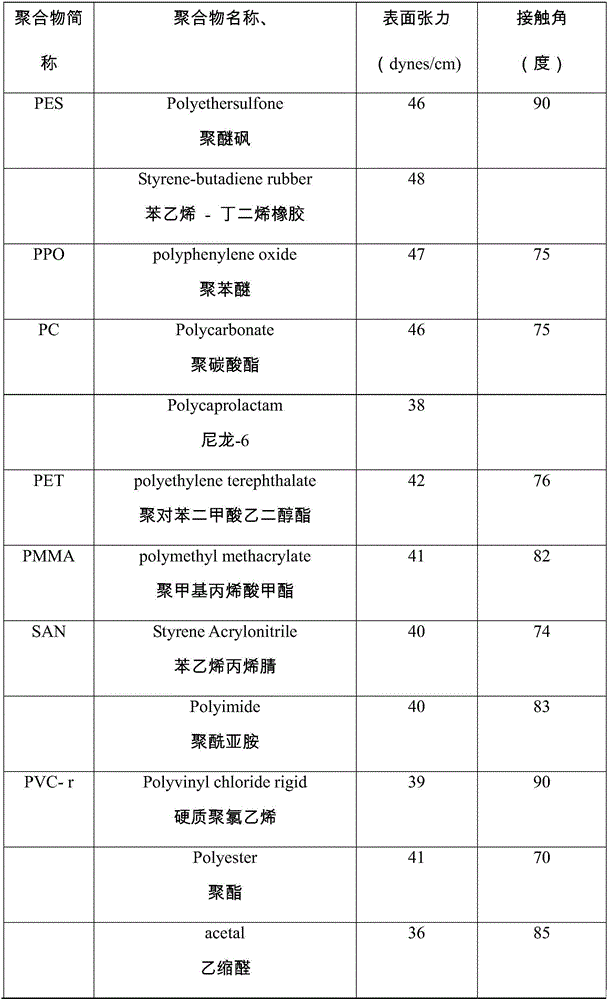

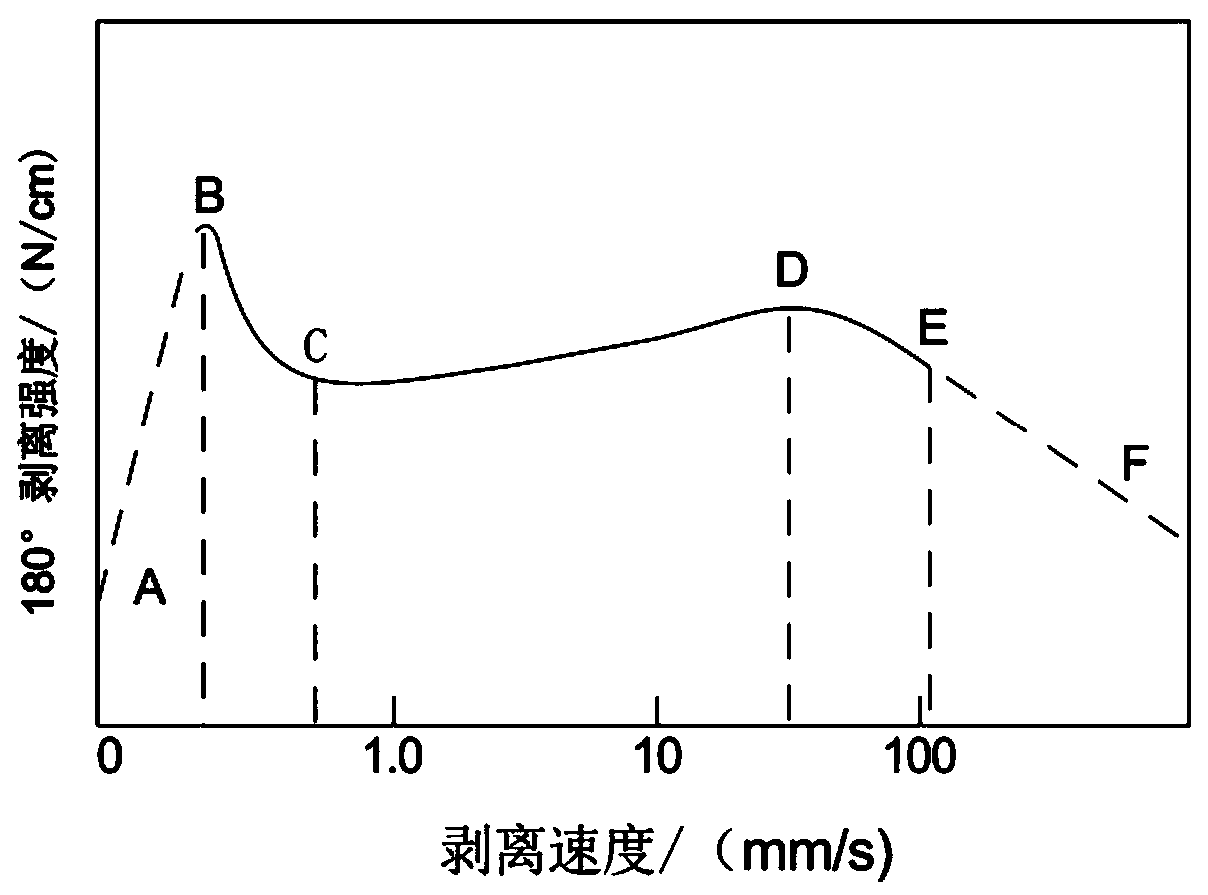

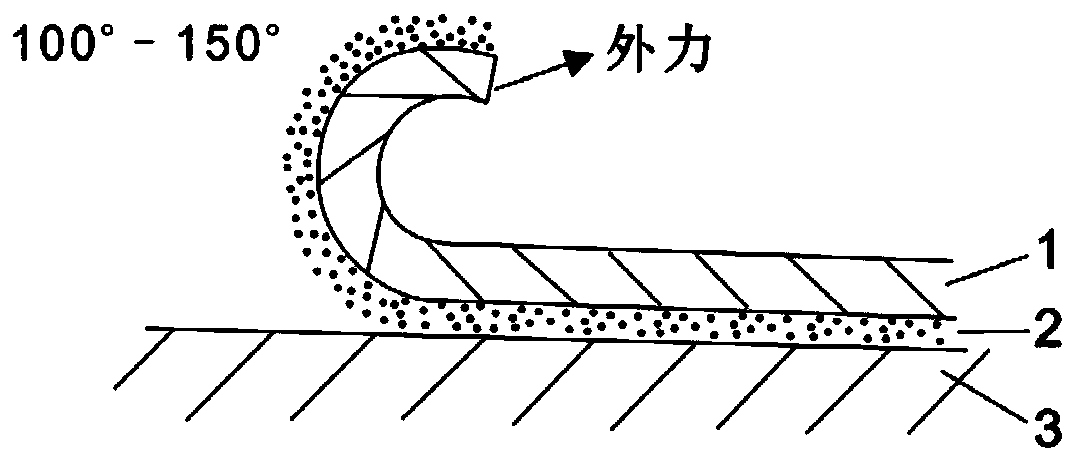

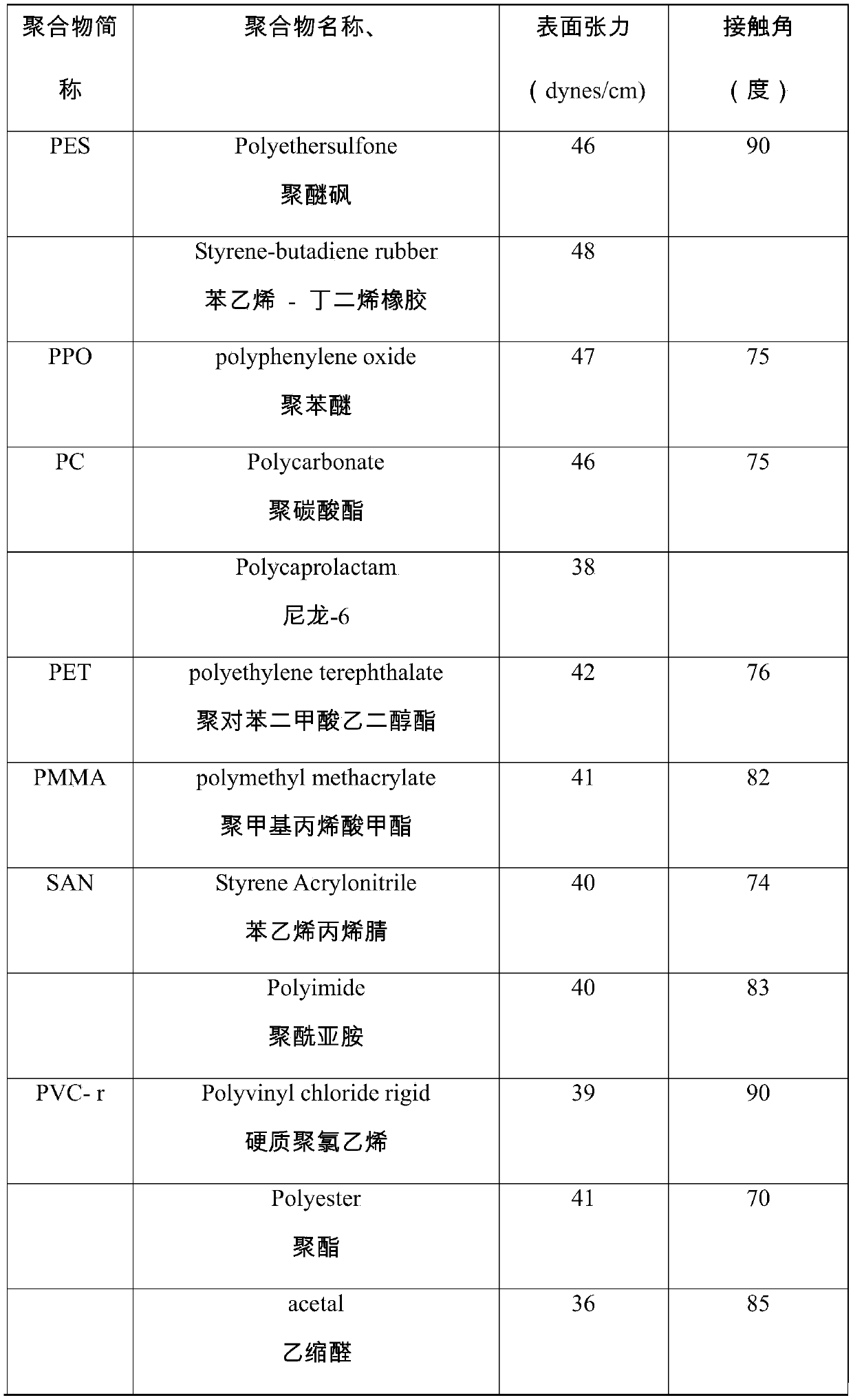

The invention discloses a method for testing the grade of adhesive residue of a pressure-sensitive adhesive product. The test method comprises the following steps: (1) selecting a test board, namely utilizing one of a metal plate, a metal sheet, a plastic board and a plastic plate as the test board; (2) setting parameters of the test board, wherein the surface tension of the test board is 32-50mN / m, the size of the test board is greater than or equal to 150mm*35mm, and the thickness of the test board is greater than or equal to 50 microns; (3) manufacturing an assembly, namely adhering a to-be-tested pressure-sensitive adhesive test piece onto the test board so as to form the assembly; (4) processing the assembly, namely respectively placing the assembly in a thermo-hygrostat which has temperature higher than 30 DEG C and humidity higher than 60% or a thermostat at a temperature lower than 30 DEG C; and (5) performing a stripping test, namely stripping the test piece in the assembly treated in the step (4) from the test board. The test method disclosed by the invention can be used for determining the grade of adhesive residues of the pressure-sensitive adhesive, thus determining the viscous force of the pressure-sensitive adhesive product and the adhesion quality of the pressure-sensitive adhesive product and an adhered object.

Owner:GUANGZHOU JINWANZHENG PRINTING MATERIAL CO LTD

Air-supplementing pressurized-water control method for phase modulation of water-turbine generator set

InactiveCN102953923AReduce points of failureSolve the problem of high loop failure rateHydro energy generationMachines/enginesWater turbineEngineering

The invention discloses an air-supplementing pressurized-water control method for the phase modulation of a water-turbine generator set. An electromagnetic valve arranged on a pipeline and controlling convey of compressed air to a runner chamber in an air-supplementing pressurized-water control loop for the phase modulation of a water-turbine generator set is included; the method is mainly implemented through taking the active power consumed when the water-turbine generator set is subjected to phase modulation as a criterion of the blocking / deblocking of an air-supplementing pressurized-water electromagnetic valve for phase modulation, acquiring the analog quantity of an active transducer of the water-turbine generator set by using a PLC (programmable logic controller) of the water-turbine generator set, and realizing the control on the blocking / deblocking of the air-supplementing pressurized-water electromagnetic valve according to preset active power limiting values, wherein the PLC is provided with built-in related logic programs; and the preset active power limiting values are as follows: firstly, an active power limiting value P1 consumed by the water-turbine generator set when the water lever of the runner chamber of the water-turbine generator set is at the upper limit and an active power limiting value P2 consumed by the water-turbine generator set when the water lever of the runner chamber of the water-turbine generator set is at the lower limit are determined; when an active power limiting value P consumed by the water-turbine generator set is greater than P1, the air-supplementing pressurized-water electromagnetic valve is blocked; and when the active power limiting value P consumed by the water-turbine generator set is less than P2, the air-supplementing pressurized-water electromagnetic valve is deblocked.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER +1

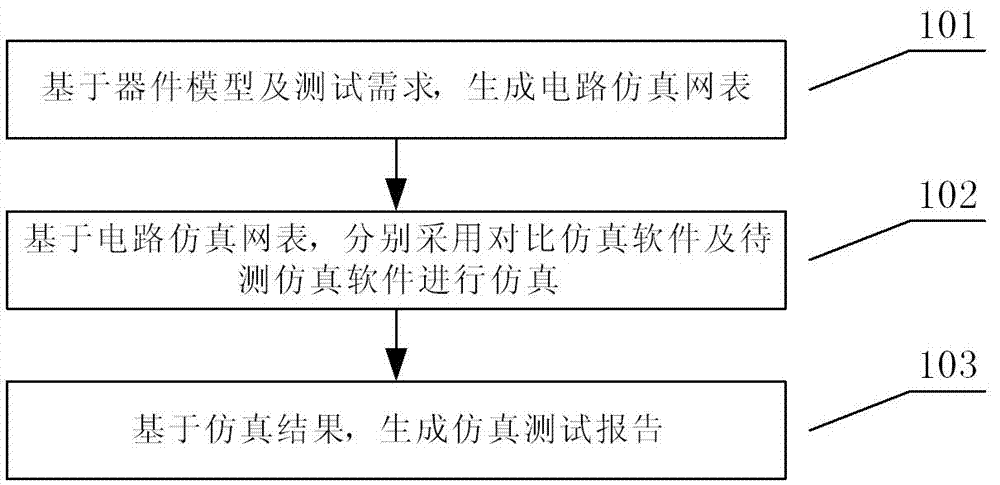

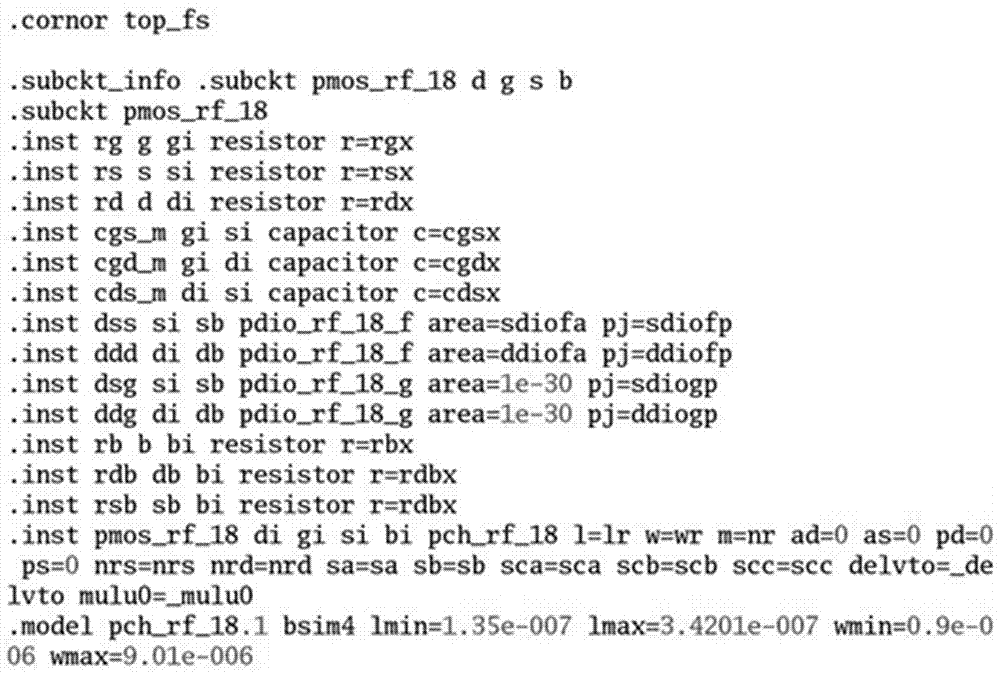

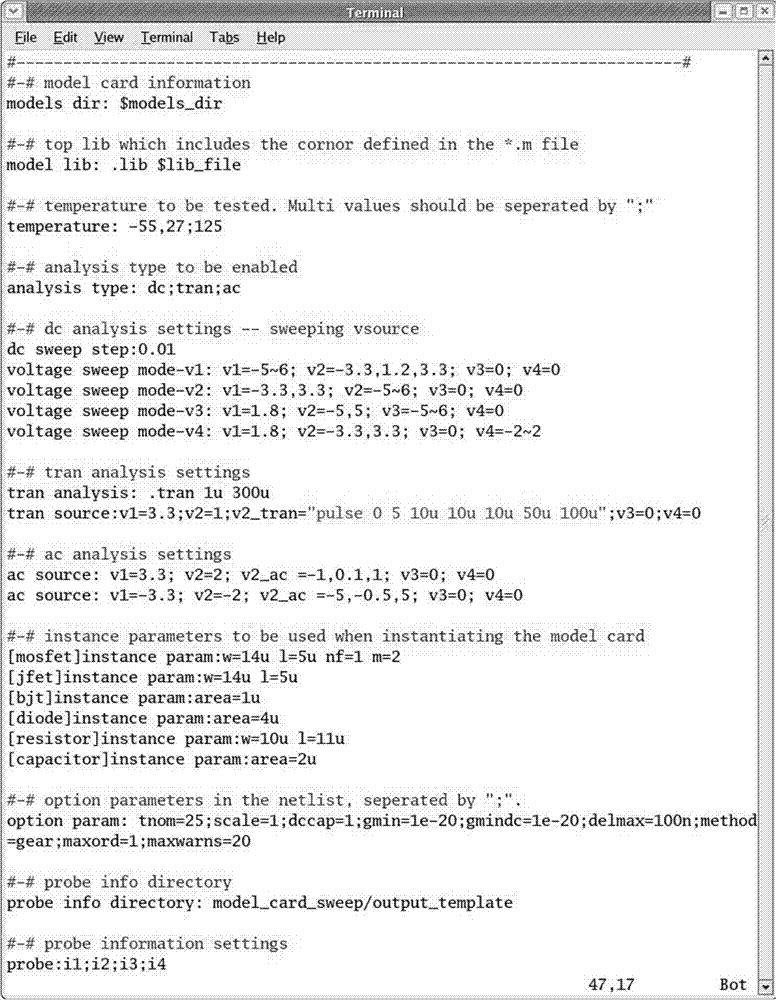

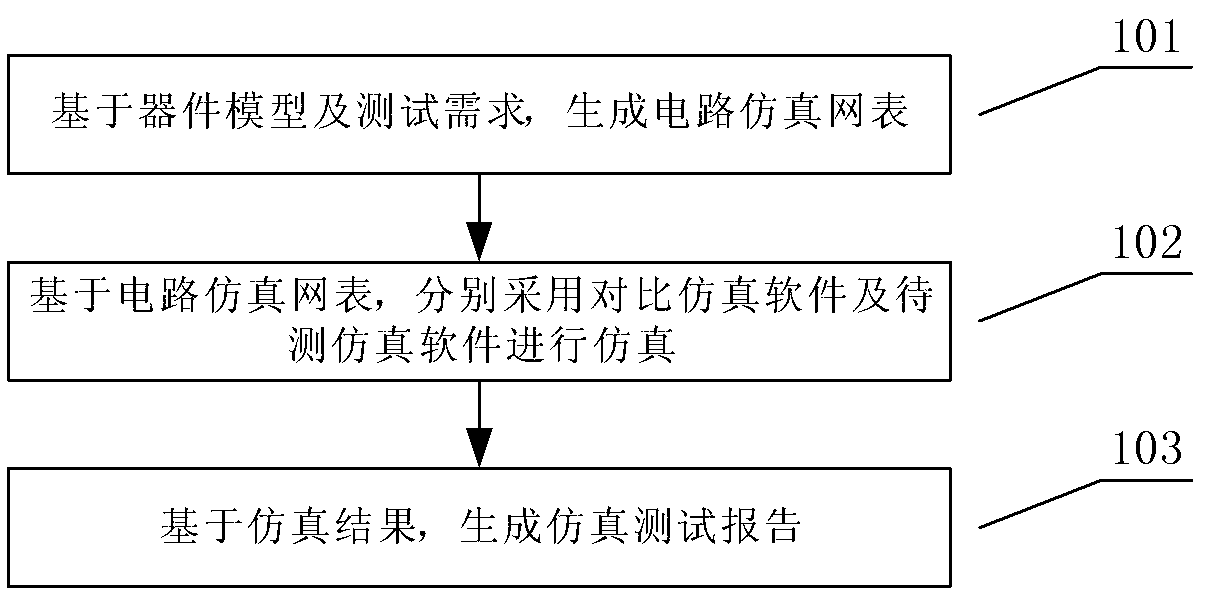

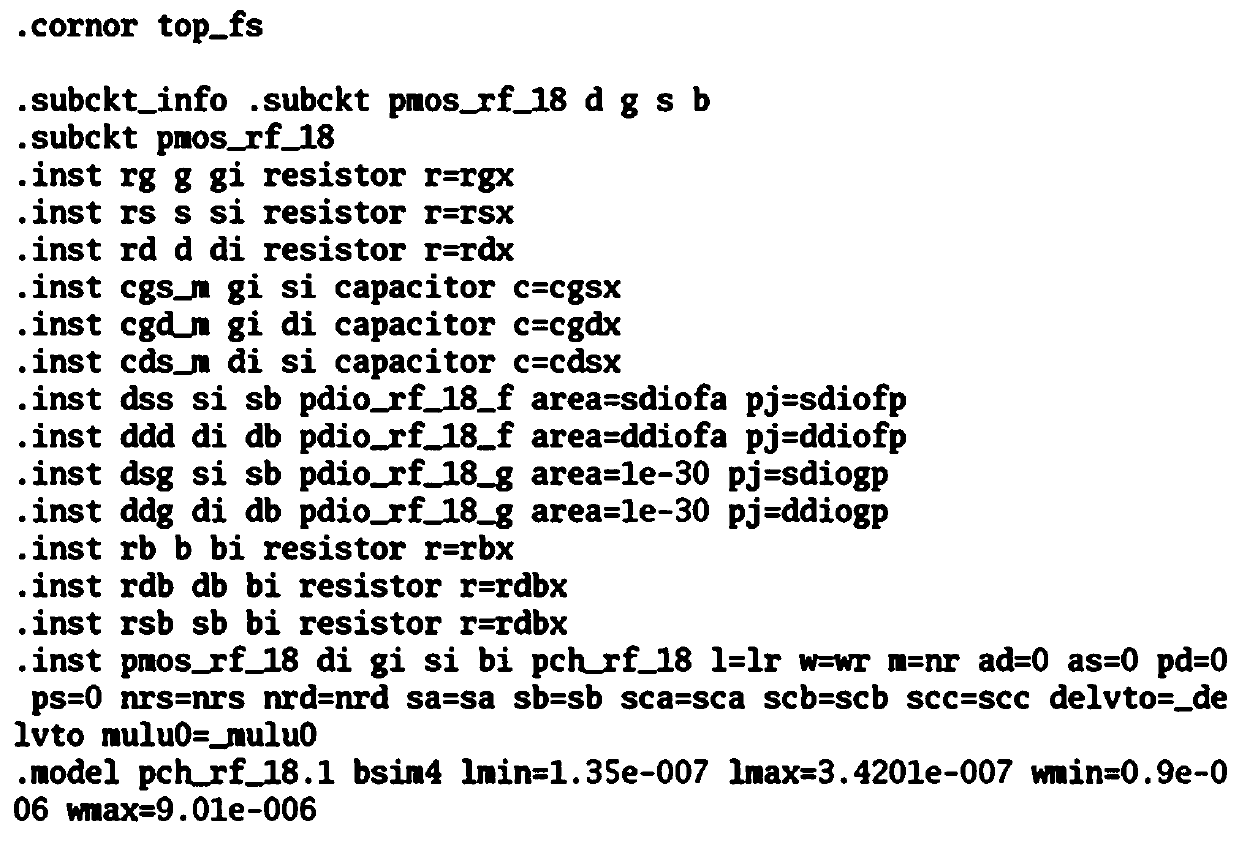

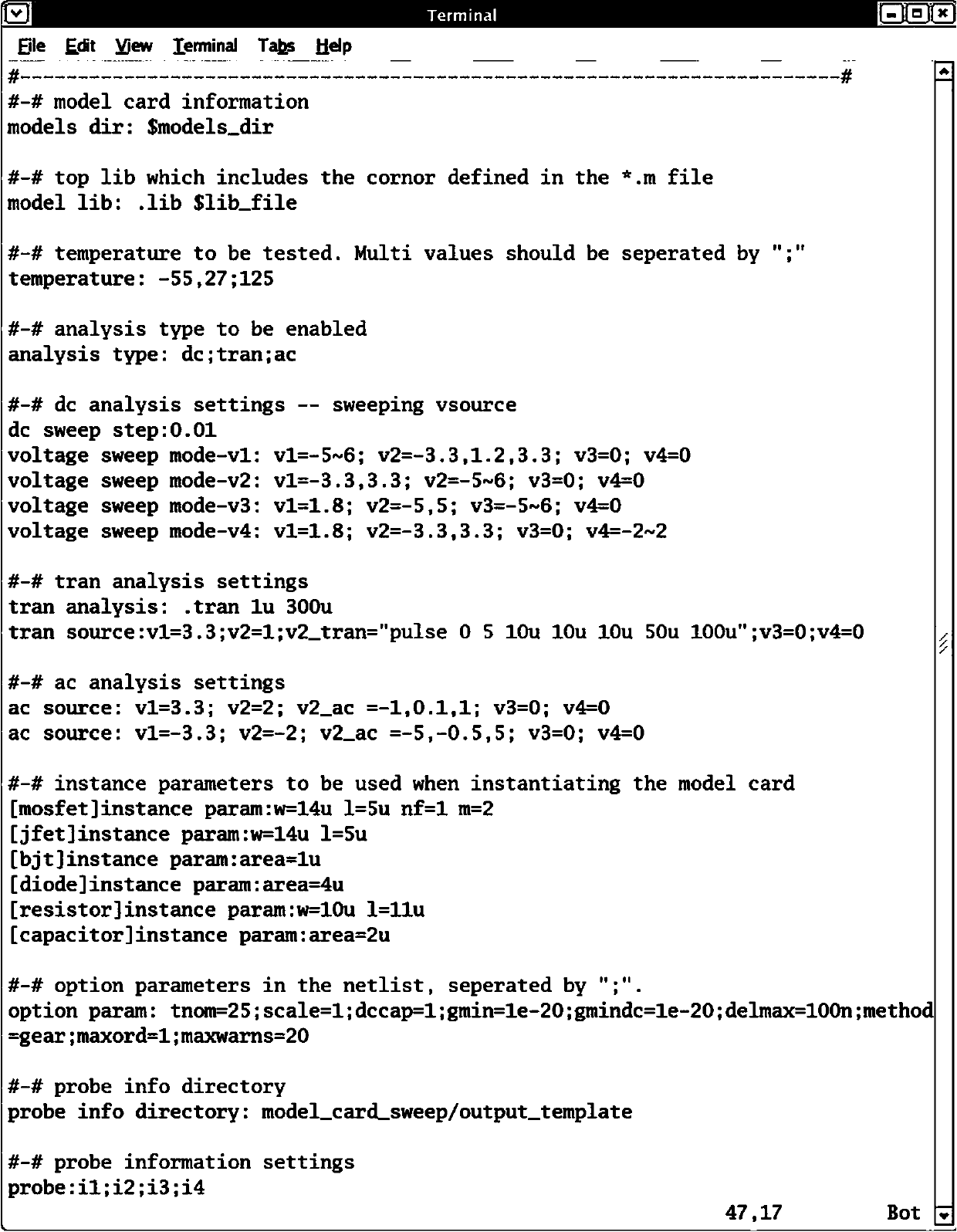

Method for testing correctness of device model simulation results

ActiveCN106934121AEasy to checkEfficient test methodSpecial data processing applicationsVisual testParallel computing

The invention provides a method for testing correctness of device model simulation results. The method comprises the following steps of: generating a circuit simulation netlist on the basis of a device model and a test demand; respectively carrying out simulation by adoption of comparative simulation software and to-be-tested simulation software on the basis of the circuit simulation netlist; and generating a simulation test result on the basis of the simulation result. The method for testing correctness of device model simulation results is an efficient and visual test method; according to the method, a most basic device model building circuit is simulated; and the method is compared with a gold analysis tool to generate a result report which is easy to check, so that simulation software engineers are helped to rapidly and conveniently check the result of supporting the device model by the simulation software so as to save the debugging cost, and circuit design engineers of design companies are helped to rapidly assess whether the support, for the device model, of new simulation software is consistent with the support, for the device model, of the existing simulation software or not so as to save the assessment cost.

Owner:北京华大九天科技股份有限公司

Method for on-line detection of coagulation bath concentration in production of polyacrylonitrile strands for carbon fibers

InactiveCN101871887AImprove timelinessFast test methodPhase-affecting property measurementsChemistryStandard curve

The invention relates to a method for the on-line detection of coagulation bath concentration in the production of polyacrylonitrile strands for carbon fibers, which comprises the following steps: 1) preparing a dimethyl sulfoxide standard solution; 2) manufacturing a standard curve equation; 3) connecting devices; 4) carrying out on-line detection; and 5) calculating the concentration. The invention solves the technical problems that the existing coagulation bath concentration detecting method is time-consuming, the detection result is inaccurate and the on-line detection can not be realized. Besides, the invention is beneficial to improving the timeliness, the dynamic nature and the accuracy of the concentration control of dimethyl sulfoxide in the coagulation bath. The detecting method is fast, accurate and visual, and is suitable for automatic production.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

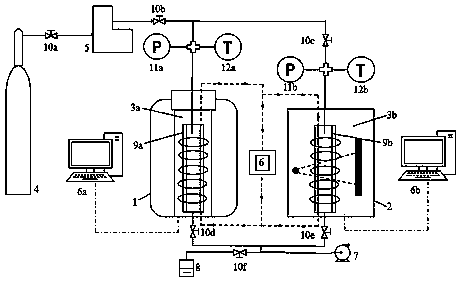

Device and method for measuring minimum miscible pressure of oil gas by comprehensive NMR and CT scanning

InactiveCN110261266AImprove experimental precisionRealize dynamic visual analysisMaterial analysis using wave/particle radiationSurface/boundary effectNMR - Nuclear magnetic resonanceCt scanners

The invention provides a device and a method for measuring the minimum miscible pressure of oil gas by comprehensive NMR and CT scanning, and simultaneously adopts a nuclear magnetic resonance imager and a CT scanner to measure the minimum miscible pressure of oil gas at different temperatures, thereby achieving the visualization of the transfer process of substances mutually dissolved by oil gas, revealing the equilibrium law of oil gas phase, and comprehensively considering the measurement results of the nuclear magnetic resonance imager and the CT scanner, so that the experimental precision is higher; and moreover, the measuring method can visually and nondestructively measure the minimum miscible pressure of the oil gas, has operability and repeatability, and can accurately and quickly measure the minimum miscible pressure of the oil gas.

Owner:SOUTHWEST PETROLEUM UNIV

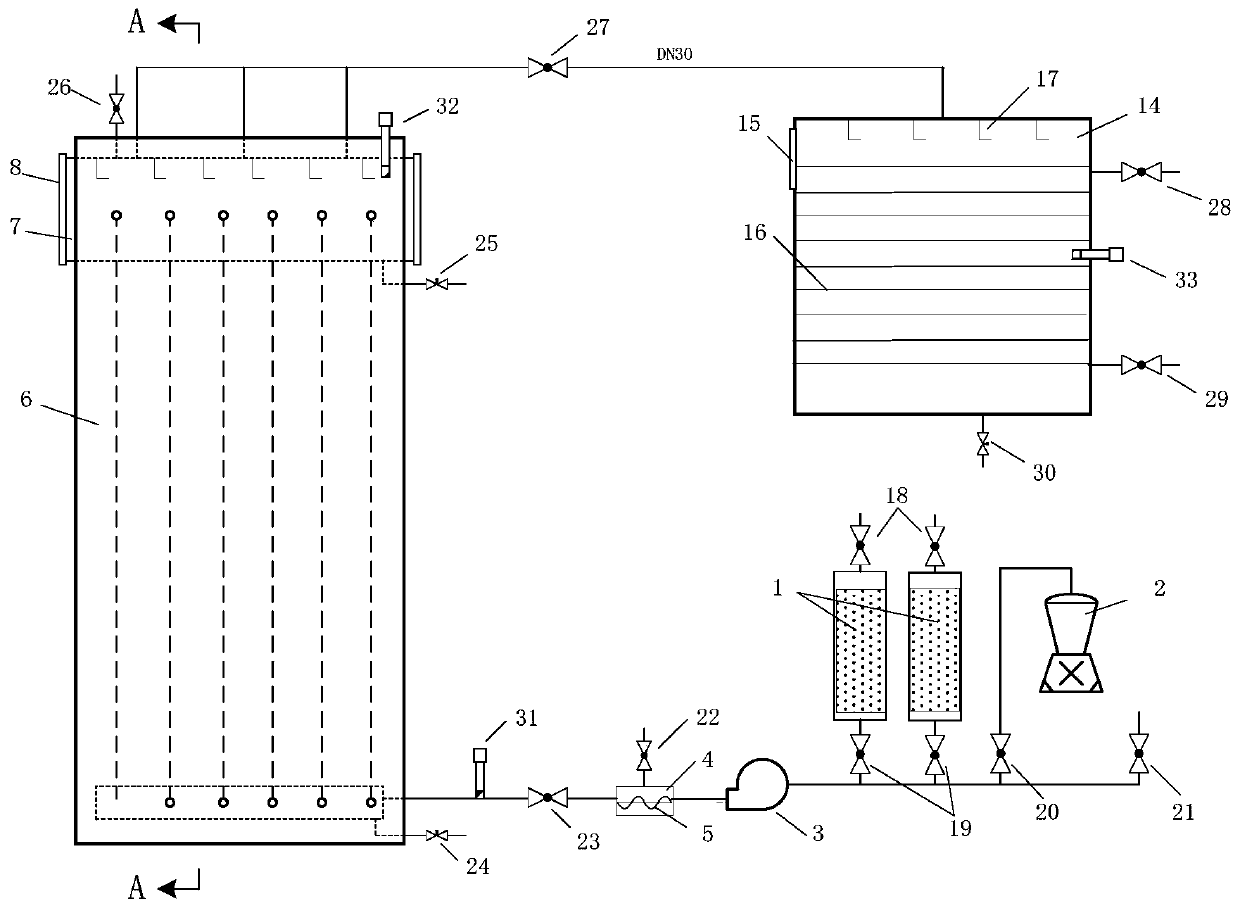

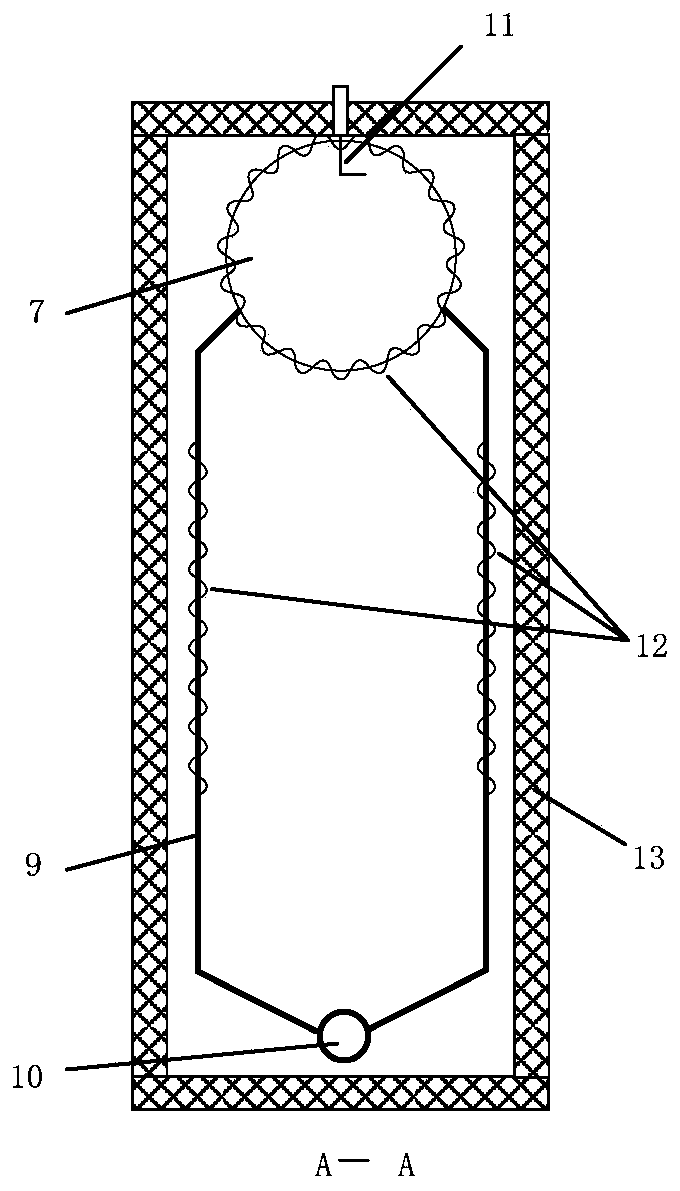

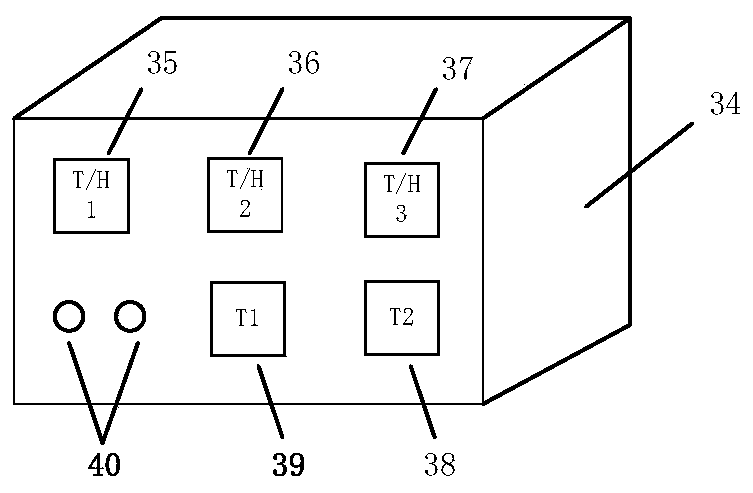

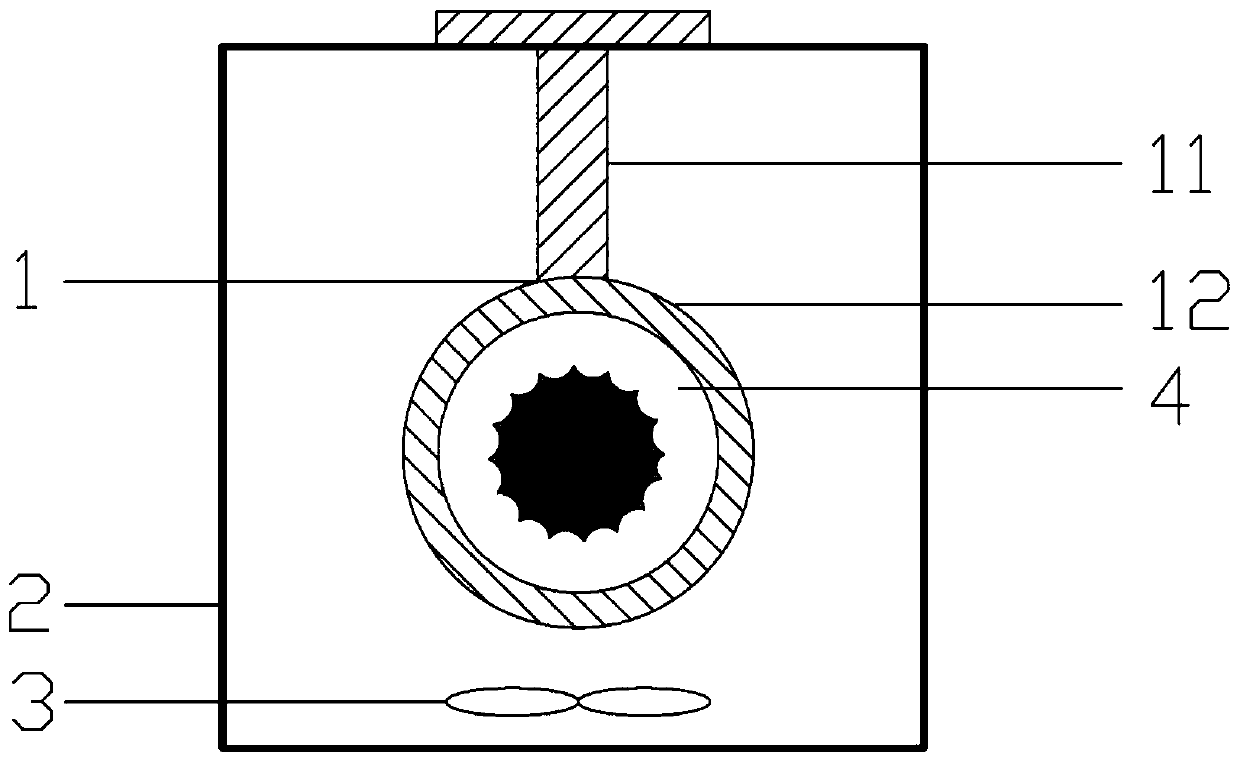

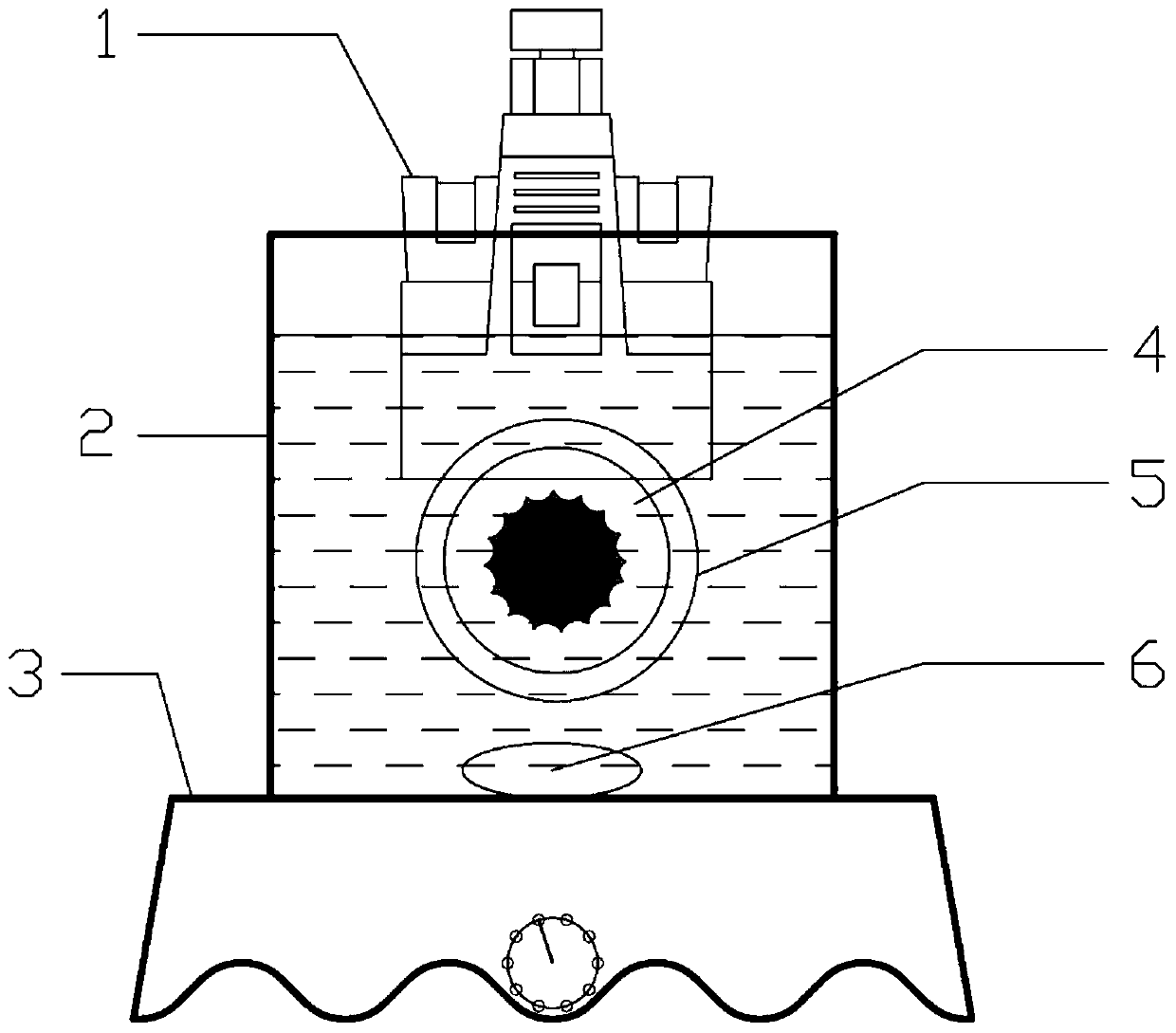

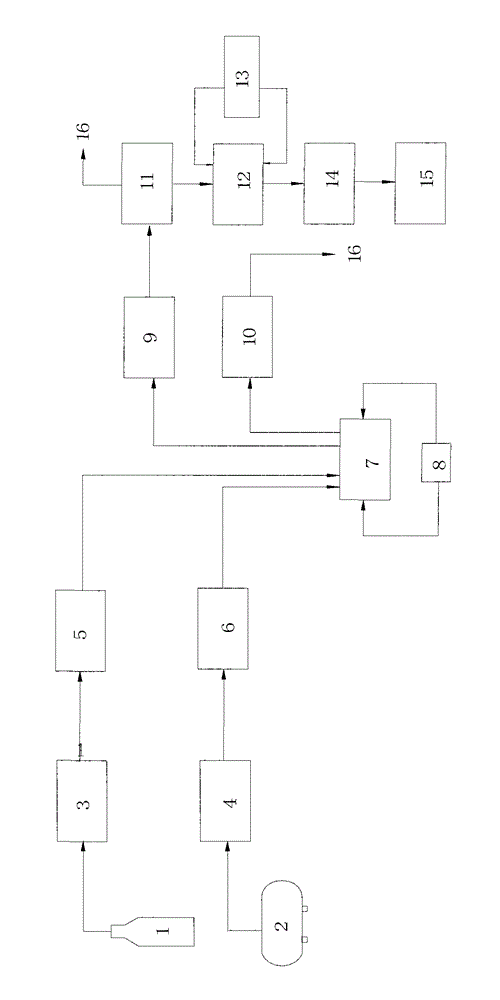

Simulation test device for shutdown corrosion of thermal equipment

PendingCN110361321ASimple test methodIntuitive test methodWeather/light/corrosion resistanceAir pumpEngineering

The invention discloses a simulation test device for shutdown corrosion of thermal equipment. The simulation test device comprises an air dryer, an air humidifier, an air pump, a dosing tank, a boilermodel and a condenser model. The dryer and the humidifier are installed side by side at the inlet of the air pump. The relative humidity inside the test device can be controlled by adjusting a proportion of wet air to dry air. The air pump, the dosing tank, the boiler model, and the condenser model are sequentially connected in series by a pipe; ventilation of the dosing tank, the boiler model and the condenser model is realized by the air pump. A volatile vapor phase corrosion inhibitor is arranged in the dosing tank; the volatilized agent is transported to the inside of the boiler model byair carrying. According to the invention, the internal temperature and humidity environment and the water accumulation environment of the thermal system equipment after shutdown can be simulated; theresearch on the corrosion law of the thermal equipment shutdown is carried out; and thus the basis is provided for making the shutdown corrosion protection strategy.

Owner:HANGZHOU E ENERGY ELECTRIC POWER TECH +3

Online testing method for oil solution concentration of polyacrylonitile production used in carbon fiber

ActiveCN101017136AImprove timelinessImprove dynamic performancePhase-affecting property measurementsCarbon fibersOnline test

This invention belongs to measurement technique and relates to one carbon fiber polyacryl-nitrile protofilament process oil agent concentration online test method, which is characterized by the following: it uses series oil agent work pool to feed materials tube or to exit pipe online reflection index meter for online test and comprises the steps as: getting oil agent concentration and reflection index or sugar degree standard curve; optimizing line equation; online testing.

Owner:WEIHAI TUOZHAN FIBER

Test method for evaluating decontamination effect of detergent

ActiveCN110118855AIntuitive test methodFast test methodColor/spectral properties measurementsProteinase activityEngineering

The invention discloses a test method for evaluating decontamination effect of a detergent. The test method comprises the following steps of 1) contaminating the surface of the fabric with contaminants to produce a contaminated fabric contaminated with stains; 2) preparing washing devices including a fixing member, a stirrer and a washing container; 3) adding water and the detergent to be tested to the washing container of the washing device for stirring and mixing to obtain a detergent solution; and 4) fixing the contaminated fabric in the washing container by the fixing member of the washingdevices such that the detergent solution immerses the contaminated fabric, carrying out stirring and washing, and observing the stain change of the contaminated fabric to evaluate the decontaminationeffect of the detergent. The test method provided by the invention has the advantages of being intuitive, quick, simple to operate, easy to display and the like. By applying the test method providedby the invention, the decontamination ability of the detergent can be evaluated, the decontamination effect of the detergent can be demonstrated, and the effect of the detergent claiming to contain protease and amylase can be preliminarily evaluated.

Owner:GUANGZHOU BLUE MOON IND

Testing method for corrosion resistance of magnesia carbon bricks by adopting small intermediate-frequency furnace

InactiveCN107290271ASimple test methodIntuitive test methodWeather/light/corrosion resistanceIntermediate frequencySlag

The invention discloses a testing method for corrosion resistance of magnesia carbon bricks by adopting a small intermediate-frequency furnace. A sample is cut into a long strip and bound to the peripheral surface of a mold core after original size is recorded, and a mold is assembled; a crucible is prepared through casting with a corundum material, maintenance and drying; a steel block is added for low-temperature baking of the intermediate-frequency furnace after the crucible is fixed in an induction coil of the intermediate-frequency furnace; after the steel block is molten, a certain amount of slag is added, the temperature in the furnace is controlled at 1680 DEG C plus / minus 30 DEG C, counting starts when the slag is molten completely, and molten steel and the slag are poured out after heat is preserved for 120 min; the crucible is taken out after being completely cooled and is cut transversely along an corrosion line, and corrosion thickness at the corrosion line is measured and compared with the original size; the crucible is knocked open, the sample is taken out and subjected to material change analysis microscopically. The testing method is simple and direct and has guiding significance in production, research and development work, and advantages and disadvantages of slag corrosion resistance of work-layer refractory material products adopting different technical formulae and applied to the magnesia carbon bricks or steel ladles can be compared by simulating conditions of actual work sites.

Owner:ZHENGZHOU ZHENDONG TECH

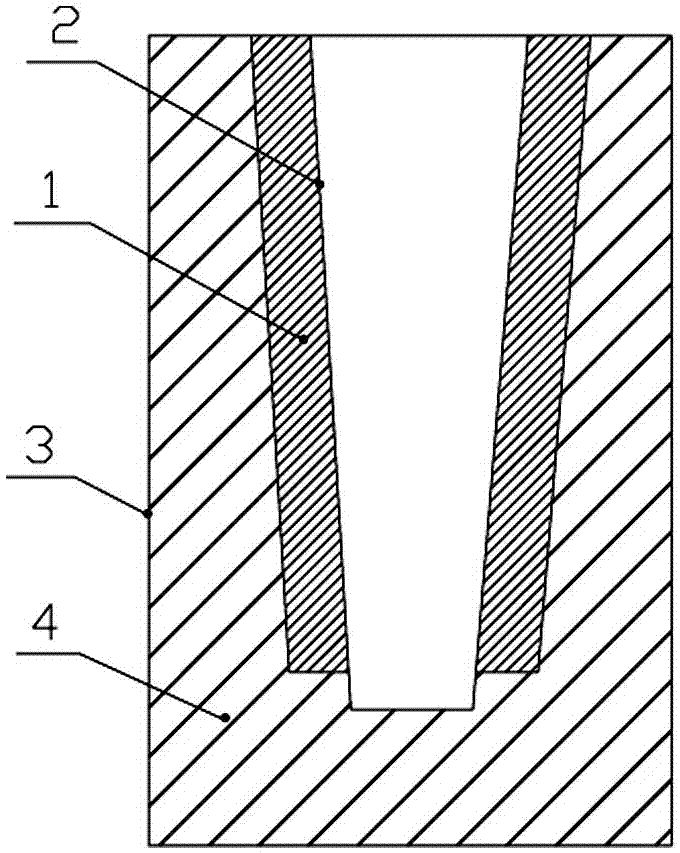

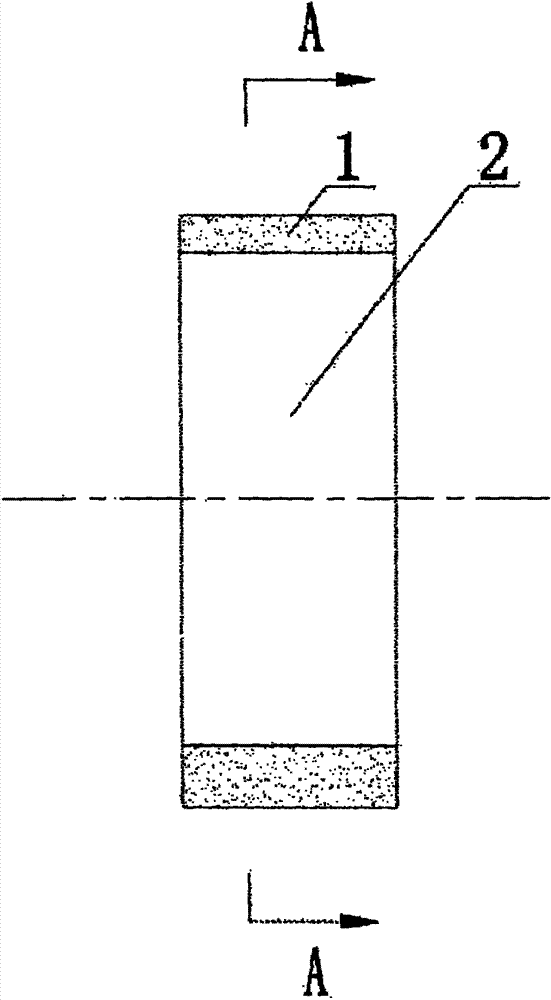

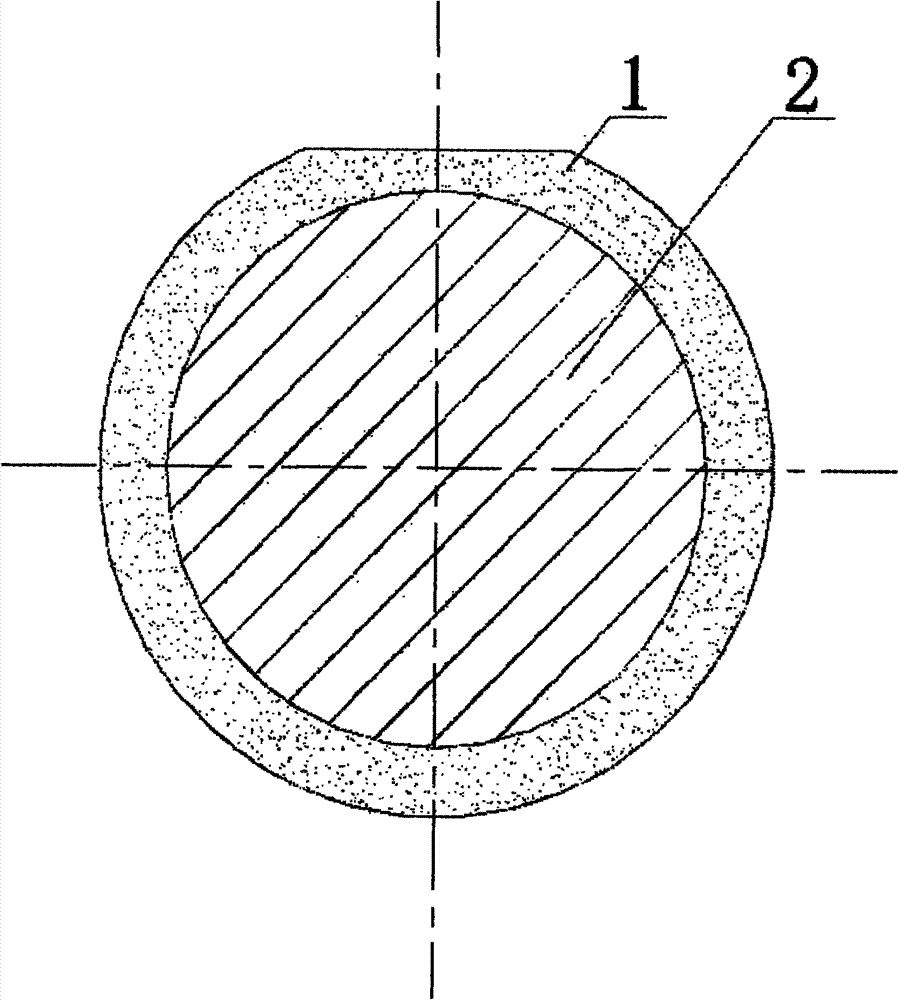

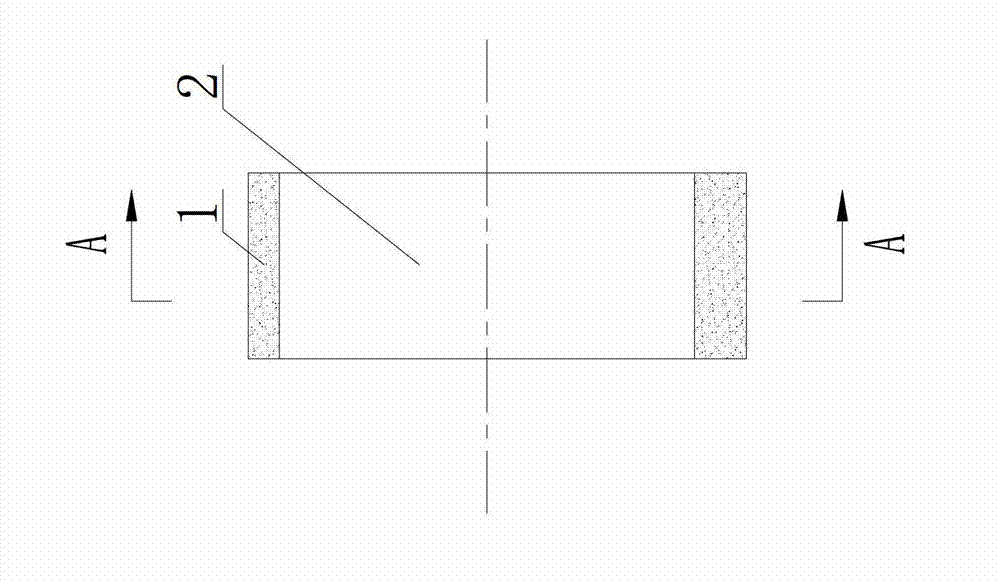

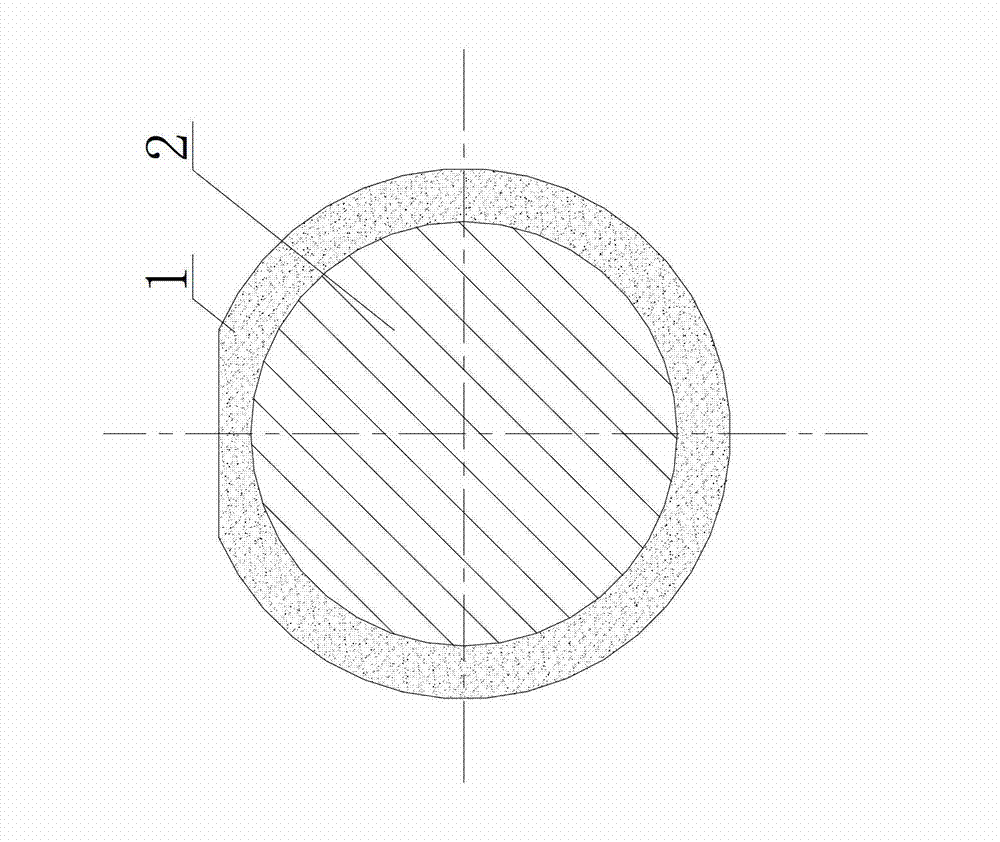

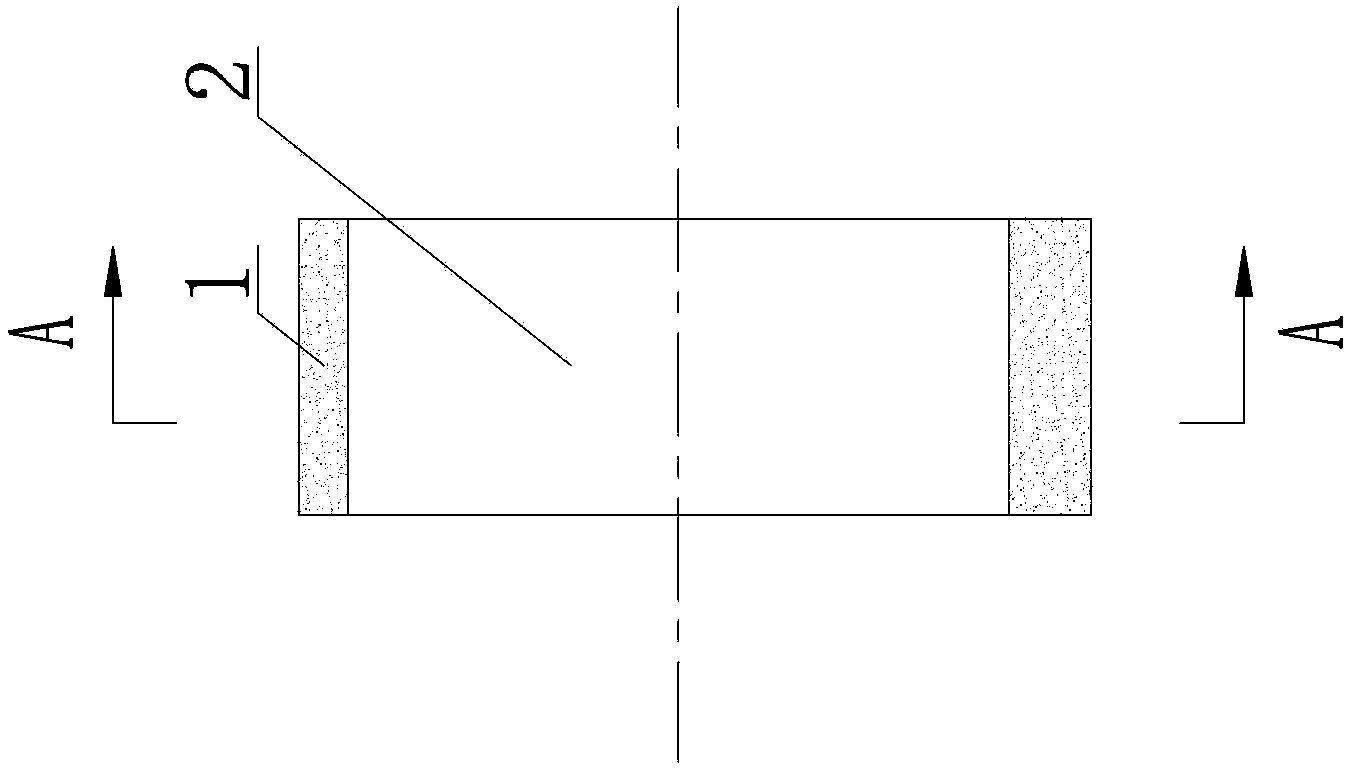

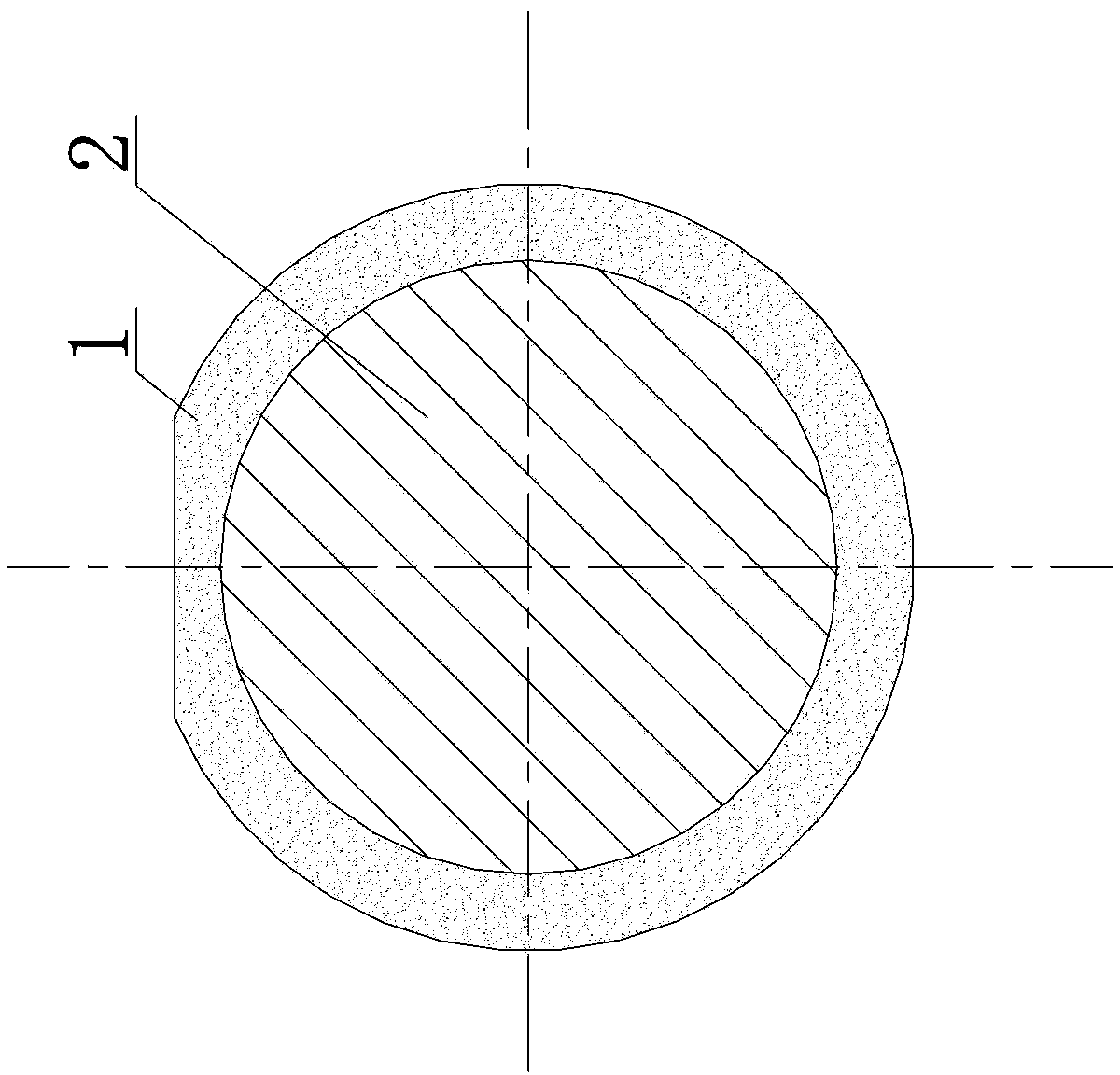

Compressive strength testing method of shaft

InactiveCN103808566ASimple test methodIntuitive test methodMaterial strength using tensile/compressive forcesOperabilityUltimate tensile strength

The invention relates to a compressive strength testing method of a shaft. The range of pressure capable of breaking a workpiece can be determined by loading workpieces step by step; then the pressure value for breaking is determined precisely by a bisection method. The compressive strength testing method of the shaft has the advantages of simplicity, convenience, intuition, high operability, data reliability and accuracy and the like.

Owner:YUYAO DIANBO MACHINERY

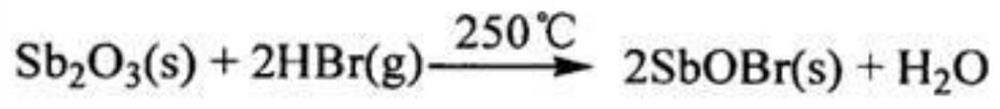

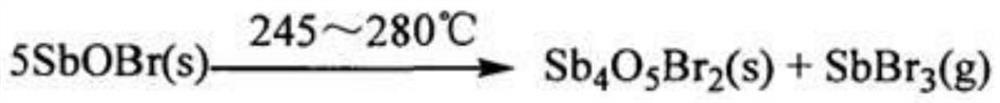

Efficient flame-retardant master batch for high-density polyethylene

InactiveCN111662502ASmall particle sizeGood compatibilityFlame-proof filament manufactureMonocomponent polyolefin artificial filamentElastomerPolymer science

The invention provides an efficient flame-retardant master batch for high-density polyethylene. The efficient flame-retardant master batch is prepared from components through a double-screw extruder,and the components comprise, by weight, 28-34 parts of a powdery polyolefin elastomer, 65-70 parts of a compound flame retardant, 0.5-1 part of an auxiliary agent and 0.5-1 part of a coupling agent; the coupling agent is an aluminate coupling agent; and the auxiliary agent is an antioxidant. According to the efficient flame-retardant master batch for the high-density polyethylene, the flame retardant adopted in the formula is a compound flame retardant of decabromodiphenyl ethane and antimonous oxide, the bromine-antimony ratio is 1: 1.055, and the proportion is accurate and reasonable; and all the components in the formula have a synergistic effect, so that a very good flame-retardant effect can be achieved under the condition of a very small addition amount. The efficient flame-retardantmaster batch is applied to spinning and film blowing production of HDPE materials under the condition of hardly influencing mechanical properties; and the preparation method is simple, the used equipment is a common water brace twin-screw extruder with very wide applicability, and large-scale production is easy to realize.

Owner:太仓市华鼎塑料有限公司

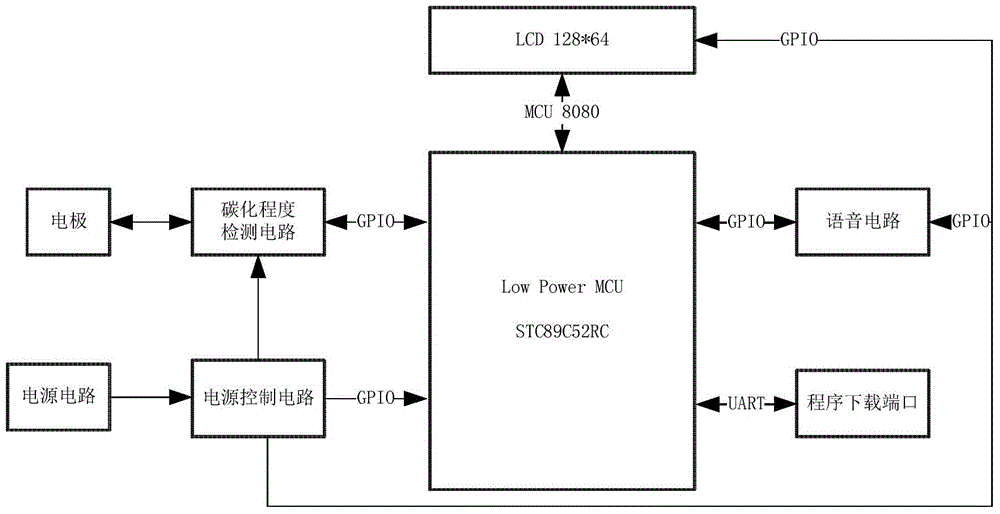

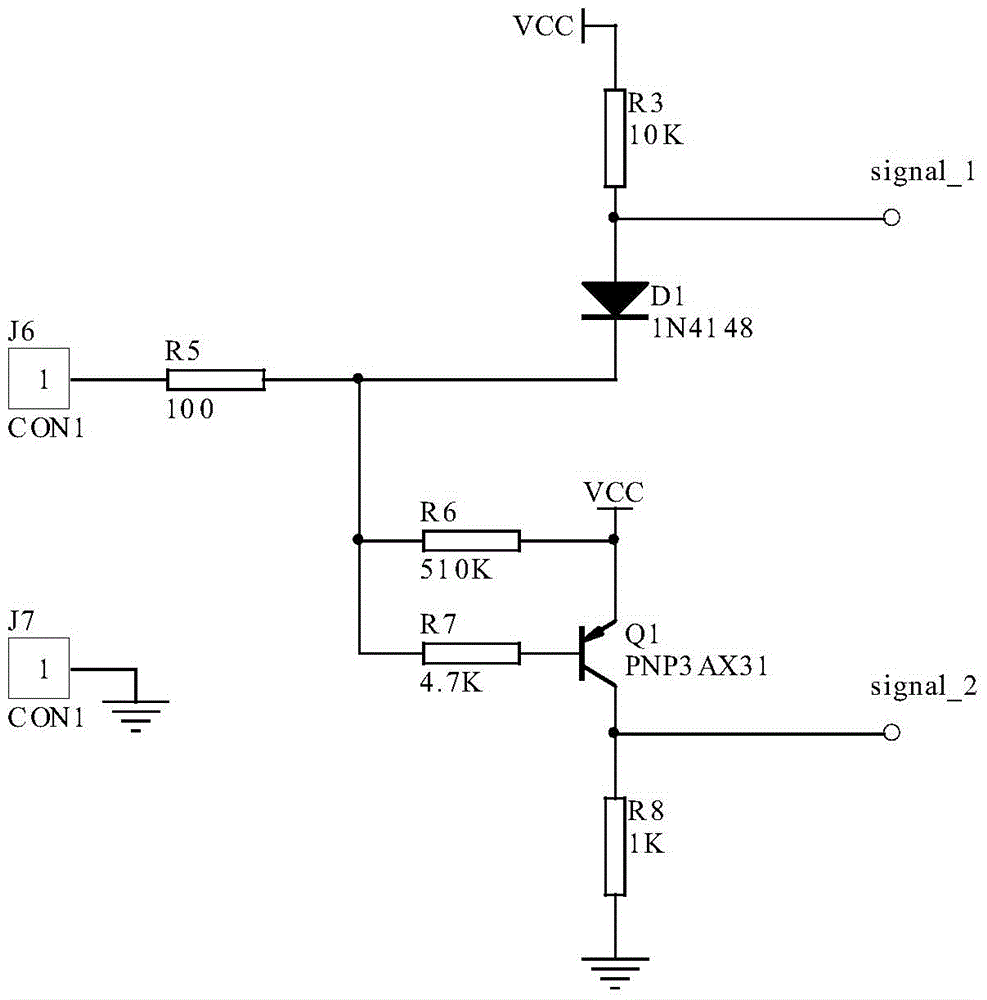

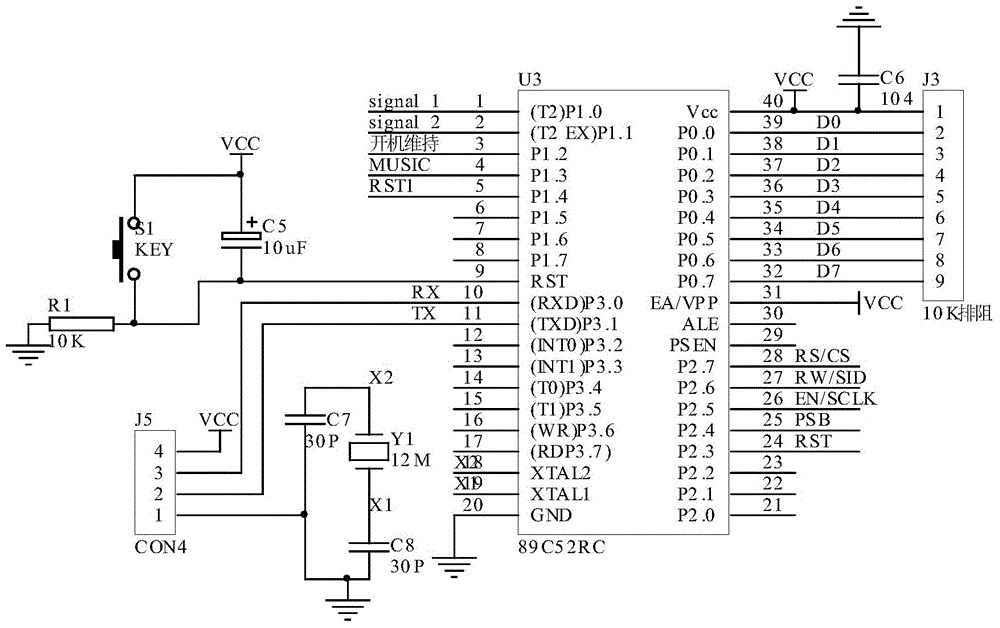

Bamboo charcoal carburization degree testing device

ActiveCN104833706ASimple test methodIntuitive test methodMaterial resistancePower circuitsElectric signal

The invention discloses a bamboo charcoal carburization degree testing device. The bamboo charcoal carburization degree testing device comprises a processor module, a carburization degree detecting circuit, a power circuit and an outputting circuit, wherein the carburization degree detecting circuit, the power circuit and the outputting circuit are respectively connected with the processor module; the carburization degree detecting circuit detects signals of bamboo charcoal to be tested and transmits the signals of the bamboo charcoal to be tested to the processor module to be sampled; the processor module controls an outputting result of the outputting circuit according to a processing result; and the power circuit is respectively connected with the carburization degree detecting circuit and the outputting circuit and respectively provides electric signals for the processor module, the carburization degree detecting circuit and the outputting circuit. By the bamboo charcoal carburization degree testing device, whether the bamboo charcoal is subjected to carburization treatment or not and the carburization degree of the bamboo charcoal can be tested visually. The bamboo charcoal carburization degree testing device is convenient to use.

Owner:厦门市欣泰康环境科技有限公司

Compressive strength test method for surface strengthening layer and substrate of axial part

ActiveCN103048196ASimple test methodIntuitive test methodPreparing sample for investigationMaterial strength using tensile/compressive forcesOperabilityUltimate tensile strength

The invention relates to a compressive strength test method for the surface strengthening layer and the substrate of an axial part. The method comprises the following steps: loading workpieces step by step to determine the pressure range for realizing damage on the workpieces, and then adopting a bisection approach method to precisely determine the pressure value for realizing damage. The method is simple, convenient and intuitive and has the advantages of strong operability reliable and accurate data and the like.

Owner:TIANJIN ENG MACHINERY INST

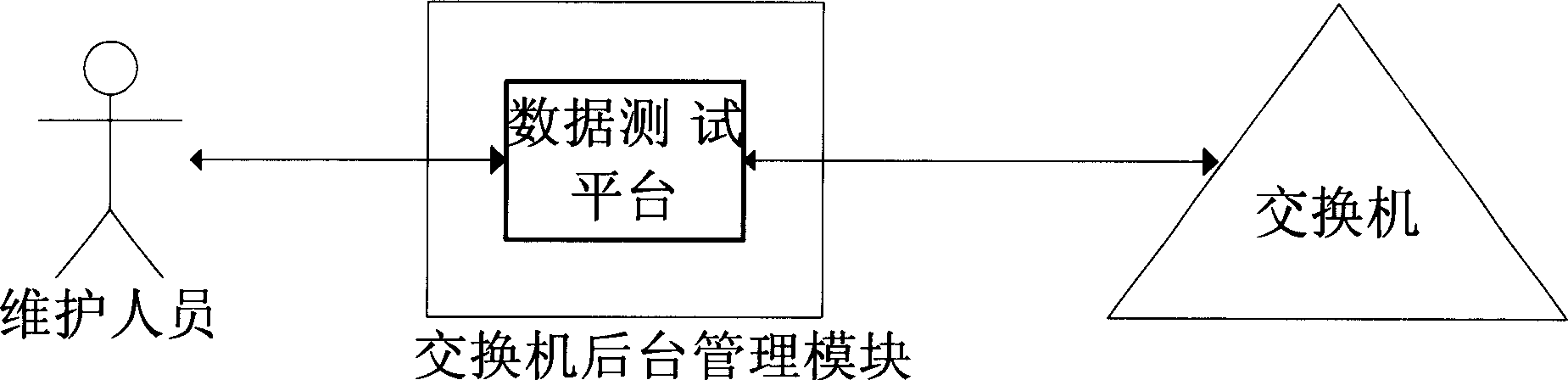

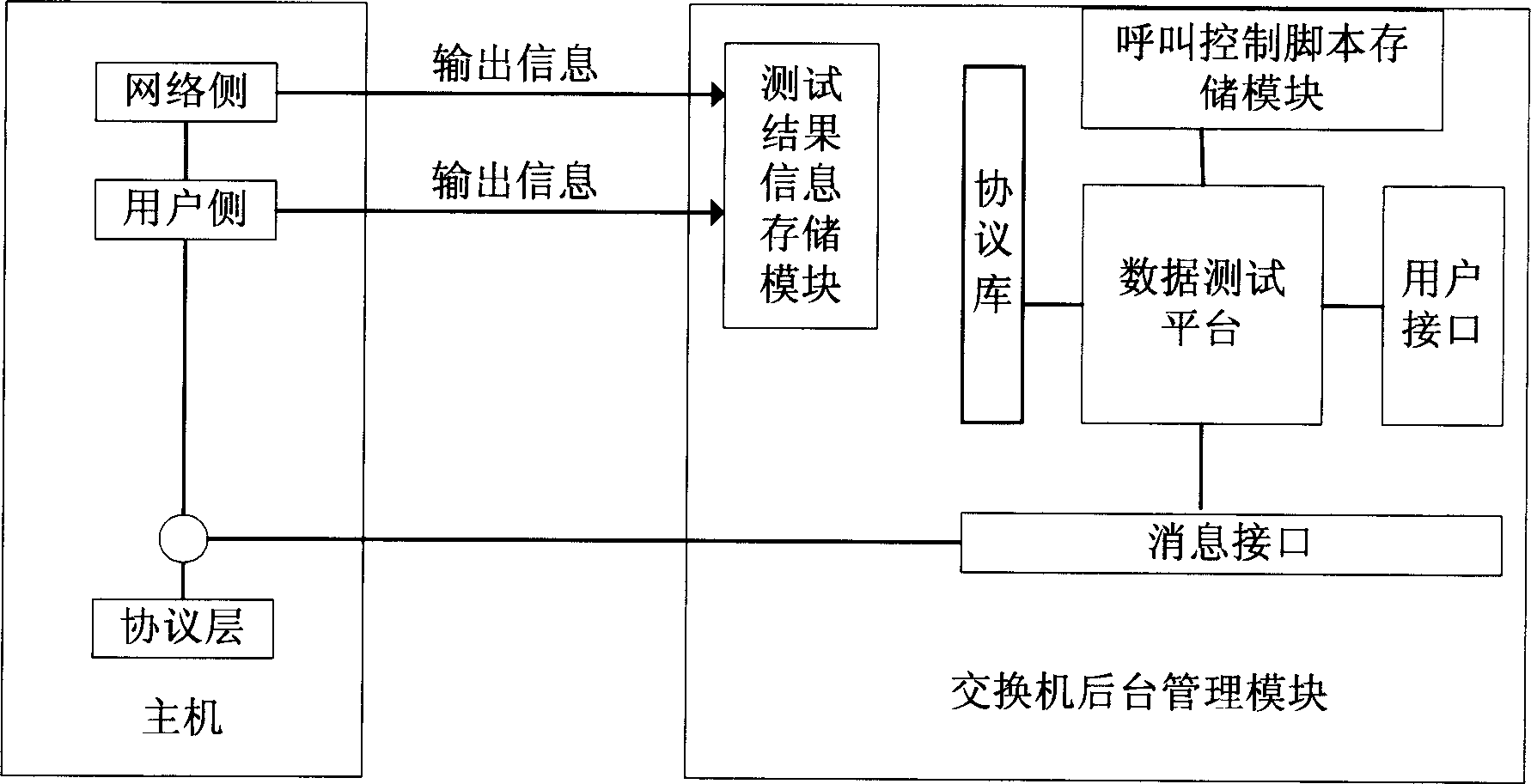

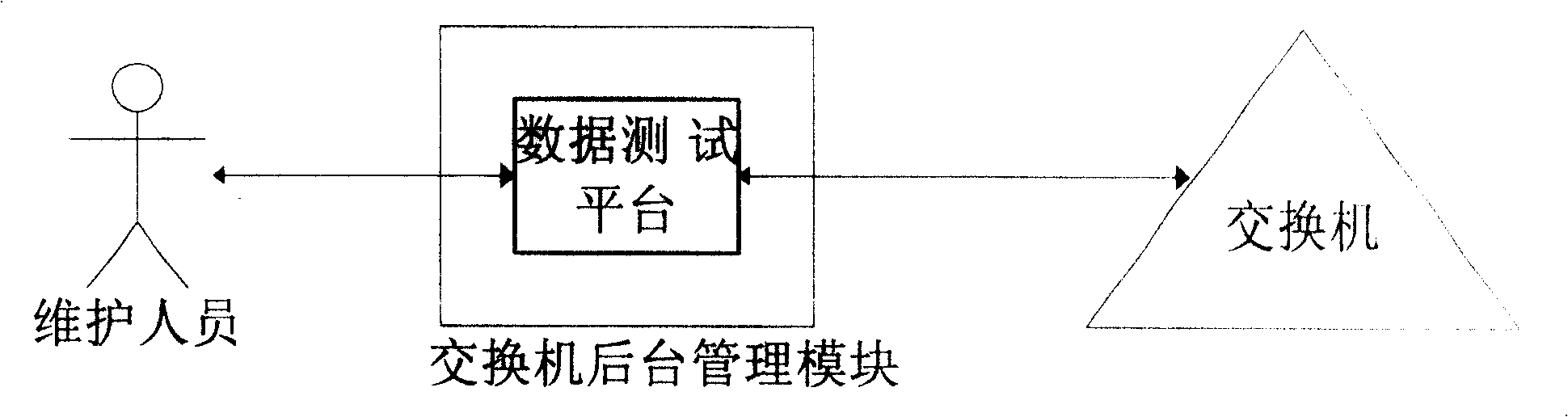

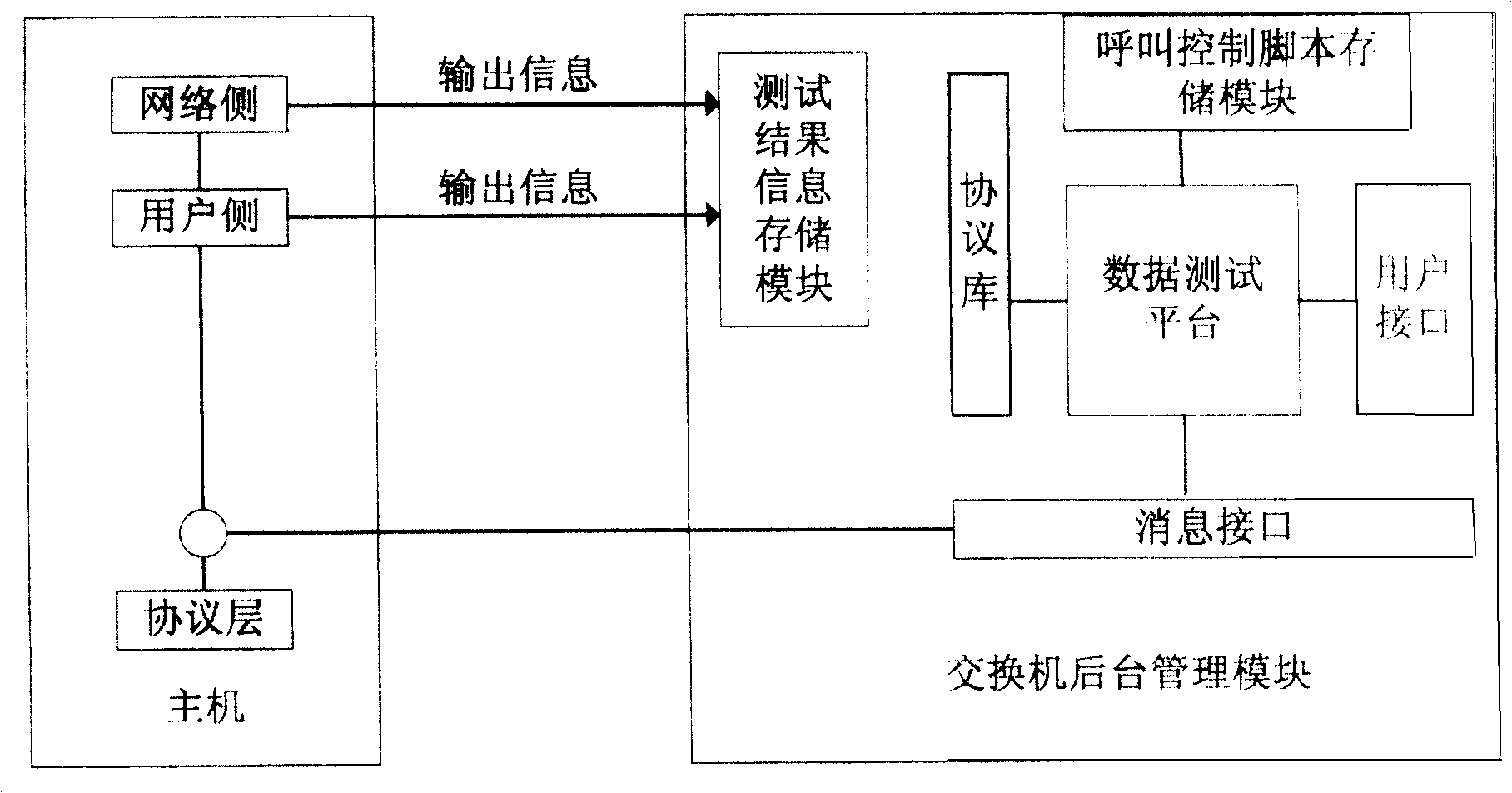

Exchange data testing system and method

InactiveCN1870548AIntuitive test methodSimple test methodData switching networksComputer hardwareTest order

This invention relates to a exchange data test system and a method, in which, the system includes: a data test platform, an information interface, a protocol library, a call control script storage module, a user interface and a storage module for storing test result information, said method includes the following steps: A, a maintenance person sends data test order to a switch by a data test platform, B, the switch receives the test order sent by the test platform and sends starting up test response to the data test platform, C, the data test platform receives the confirmation response for starting up the test sent by the data test platform to structure the start up call information and sends it to the switch, D, the switch receives the information and interacts information with the data test platform, E, the maintenance person analyzes the information sent by the switch.

Owner:HUAWEI TECH CO LTD

Online testing method for oil solution concentration of polyacrylonitile production used in carbon fiber

ActiveCN101017136BImprove timelinessImprove dynamic performancePhase-affecting property measurementsCarbon fibersOnline test

This invention belongs to measurement technique and relates to one carbon fiber polyacryl-nitrile protofilament process oil agent concentration online test method, which is characterized by the following: it uses series oil agent work pool to feed materials tube or to exit pipe online reflection index meter for online test and comprises the steps as: getting oil agent concentration and reflectionindex or sugar degree standard curve; optimizing line equation; online testing.

Owner:WEIHAI TUOZHAN FIBER

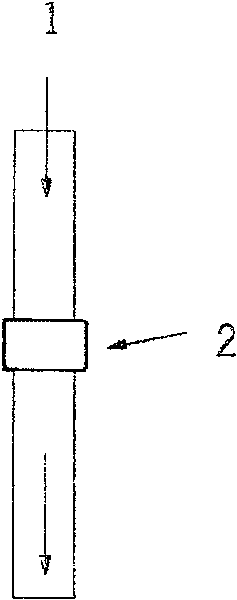

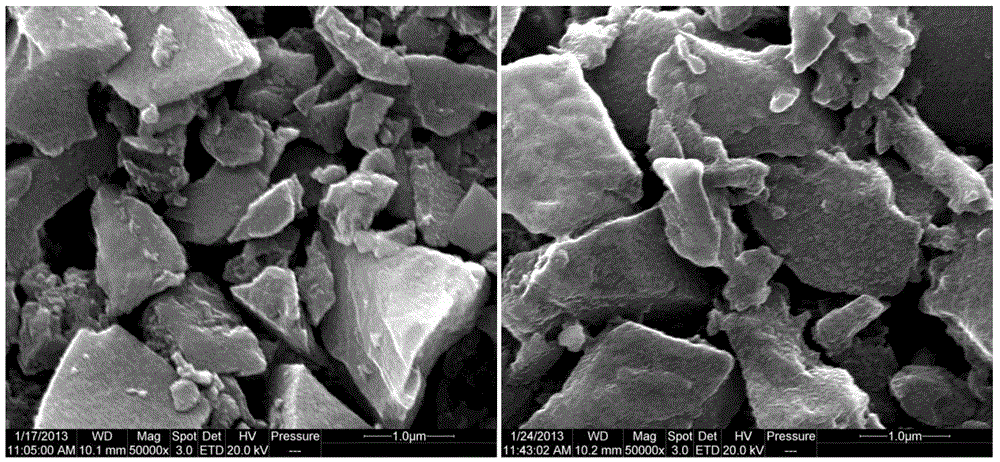

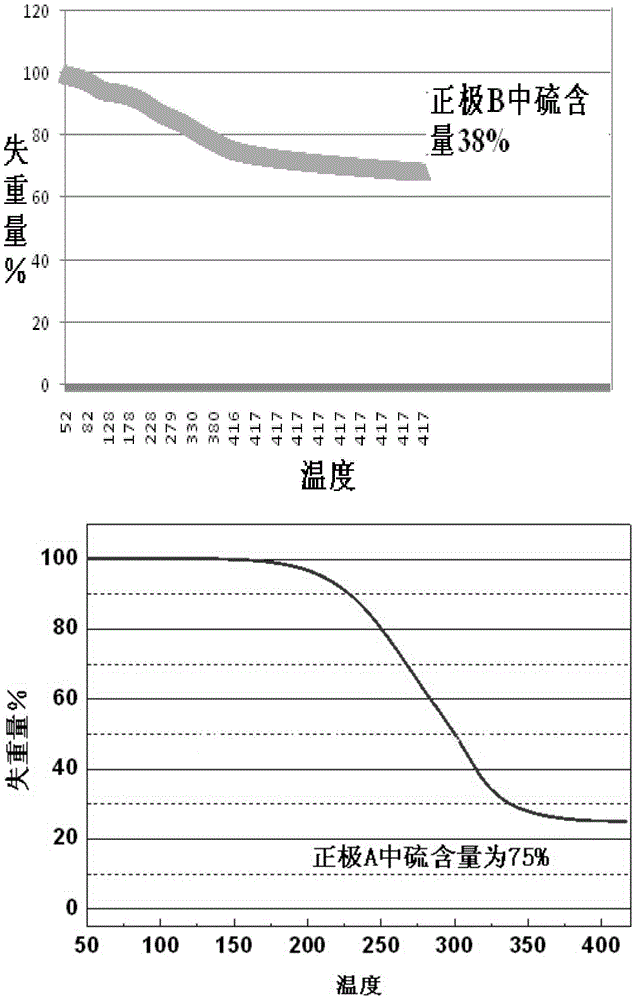

A detection method for the sulfur fixation performance of cathode materials for lithium-sulfur batteries

ActiveCN105319321BAchieving sulfur fixation capacityAccurately reflect the confinement effectMaterial analysisLithium–sulfur batterySulfur electrode

The invention relates to a detection method for the sulfur-fixing performance of a cathode material of a lithium-sulfur battery. The method adopts sulfur content testing equipment and a sulfur electrode shape change testing device to detect the dissolution and loss of elemental sulfur during battery operation. Put the positive electrode materials in different charging and discharging states during the cycle test into the sulfur content detection equipment to obtain the load of elemental sulfur in the positive electrode material in this state; at the same time, the electrode morphology testing device is used to detect the change of the electrode morphology, from the essence The sulfur fixation ability of the positive electrode material was obtained through the above characterization. The detection method can realize the in-situ characterization of the sulfur fixation ability of the cathode material, can accurately reflect the confinement effect of the material on the elemental sulfur, and has a simple, easy-to-control, and good repeatability testing process.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

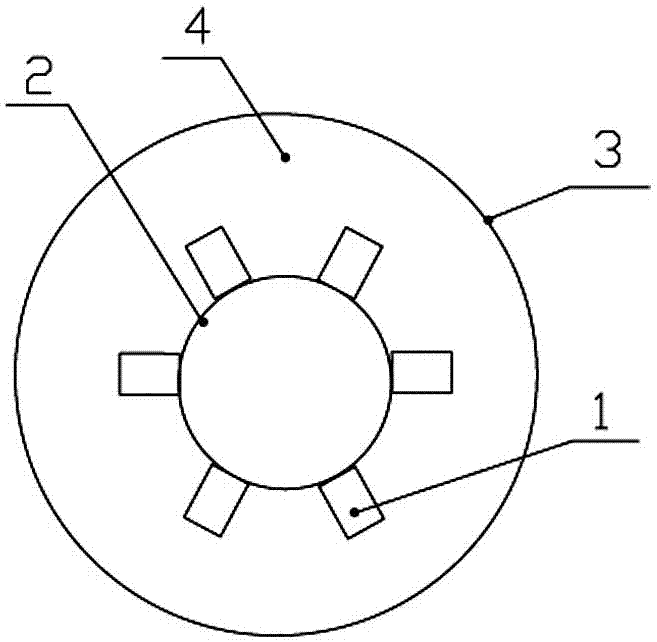

A method for diagnosing and controlling the out-of-control signal of a hydraulic turbine governor

ActiveCN103452746BAccurate calculationAvoid errorsHydro energy generationMachines/enginesProportion integration differentiationControl signal

The invention relates to hydraulic turbine governor out-of-control signal diagnosis and control methods. The diagnosis method is mainly based on electrical feedback signals acquired by a measuring unit of a hydraulic turbine governor; when the governor receives a command for opening or closing a guide vane, a difference value exists between control output, namely a target value that the guide vane needs to reach, and actual guide vane opening, and the difference value is higher than a set dead zone value; on normal conditions, a main distributing valve of the governor is controlled by PID (proportion integration differentiation) computation of a PLC (programmable logic controller) to be opened towards a target direction by a certain opening, and the guide vane is controlled to move towards the target direction; then periodical scanning is performed through a PLC program to read whether the opening of the guide vane moves towards the target direction or not and judge whether a movement speed meets the requirement for governing computation on-off time or not, and if a change value, read within a certain delay time, of the guide vane opening does not reach a change rate towards the target direction, the governor is judged to be out of control, and safety of a generator set is protected.

Owner:STATE GRID CORP OF CHINA +1

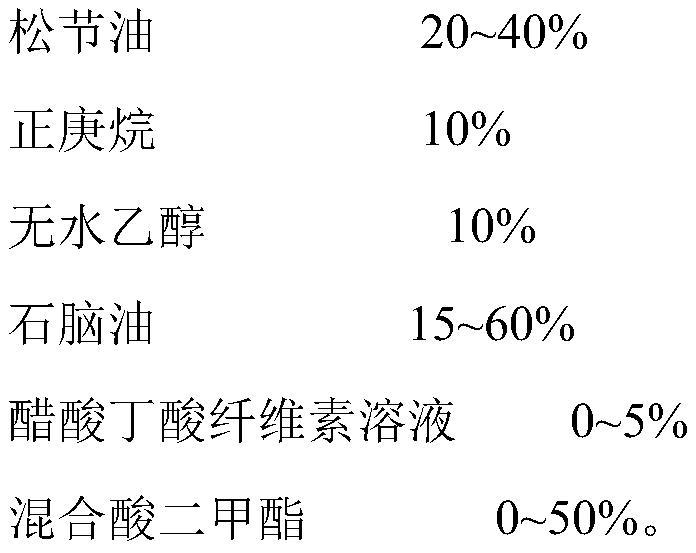

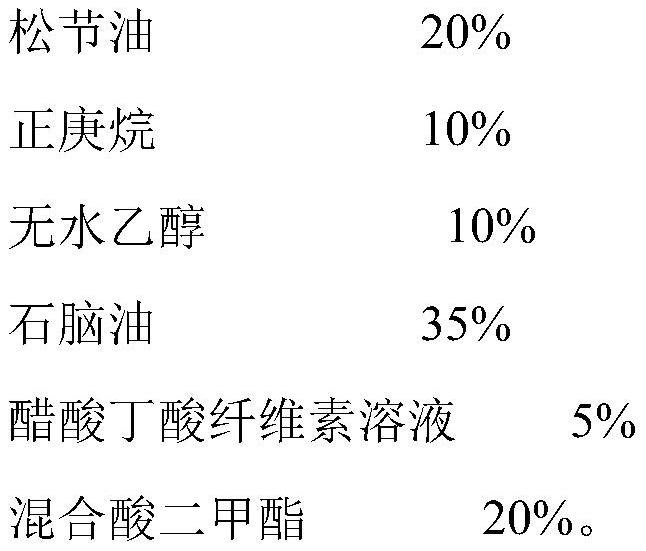

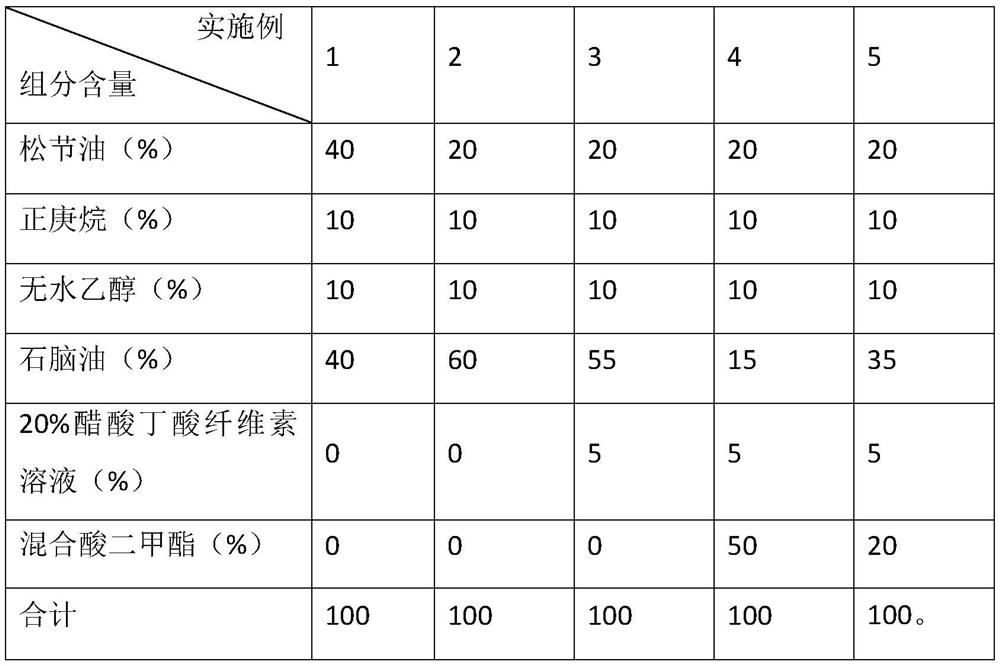

A cleaning agent for postage stamp back glue

ActiveCN111454789BClean completelyEasy to useColor measuring devicesDetergent mixture composition preparationCelluloseTurpentine

The invention provides a high-performance stamp gum cleaning agent, which comprises the following components by weight: turpentine 20-40%, n-heptane 10%, absolute ethanol 10%, naphtha 15-60%, butyl acetate Acid cellulose solution 0~5%, mixed acid dimethyl ester 0~50%. The high-performance cleaning agent for stamp gum of the present invention adopts cellulose acetate butyrate as a film-forming substance, naphtha as a main solvent, absolute ethanol, n-heptane, and turpentine as an auxiliary solvent. The solvent with naphtha as the main component will quickly penetrate into the gap between the stamp and the envelope, and reach the glue film to separate the glue film from the back of the stamp. At this time, the glue film can be peeled off quickly; at the same time, the film-forming substance can also keep the stamp. Glossiness and saturation of pattern colors are not affected. The preparation method of the high-performance stamp back glue cleaning agent of the invention is simple and convenient to use.

Owner:SUZHOU CHIEN SHIUNG INST OF TECH

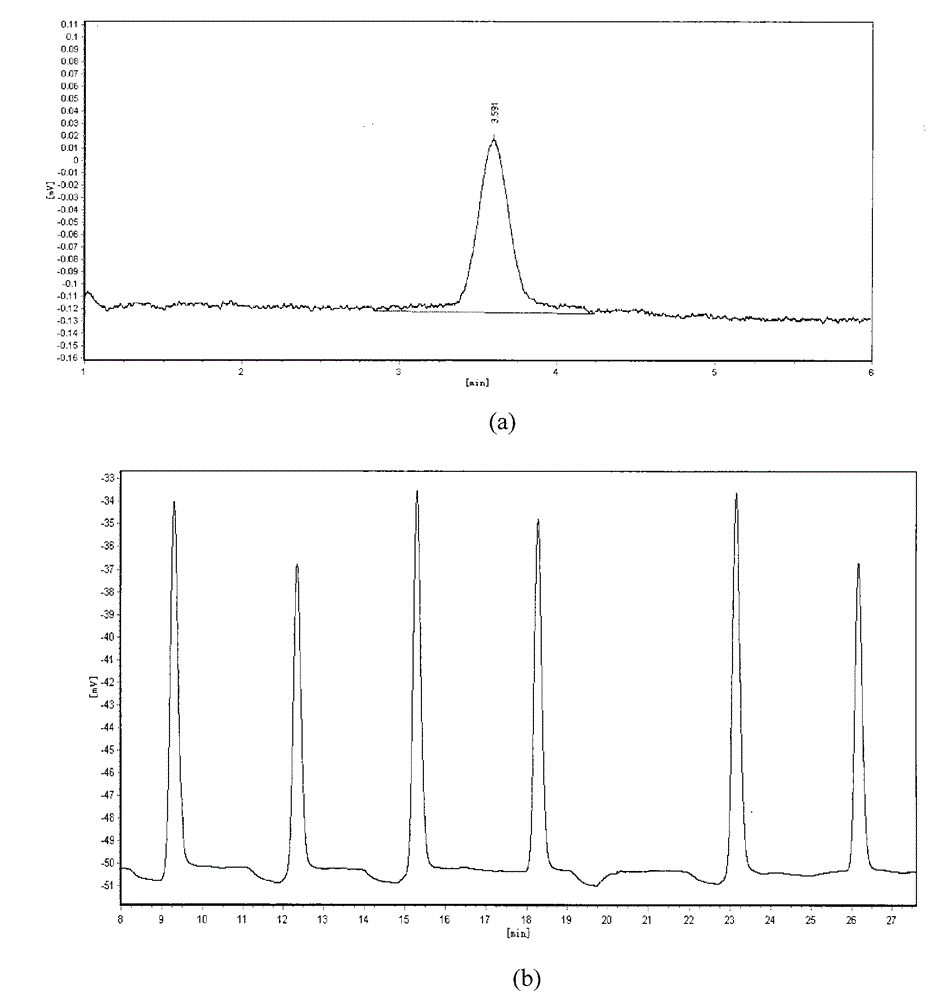

Online detection method of carbon corrosion in membrane electrode

InactiveCN102297906BIntuitive test methodImprove accuracyComponent separationMethod testCarbon corrosion

The invention discloses an online detection method of carbon corrosion condition in proton exchange membrane fuel cell membrane electrode (MEA). The method tests the carbon corrosion condition of MEA in actual running process using Cox reformer and gad detection equipment. Tail gas of anode outlet or tail gas of cathode outlet of a fuel cell in normal running is fed into the Cox reformer through a gas controller; the tail gas converted by the reformer is fed into the gas detection equipment to obtain the condition of carbon corrosion. The test method comprises a tail gas controller, a gas reformer, catalyst, a temperature controller, a sampling system, the gas detection equipment and a gas pipeline. Through the detection method, the concentration of carbon corrosion product in MEA can be automatically detected on line, and the corrosion condition of carbon accurately can be reflected in time; and furthermore, the detection method is featured by simple test process, easy control and good repeatability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

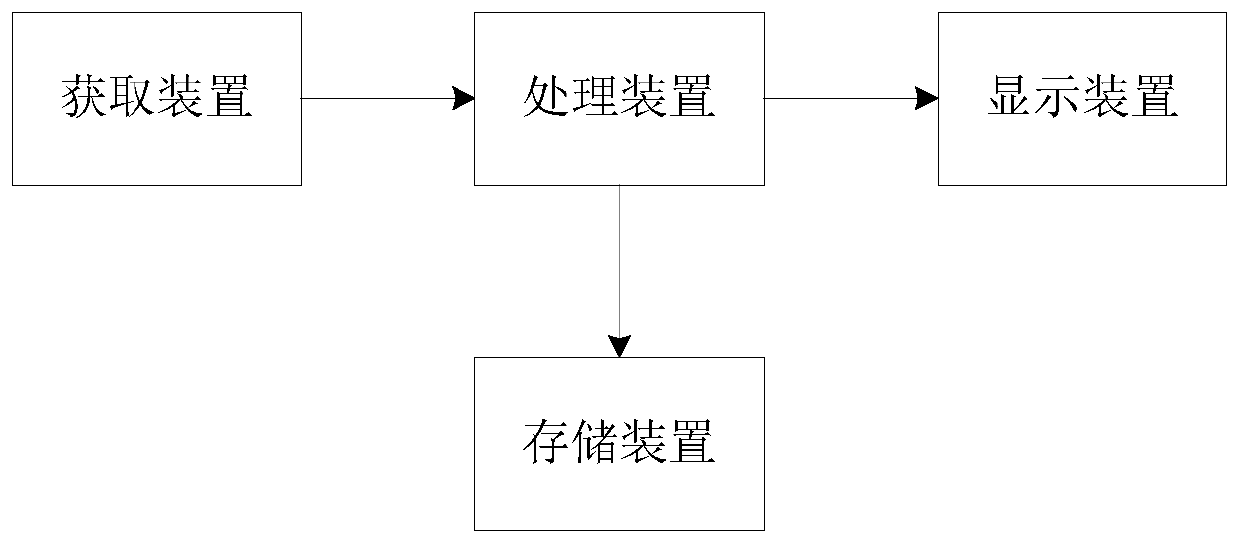

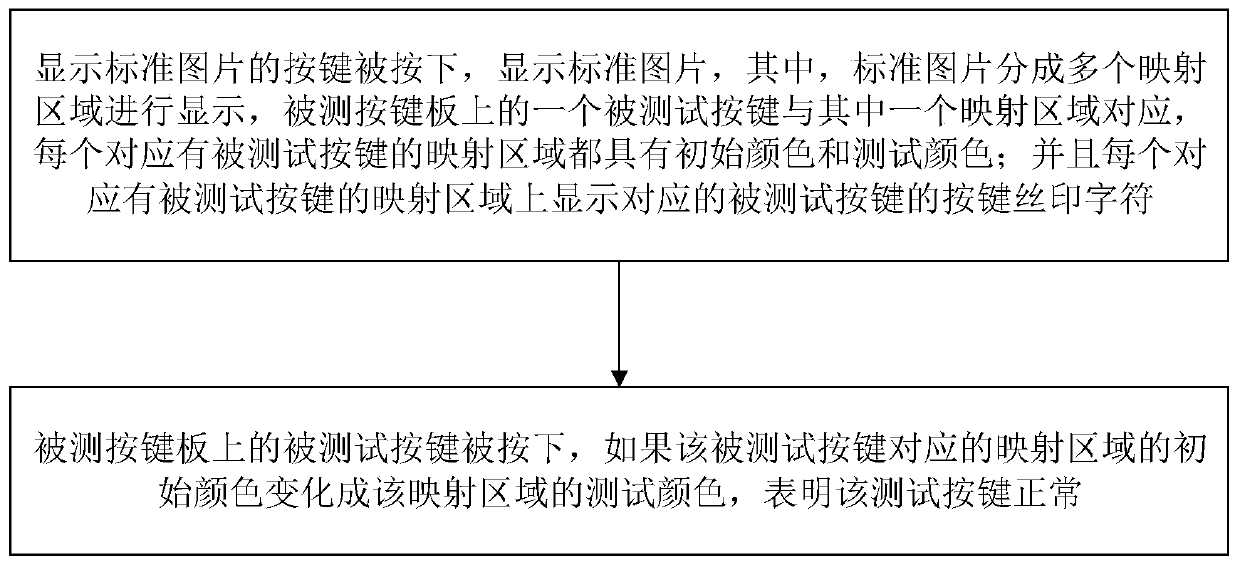

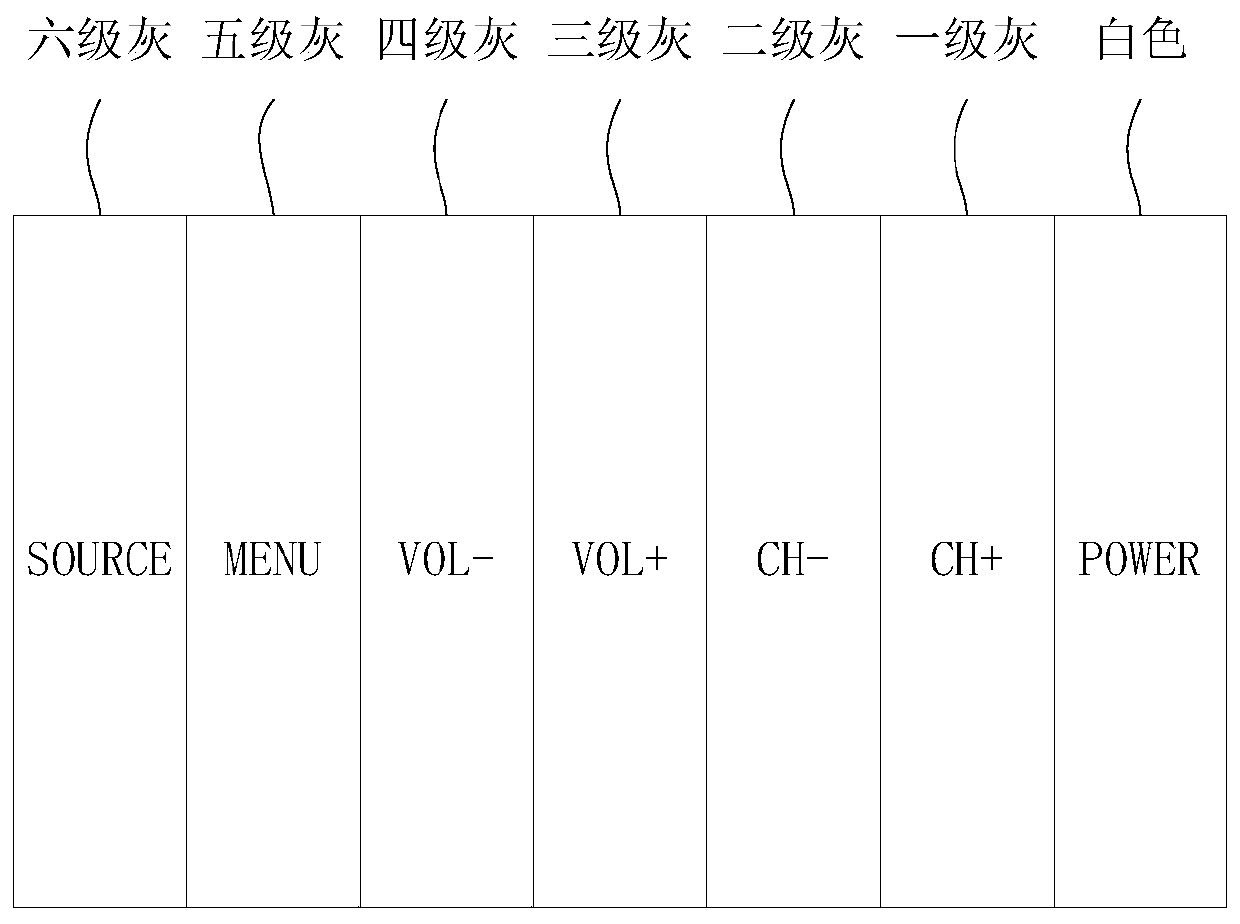

A keypad testing device and testing method

ActiveCN107219458BIntuitive test methodEasy to viewCircuit interrupters testingKey pressingDisplay device

The invention relates to a keypad testing device and a testing method. The test device comprises a storage device, an obtaining device, a display device and a processing device, wherein the storage device stores standard pictures; the processing device is respectively connected with the storage device and the display device; obtains standard pictures from the storage device, wherein each standard picture includes a plurality of mapping areas, each mapping area corresponding to a key to be tested has an initial color and a test color; the obtaining device obtains action signals of the key to be tested, the processing device is further connected with the obtaining device to process the action signals and identify the corresponding key to be tested, the display device is connected with the processing device, displays the standard pictures and the initial color sent by the processing device, and changing the initial color of the mapping area corresponding to the key to be tested to the test color when the key to be tested corresponding to the action signals is identified. The technical scheme provided in the embodiment makes the test direct and more efficient.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD

Compressive strength test method for surface strengthening layer and substrate of axial part

ActiveCN103048196BSimple test methodIntuitive test methodPreparing sample for investigationMaterial strength using tensile/compressive forcesOperabilityUltimate tensile strength

The invention relates to a compressive strength test method for the surface strengthening layer and the substrate of an axial part. The method comprises the following steps: loading workpieces step by step to determine the pressure range for realizing damage on the workpieces, and then adopting a bisection approach method to precisely determine the pressure value for realizing damage. The method is simple, convenient and intuitive and has the advantages of strong operability reliable and accurate data and the like.

Owner:TIANJIN ENG MACHINERY INST

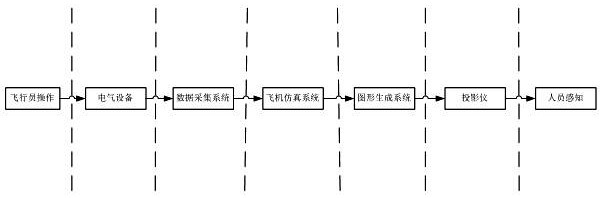

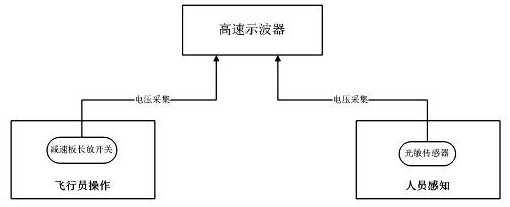

Device and method for testing time delay of aircraft simulator system

The invention relates to a device and a method for testing time delay of an aircraft simulator system, and belongs to the technical field of computer distributed simulation application. The invention discloses a device and a method for testing time delay of an aircraft simulator system. The device comprises a high-speed oscilloscope and a photosensitive sensor. The photosensitive sensor is used for converting an image brightness change signal of the visual system into a voltage change signal; the high-speed oscilloscope is used for receiving cabin control signals and photosensitive sensor signals, and the cabin control signals and the photosensitive sensor signals belong to different channels; wherein the cabin control signal is an electric signal converted from a control instruction of a cabin control device acquired by a digital quantity and / or analog quantity acquisition module. The method has the following advantages: 1, the transmission delay of the aircraft simulator system is detected by using the high-speed oscilloscope, so that relatively accurate delay time can be obtained; and 2, the test method is rapid and visual, and has relatively high reliability and relatively strong universality.

Owner:JIANGXI HONGDU AVIATION IND GRP

A method for testing the correctness of device model simulation results

ActiveCN106934121BEasy to checkEfficient test methodComputer aided designSpecial data processing applicationsVisual testAlgorithm

Owner:北京华大九天科技股份有限公司

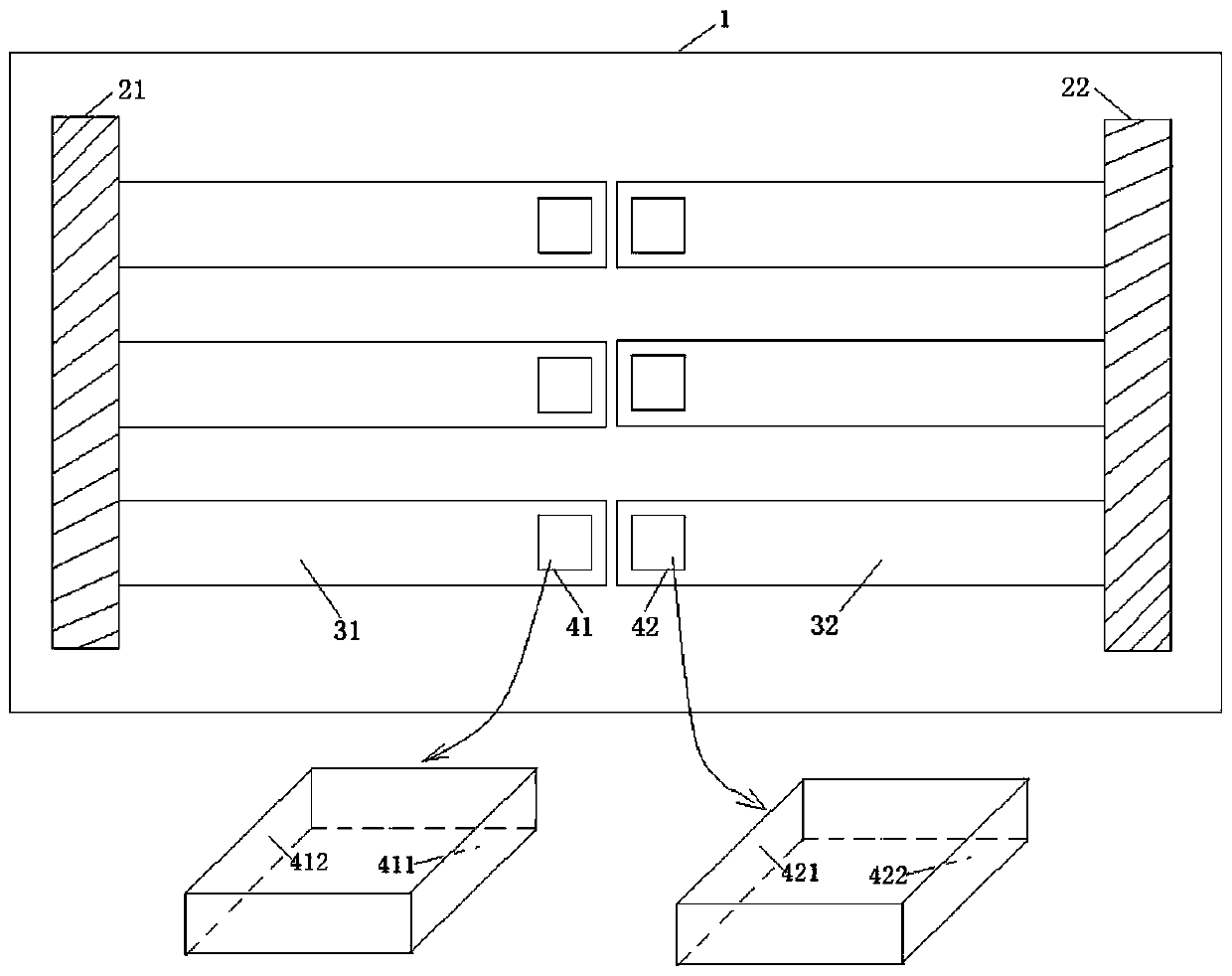

A test structure and measurement method for the stress gradient of a mems microbeam with a detection hole

ActiveCN105547542BDeduce the degree of bendingReliable test resultsForce measurement by measuring optical property variationCantilevered beamClassical mechanics

The invention discloses a structure for testing the stress gradient of an MEMS micro beam with a detection hole, and a measurement method. The structure comprises a substrate, two long anchor regions, and six tested cantilever beams with detection holes. The two long anchor regions are fixed on the upper surface of the substrate. One end of each tested cantilever beam is fixed on a side surface of the corresponding long anchor region, and the other end of each tested cantilever beam is provided with a square through hole in an etching manner, wherein the square through holes serve as the detection holes, and side wall of the detection holes are perpendicular to the surface. Each three tested cantilever beams serve as a group, and each group of tested cantilever beams are fixed in the corresponding long anchor region. The suspension ends of the two groups of tested cantilever beams are opposite to each other, and are oppositely arranged in a completely symmetric manner. When the tested cantilever beams are bent upwards or downwards because of the stress gradient, the side walls of the detection holes will be inclined accordingly. The mechanism can judge the bending condition of the tested cantilever beams according to the observed projection area of the front or rear side walls on a horizontal plane. The method can reduce the requirements for observation equipment, and is visual and convenient.

Owner:SOUTHEAST UNIV

Exchange data testing system and method

InactiveCN100426762CIntuitive test methodSimple test methodData switching networksComputer hardwareTest order

This invention relates to a exchange data test system and a method, in which, the system includes: a data test platform, an information interface, a protocol library, a call control script storage module, a user interface and a storage module for storing test result information, said method includes the following steps: A, a maintenance person sends data test order to a switch by a data test platform, B, the switch receives the test order sent by the test platform and sends starting up test response to the data test platform, C, the data test platform receives the confirmation response for starting up the test sent by the data test platform to structure the start up call information and sends it to the switch, D, the switch receives the information and interacts information with the data test platform, E, the maintenance person analyzes the information sent by the switch.

Owner:HUAWEI TECH CO LTD

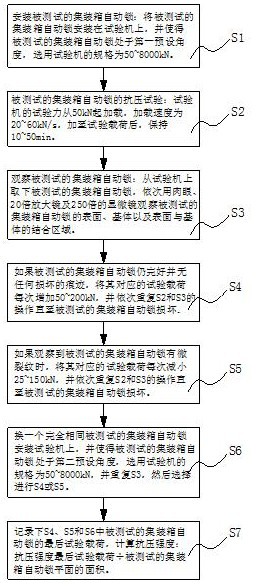

Testing method capable of simultaneously testing strength of multiple automatic container locks

PendingCN112461524AImprove test accuracyImprove test efficiencyMachine part testingMaterial strength using tensile/compressive forcesMachineCompression test

The invention is suitable for the technical field of automatic locks of containers, and provides a testing method capable of simultaneously testing the strength of a plurality of automatic container locks. The testing method comprises the following steps of: installation of a tested automatic container lock: installing the tested automatic container lock on a testing machine, enabling the tested automatic container lock to be at a first preset angle, and enabling the tested container automatic lock to be at a second preset angle, wherein the specification of the selected testing machine is 50-8000 kN; and compression test of the tested automatic container lock: conducting loading with the test force of the testing machine of 50 kN as a start point, wherein a loading speed is 20-60 kN / s, keeping the test load for 10-50 min after a test load is reached, and then conducting unloading. According to the invention, the automatic container lock to be tested is tested and observed, loading iscarried out step by step according to an observation result, and operation is repeated until a pressure range capable of damaging the automatic container lock to be tested is determined; and the method has the advantages of being easiness, convenience in implementation, visualness, high operability, reliable and accurate data, high testing efficiency and the like.

Owner:苏州卓胜工贸有限公司

Test method for residual adhesive level of pressure-sensitive adhesive products

ActiveCN106290150BTest Method SpecificationTest method can be replicatedUsing mechanical meansMaterial analysisEngineeringThermostat

Owner:GUANGZHOU JINWANZHENG PRINTING MATERIAL CO LTD

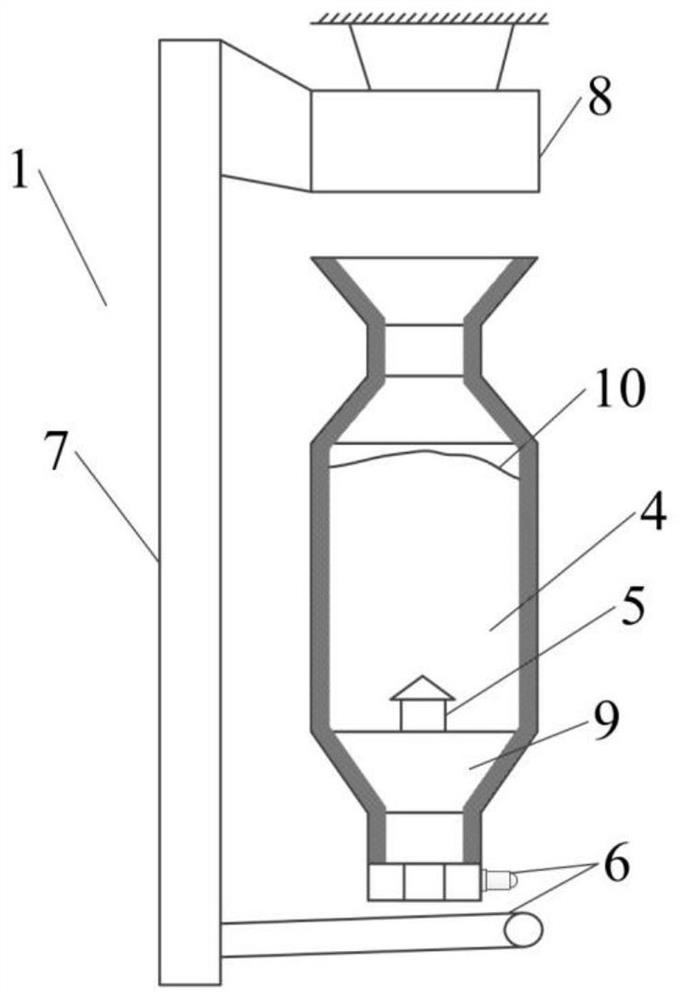

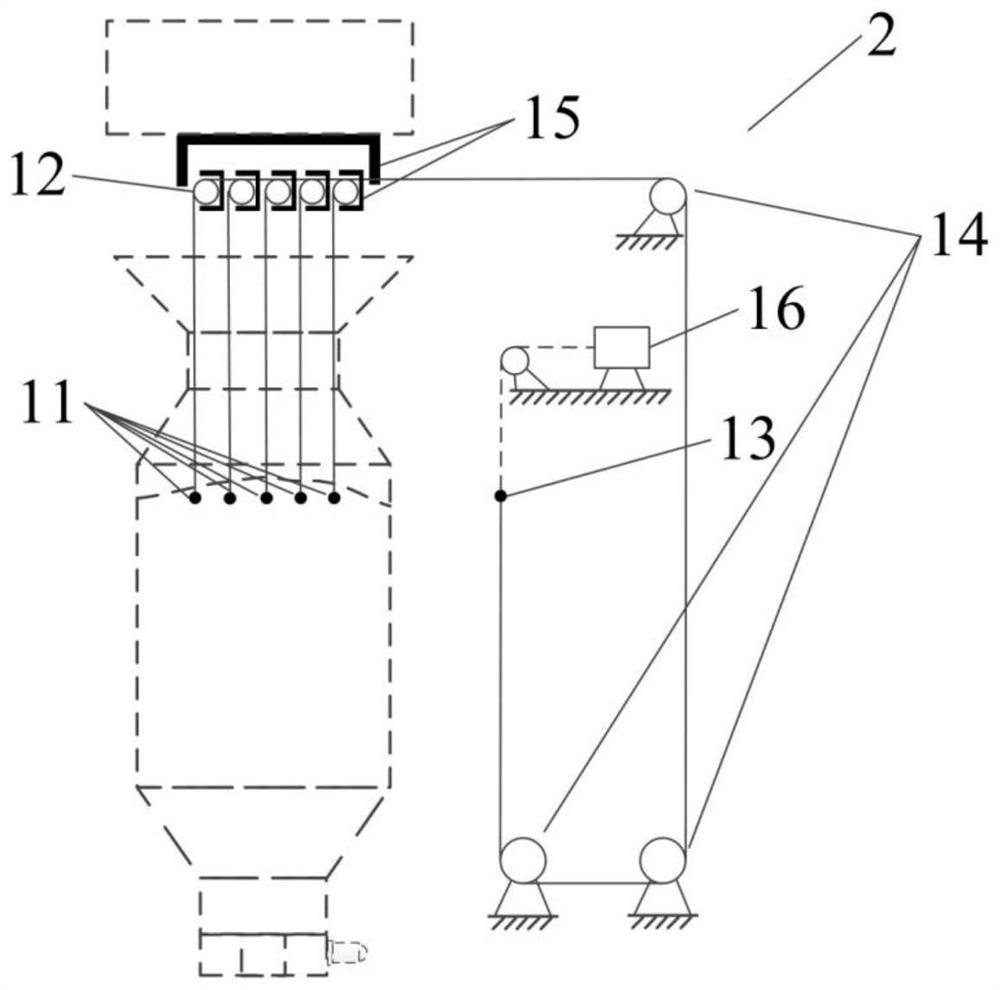

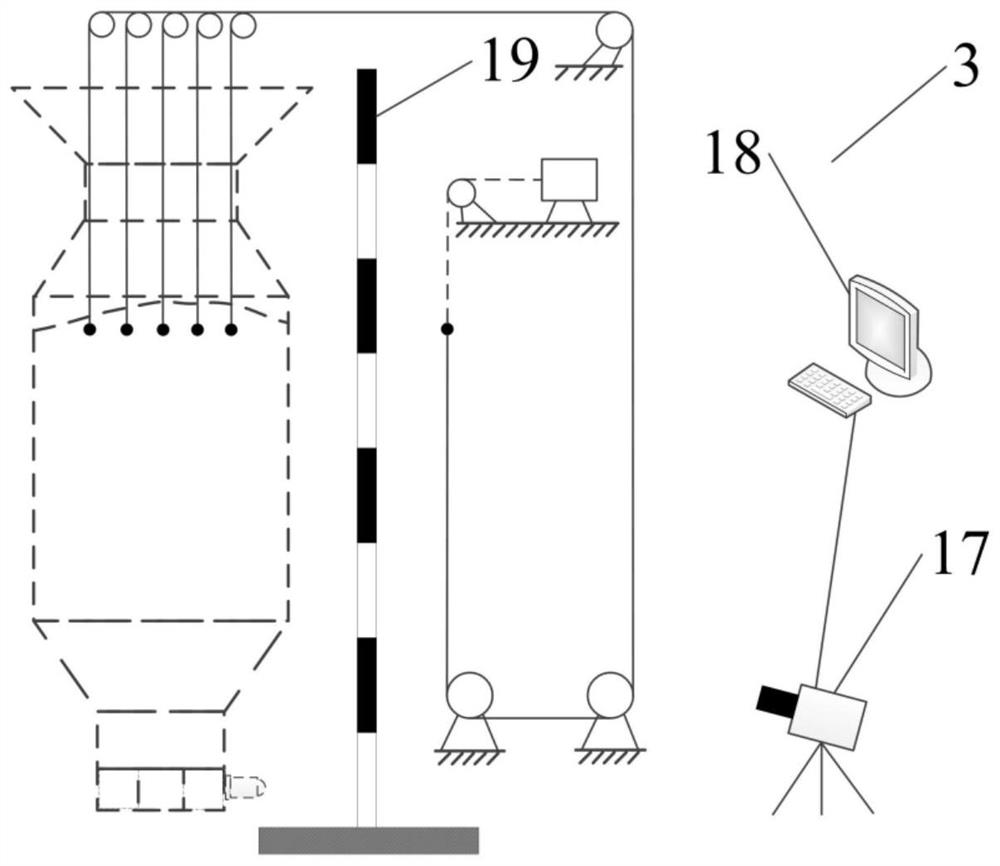

Tracer chain detection method and device for tracking flow track and speed of bulk material

ActiveCN113188950AIntuitive test methodThe test data is accurateConveyorsLoading/unloadingInformation transmissionBlock and tackle

The invention relates to a tracer chain detection device for tracking the flowing track and speed of a bulk material. The device is characterized by comprising a vertical bulk material device for loading a bulk material, a tracer chain transmission system for tracking the flowing of the bulk material, and a tracer chain detection system, wherein the vertical bulk material device comprises a stock bin, a distributing mechanism and a discharging hopper, the distributing mechanism is arranged at the top of the stock bin, the discharging hopper is arranged at the lower end of the stock bin, the bulk material is distributed by the distributing mechanism to enter the stock bin and then discharged by the discharging hopper from the bottom of the stock bin, in the tracer chain transmission system, a front-end tracer and a tail-end marker are connected through a pulley block and a lifting rope, the front-end tracer is arranged in a stock bin, the tail-end marker is arranged outside the stock bin, the motion direction of a tail end marker in the tracer chain transmission system is changed through a pulley block, and the motion change of the tail end marker forms real-time flow parameters, and the real-time flow parameters are transmitted to a flow field calculation unit through an information transmission unit for measurement and calculation of a flow track, speed distribution, residence time and a moving distance.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

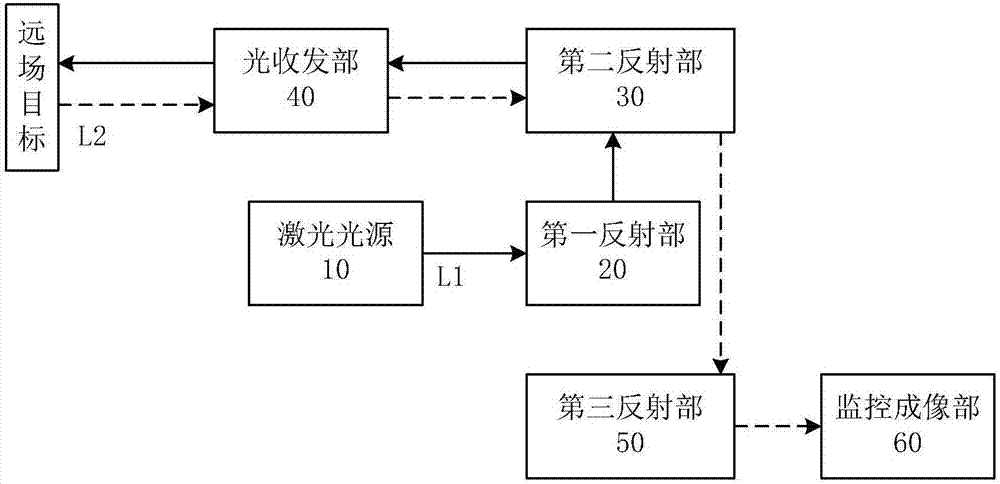

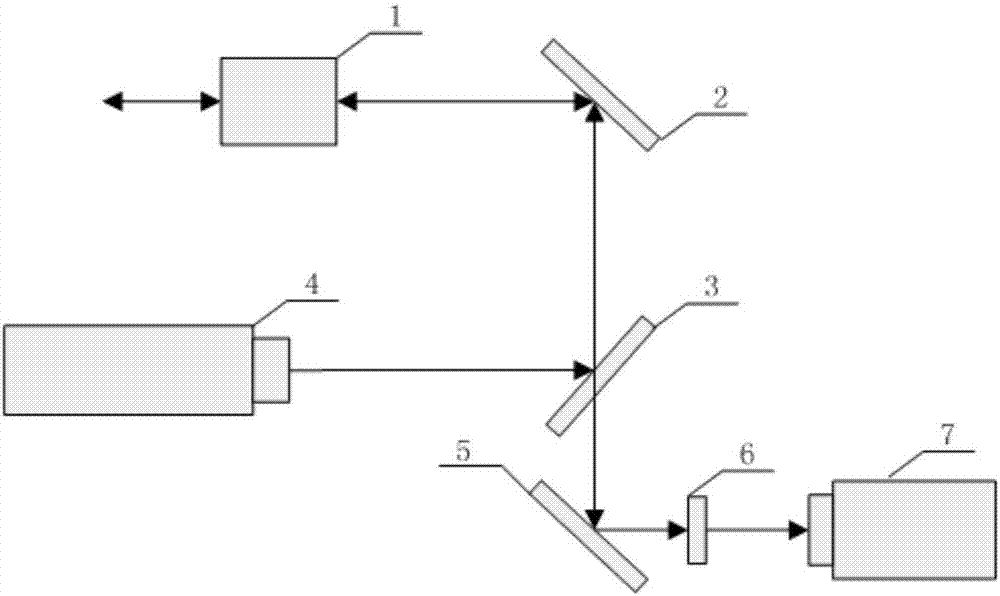

Light spot monitoring imaging device

The present invention discloses a light spot monitoring imaging device and belongs to the optical technical field. The invention aims to solve the problems of long optical focal length and high difficulty in processing and installation of a light spot monitoring imaging device in the prior art. The light spot monitoring imaging device includes a first reflecting portion, a second reflecting portion, a light transmitting-receiving portion, a third reflecting portion and a monitoring imaging portion; laser emitted from a laser light source is reflected by the first reflecting portion and the second reflecting portion sequentially, the reflected laser is emitted out through the light transmitting-receiving portion and is focused at a far field so as to form a light spot image; the light transmitting-receiving portion detects the diffusedly reflected light of the light spot image; after the diffusedly reflected light is reflected by the second reflecting portion, part of the diffusedly reflected light skims over the edge of the first reflecting portion and directly enters the third reflecting portion; and the third reflecting portion reflects the part of the diffusedly reflected light which enters the third reflecting portion to the monitoring imaging portion.

Owner:11TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

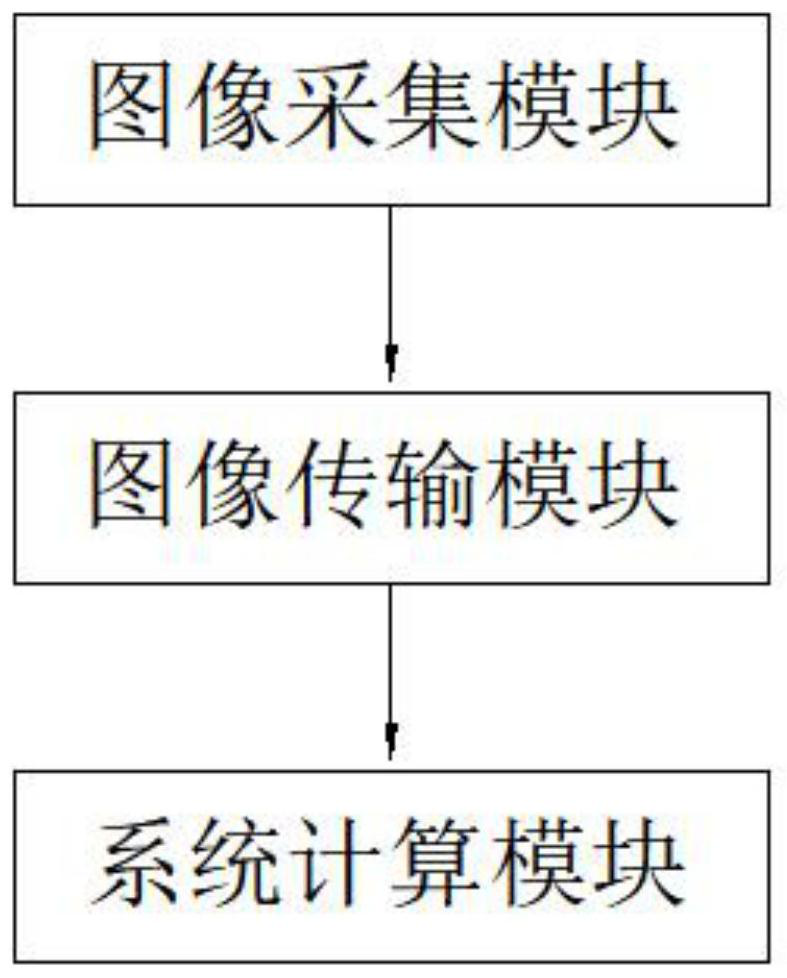

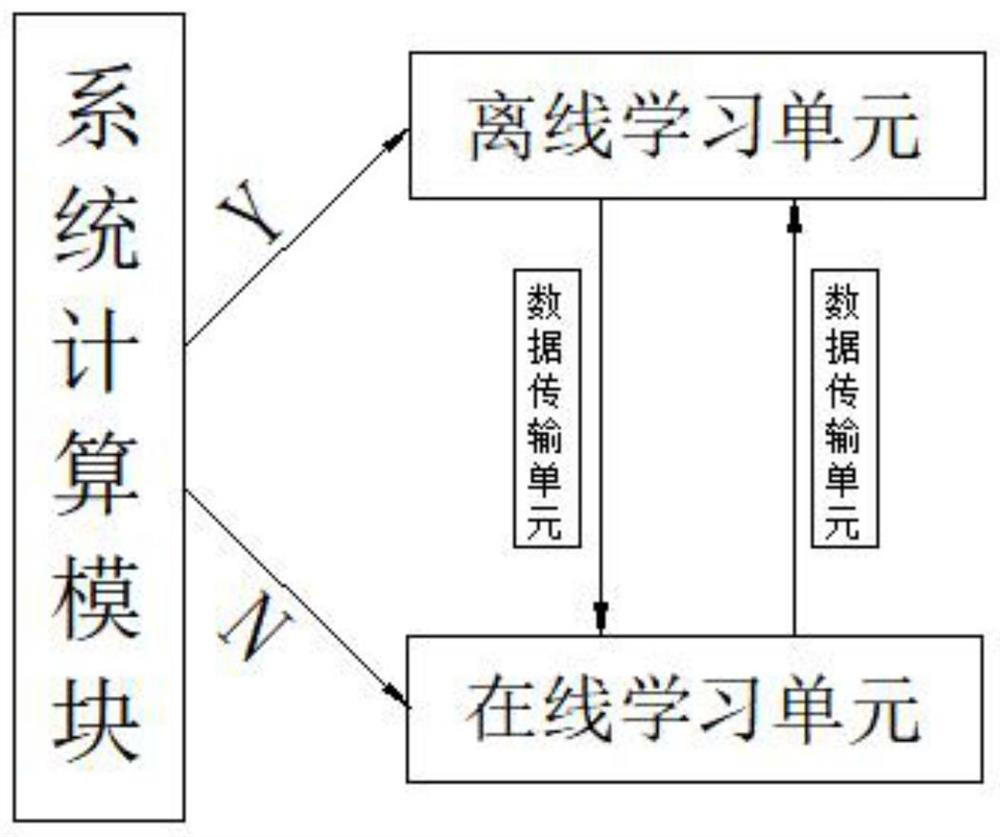

Front-end water level detection system based on combination of online learning and offline learning

PendingCN113822931AImprove generalization abilityImprove real-time performanceImage enhancementImage analysisOffline learningLearning unit

The invention discloses a front-end water level detection system based on the combination of online learning and offline learning. Thefront-end water level detection system comprises an image acquisition module, an image transmission module and a system calculation module; the output end of the image acquisition module is connected with the image transmission module, and the output end of the image transmission module is connected with the system calculation module; the system calculation module comprises an off-line learning unit, an on-line learning unit and a data transmission unit, the off-line learning unit is connected with the on-line learning unit through the data transmission unit, and the image acquisition module further comprises a video acquisition unit which is used for carrying out image transmission when the water volume is increased too fast. According to the system, the detection process is simple and convenient, online learning and offline learning are combined, the environment generalization ability is improved, when the rainfall change is large, the analysis interval between video frames is automatically reduced, and the video clip at the specified time is generated, so that the real-time performance of water surface early warning is improved, and the key moment described by the video clip is further configured; and the system is suitable for popularization and use.

Owner:湖北亿立能科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com