Test method for evaluating decontamination effect of detergent

A test method and detergent technology, applied in the direction of measuring device, color/spectral characteristic measurement, instrument, etc., can solve the problems of using large equipment, complicated operation, not suitable for display, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

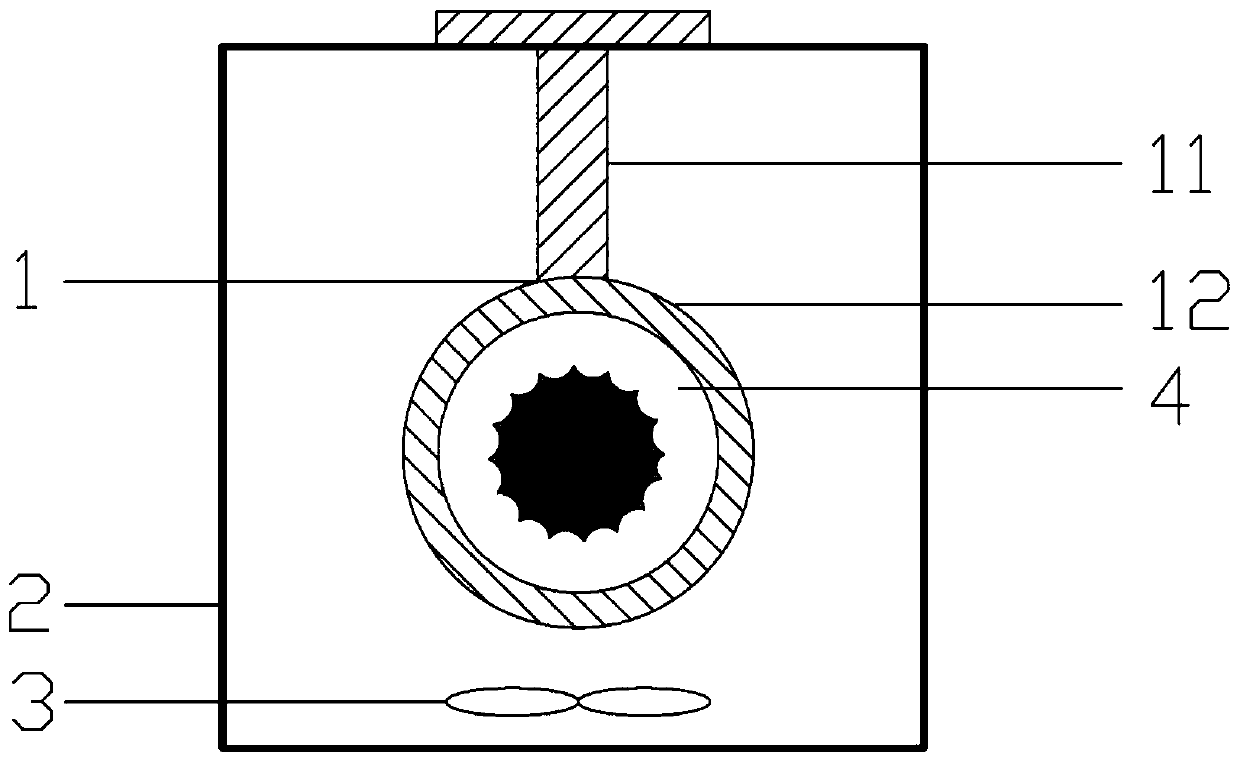

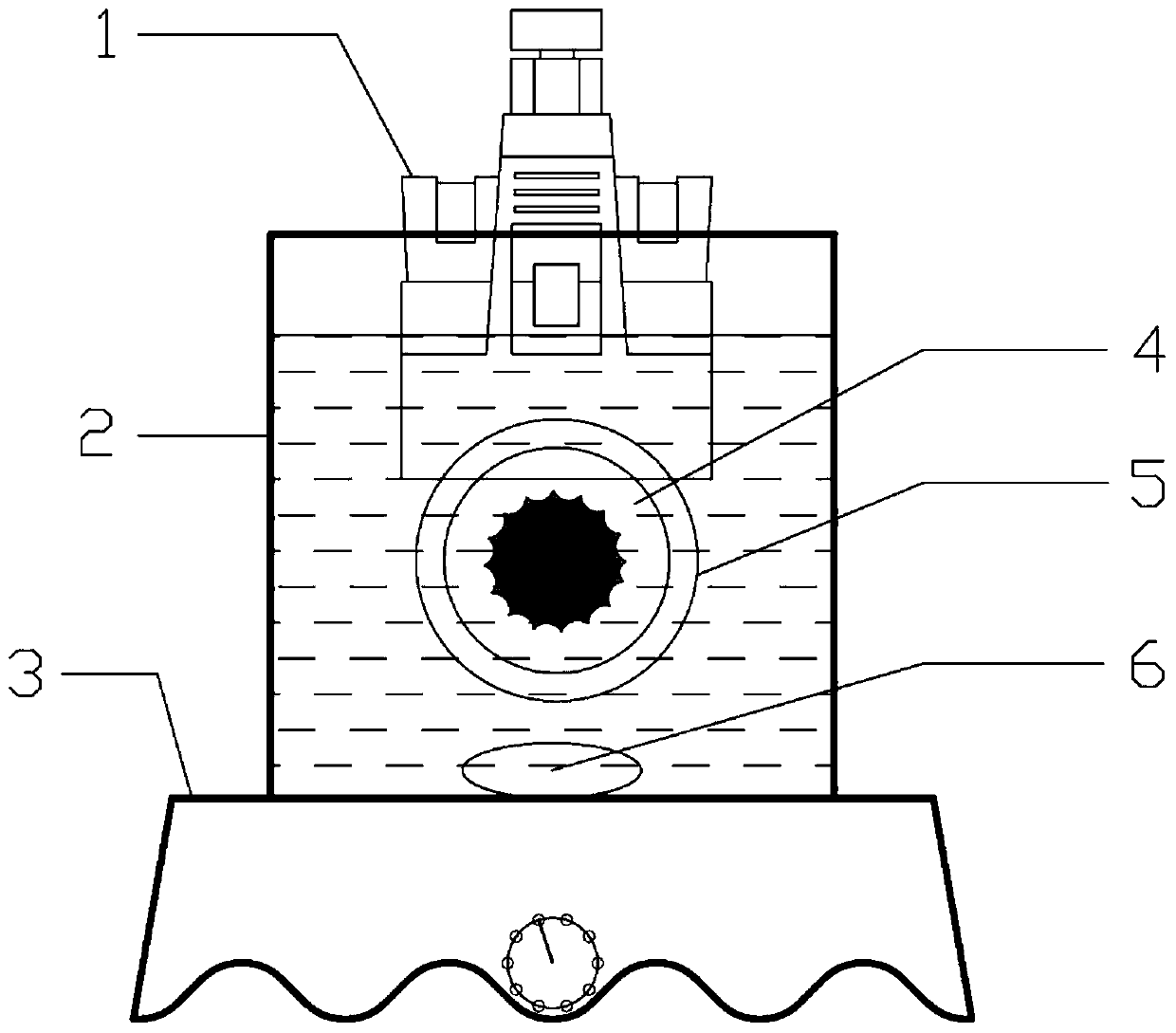

[0101] 1) Weigh 0.50 g of pollutant 1 using the reduction method, and evenly smear the pollutant on a pure cotton cloth with a round-headed plastic rod (the cloth is 5 cm in diameter, and the stain is located in the center of the cloth, and the diameter is About 3 cm round), aged in a 45°C oven for 1 hour to obtain a stained cloth;

[0102] 2) Pour 500 ml of deionized water into a transparent glass washing container with a volume of 600 ml, put in the rotor, turn on the magnetic stirrer, adjust the speed to 500 rpm, and add detergent to prepare a detergent solution (concentrated detergent The dosage is 3ml, and the dosage of ordinary detergent is 15ml);

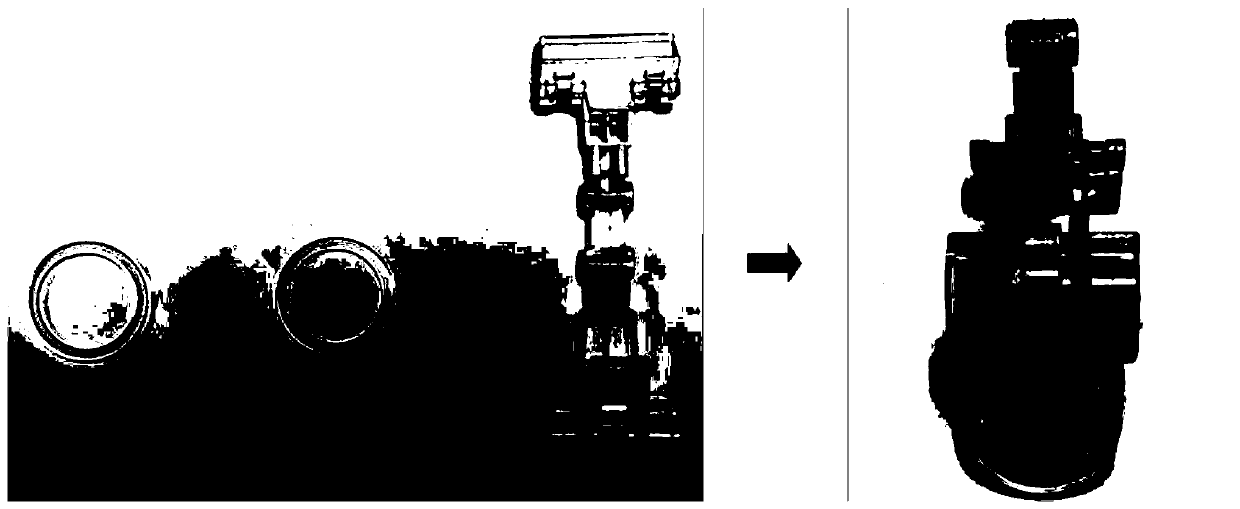

[0103] 3) Put the stained cloth between two transparent plastic rings, clamp and fix the stained piece with clips, put it into the detergent solution for washing, observe the speed of the stain falling off within 10 to 20 minutes of washing, and record the time when the stain finally falls off time;

[0104] 4) Compare the ...

Embodiment 2

[0107] 1) Weigh 0.50 g of pollutant 2 using the reduction method, and evenly smear the pollutant on a pure cotton cloth with a round-headed plastic rod (the cloth is 5 cm in diameter, the stain is located in the center of the cloth, and the diameter is About 3 cm round), aged in a 45°C oven for 1 hour to obtain a stained cloth;

[0108] 2) Pour 500 ml of deionized water into a transparent glass washing container with a volume of 600 ml, put in the rotor, turn on the magnetic stirrer, adjust the speed to 600 rpm, add detergent to prepare a detergent solution (concentrated detergent The dosage is 3ml, and the dosage of ordinary detergent is 15ml);

[0109] 3) Put the stained cloth between two transparent plastic rings, clamp and fix the stained piece with clips, put it into the detergent solution for washing, observe the speed of the stain falling off within 10 to 20 minutes of washing, and record the time when the stain finally falls off time;

[0110] 4) Compare the results ...

Embodiment 3

[0113] 1) Absorb pollutant 3 with a straw, add 2 drops (about 0.07 g) dropwise to the center of a pure cotton cloth piece with a diameter of 5 cm, and age it in an oven at 45°C for 1 hour to obtain a stained cloth;

[0114] 2) Pour 500 ml of deionized water into a transparent glass washing container with a volume of 600 ml, put the rotor in, turn on the magnetic stirrer, adjust the speed to 400 rpm, add detergent to prepare a detergent solution (concentrated detergent The dosage is 3ml, and the dosage of ordinary detergent is 15ml);

[0115] 3) Put the stained cloth between two transparent plastic rings, clamp and fix the stained sheet with clips, put it into the detergent solution for washing, and record the time when the stain finally falls off;

[0116] 4) Compare the results after washing for 15 minutes, evaluate and take pictures, and use computer software to count the number of stain pixels before washing and after washing, and calculate the area ratio of residual stains...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com