Testing method capable of simultaneously testing strength of multiple automatic container locks

A test method and automatic locking technology, applied in the testing of mechanical parts, the use of stable tension/pressure to test the strength of materials, the testing of machine/structural parts, etc., can solve the problem of low test efficiency and difficulty in effectively testing whether the container lock strength Up to standard, it is difficult to judge the compressive strength of container lock, etc., to achieve the effect of high test efficiency, improved test accuracy and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

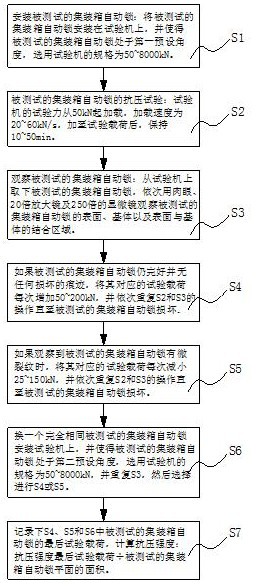

[0038] A test method capable of simultaneously testing the strength of multiple container automatic locks, comprising the following steps:

[0039] S1. Install the tested automatic container lock: install the tested container automatic lock on the testing machine, and make the tested container automatic lock at the first preset angle. The specification of the selected testing machine is 50~8000kN;

[0040] S2. Compression test of the tested container automatic lock: the test force of the testing machine is loaded from 50kN, the loading speed is 30kN / s, after adding to the test load, keep it for 30min, and then unload;

[0041] S3. Observe the tested automatic container lock: remove the tested container automatic lock from the testing machine, and observe the surface, substrate and surface-to-substrate contact of the tested container automatic lock with the naked eye, a 20-fold magnifying glass, and a 250-fold microscope. binding area;

[0042] S4. The tested container automat...

Embodiment 2

[0046] A test method capable of simultaneously testing the strength of multiple container automatic locks, comprising the following steps:

[0047] S1. Install the tested automatic container lock: install the tested container automatic lock on the testing machine, and make the tested container automatic lock at the first preset angle. The specification of the selected testing machine is 50~8000kN;

[0048] S2. Compression test of the tested container automatic lock: the test force of the testing machine is loaded from 50kN, the loading speed is 50kN / s, after adding to the test load, keep it for 40min, and then unload;

[0049] S3. Observe the tested automatic container lock: remove the tested container automatic lock from the testing machine, and observe the surface, substrate and surface-to-substrate contact of the tested container automatic lock with the naked eye, a 20-fold magnifying glass, and a 250-fold microscope. binding area;

[0050] S5. When microcracks are observe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com