Test method for residual adhesive level of pressure-sensitive adhesive products

A test method, pressure-sensitive adhesive technology, applied in the field of grade test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1- Embodiment 9

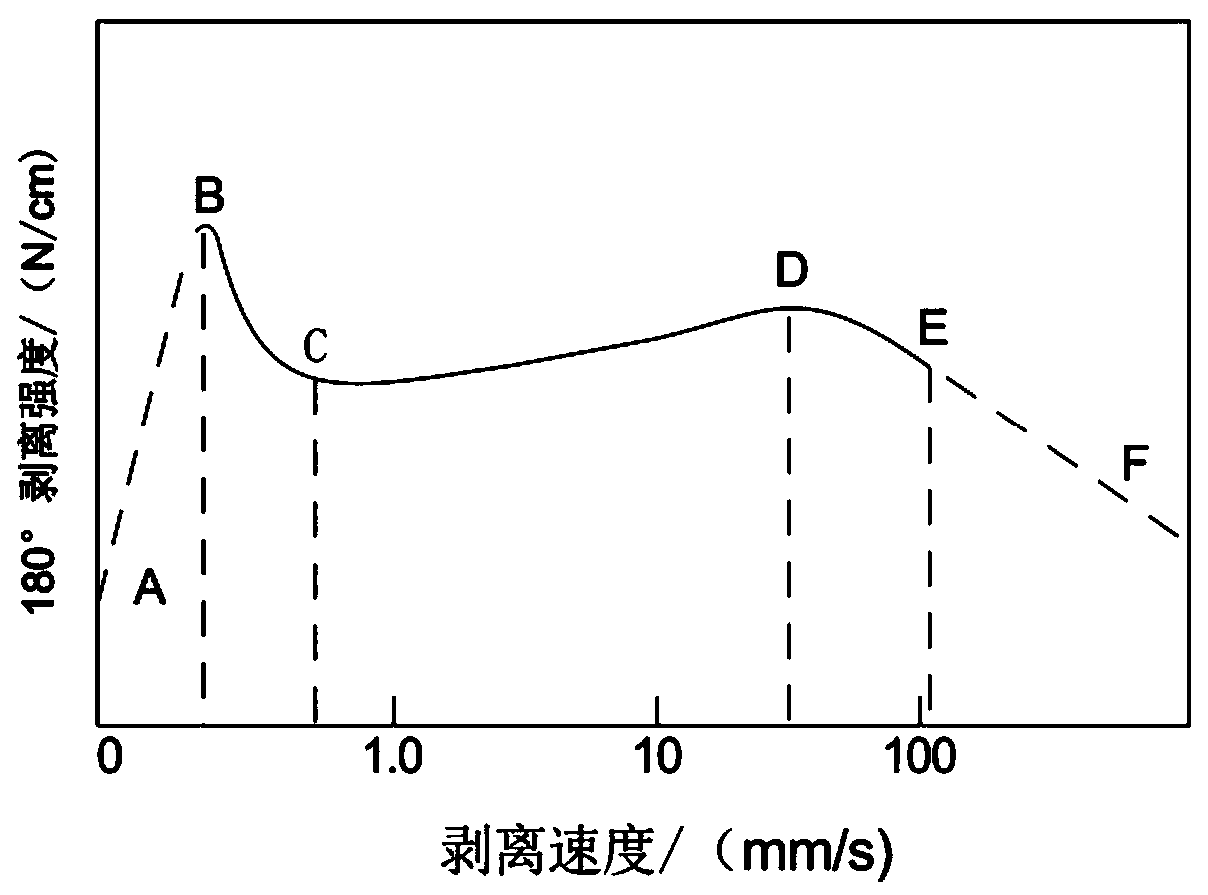

[0068] Above-mentioned embodiment 1-embodiment 9 carries out test according to following method respectively:

[0069] Test method for residual adhesive level of pressure-sensitive adhesive products, the test method includes the following steps:

[0070] 1) Selection of test boards;

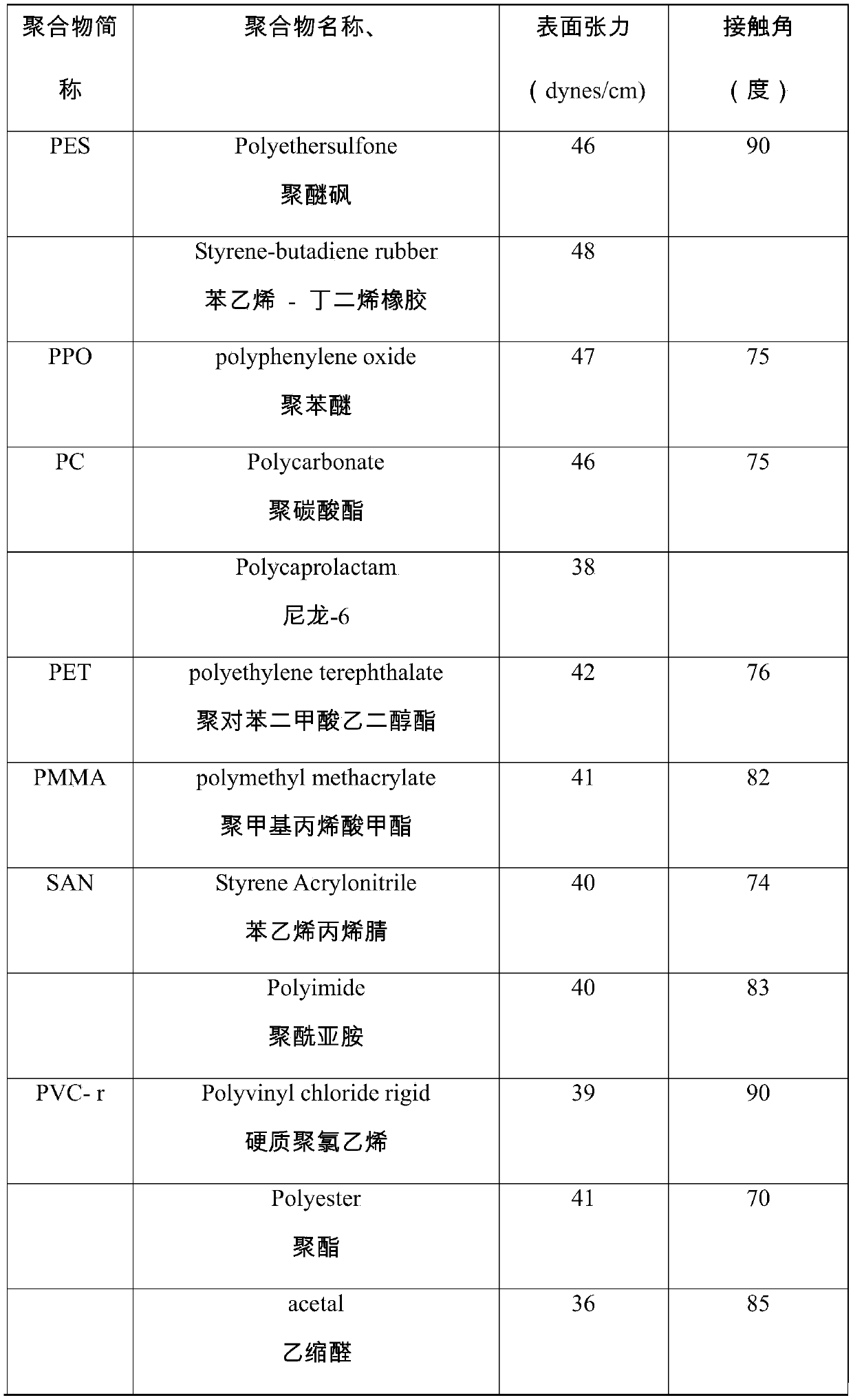

[0071] 2) Set the test plate parameters: the surface tension of the test plate is 32-50mN / m; the size of the test plate is ≥150mm×35mm; the thickness of the test plate is ≥50μm;

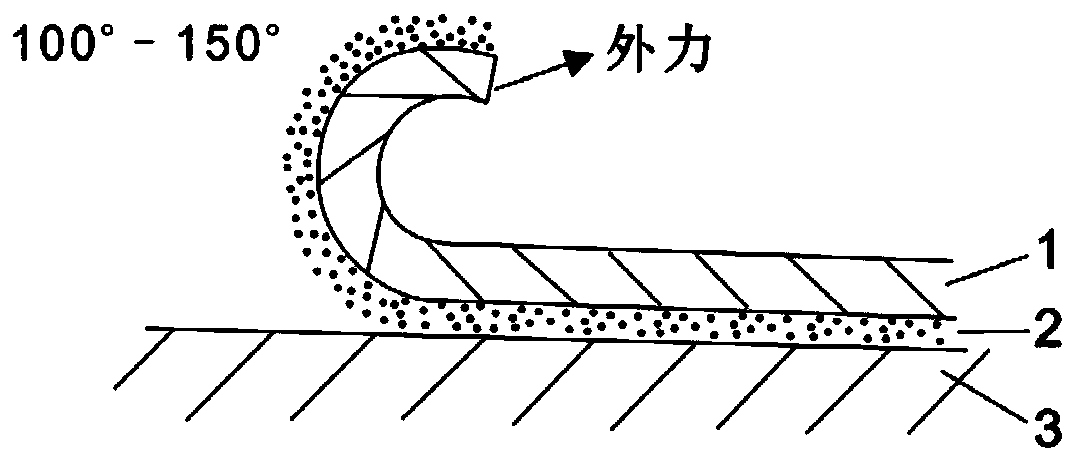

[0072] 3) Make the assembly: the pressure-sensitive adhesive test piece to be tested and the test plate are pasted by a cylindrical steel roller covered with rubber by manual or motorized methods. The quality of the paste is tested with the pressure-sensitive adhesive. It is qualified if there are no air bubbles and false pasting after the parts are pasted; the diameter of the steel pressure roller is 100mm, the width is 200mm, and there is no unevenness on the surface; the pressure-sensitive adhesive test piece is lon...

Embodiment 10- Embodiment 19

[0080] Test method for residual adhesive level of pressure-sensitive adhesive products, the test method includes the following steps:

[0081] 1) Selection of test board: smooth polyester board is used as the test board,

[0082] 2) Set the parameters of the test plate: reduce the surface tension by coating the surface with chemical substances (such as coating different doses of silicone oil or non-polar emulsion; adjust the surface tension of the test plate to 32mN / m ( Example 10), 34mN / m (Example 11), 36mN / m (Example 12), 38mN / m (Example 13), 40mN / m (Example 14), 42mN / m (Example 15), 44mN / m (embodiment 16), 46mN / m (embodiment 17), 48mN / m (embodiment 18), 50mN / m (embodiment 19) are used as pressure-sensitive adhesive products residual glue level gradient test; The size is 160mm×50mm; the thickness of the test plate is 1000μm;

[0083] 3) Make the assembly: the energy efficiency label applied to an electrical appliance is pasted on the test board by a cylindrical steel rolle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com