Shotcrete rebound rate testing method

A technology of sprayed concrete and rebound rate, which is applied in the test of shotcrete rebound rate test and the test field of rebound rate test of shotcrete support concrete in tunnel engineering, which can solve the problems of non-standard test methods and no clear test methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] A method of shotcrete rebound rate test:

[0021] 1. Lay non-absorbent canvas on the ground of the spray support surface, the edge of the laying surface should be 30mm larger than the spray support surface, and weigh the mass of the canvas in m 0 , accurate to 0.1kg.

[0022] 2. Test the density ρ of shotcrete and count the volume V of shotcrete used for the shotcrete support surface.

[0023] 3. After the spraying operation is completed, weigh the mass m of the sprayed concrete and canvas that fell to the ground 1 .

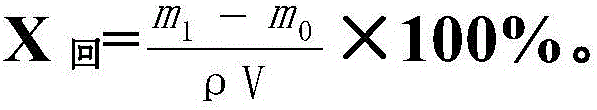

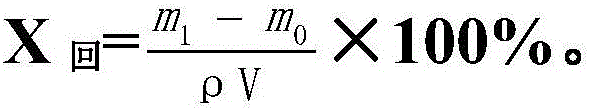

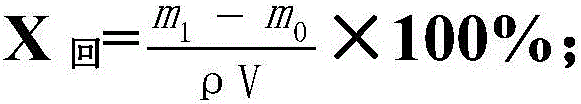

[0024] 4. Resilience test results X 回 Calculate according to the formula, accurate to 0.1%.

[0025]

[0026] Where: X 回 — Rebound rate of shotcrete, %.

[0027] m 0 - the mass of the canvas in kilograms (kg).

[0028] m 1 —The mass of the shotcrete and canvas on the ground, in kilograms (kg).

[0029] ρ—the density of shotcrete, in kilograms per cubic meter (kg / m 3 ).

[0030] V—the use volume V of shotcrete, in cubic meters (m 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com