Simulation test device for shutdown corrosion of thermal equipment

A technology for simulating tests and thermal equipment, applied in measurement devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of uneconomical, large environmental differences, thermal system shutdown, corrosion law and anti-corrosion effect. and other problems, to achieve the effect of a wide range of applications and a simple test method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the present invention easier to understand, specific implementation cases of the present invention will be further described below.

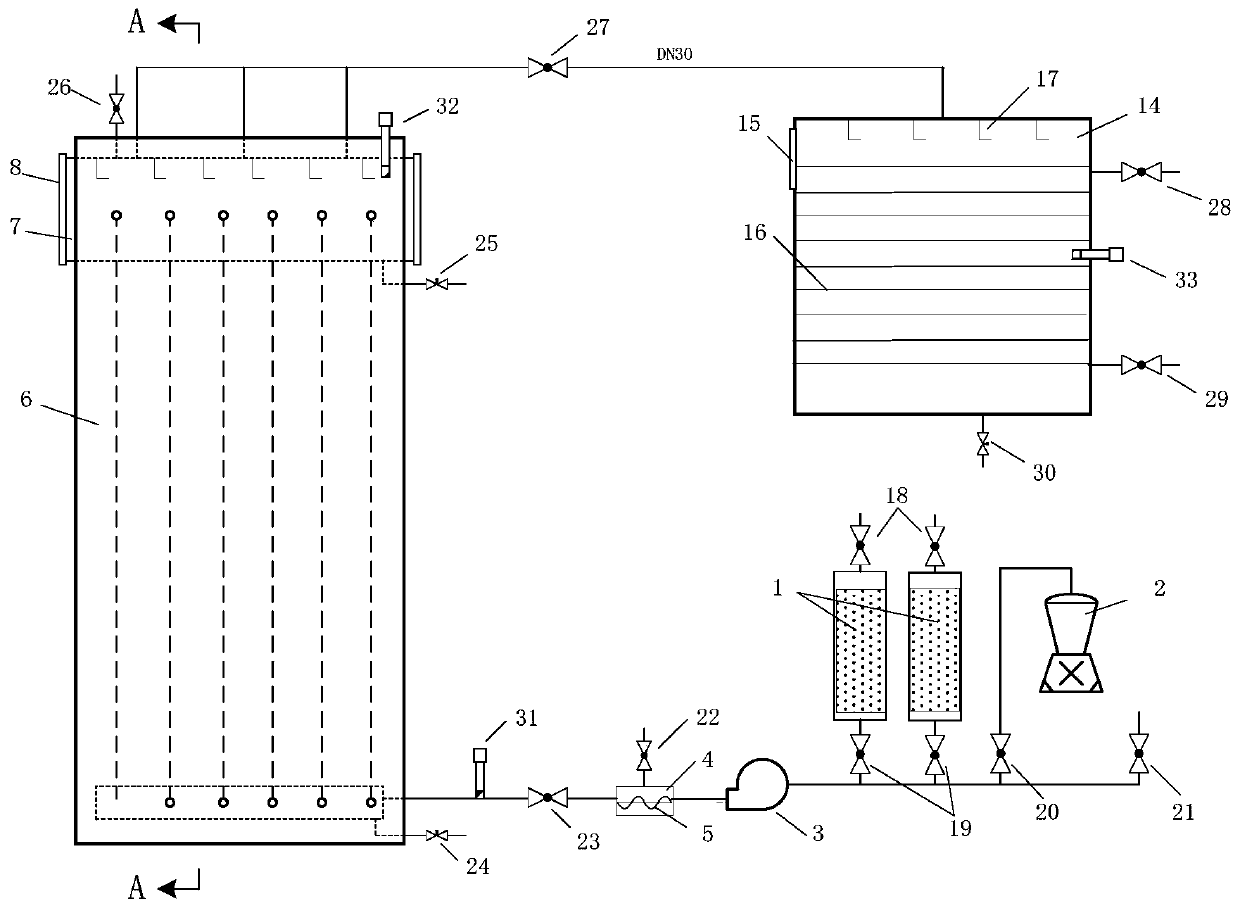

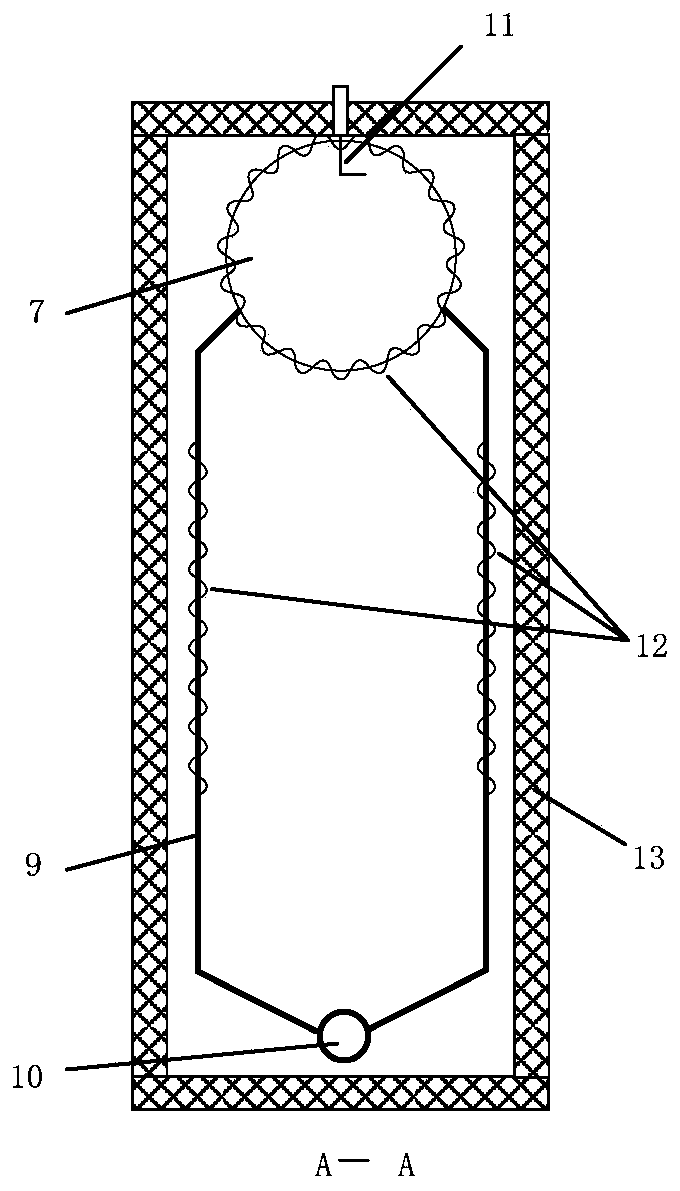

[0025] Such as figure 1 Shown is a thermal equipment outage corrosion simulation test device, which mainly includes an air dryer 1, an air humidifier 2, an air pump 3, a dosing tank 4, a boiler model 6 and a condenser model 14. DN30 carbon steel pipes are connected to valves, where air dryer 1 and air humidifier 2 are installed side by side at the inlet of air pump 3, and air pump 3, dosing tank 4, boiler model 6, and condenser model 14 are connected in series in sequence.

[0026] The air dryer 1 is arranged at the inlet of the air pump, and uses dehumidifying silica gel particles to dehumidify and dry the passing air. The silica gel is placed in a transparent cylindrical plexiglass container with a diameter of 200 mm and a height of 600 mm, which is convenient for observing the discoloration of the silica gel to determi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com