Testing method for corrosion resistance of magnesia carbon bricks by adopting small intermediate-frequency furnace

An intermediate frequency furnace, anti-corrosion technology, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc. Research on carbon bricks and other issues to achieve the effect of short melting time, small temperature difference between core and surface, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in more detail below through specific examples.

[0021] Purpose of the test: To compare the corrosion resistance of ordinary magnesia-carbon bricks (marked as No. 1) and magnesia-carbon bricks processed with modified binders (marked as No. 2).

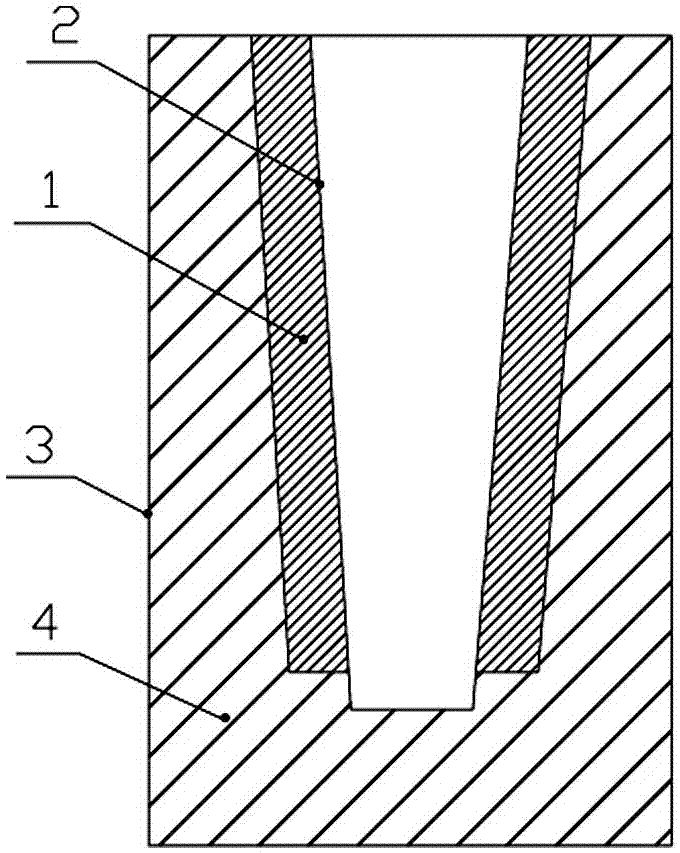

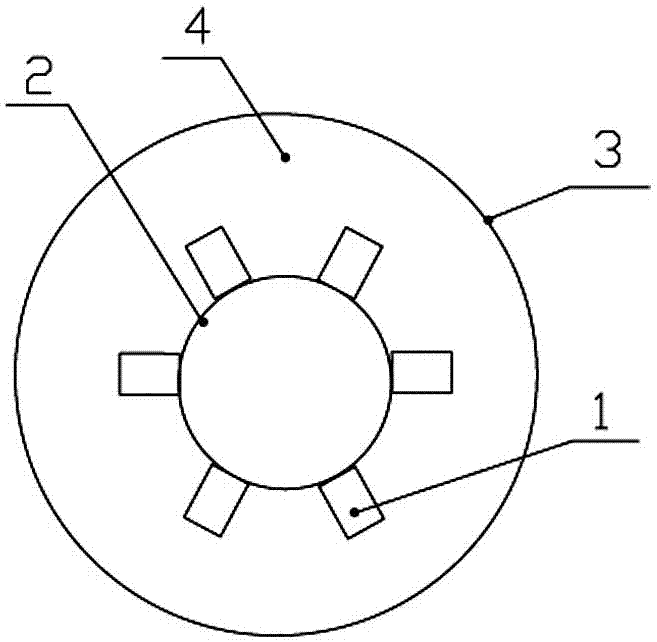

[0022] first step, preparation

[0023] Select three ordinary magnesia-carbon bricks and three magnesia-carbon bricks processed with modified binders, cut them into splines 1 with a size of 20mm×20mm×200mm, measure the original size of each spline 1, record the data, and Make a mark on the spline. Bind the spline evenly on the mold core 2. The mold core 2 is a hollow cone with a bottom, the inner diameter of the bottom is 80mm, the inner diameter of the top is 80mm, and the height is 201mm. The outer mold 3 is assembled into a circle with an inner diameter of 160mm and a height of 270mm. Cylindrical shape; after the mold is assembled, use corundum castable 4 (or casting seat brick) to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com