A cleaning agent for postage stamp back glue

A cleaning agent and stamp technology, which is applied in the preparation of detergent compositions, non-surface active detergent compositions, detergent mixture compositions, etc., can solve the problems of stamp ink damage, long soaking time, and incomplete cleaning, etc. To achieve the effect of easy handling, simple application method and unaffected gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

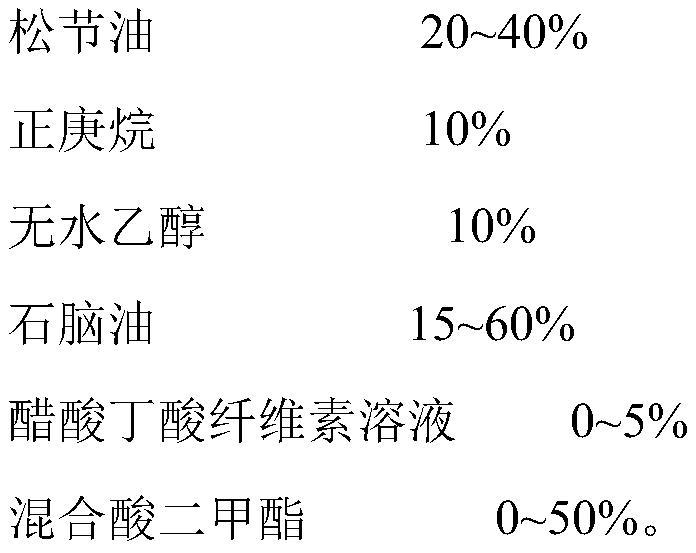

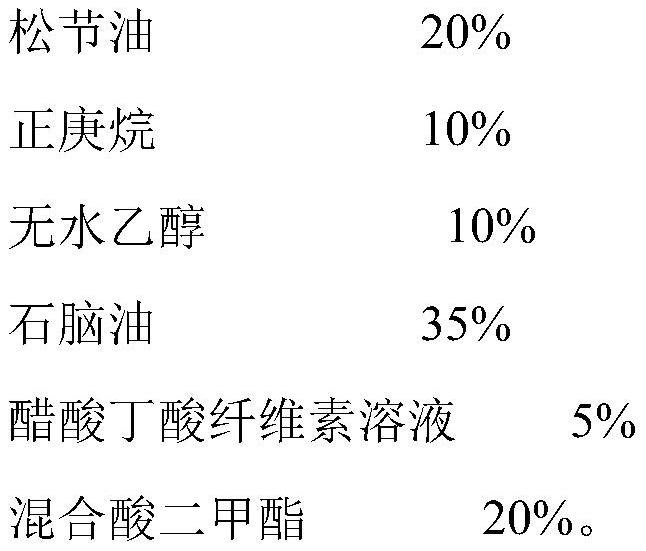

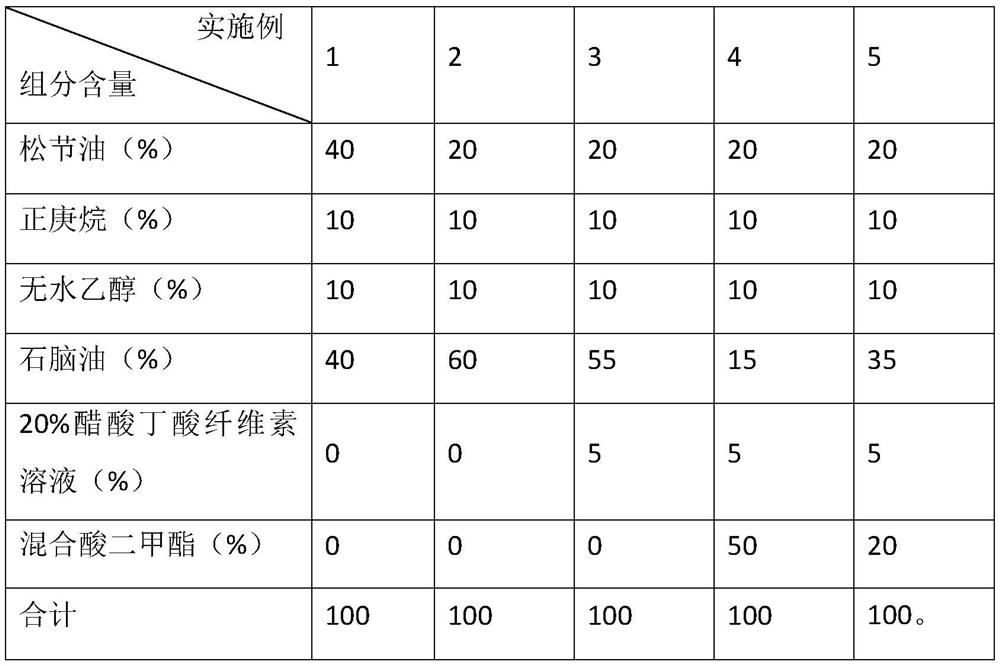

[0030] A kind of postage stamp gum cleaning agent, its composition is as follows:

[0031] Turpentine: 40%

[0032] Heptane: 10%

[0033] Ethanol: 10%;

[0034] Naphtha: 40%;

[0035] Total: 100%

[0036] The preparation method of stamp gum cleaning agent is as follows: measure each component according to the volume required by the formula, set the speed of the disperser at 600-1200r / s at 20°C, stir for 5-10 minutes, and stand still for 5 minutes to test.

[0037] Instruments and equipment: 60-degree angle gloss meter, analytical balance, blast drying oven, film thickness tester, etc.

[0038] The test method of postage stamp gum cleaning agent comprises the following steps: (1) first dry the stamp, and measure the quality, thickness and gloss of the stamp; the drying temperature is 60°C, and the drying time is 30min; (2) then Soak the stamps in the cleaning agent with the above ratio, and separate the stamps and envelopes after 5 minutes; (3) Continue soaking the separat...

Embodiment 2

[0046] A kind of postage stamp gum cleaning agent, its composition is as follows:

[0047] (1) Turpentine: 20%

[0048] (2) Heptane: 10%

[0049] (3) Ethanol: 20%

[0050] (4) Naphtha: 60%

[0051] Total: 100%

[0052] The preparation method of stamp back glue cleaning agent is as follows: Measure each component according to the volume required by the formula, put it in a disperser at 20°C with a speed of 600-1200r / s, stir for 30 minutes, and stand still for 5 hours to test.

[0053] Instruments and equipment: 60-degree angle gloss meter, analytical balance, blast drying oven, film thickness tester.

[0054] The test method of postage stamp gum cleaning agent comprises the following steps: (1) first dry the stamp, and measure the quality, thickness and gloss of the stamp; the drying temperature is 60°C, and the drying time is 30min; (2) then Soak the stamps in the cleaning agent with the above ratio, and peel off the stamps and envelopes after 15 minutes; (3) Continue soa...

Embodiment 3

[0062] A kind of postage stamp gum cleaning agent, its composition is as follows:

[0063] (1) Turpentine: 20%

[0064] (2) Heptane: 10%

[0065] (3) Ethanol: 10%

[0066] (4) 20% cellulose acetate butyrate solution 5%

[0067] (5) Naphtha: 55%

[0068] Total: 100%

[0069] The preparation method of stamp back glue cleaning agent is as follows: Measure each component according to the volume required by the formula, put it in a disperser at 20°C with a speed of 600-1200r / s, stir for 30 minutes, and stand still for 5 hours to test.

[0070] Preparation method of 20% cellulose acetate butyrate solution: Weigh 10 g each of cellulose acetate butyrate 381-2 and cellulose acetate butyrate 531-1, and 80 g of n-butyl acetate, put them in a disperser, Stir at a high speed of 1200-2000r / s for 60min to completely dissolve cellulose acetate butyrate in n-butyl acetate; since cellulose acetate butyrate (381-2; 531-1) is supplied in solid form, it should be It needs to be dissolved int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com