A test structure and measurement method for the stress gradient of a mems microbeam with a detection hole

A technology for testing structures and stress gradients, which is applied in the direction of measuring the force of changes in optical properties of materials when they are stressed, can solve problems such as out-of-plane bending, affecting device performance, and buckling, and achieve lower requirements and intuitive observation methods , Accurate and reliable measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

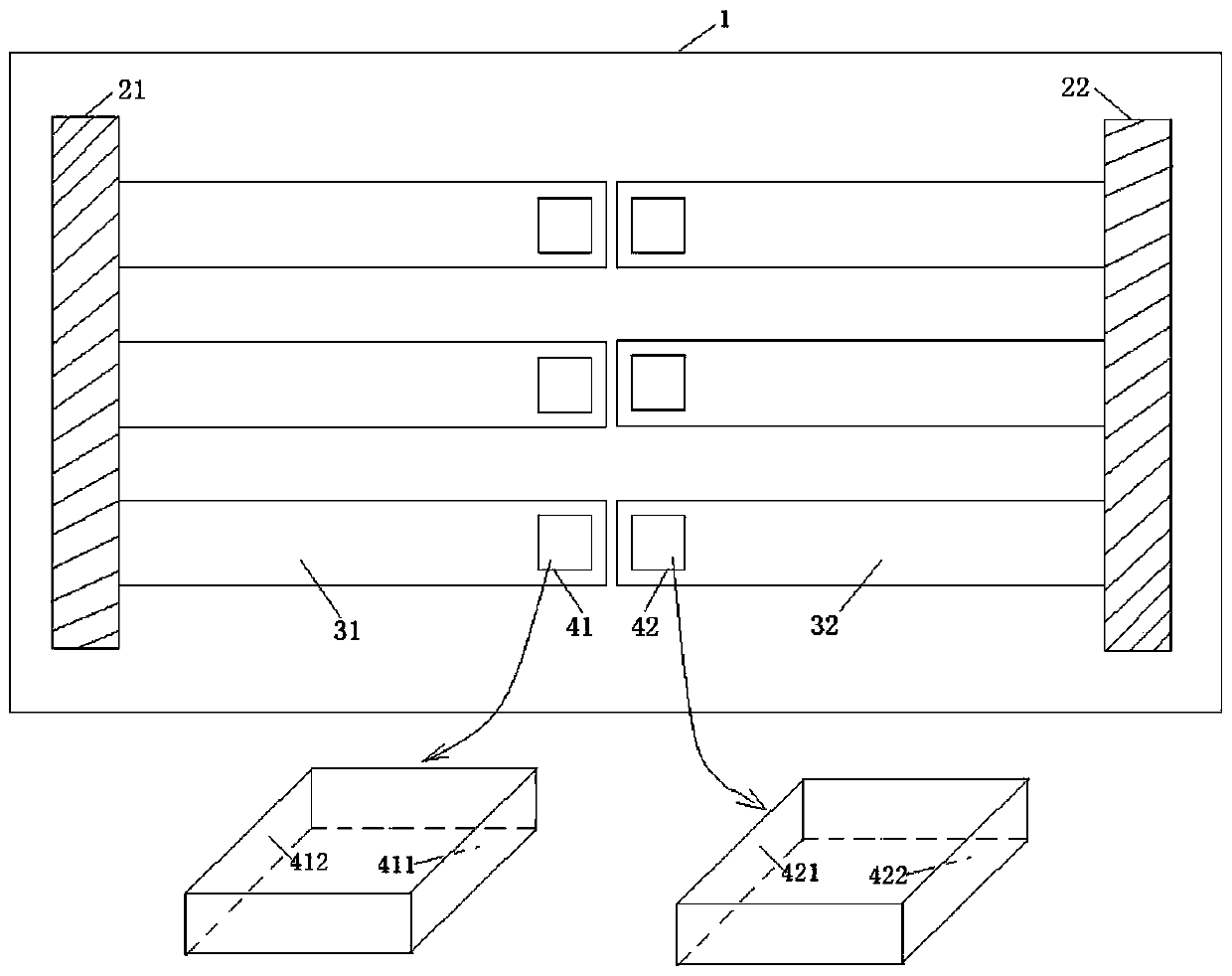

[0021] Such as figure 1 As shown, a test structure of a MEMS micro-cantilever stress gradient with a detection hole, including a substrate 1, two long anchor regions 21 and 22 and six measured cantilever beams with detection holes;

[0022] The two long anchor regions 21 and 22 are respectively fixed on the upper surface of the substrate 1;

[0023] One end of the tested cantilever beam is fixed on one side of the long anchorage area, and a square through hole is etched near the end of the other end as a detection hole, and the side wall of the detection hole 41 or 42 is perpendicular to the surface;

[0024] The six cantilever beams with detection holes are fixed in groups of three in parallel to each other on the side of a long anchorage area 21 or 22; the suspension ends of the two groups of cantilever beams 31 and 32 to be tested correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com