Online testing method for oil solution concentration of polyacrylonitile production used in carbon fiber

A polyacrylonitrile and carbon fiber technology, applied in the field of measurement, can solve the problems of time-consuming, cumbersome, low efficiency, etc., and achieve the effect of fast test method and improved timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

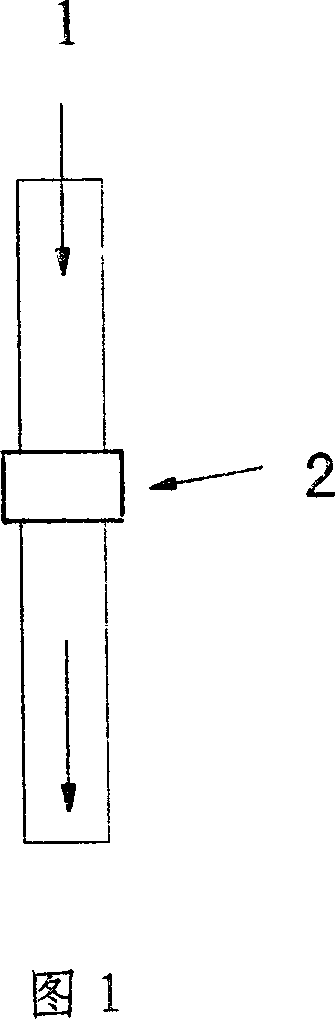

Image

Examples

example 1

[0027] Example 1, online detection of oil concentration of a certain brand

[0028] 1. Obtain the standard curve of oil concentration and refractive index;

[0029] 1.1. Prepare the oil concentration standard solution; assume that the integer value of the measured oil concentration value is α%; then the number of prepared concentration standard solutions is at least 5, one of which is α%, and the remaining half of the concentration standard solution is α%. The value is less than α%; the value of the other half of the concentration standard solution is greater than α%, and the distance between the concentration values of two adjacent standard solutions is 0.1*α%~0.5*α%; 12 points are selected in this example, and the specific content is shown in the table 1.

[0030] The concentration of table 1 oil agent concentration standard solution

[0031] Sample serial number

Concentration (%)

1

2.49966

2

2.993

3

...

example 2

[0046] Example 2, online detection of oil concentration of a certain brand

[0047] 1. Obtain the standard curve of oil concentration and refractive index;

[0048] 1.1. Prepare the oil concentration standard solution; if the integer value of the measured oil concentration value is α%, then the prepared concentration standard solution must have at least 5, one of which is α%, and the remaining half of the concentration standard solution is α%. If the value is less than α%, the value of the other half of the concentration standard solution is greater than α%, and the distance between the concentration values of two adjacent standard solutions is 0.1*α%~0.5*α%; 10 points are selected in this example, and the specific content is shown in the table 4.

[0049] The concentration of table 4 oil agent concentration standard solution

[0050] Sample serial number

Concentration (%)

1

9.97392

[0051] 2

11.988

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com