Anti-reverse-pole catalyst for battery and preparation method and application thereof

A catalyst and electrode technology, applied in the field of anti-reverse electrode catalyst for battery and its preparation, can solve the problem of insufficient anti-reverse electrode ability of anode catalyst, and achieve the effect of enhancing the anti-reverse electrode performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

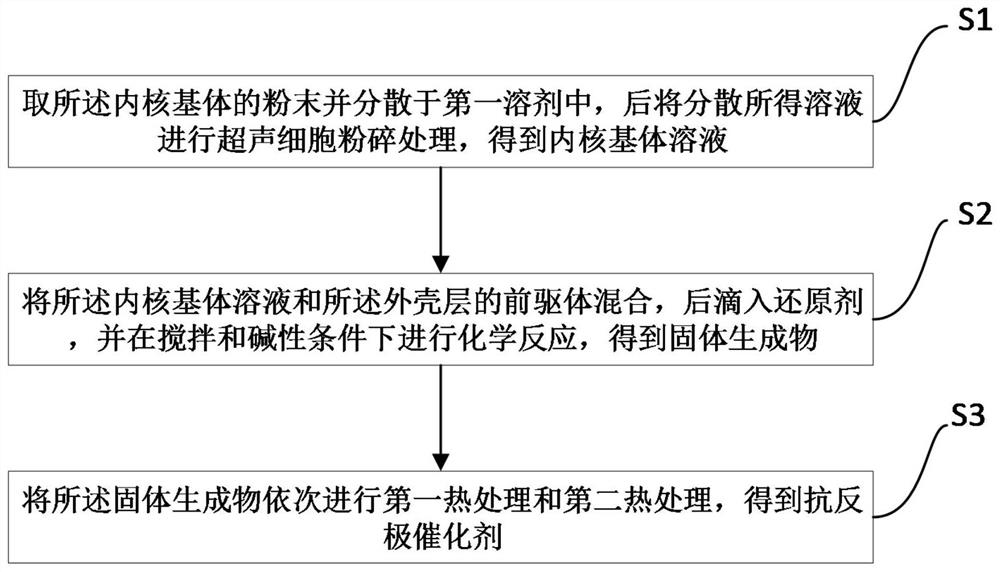

[0034] Such as figure 2 Shown, the application provides a kind of preparation method of anti-reversed pole catalyst, described method comprises:

[0035] S1. Taking the powder of the inner core matrix and dispersing it in the first solvent, and then subjecting the dispersed solution to ultrasonic cell crushing to obtain the inner core matrix solution;

[0036] S2. Mix the inner core matrix solution and the precursor of the coating layer, then drop a reducing agent, and carry out a chemical reaction under stirring and alkaline conditions to obtain a solid product, which contains the a mixture of the first active noble metal element and the second active noble metal element;

[0037] S3. The solid product is subjected to the first heat treatment and the second heat treatment in sequence to obtain an anti-anti-electrode catalyst; the catalyst has a core-shell structure, wherein the core matrix is a chemical substance containing the first active noble metal element, including ...

Embodiment 1

[0040] (1) For the anti-anti-reverse catalyst: select a certain amount of ruthenium powder and put it into a beaker, add deionized water and alcohol, the ratio of alcohol to water is 1:1, mix well and put it into an ultrasonic cell pulverizer for ultrasonic treatment for 0.5h; Add chloroiridic acid into the uniformly dispersed solution, then add dropwise sodium hydroxide and sodium borohydride solutions, and maintain a vigorous magnetic stirring state when adding the above solutions. After standing still, a mixture of iridium and ruthenium is obtained. After filtering and cleaning, the mixture is baked at a temperature of 90°C, and then roasted at a high temperature at a temperature of 500°C to obtain IrO 2 Ru core-shell structure anti-anti-electrode catalyst;

[0041] (2) For the anode catalyst: choose the Pt / C catalyst with a Pt content of 50%, add deionized water for wetting, then add a certain amount of Nafion emulsion and isopropanol with a mass fraction of 5%, and contro...

Embodiment 2

[0045] (1) For the anti-anti-reverse catalyst: select a certain amount of ruthenium powder and put it into a beaker, add deionized water and alcohol, the ratio of alcohol to water is 1:1, mix well and put it into an ultrasonic cell pulverizer for ultrasonic treatment for 0.5h; Add ruthenium chloride into the uniformly dispersed solution, then add sodium hydroxide and sodium borohydride solution dropwise, and maintain a vigorous magnetic stirring state when adding the above solution. After standing still, a mixture of iridium and ruthenium is obtained. After filtering and cleaning, the mixture is baked at a temperature of 90°C, and then roasted at a high temperature at a temperature of 500°C to obtain RuO 2 Ru core-shell structure anti-anti-electrode catalyst;

[0046] (2) For the anode catalyst: choose the Pt / C catalyst with a Pt content of 50%, add deionized water for wetting, then add a certain amount of Nafion emulsion and isopropanol with a mass fraction of 5%, and control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com