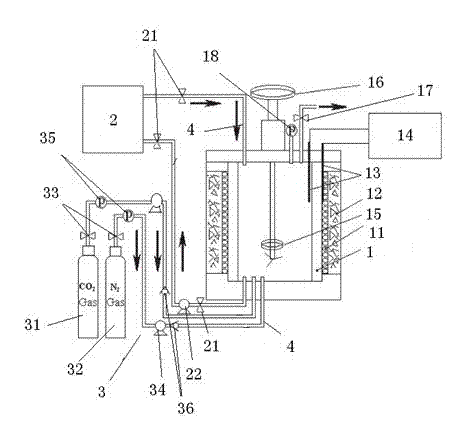

Contrast simulation testing device for carbon dioxide corrosion resistant performance of steel and testing method thereof

A corrosion performance and simulation test technology, applied in the field of material corrosion, can solve the problems of high cost, different functions and purposes, high cost and inconvenient, etc., and achieve the effect of high control precision, stable performance and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Temperature: 90°C

[0037] CO 2 Partial pressure: 1 MPa

[0038] Experimental materials: Q235B, L415, 304, 316L

[0039] The specific operation is as follows:

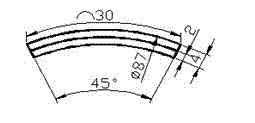

[0040] (1) Process the steel into an arc-shaped sample of φ87mm, after being polished with 800# sandpaper, immerse it in a beaker filled with acetone, put it into an ultrasonic cleaner for 20 minutes, and remove the oil stain on the surface of the sample, Alcohol cleaning cold air drying;

[0041] (2) Place the sample on an electronic analytical balance with an accuracy of 0.1 mg to weigh it, measure the size with a vernier caliper with an accuracy of 0.02 mm, calculate the area of the corrosion surface of the sample, and record the measured data; each group of experiments is inlaid with multiple arcs Put the sample on the sample holder and put it into the reaction kettle;

[0042] (3) Proportioning test solution A, with CO 2 After deoxygenation for 10 hours, pass it into the solution pool and the reaction...

Embodiment 2

[0050] Temperature: 120°C

[0051] CO 2 Partial pressure: 2.4 MPa

[0052] Experimental materials: Q235B, L415, 304, 316L

[0053] Specific operation in addition to solution, temperature, CO 2 Partial pressure is different, and other processes are with embodiment 1:

[0054] The corrosion rates (mm / a) of the experimental steel types are Q235B, 2.05; L415, 1.85; 304, 0.007; 316L, 0.003.

[0055] The order of corrosion rate from high to low in Example 1 is L415 > Q235B > 304 stainless steel > 316L stainless steel;

[0056] The order of the corrosion rate of embodiment 2 from high to low is Q235B > L415 > 304 stainless steel > 316L stainless steel;

[0057] The experimental device of the present invention has simple structure, stable performance, high control precision and simple operation, and can be used for the anti-CO 2 Comparative simulation test of corrosion performance. Provide simulated CO in crude oil 2 The corrosion of steel under corrosion conditions provides m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com