Patents

Literature

68 results about "Co2 partial pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

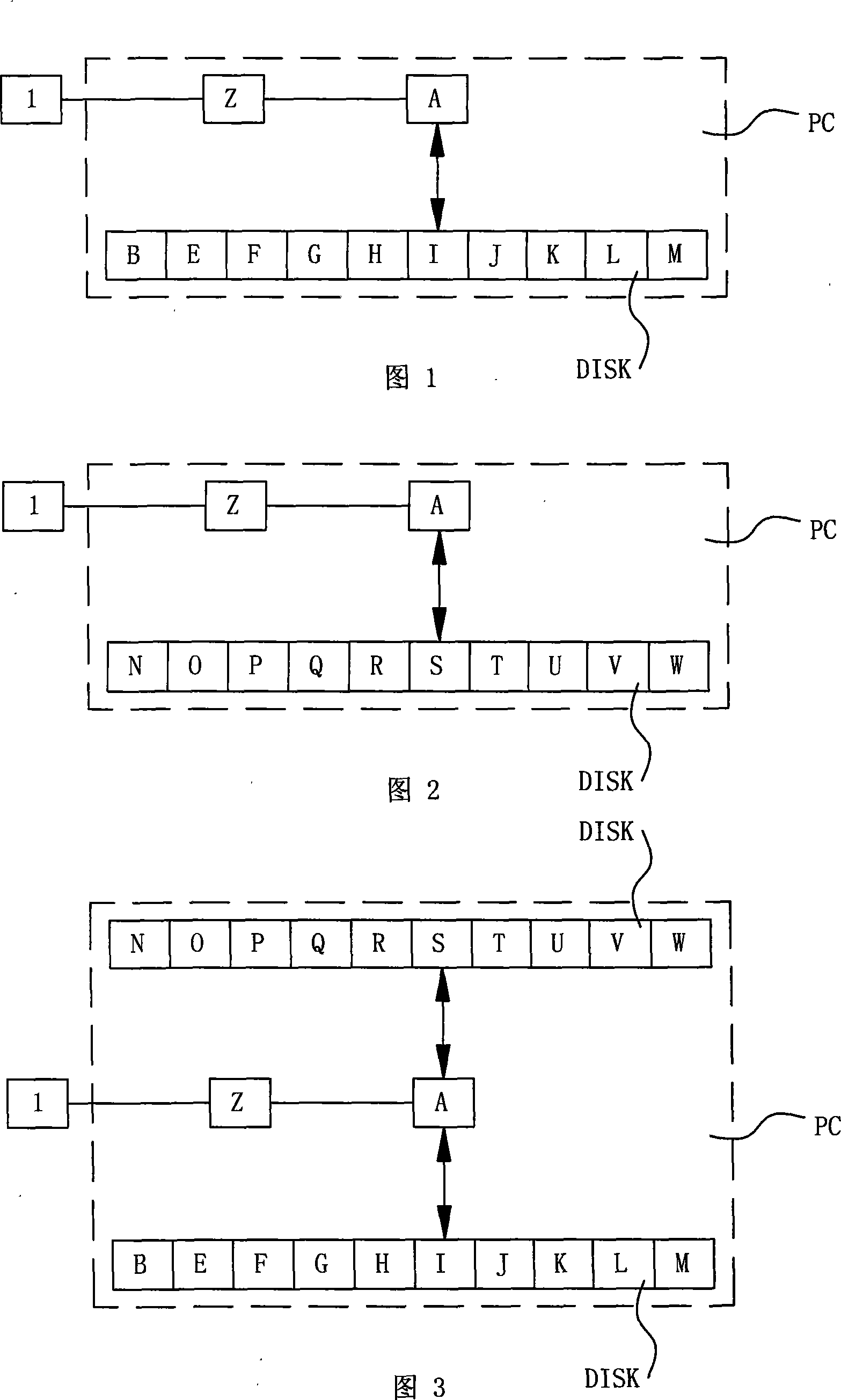

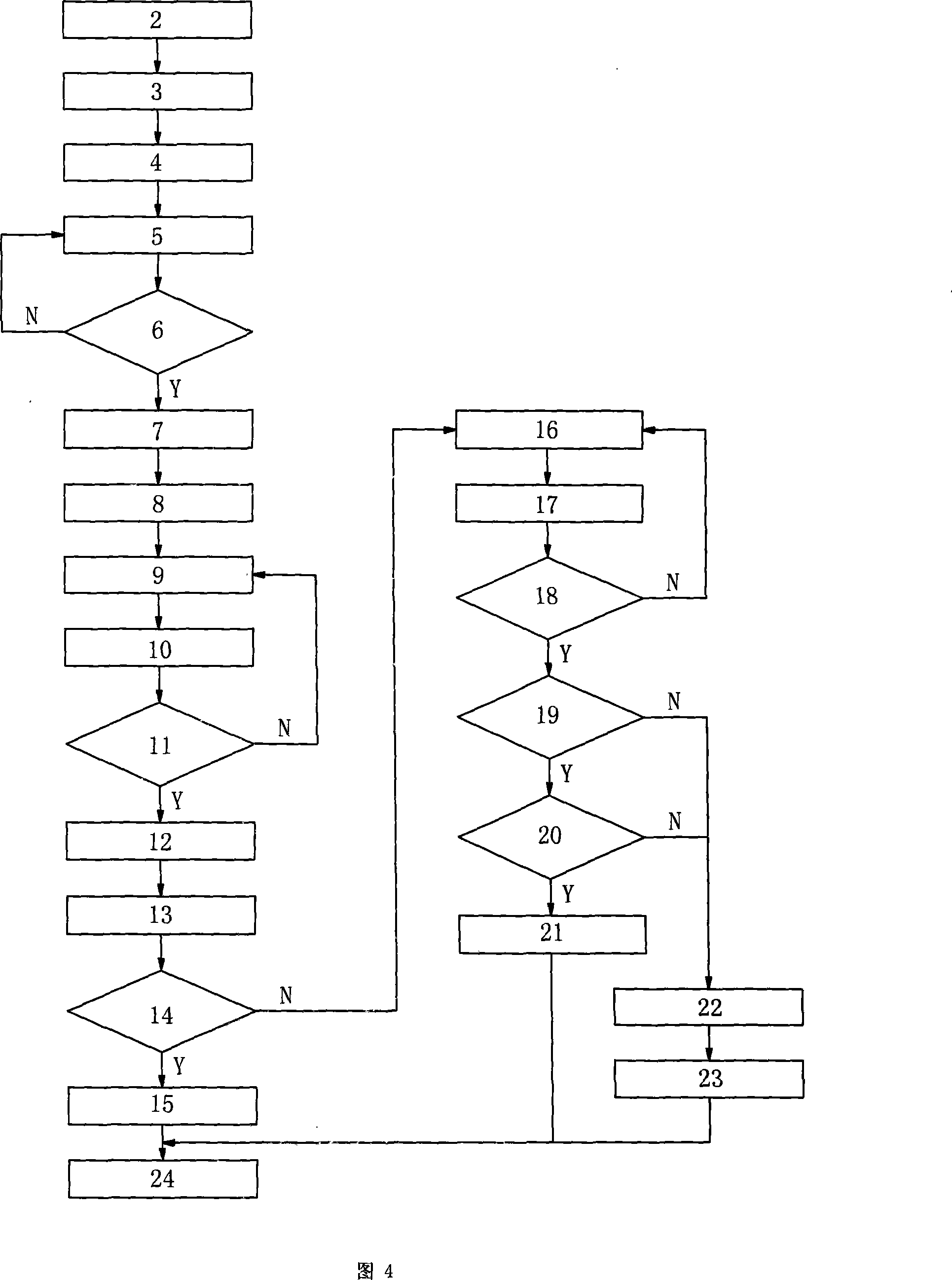

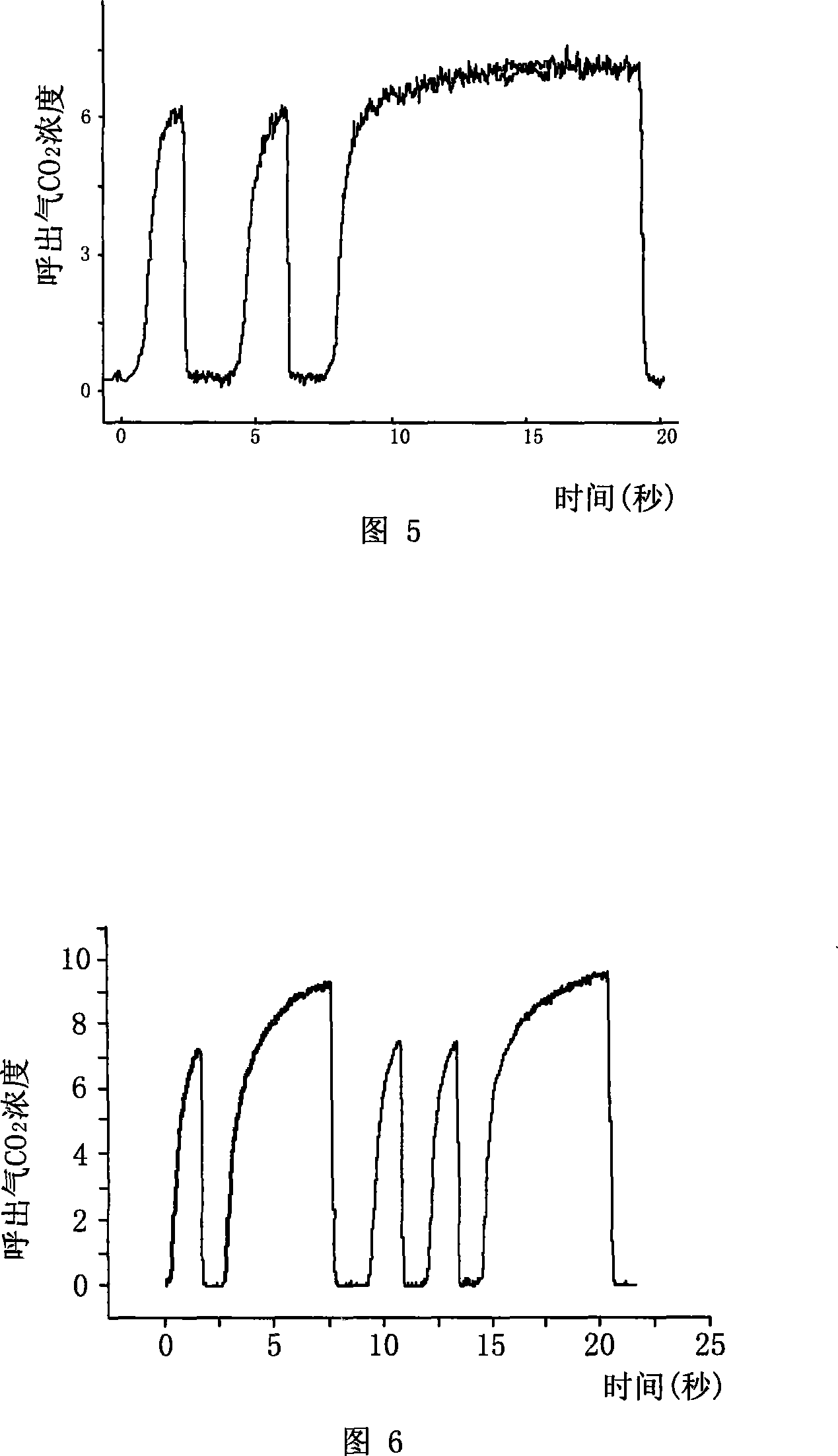

Method and device for pressure dividing monitoring and estimating arterial blood CO2 by using respiratory gas CO2

InactiveCN101214151ARealize non-invasive dynamic continuous monitoringHigh clinical application valueBiological testingBlood characterising devicesMathematical modelBlood arterial

The invention discloses a method and a device using the expired gas partial pressure of CO2 to monitor and estimate the CO2 partial pressure of arterial blood, belonging to the clinical respiratory monitoring technology field. The technical points includes using a CO2 analyzing and monitoring instrument for the real-time acquisition on the expiratory flow, the time and CO2 partial pressure PaCO2 to be input into a computer; processing input data; when the instant flow is 22.25 plus or minus 0.08 percent or the instant slope of the flow speed / time curve is 0.13 plus or minus 0.19, (a) and the difference of the corresponding CO2 partial pressures is within about 5 percent, the average value of the corresponding CO2 partial pressure is basically the same with the arterial blood CO2 partial pressure; (b) the corresponding CO2 partial pressure difference is over about 5 percent, the mathematical model fitting is implemented on the CO2 partial pressure / time curve to estimate the corresponding arterial blood CO2 partial pressure. The invention can be applied to clinical wound-free monitoring COPD patients, especially the PaCO2 of severe COPD patients.

Owner:THE FIRST AFFILIATED HOSPITAL OF GUANGZHOU MEDICAL UNIV (GUANGZHOU RESPIRATORY CENT) +1

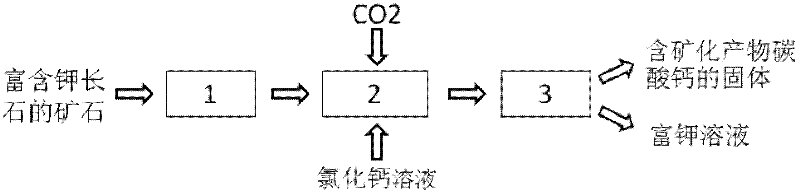

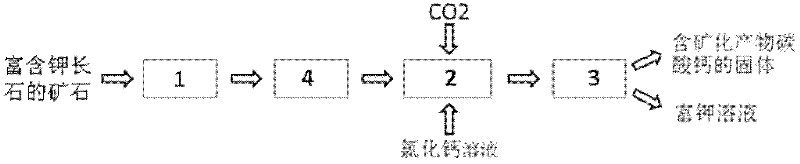

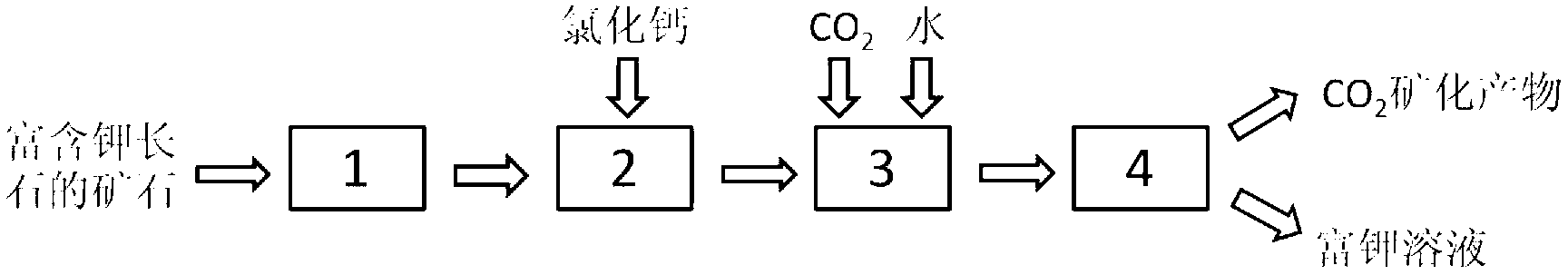

CO2 mineralization method for co-producing potassium-rich solution

InactiveCN102491795AOvercoming the shortage of production resourcesTroubleshoot technical issuesCalcareous fertilisersProductsCo2 partial pressureSlurry

The invention discloses a CO2 mineralization method for co-producing potassium-rich solution, which mainly comprises the following process steps: smashing ores containing potassium feldspars into powder; placing smashed ore powder in a reactor, adding calcium chloride solution into the reactor and feeding CO2 gas into the reactor to perform mineralization reaction under the conditions of temperature of 150-350DEG C and CO2 partial pressure of no less than 1.0MPa, wherein the CO2 is mineralized to produce calcium carbonate, and the potassium feldspars are dissolved to produce solution rich in potassium ions; sending obtained slurry after complete reaction to a separation device to perform solid-liquid separation, wherein obtained solid phase is a solid body containing mineralization product calcium carbonate and obtained liquid phase is the potassium-rich solution rich in the potassium ions. The potassium-rich solution is co-produced in the CO2 mineralization process, the bottlenecks that the additional value of CO2 mineralization products by means of an existing CO2 mineralization method is low and industrialization of the CO2 mineralization technology is difficult to implement are broken through, and the problem of CO2 emission reduction is solve. Simultaneously, sufficient potassium resources are provided for potash fertilizer production, and the trouble of shortage of the potash fertilizer production resources in China is solved.

Owner:SICHUAN UNIV

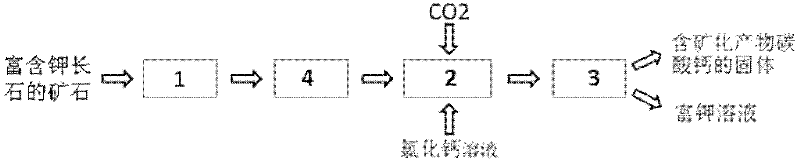

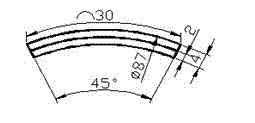

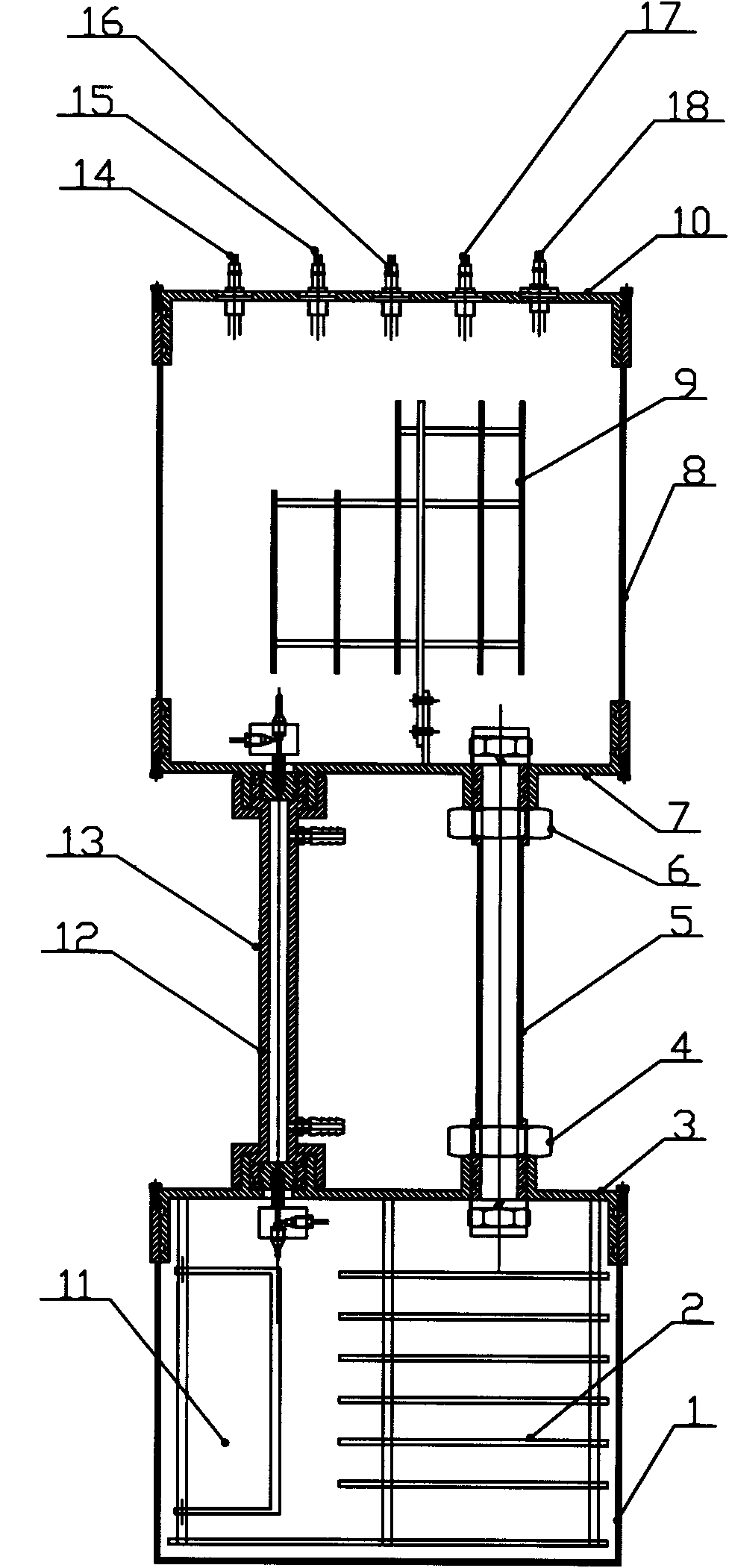

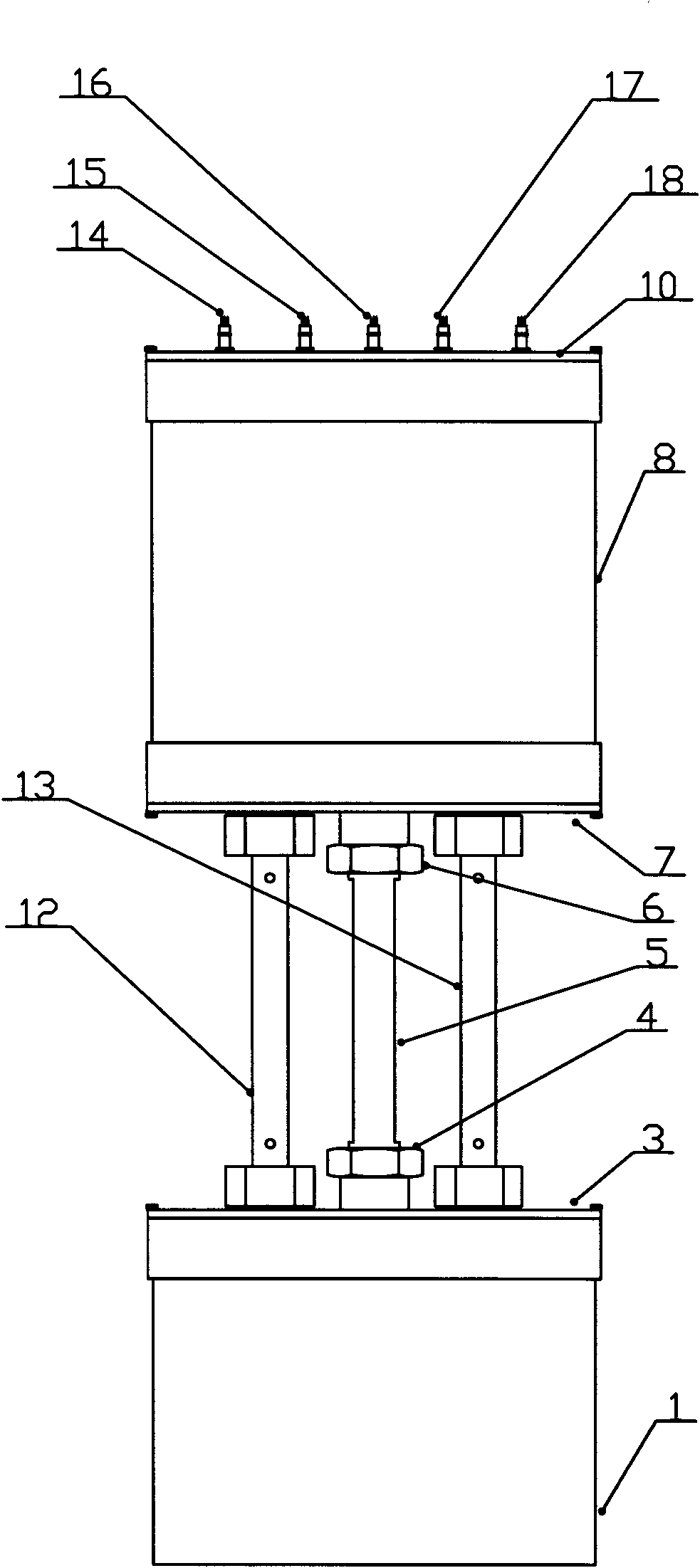

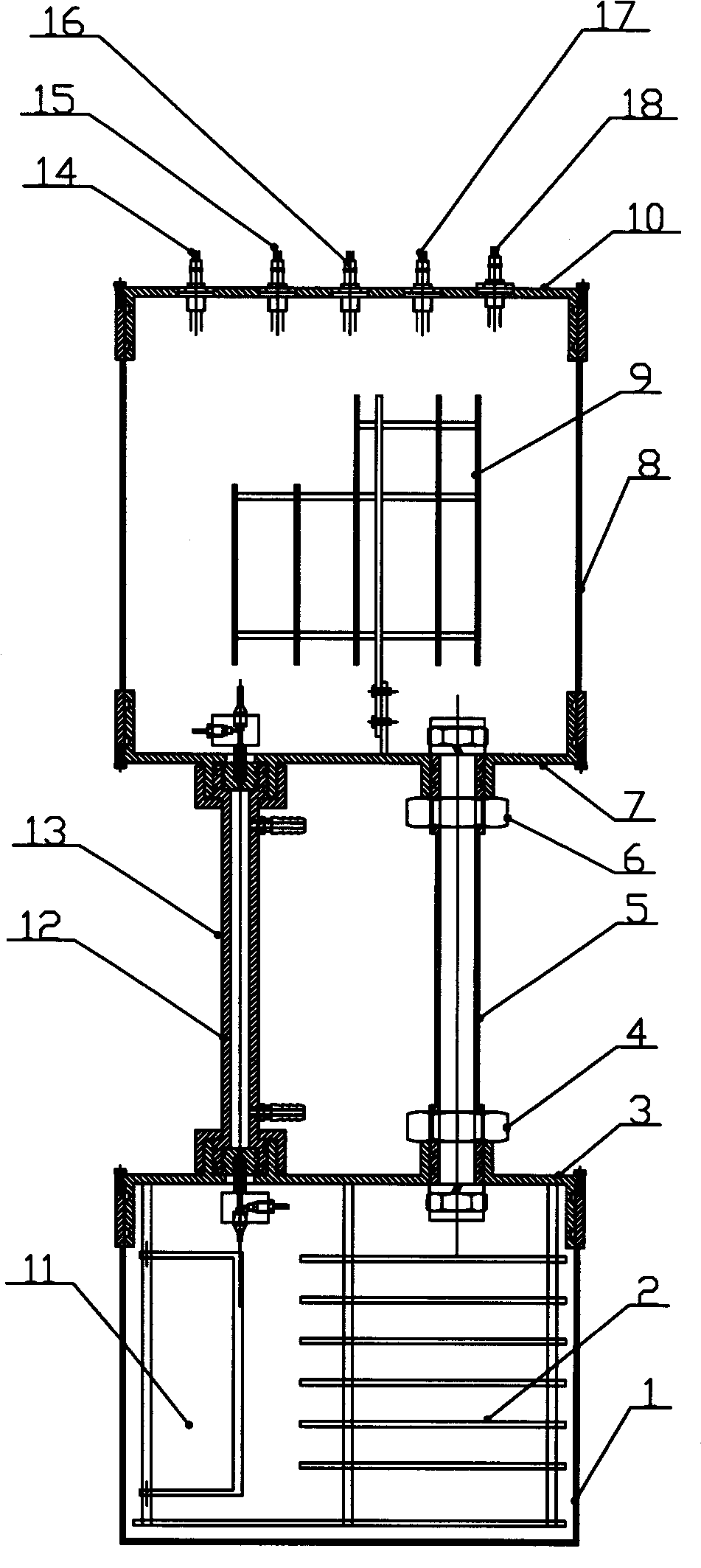

Contrast simulation testing device for carbon dioxide corrosion resistant performance of steel and testing method thereof

InactiveCN102854127ASatisfy Comparative Corrosion TestSimple structureWeather/light/corrosion resistancePreparing sample for investigationCarbon corrosionCarbon dioxide corrosion

The invention discloses a contrast simulation testing device for carbon dioxide corrosion resistant performance of steel and a testing method thereof. The device comprises a reaction kettle, a solution pond and a pressure adjusting device, wherein the solution tank is connected with the reaction kettle by a liquid control valve; a heating rod and a heat insulation material are wound on the outer wall of the reaction kettle; a thermal couple and a temperature adjuster are arranged in the reaction kettle; a sample clamp connected with a stirring device is arranged in the reaction kettle; and a pressure adjusting device comprises a CO2 gas tank and an N2 gas tank which are connected with the bottom of the reaction kettle. The method is used for contrasting and simulating a condition that a pipeline steel material is corroded by CO2 in crude oil so as to evaluate corrosion velocity of the steel material of which the temperature is between 90 and 120 DEG C, CO2 partial pressure is between 1 and 2.4MPa in the solution. The CO2 corrosion resistant performance of the steel with different materials, steel levels and thicknesses can be tested at the same time, and the test is convenient and easy. Corrosion simulation test of various oil fields is performed by adjusting the temperature, partial pressure and solution components.

Owner:NANJING IRON & STEEL CO LTD

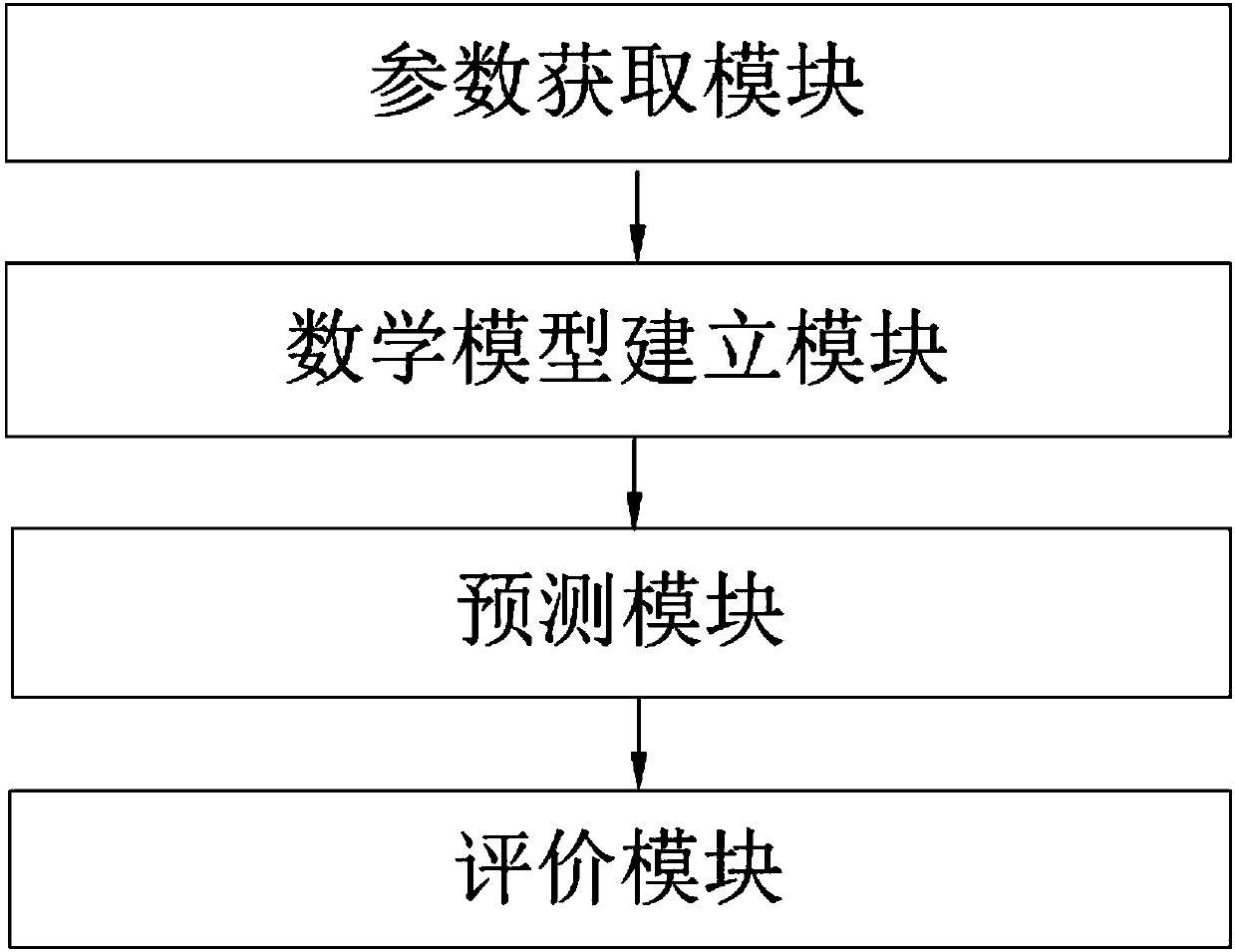

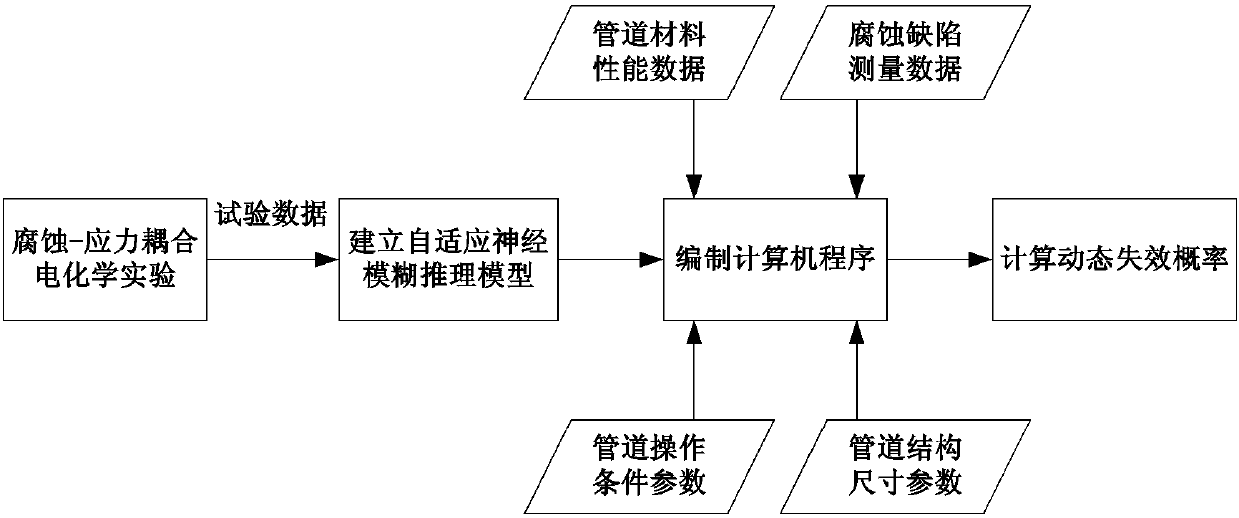

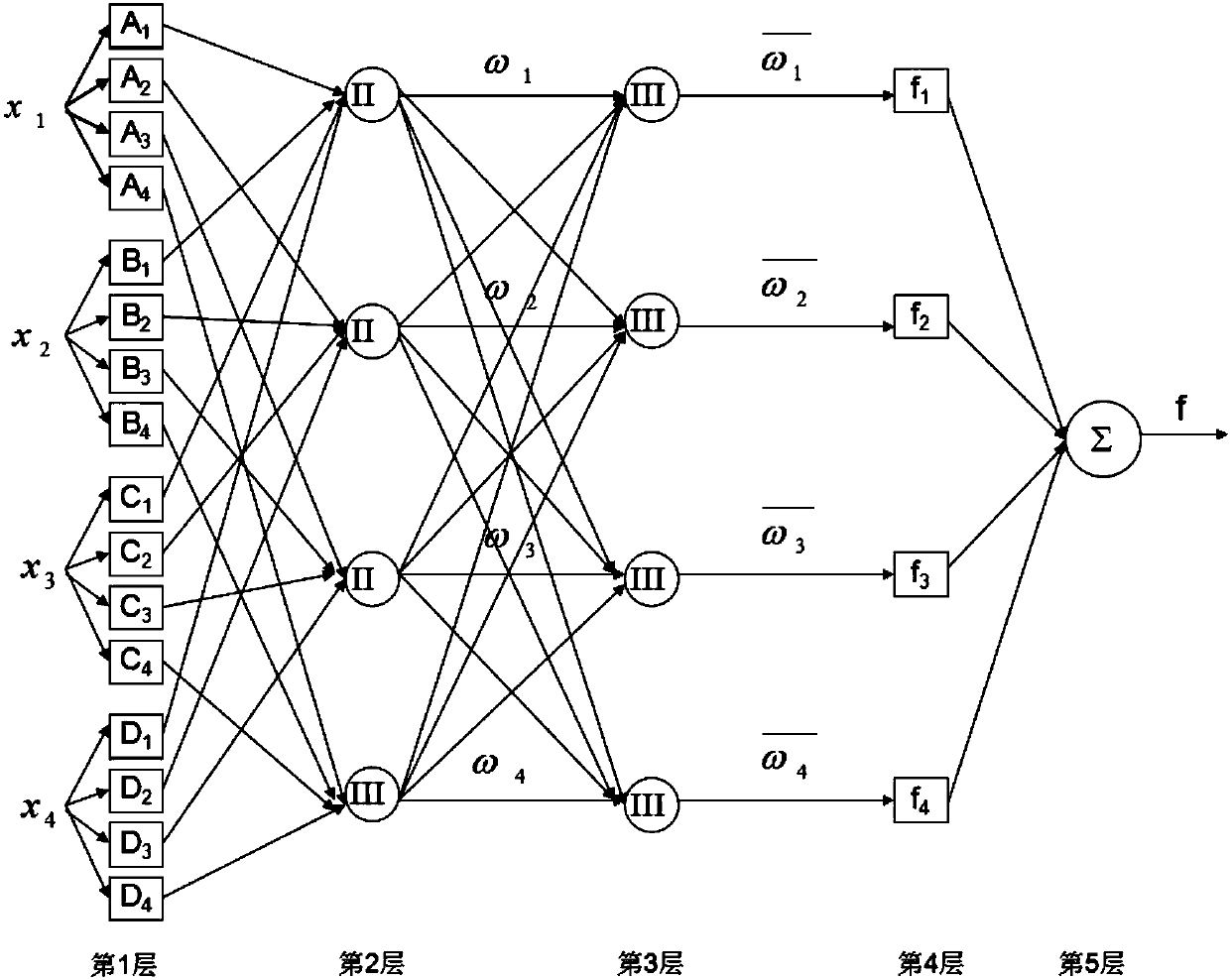

Method and apparatus for dynamically and safely determining corrosive defects inside conveying pipeline

ActiveCN107063991ARapid assessmentAccurate assessmentWeather/light/corrosion resistanceTesting metalsMathematical modelMetallic materials

The invention provides a method and an apparatus for dynamically and safely determining corrosive defects inside a conveying pipeline. The method comprises the following steps: acquiring a corrosion expansion rate of a conventional metal material for a conveying pipeline under different CO2 partial pressure, H2S partial pressure, chloride contents and different stress levels; establishing a mathematic model of the corrosion expansion rate by utilizing a self-adaptive neural-fuzzy inference system according to the acquired corrosion expansion rate; acquiring the CO2 partial pressure, a H2S content, the chloride content and the stress level of a pipe section at which a corroded portion of the pipeline is located, and predicting the corrosion expansion rate according to the established mathematic model; and establishing a pipeline limit-state equation, and acquiring a safety state of the pipeline. The invention also provides the apparatus for dynamically and safely determining the corrosion defects inside the conveying pipeline. By adopting the method and the apparatus for dynamically and safely determining the corrosion defects inside the conveying pipeline, the problem that the safety state of the oil-gas conveying pipeline containing the corrosion defects is difficult to determine dynamically and accurately can be solved.

Owner:PETROCHINA CO LTD

CO2 mineralization method capable of co-producing potassium-enriched solution by high temperature method

InactiveCN102701253AMineralization achievedImplement extractionCalcium/strontium/barium carbonatesPotassium fertilisersPotassium ionsChloride

The invention discloses a CO2 mineralization method capable of co-producing potassium-enriched solution by a high temperature method, which mainly comprises the following steps of: adequately and evenly mixing smashed potash feldspar-enriched ore power and calcium chloride, and carrying out conversion reaction under the condition that the temperature is not lower than 600 DEG C; putting material which is adequately converted into a reactor, adding water, charging CO2, and carrying out mineralization reaction under the condition that the CO2 partial pressure is 0.3-15MPa, and the temperature is 50-350 DEG C; and charging material liquid which is adequately mineralized into separation equipment to separate the solid from the liquid, wherein the liquid phase is the potassium ion-enriched potassium-enriched solution, and the solid phase is the calcium carbonate-containing mineralized product. The CO2 is mineralized by the technical method disclosed by the invention, and the conversion rate of the potash feldspar component in the ore reaches 96%, so that compared with the highest conversion rate 13% of the existing CO2 mineralization method capable of co-producing the potassium-enriched solution, the conversion rate of the CO2 mineralization method is improved by over 6.3 times.

Owner:SICHUAN UNIV

Chinese medicine composition prescription for treating pulmonary heart disease and its preparation process

InactiveCN1294926CReduce partial pressureLow costPharmaceutical delivery mechanismRespiratory disorderCardiopulmonary diseaseCoronary heart disease

The present invention is one kind of the recipe and preparation process of cardiopulmonary disease treating Chinese medicine composition. The Chinese medicine composition includes main material comprising astragalus root, pepperweed seed, Chuanxiong rhizome and trichosanthes peel, as well as supplementary material. The Chinese medicine composition as one kind of Chinese medicine injection for treating cardiopulmonary disease is superior to available medicines in that it can obviously lower CO2 partial pressure and raise oxygen partial pressure.

Owner:SHANGHAI YUZHIHUA MEDICAL TECH CO LTD

Removal of co2 from gases having low co2 partial pressures, using 2,2'-(ethylenedioxy)-bis-(ethylamine) (edea)

Use of an absorption agent for removing acid gases from a fluid flow, comprising an aqueous solution of 2,2'-(ethylenedioxy)-bis-(ethylamine).

Owner:ТІССЕНКРУПП УДЕ ҐМБГ

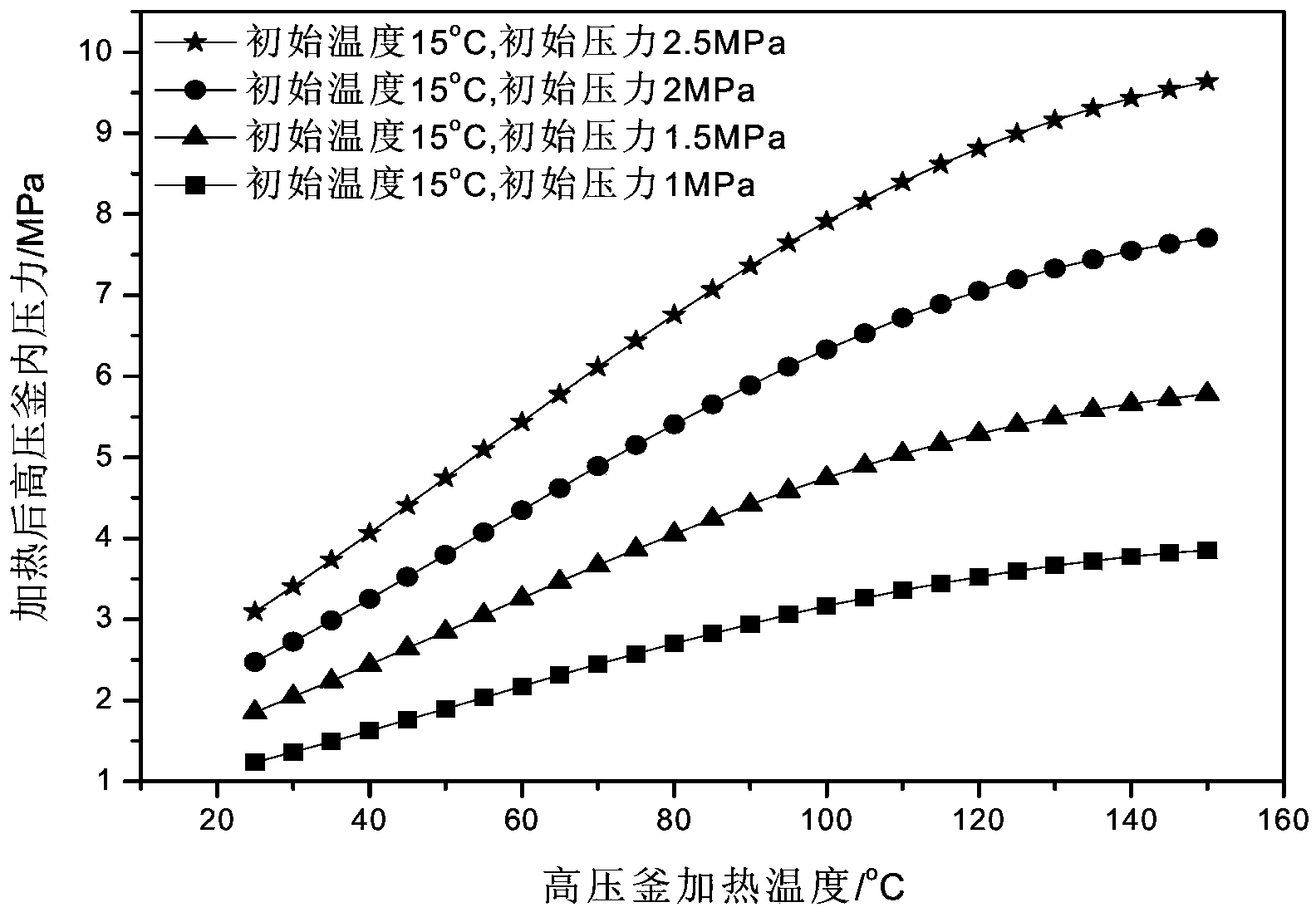

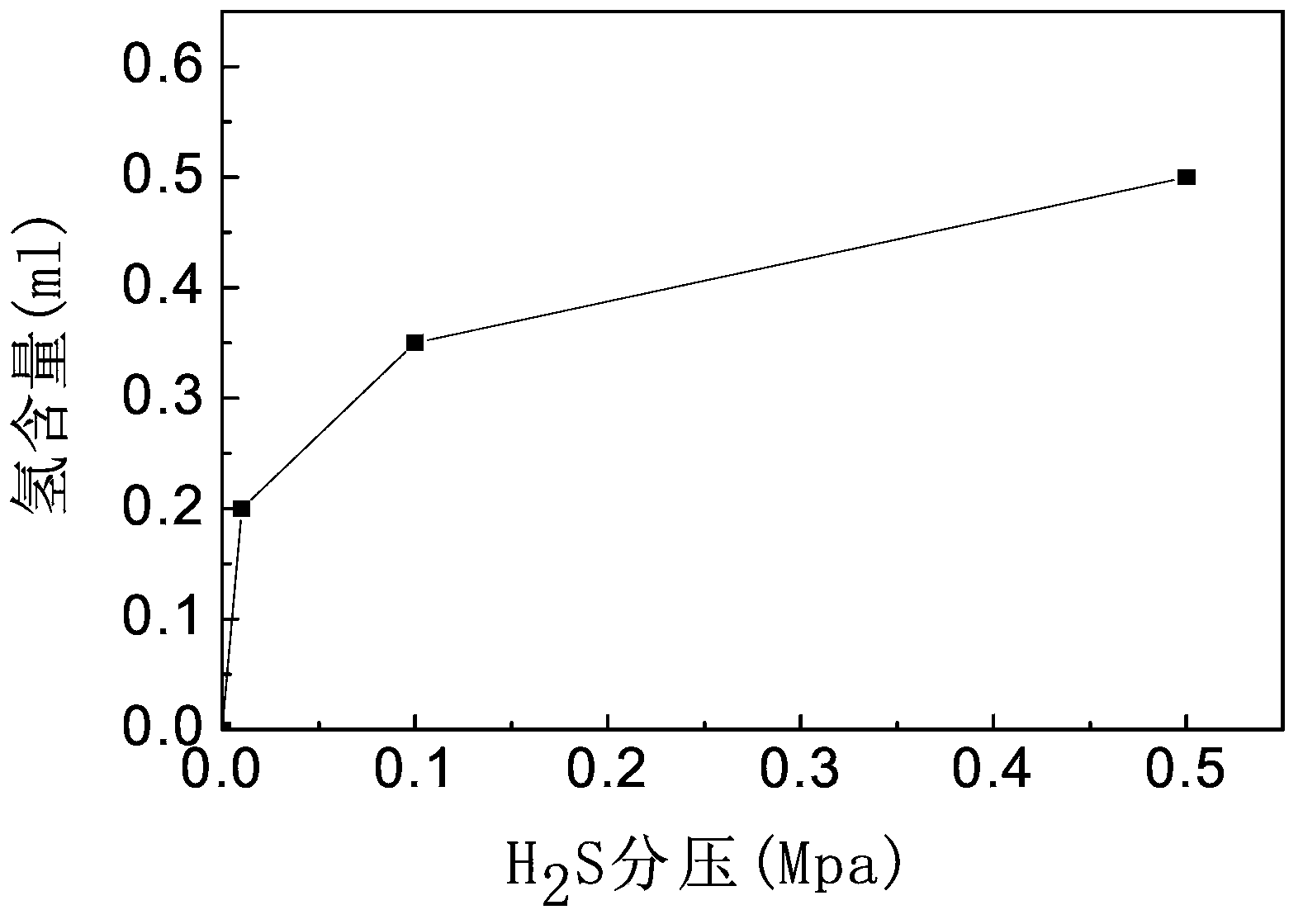

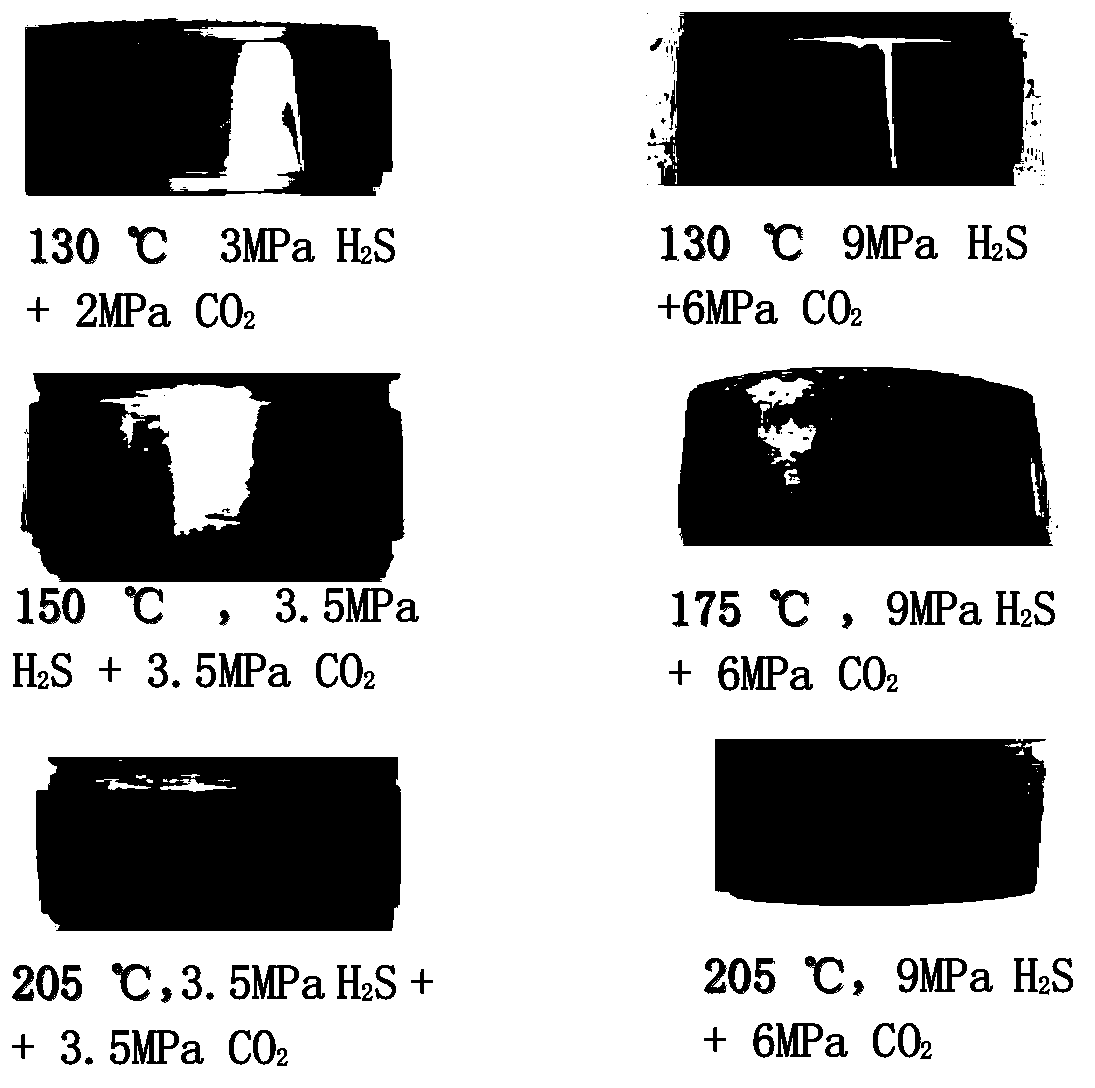

High-acidity gas field wellbore string material optimization evaluation system and method

ActiveCN104251812ASolve unfounded puzzlesPromote localizationWeather/light/corrosion resistanceSulfurCo2 partial pressure

The invention provides a high-acidity gas field wellbore string material optimization evaluation system and method, and belongs to the field of high-acidity gas field development. The high-acidity gas field wellbore string material optimization evaluation system includes a corrosion rate prediction model and a stress corrosion cracking boundary model; the corrosion rate prediction model includes H2S partial pressure-temperature, H2S partial pressure-CO2 partial pressure and elementary substance S-pH value corrosion rate prediction drawing boards; the stress corrosion cracking boundary model includes a failure boundary of a material under conditions of the temperature and the H2S partial pressure and a failure boundary of the material after sulfur is separated out under the conditions of the temperature and the H2S partial pressure. The system and the method solve the problems that due to a corrosion simulation evaluation method and a corrosion prediction model and software, a gas field highly containing H2S / CO2 is lack of basis on material selection, and provide a theoretical support for high-acidity gas field development and safety production.

Owner:CHINA PETROLEUM & CHEM CORP +1

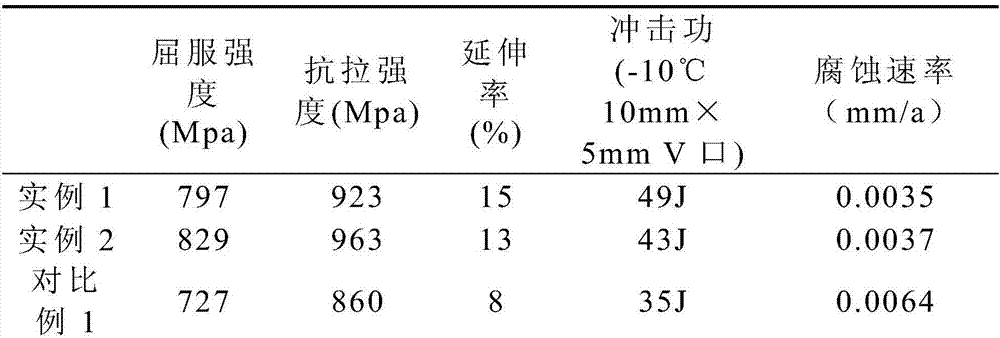

Oil layer-section oil casing pipe for exploiting thick oil by method of combustion drive and production method thereof

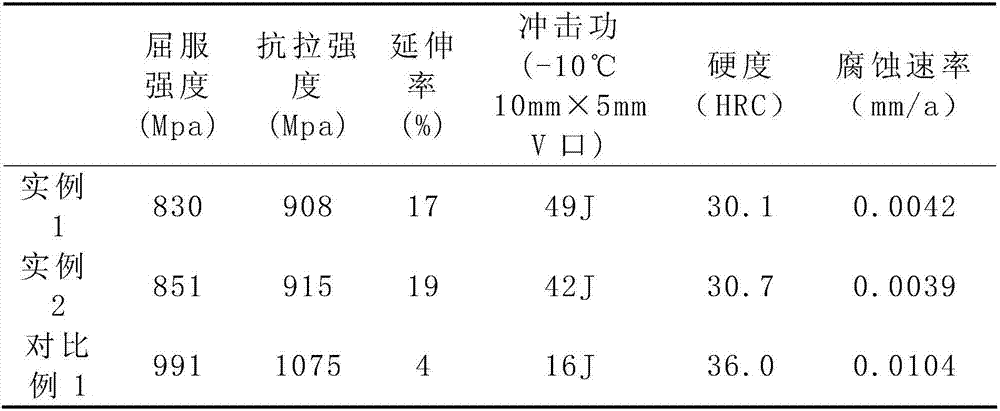

ActiveCN101655002AMeet the use requirementsLow average corrosion rateDrilling rodsMolten metal pouring equipmentsCombustionCo2 partial pressure

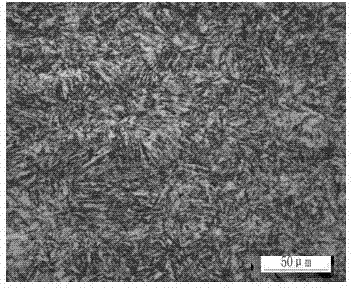

The invention provides an oil layer-section oil casing pipe for exploiting thick oil by a method of combustion drive, which comprises the following chemical components in percentage by weight: 0.06-0.14% of C, 0.20-0.50% of Si, 0.20-0.70% of Mn, P which is greater than or equal to 0 and less than or equal to 0.015, S which is greater than or equal to 0 and less than or equal to 0.010, 8.0-10% of Cr, 0.80-1.20% of Mo, Al which is greater than or equal to 0 and less than or equal to 0.015wt, Cu which is greater than or equal to 0 and less than or equal to 0.15wt, Ni which is greater than or equal to 0 and less than or equal to 0.40, and the balance of Fe. The invention also provides a production method of the oil layer-section oil casing pipe for exploiting thick oil by the method of combustion drive. The invention has the effect that the casing pipe produced according to the steel grade and the production technology has the characteristics that the yield strength of the material of the casing pipe reaches more than 580MPa at the environmental temperature of 550 DEG C, the endurance strength of 100000 hours at 650 DEG C reaches more than 70MPa, and the average corrosion rate of the casing pipe is lower than 0.32mm / year under the environmental conditions that the temperature is 150 DEG C, the CO2 partial pressure is 1.5MPa and the flow rate is 1.5m / s, thereby completely meeting the use requirements of oil layer-section casing pipes of casing pipe columns at the innermost layers of gas-injection wells and production wells for exploiting thick oil by the method of combustion drive.

Owner:TIANJIN PIPE GROUP CORP

Method for heading high-strength toughness titanium alloy drill rod material

ActiveCN107297450AMeet needsHigh resistance to hydrogen sulfide stress corrosionHeating/cooling devicesCo2 partial pressureTitanium alloy

The invention discloses a method for heading a high-strength toughness titanium alloy drill rod material. A titanium alloy drill rod is composed of, by weight, 5-7 parts of Al, 2.0-3.0 parts of Nb, 0.5-2.0 parts of Zr, 0.7-1.2 parts of Mo, 0.02-0.05 part of Fe, 0.01-0.03 part of Si and the balance being Ti. The method for heading the drill rod material composed of the compositions includes the steps that 1, smearing of glass powder is performed; 2, induction heating is performed; 3, primary heading is performed; 4, secondary heating is performed; 5, secondary heating is performed; 6, heat treatment is performed on integral pipes. The method has the advantages that after the titanium alloy drill rod material is headed, and the requirements for 110 ksi drill rod products of API standards are met, wherein mechanical properties are that the yield strength is larger than 758 Mpa, impact toughness is larger than 41 J, and the elongation rate is larger than 11%; the titanium alloy drill rod material can be used in a strict corroding environment that H2S partial pressure is 5 Mpa, CO2 partial pressure is 11 Mpa, the concentration of NaCl is 100000 ppmCl, and the native sulfur is 3 g / L. The showed capacity of resistance to hydrogen sulfide stress corrosion is far higher than that of a common API drill rod, and the titanium alloy drill rod material is the optimal material replacing carbon steel in exploitation and application of oil and gas, and meets the requirements of oil fields corroding the environment.

Owner:TIANJIN PIPE GROUP CORP

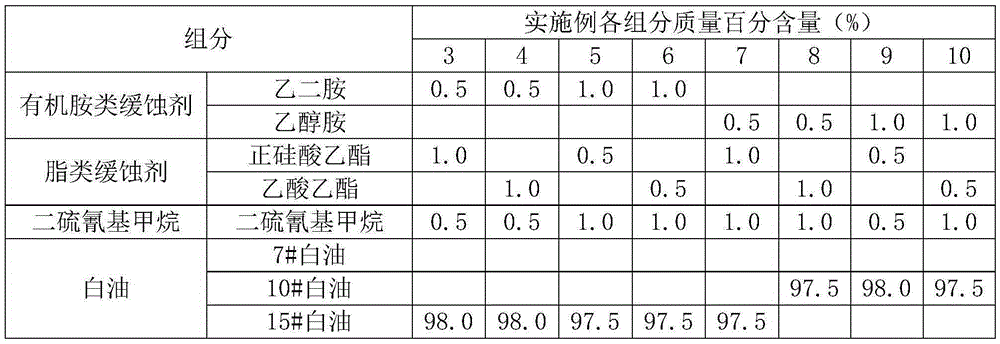

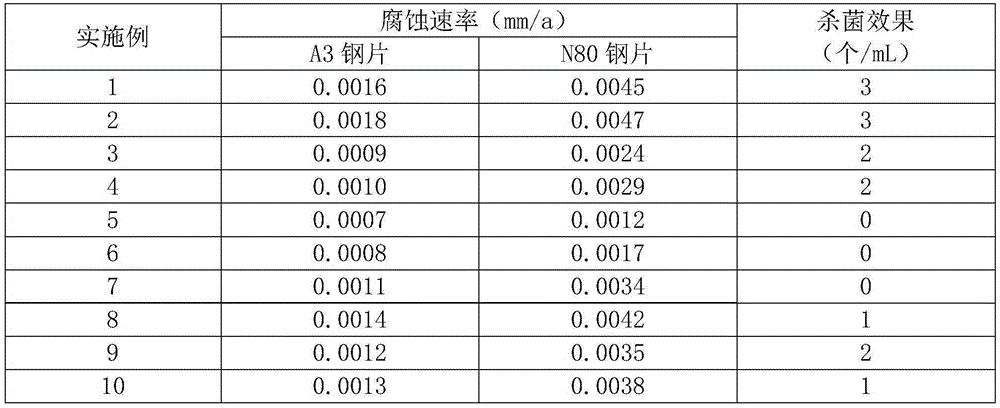

High-acidity gas well oil-based annulus protection fluid

ActiveCN105238378AImprove thermal stabilityHigh temperature resistanceDrilling compositionBorehole/well accessoriesCo2 partial pressureOil phase

The invention relates to a high-acidity gas well oil-based annulus protection fluid and belongs to the field of oil field chemical technology. The high-acidity gas well oil-based annulus protection fluid is composed of following components, by mass, 1.0-1.5% of a corrosion inhibitor, 0.5-1.5% of dithiocyanomethane and the balanced being white oil. The annulus protection fluid has good thermal stability and strong anti-high-temperature performance. Under an environment with total pressure being 7 MPa, H2S partial pressure being 1 MPa and CO2 partial pressure being 1 MPa, the annulus protection fluid is not more than 0.0018 mm / a in corrosion rate on A3 steel sheets and is not more than 0.0047 mm / a in corrosion rate on N80 steel sheets, is not more than 3 / ml in sterilization effects on saprophytic bacteria, iron bacteria and sulfate reducting bacteria. The annulus protection fluid can effectively prevent corrosion and destroy on oil pipelines in the well environment, can provide a durable protective function and greatly prolongs service life of annulus tubular column in the well. An oil phase is formed by the industrial-grade white oil so that the annulus protection fluid has low damage on human body and environment.

Owner:CHINA PETROLEUM & CHEM CORP +1

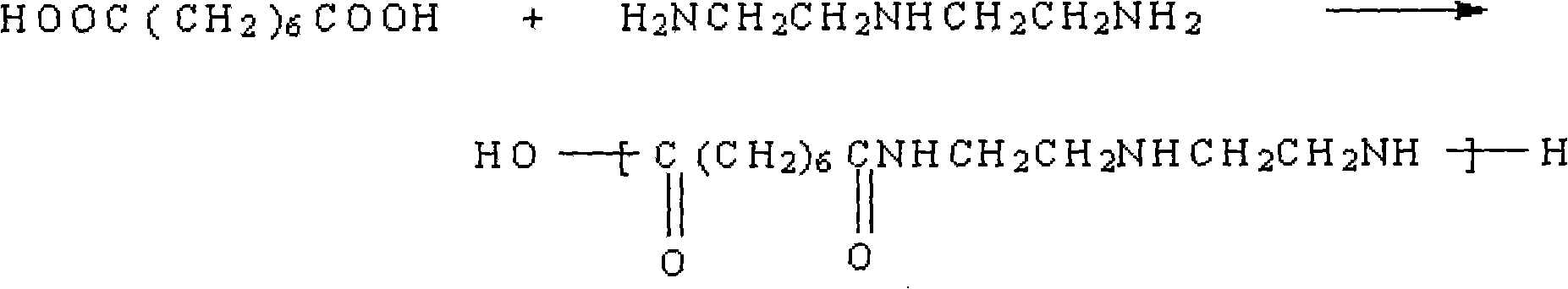

Inhibitor suitable for corrosion prevention of pitshaft of CO2 driving extraction shaft

ActiveCN101624518AThe injection process is simple and easyEasy to prepareBorehole/well accessoriesThioureaDiethylenetriamine

The invention relates to an inhibitor suitable for corrosion prevention of a pitshaft of a CO2 driving extraction shaft, which belongs to the oil filed chemical field and solves the problem that an oil sleeve is corroded in the high CO2 partial pressure environment. The inhibitor comprises the following components in percentage by weight: 15 to 23 percent of diethylenetriamine, 20 to 30 percent of decanedioic acid, 10 to 15 percent of thiourea, 4 to 7 percent of dodecyl dimethyl benzyl ammonium chloride, 1 to 3 percent of stearyl alcohol polyethenoxy ether, 5 to 10 percent of absolute ethyl alcohol and 12 to 45 percent of water. In the high CO2 partial pressure environment, the inhibitor has over 90 percent of corrosion inhibition rate without pitting corrosion, evenly forms a film on a metal tube with good adsorption effect, and has good emulsion breaking property on crude oil with 100 percent of emulsion breaking underground for two hours, no influence on the post dewatering treatment of the crude oil, as well as the advantages of low toxicity, environmental protection, simple preparation method and low cost.

Owner:PETROCHINA CO LTD +1

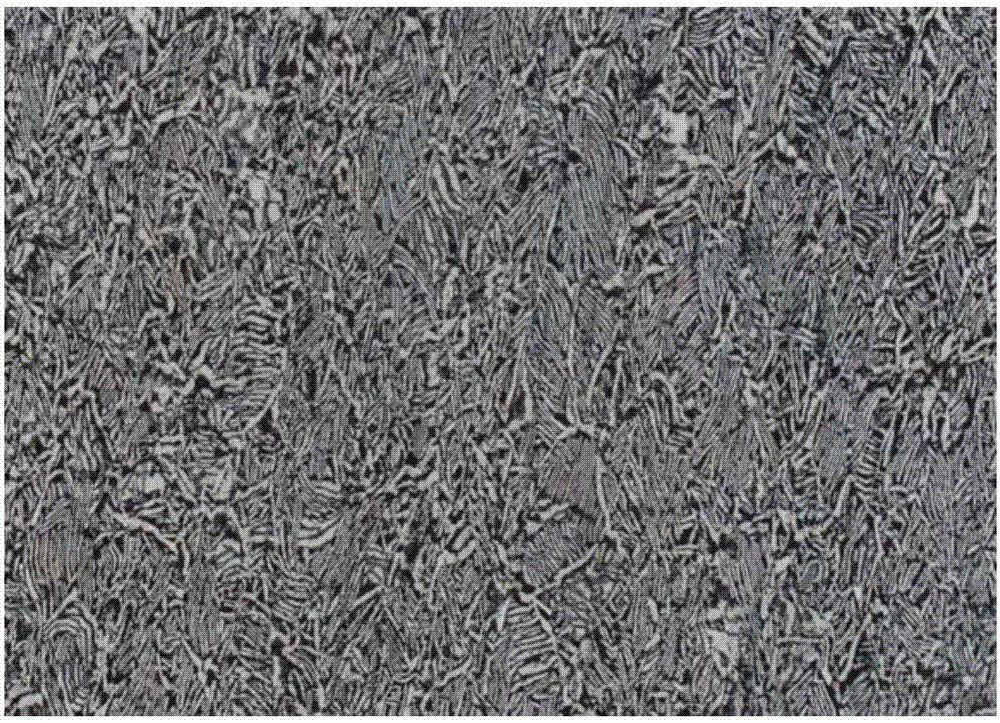

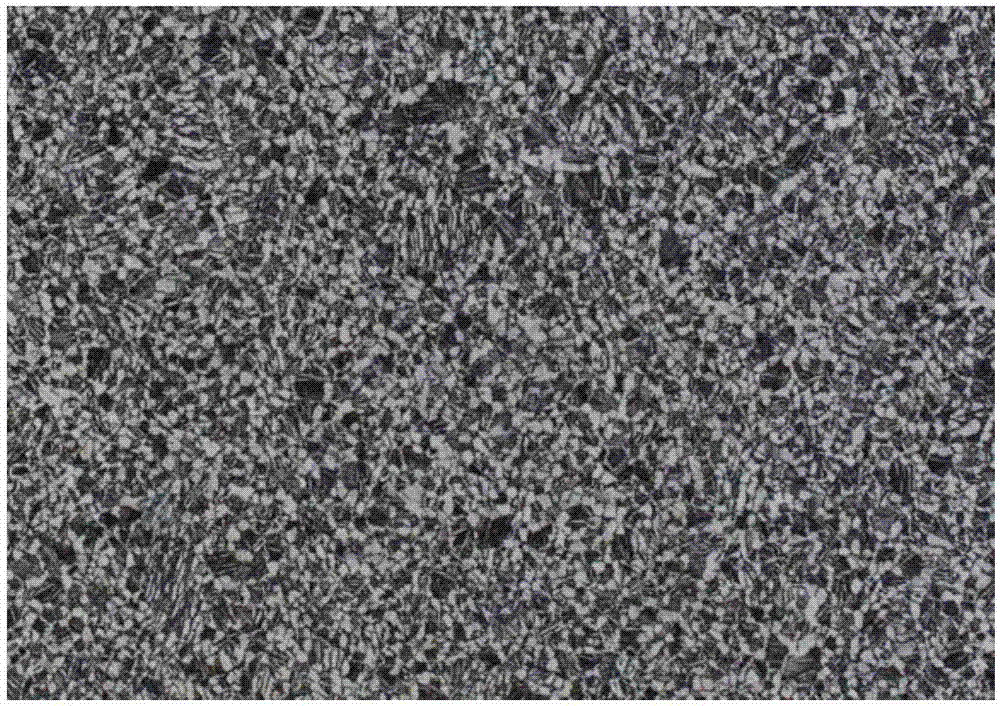

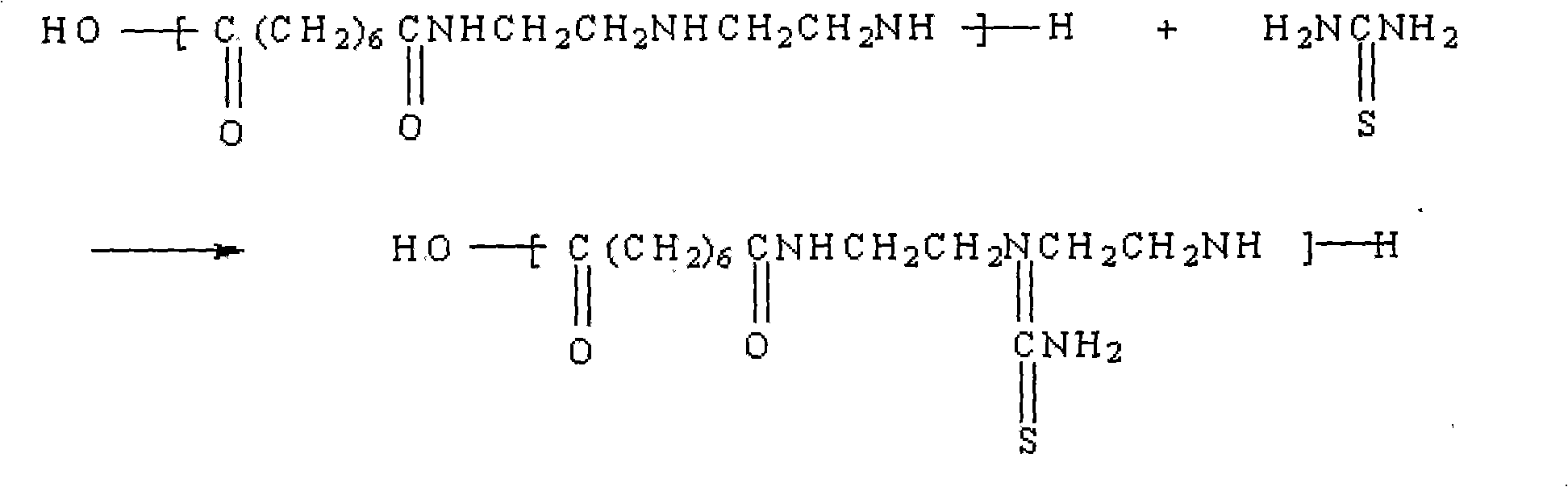

CO2 and Cl<-> corrosion resistant high-strength 15Cr oil pipe for high-temperature high-pressure wells

InactiveCN103938124AWith anti-H

<sub>2</sub>

S stress corrosion cracking performanceIncrease costRigid pipesMartensiteAntimony

A CO2 and Cl<-> corrosion resistant high-strength 15Cr oil pipe for high-temperature high-pressure wells comprises the following compositions in percent by weight: carbon, <=0.03 wt%; silicon, 0.2-0.5 wt%; manganese, 0.2-0.6 wt%; phosphorus, <= 0.02 wt%; sulfur, <= 0.005 wt%; chromium, 14.5-15.3 wt%; molybdenum, 1.7-2.4 wt%; copper, 0.6-1.0 wt%; nickel, 6.5-7.5 wt%; tungsten, 0.4-0.7 wt%; titanium, 0.002-0.007 wt%; boron, 0.001-0.005 wt%; niobium, 0.04-0.09 wt%; vanadium, 0.03-0.07 wt%; nitrogen, 0.01-0.1%; oxygen, <= 0.001 wt%; hydrogen, <= 0.000005 wt%; controlled compositions: arsenic, <=0.03 wt%; antimony, <=0.03 wt%; and antimony, <=0.03 wt%; and the balance iron. According to the 15Cr oil pipe, the minimum yield strength is 925 MPa (125ksi steel grade), the critical usage temperature is 210 DEG C, the CO2 partial pressure can be 10 MPa or more, the Cl<-> concentration can be 120000 mg / L, the 15Cr oil pipe has certain H2S stress corrosion cracking resistant performance, and compared with a super II type 13Cr martensite stainless steel oil pipe material, the increased cost is not large.

Owner:XI'AN PETROLEUM UNIVERSITY

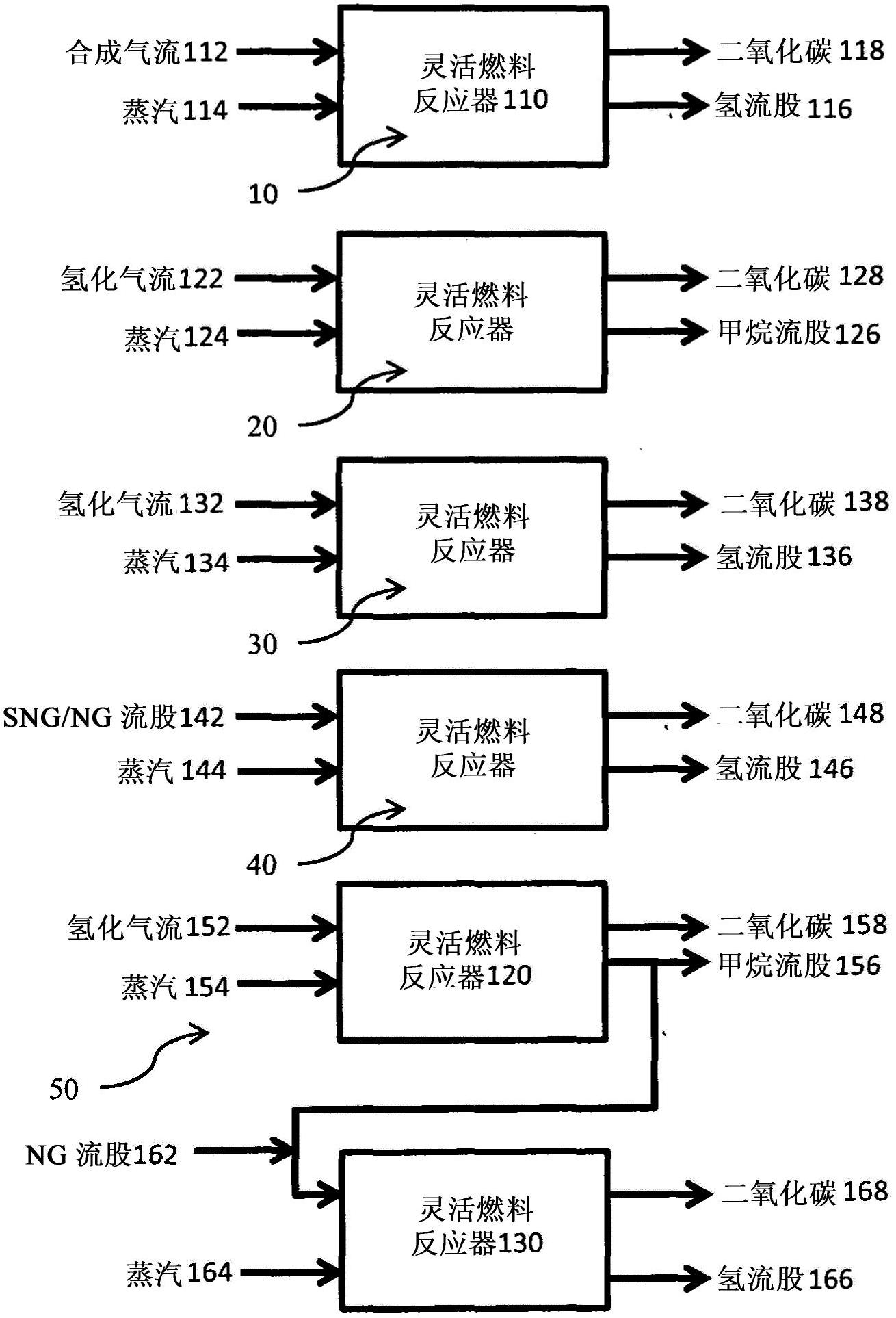

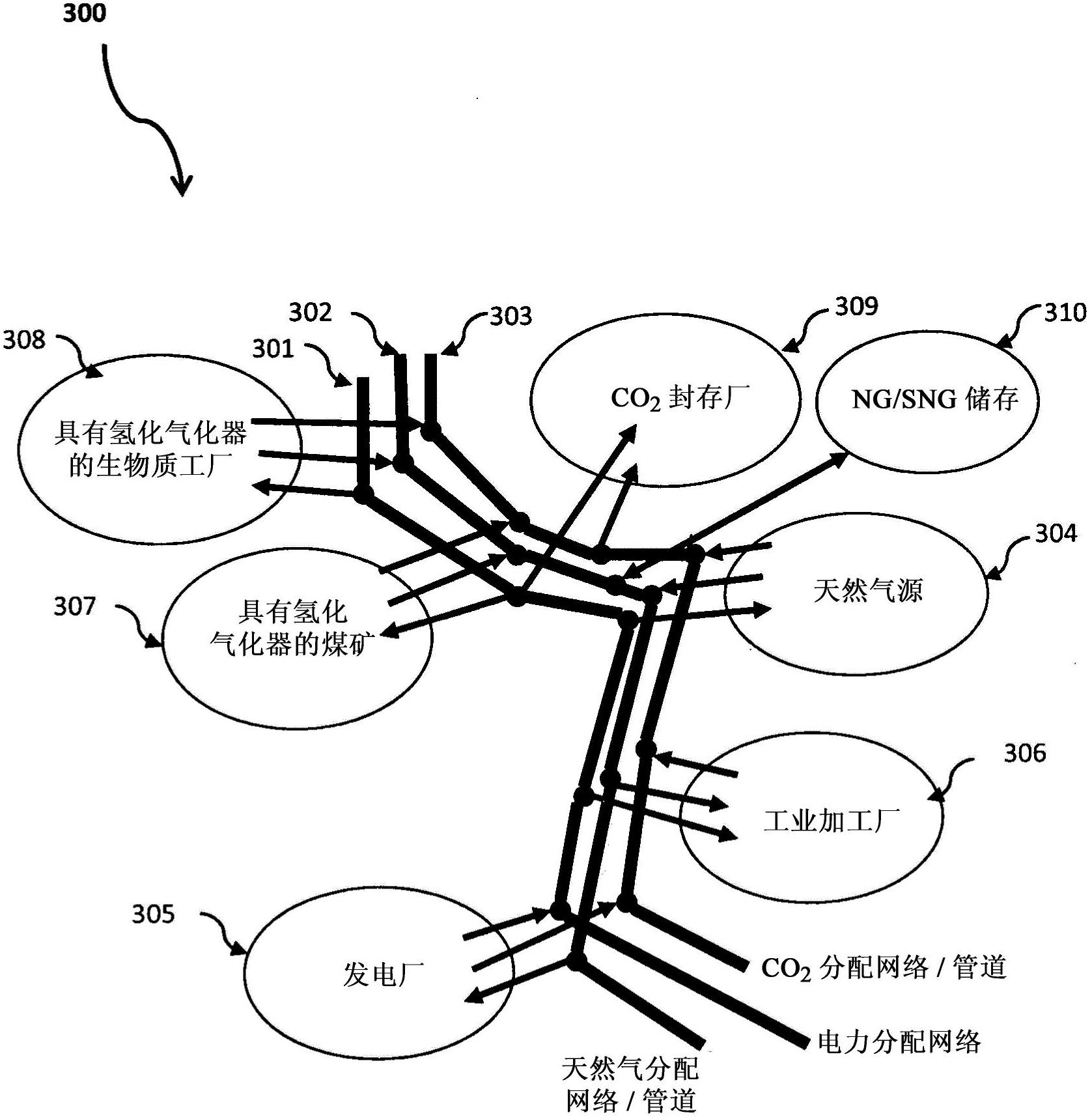

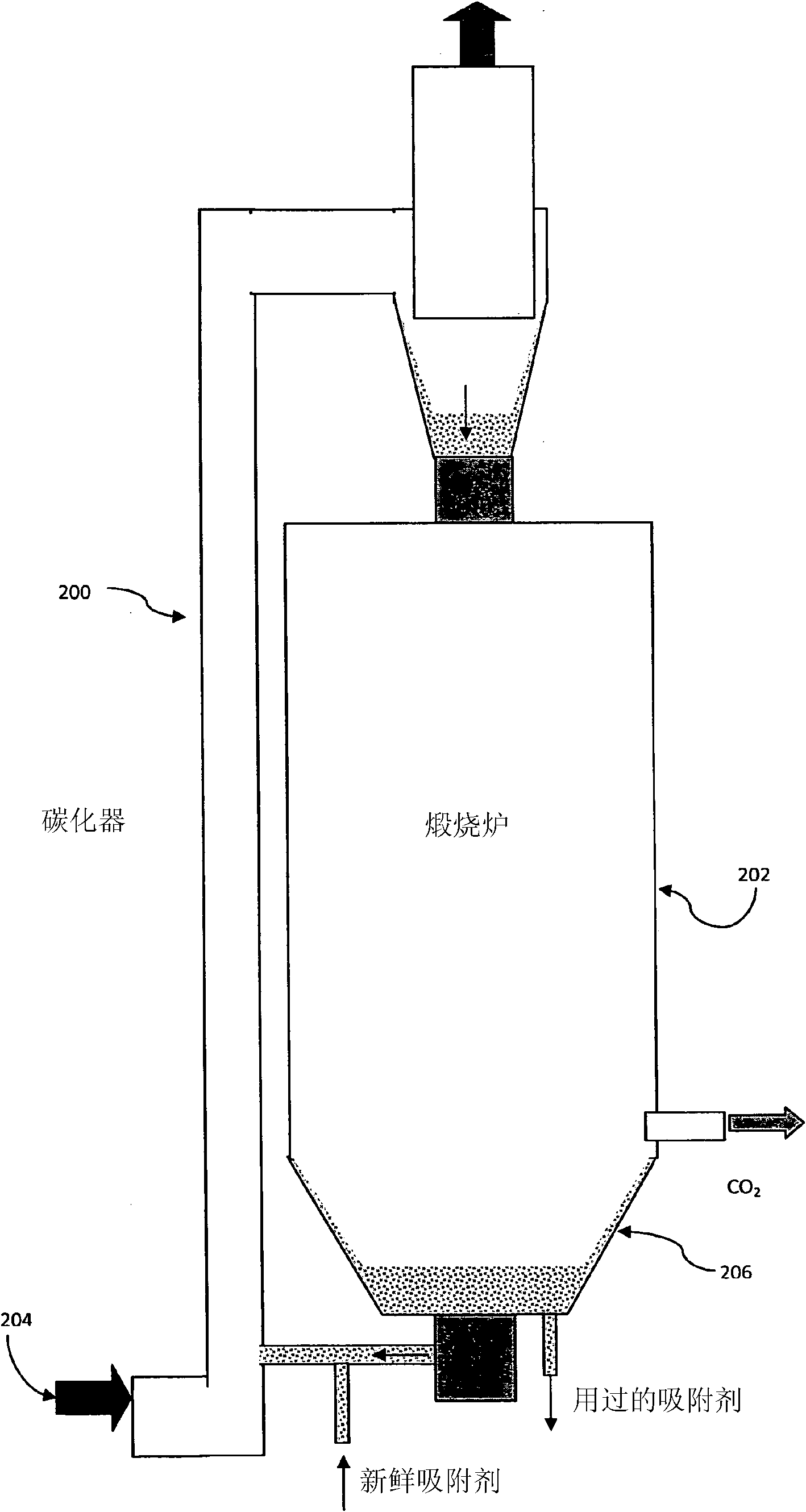

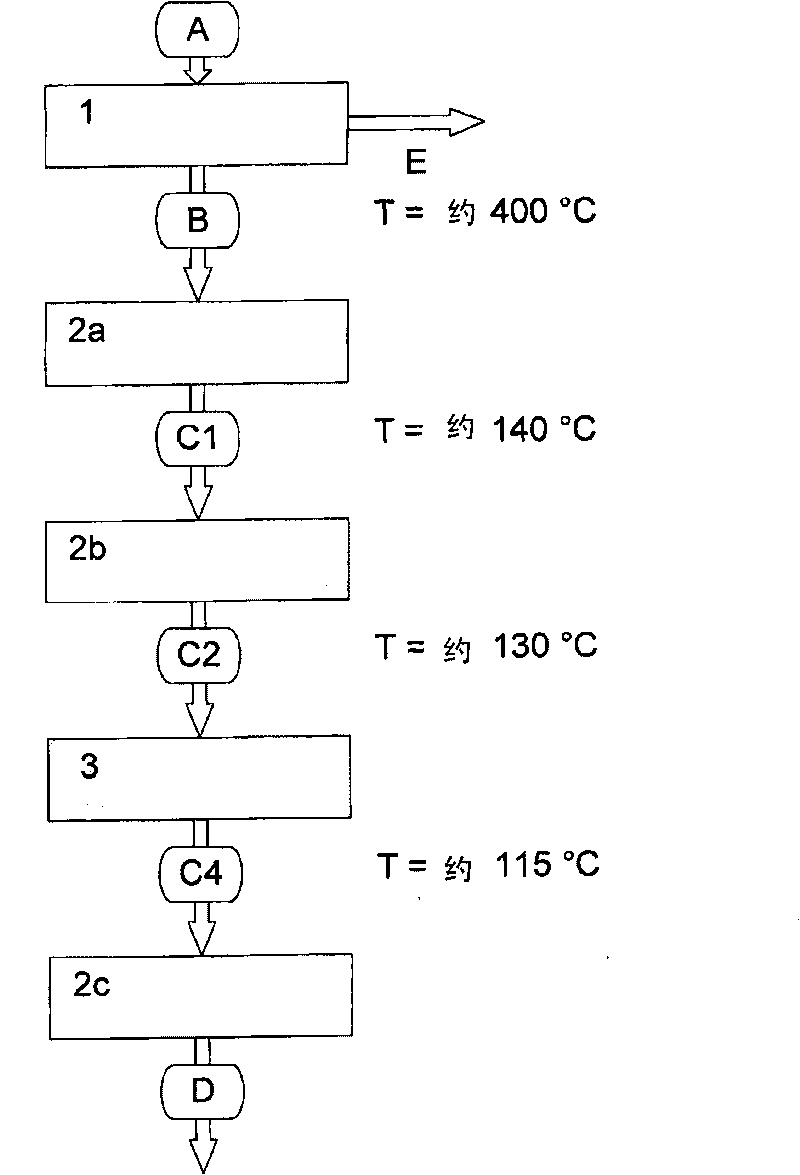

System and method for processing an input fuel gas and steam to produce carbon dioxide and an output fuel gas

A method and system for processing an input fuel gas and steam to produce separate CO2 and output fuel gas streams. The method comprises the steps of using a decarboniser segment for reacting at least a solid sorbent reacts with the fuel gas and steam to remove carbon from the input fuel gas and to produce the output fuel gas stream in an exhaust gas from the decarboniser; using a calciner segment for reacting the solid sorbent from the decarboniser segment therein to release the CO2 into the CO2 gas stream; wherein CO2 partial pressures and temperatures in the decarboniser and calciner segments respectively are controlled such that the temperature in the decarboniser segment is higher than the temperature in the calciner.

Owner:CALIX PTY LTD

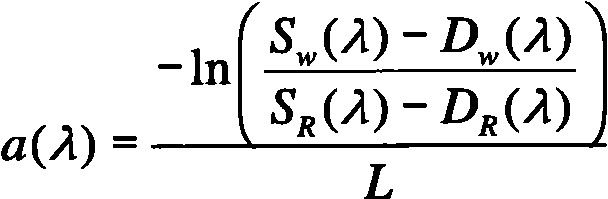

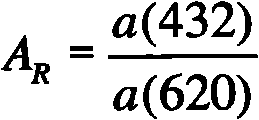

Device and method for noninvasively detecting level of carbon dioxide in human blood

ActiveCN104586395AEasy to detectHigh precisionRespiratory organ evaluationSensorsCo2 partial pressureExpired gas

The invention discloses a device for noninvasively detecting the level of carbon dioxide in human blood. The device comprises a blowing nozzle, a prolonged expiration induction device for a user to conveniently expire, an infrared adapter window body, a signal detection processing device and a terminal, wherein the prolonged expiration induction device is used for providing expiration positive pressure, limiting flow velocity and inducing the continuous prolonged expiration of expired gas; the infrared adapter window body is used for a detection gas chamber of the expired gas, and detection infrared rays pass through the infrared adapter window body; the signal detection processing device is used for emitting the detection infrared rays to the infrared adapter window body, and detecting the CO2 partial pressure of the expired gas; the terminal is used for receiving, processing and displaying the data of the signal detection processing device. According to the device, the prolonged expiration induction device can be used for providing expiration positive pressure and limiting the flow velocity, so that a patient can be helped to conveniently prolong the expiration time and improve expiration effects; with the use of the prolonged expiration induction device, the flow velocity and pressure of the expired gas are regular, the measurement standardization degree of a testee (patient) is favorably improved, and the consistency of a measurement result is ensured.

Owner:广州弘凯物联网服务有限公司

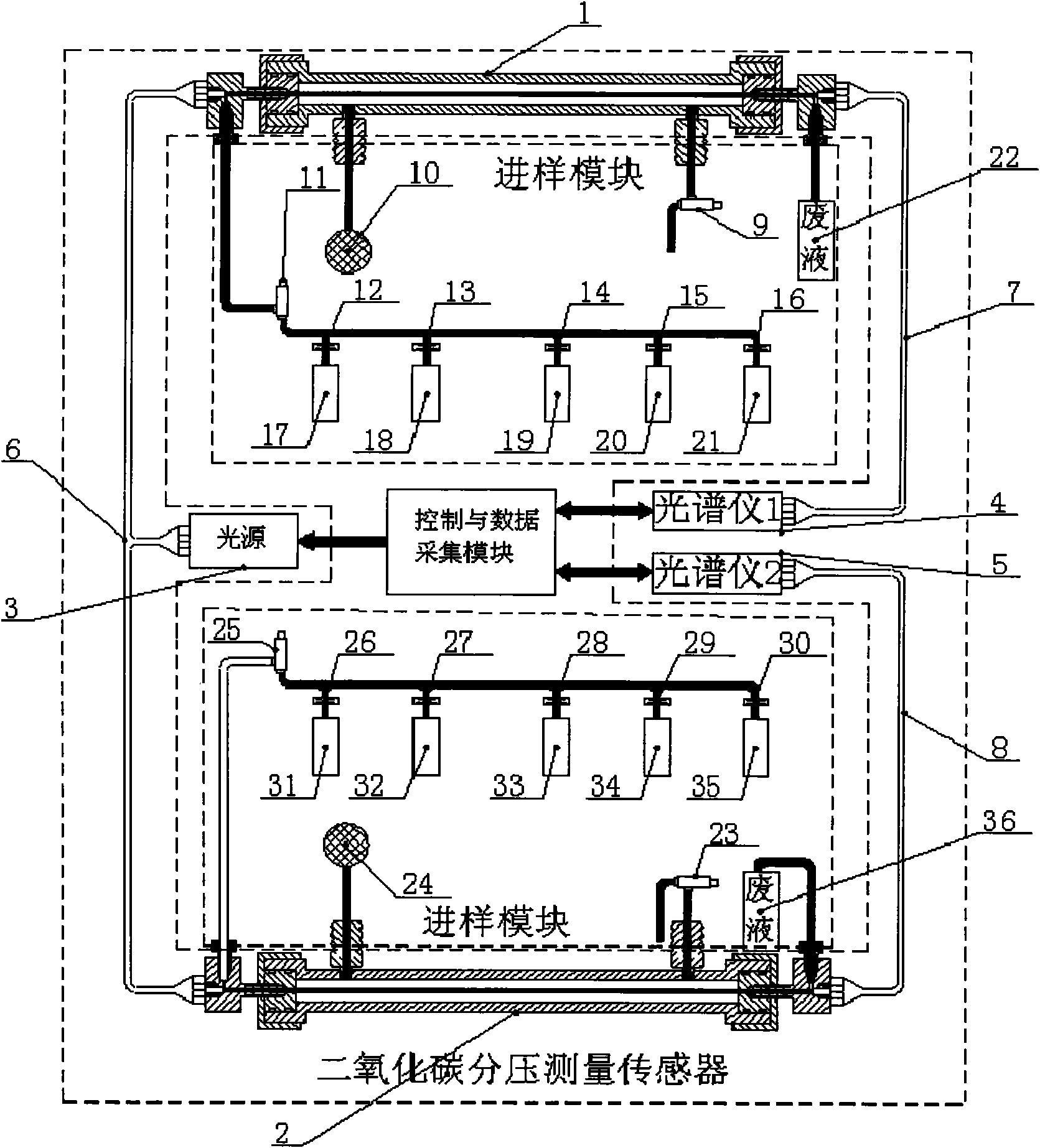

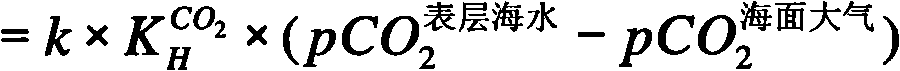

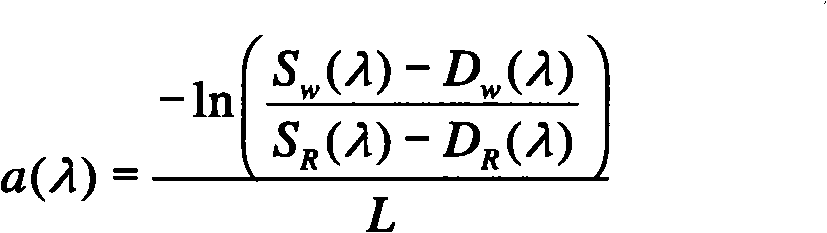

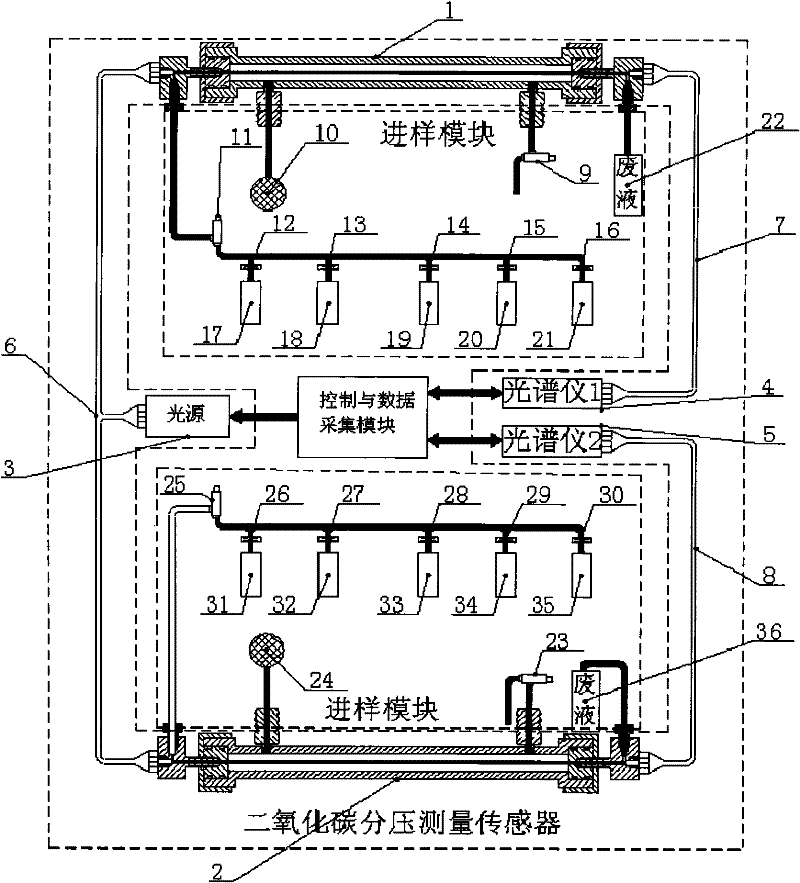

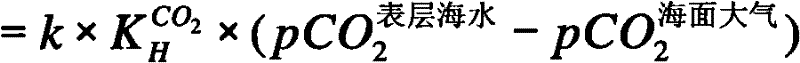

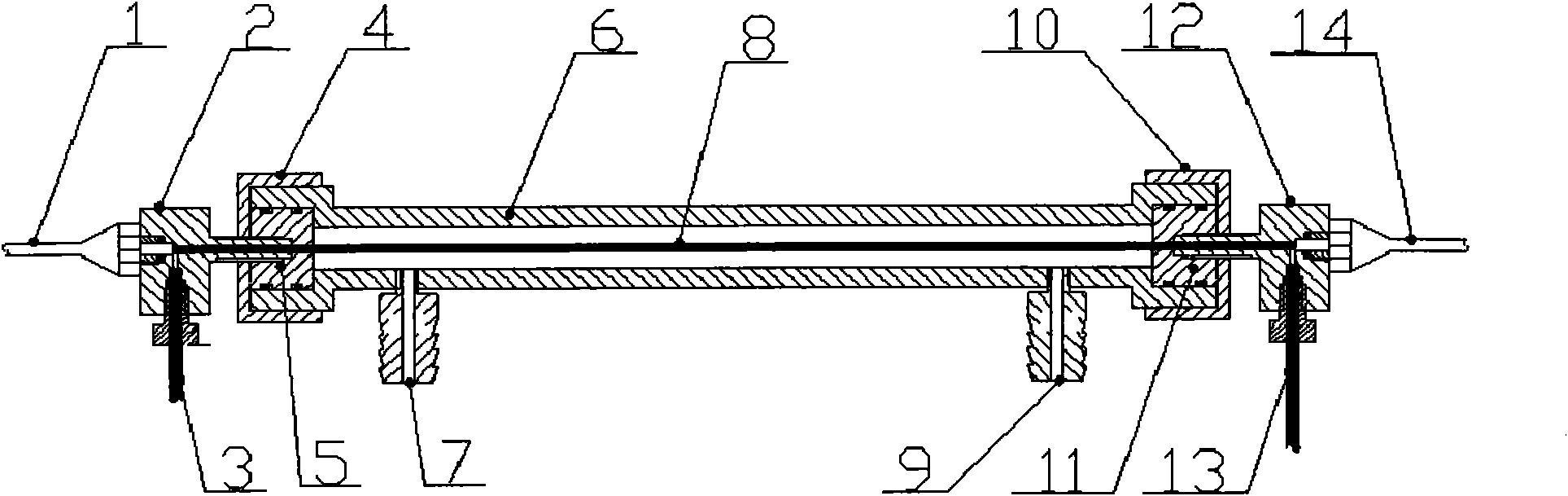

Sea-air carbon dioxide flux measuring device and measuring method thereof

InactiveCN101852723ASuitable for automatic observationSimple structureWithdrawing sample devicesColor/spectral properties measurementsMeasurement deviceAtmospheric air

The invention relates to a sea-air carbon dioxide flux measuring device and a measuring method thereof, belonging to the field of sea-air measurement. The sea-air carbon dioxide flux measuring device comprises a control and data acquisition module, a carbon dioxide partial pressure measuring sensor and a sampling module. Under the control of the control and data acquisition module, the sampling module respectively extracts a water sample and an air sample to the carbon dioxide partial pressure measuring sensor for measurement to obtain sea-air carbon dioxide flux. The invention realizes the device which is provided with the CO2 partial pressure measuring sensor based on acid-base indicators and an optical fiber technology and can synchronously measure the CO2 partial pressure in surface seawater and sea surface atmosphere to further estimate the sea-air CO2 flux. Compared with the prior art, the invention has the advantages that the structure is simple, the stability is high, the power consumption is low and the device is suitable for long-time serial automatic observation on anchored platforms.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI

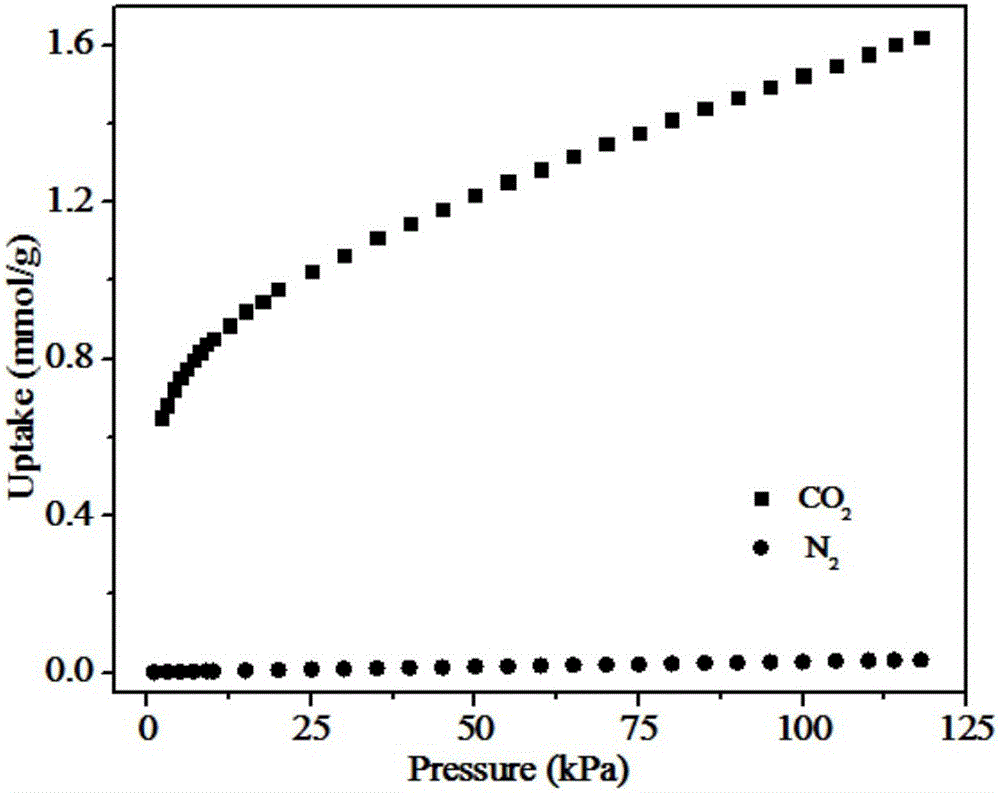

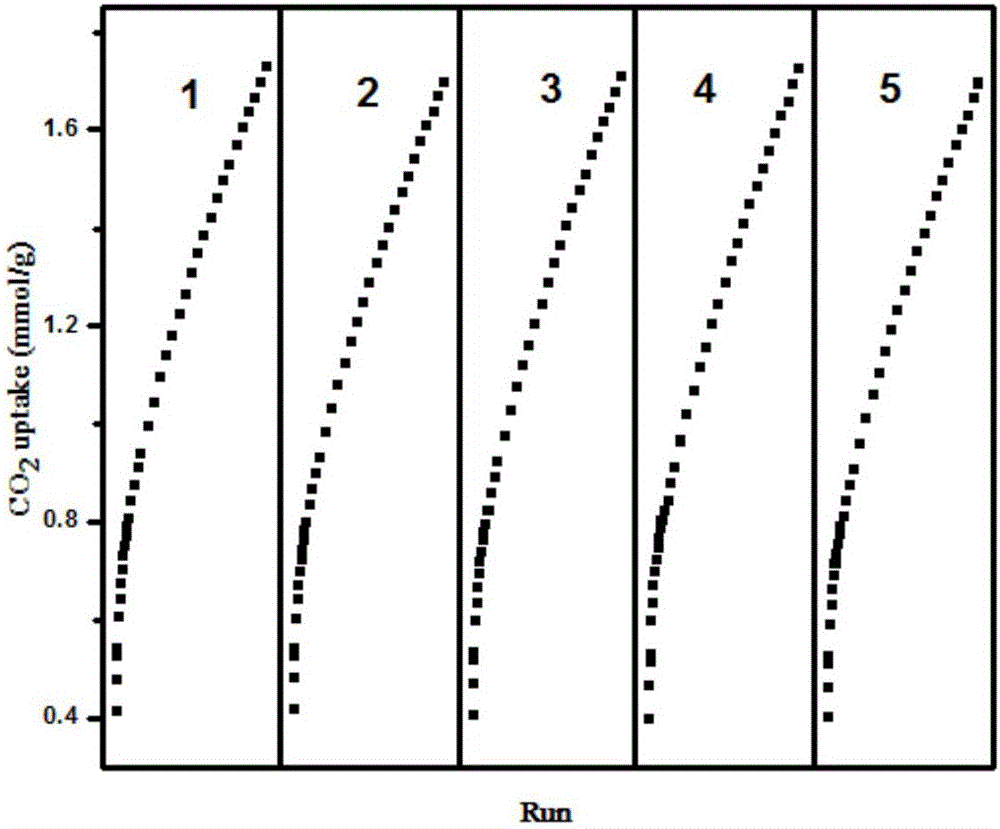

Preparation method of adsorbent for adsorbing and separating CO2

ActiveCN105944679AHigh adsorption selectivityEasy to useGas treatmentOther chemical processesOrganic solventSorbent

The invention discloses a preparation method of an adsorbent for adsorbing and separating CO2. The method comprises steps as follows: first of all, an activated UiO-66-SO3H sample is prepared; then, the modified sulfated metal organic framework material UiO-66-SO3H is post-processed with ammonium hydroxide, a reaction is performed at a temperature of 40-60 DEG C for 6.0-12.0 h, the mixture is cooled in a 0-DEG C ice and water mixture for 10 min, centrifugally washed three times with deionized water and a low-boiling-point organic solvent respectively and filtered, and white powder is obtained; the white powder is transferred to an oven to be dried at a temperature of 80-100 DEG C for 10-20 h, and the adsorbent is obtained. The adsorbent prepared with the method has higher adsorbing capacity and higher adsorptive selectivity to CO2 in the low CO2 partial pressure.

Owner:ZHEJIANG NORMAL UNIVERSITY

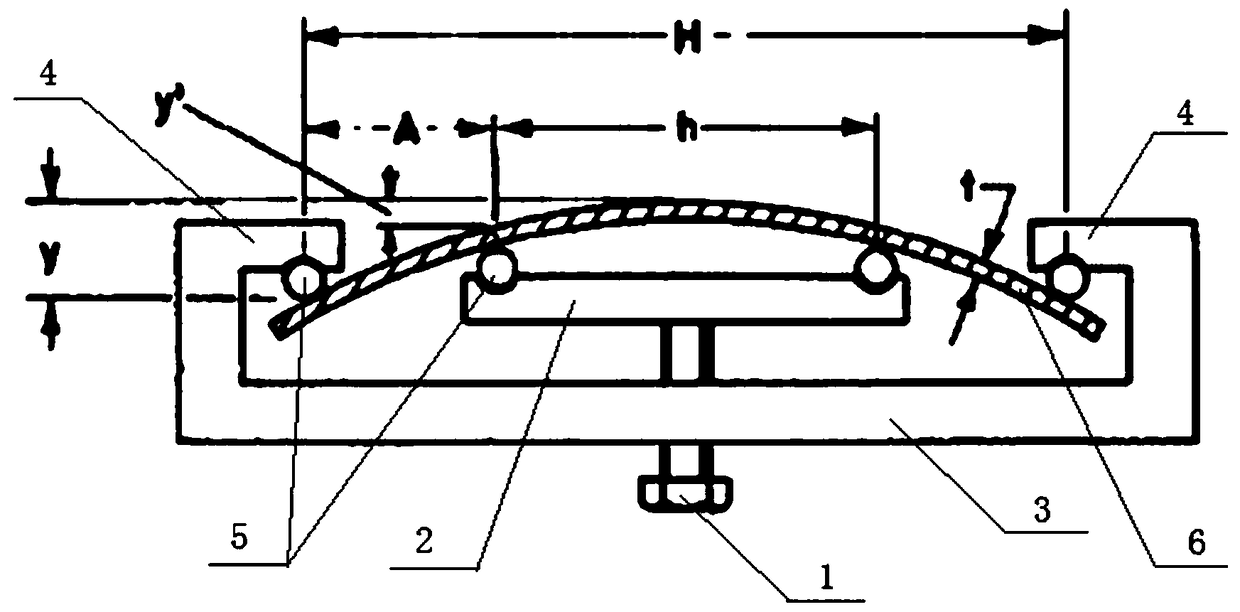

Method for testing pipeline steel for carbon dioxide corrosion under bending stress

InactiveCN108956233ASimple structureEasy to useWeighing by removing componentWeather/light/corrosion resistanceAlcoholLine tubing

The invention discloses a method for testing pipeline steel for carbon dioxide corrosion under bending stress. The method comprises the following steps: obtaining a bent pipeline steel sample; preparing a corrosion solution by adopting simulated oil well produced liquid; putting the bent pipeline sample into a closed reaction kettle, adding a corrosive solution, and introducing CO2 gas; controlling the temperature of closed reaction kettle to be 50-90 DEG C, the CO2 partial pressure to be 0.9-1.2MPa and flowing speed to be 1.3-1.7m / s; taking out the bent pipeline steel sample, soaking in a pickling solution, rinsing with deionized water and absolute ethyl alcohol, and drying by blowing; and weighing the blow-dried bent pipeline steel sample to obtain a corrosive rate R. According to the method, corrosion of pipeline steel under a service environment can be actually simulated, the CO2 corrosion resistance of pipeline steel can be quickly and accurately inspected, and the carbon dioxidecorrosion rate of the pipeline steel under the bending stress can be accurately obtained.

Owner:武汉钢铁有限公司

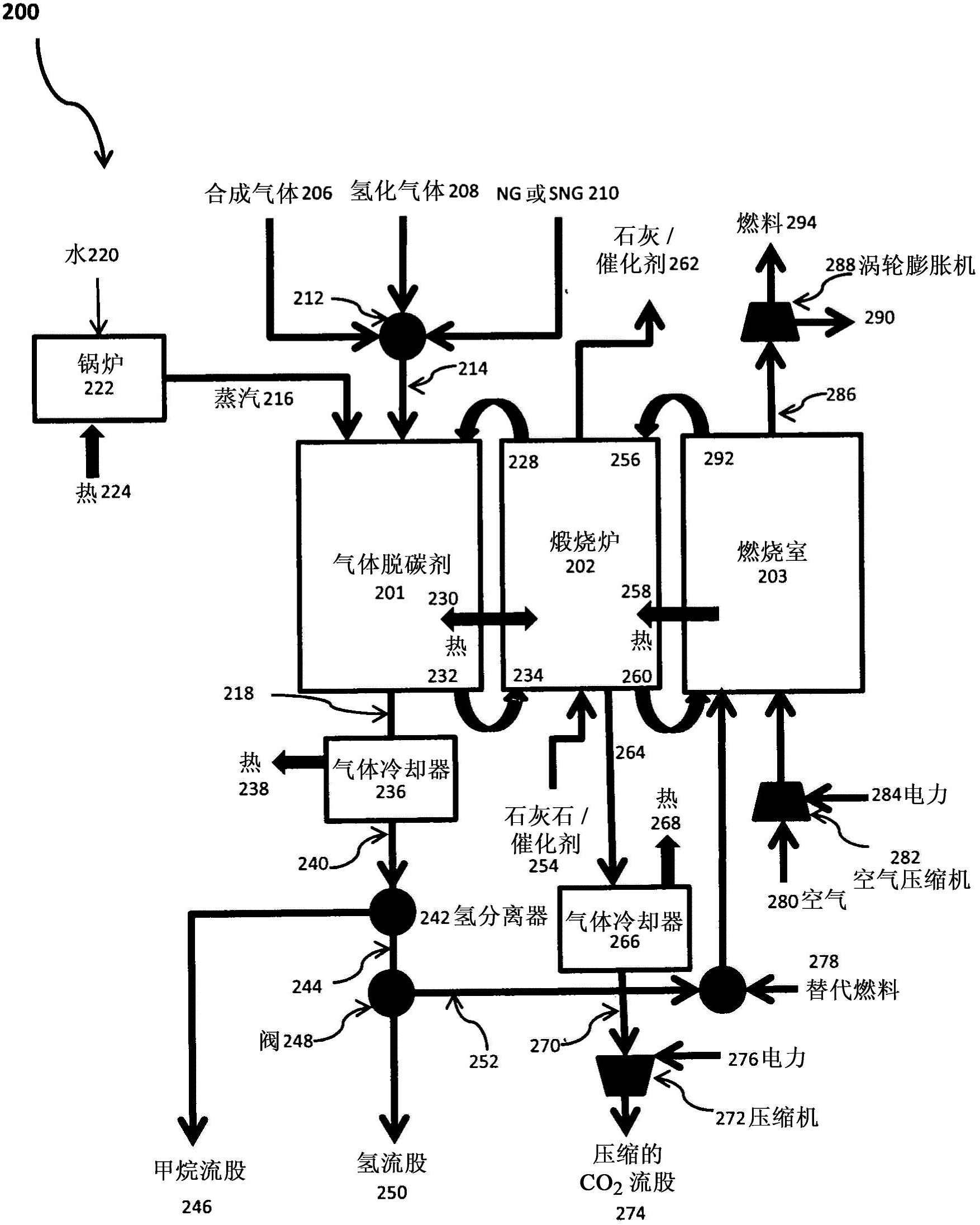

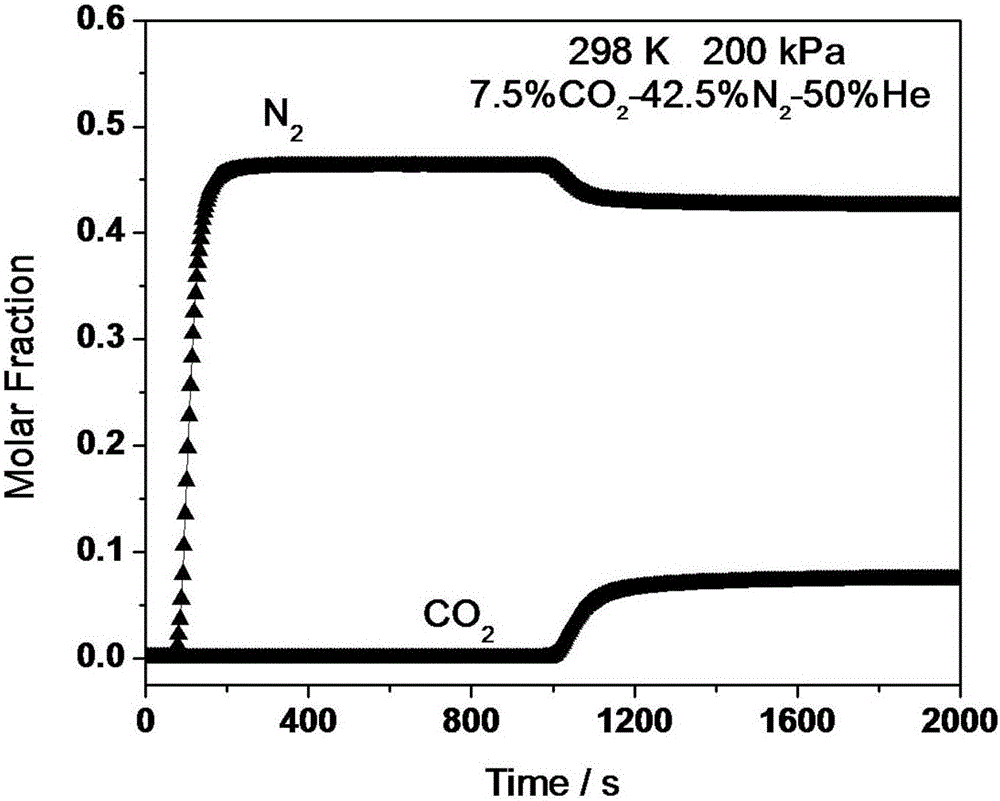

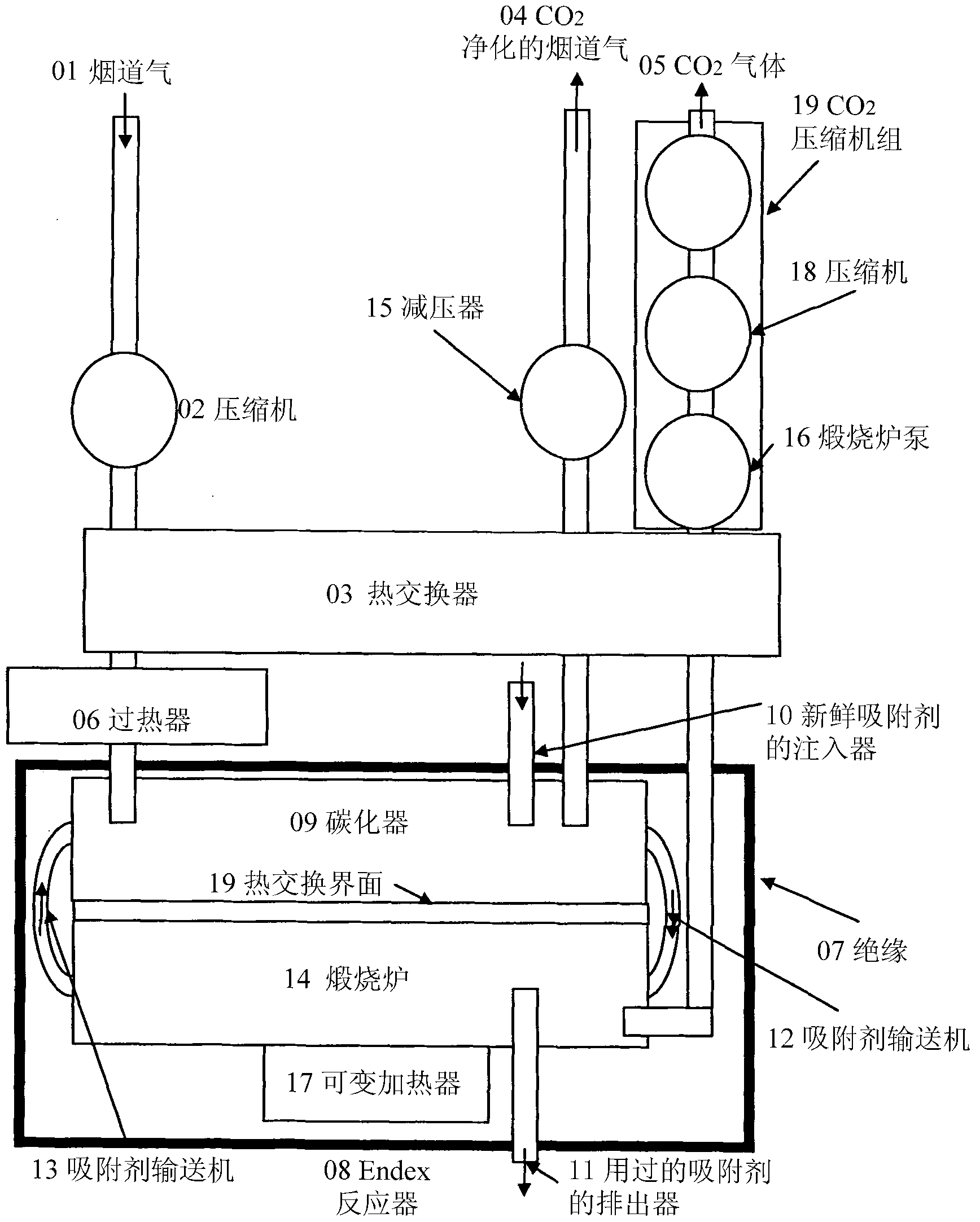

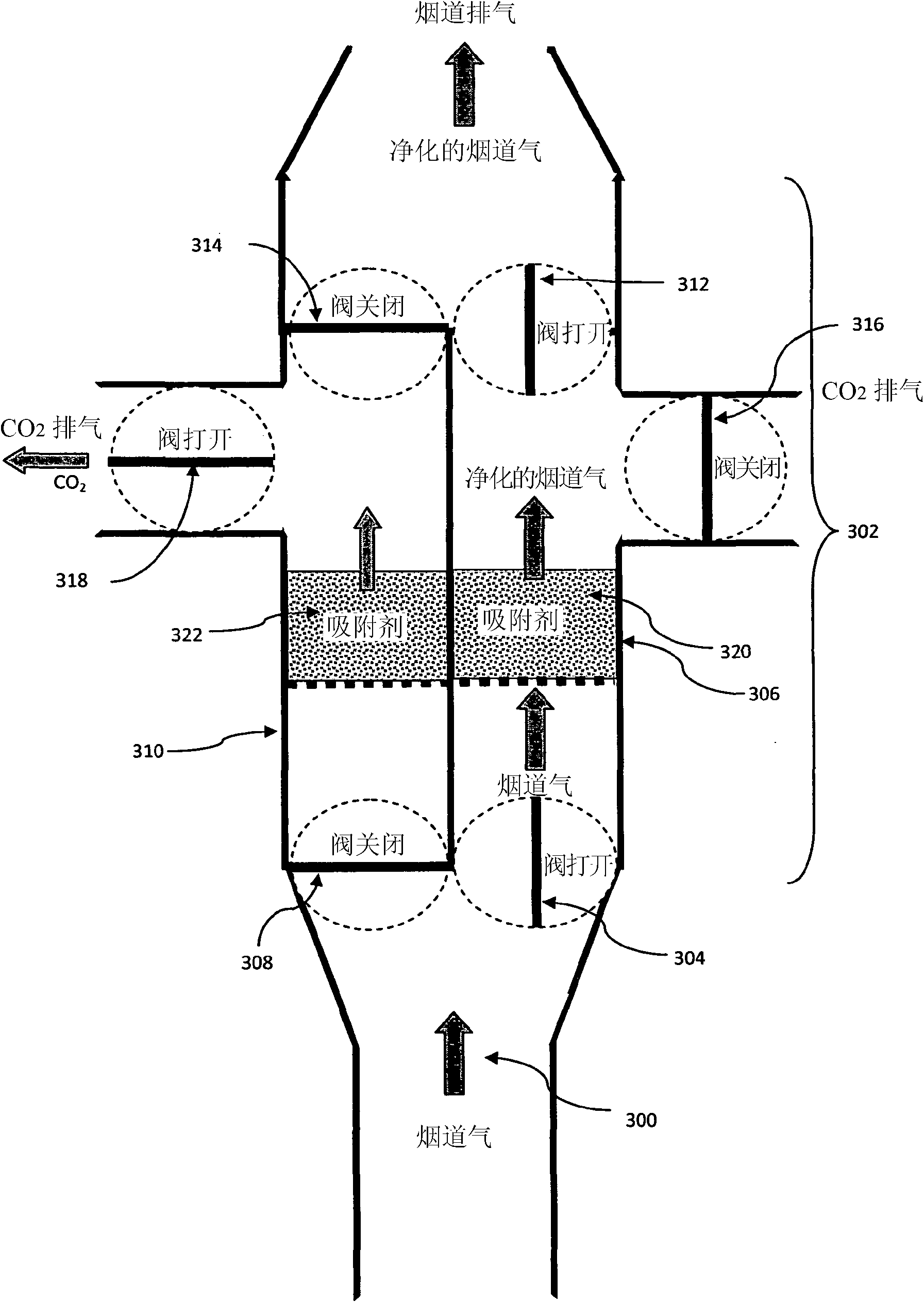

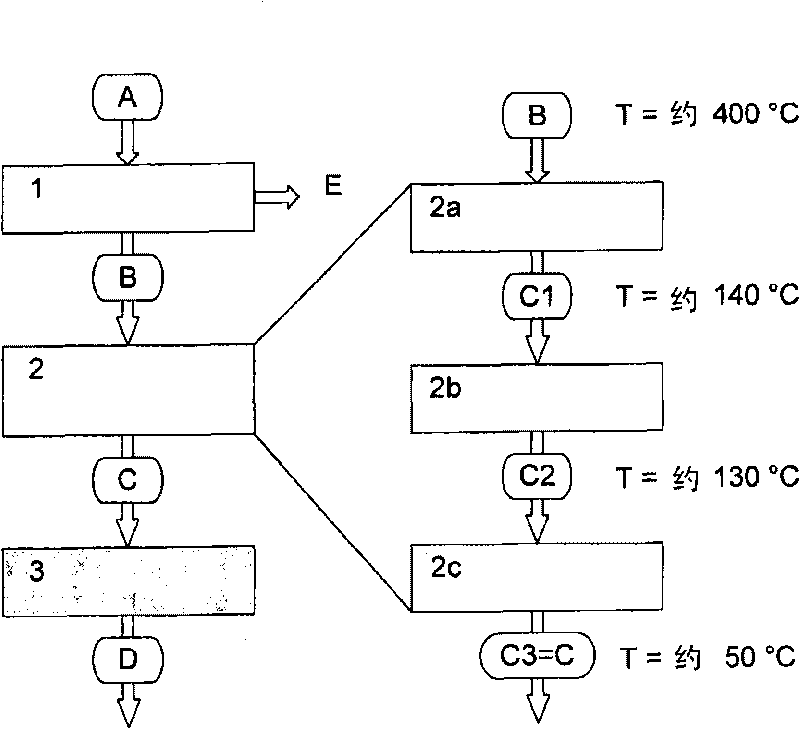

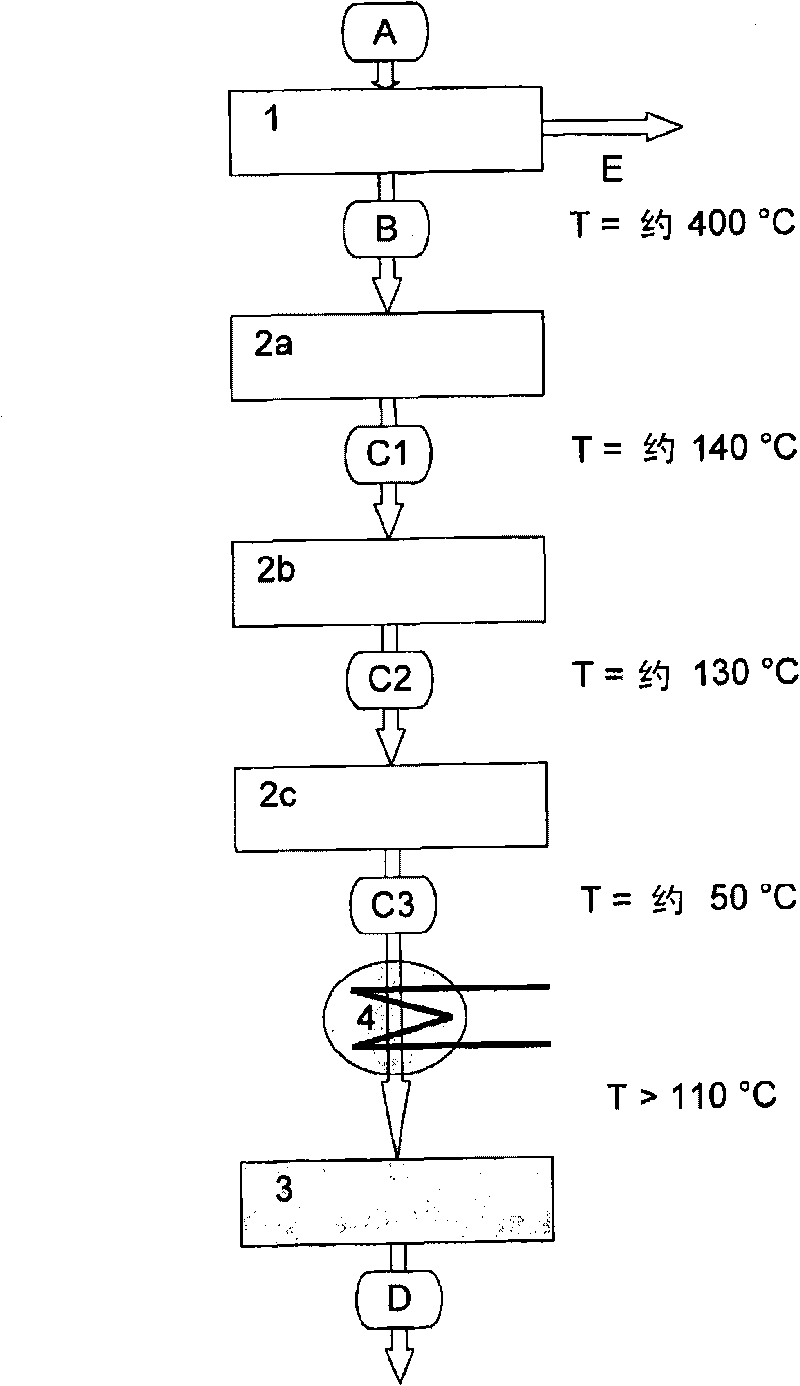

System and method for processing flue gas

The invention relates to a system and a method for removing CO2 from an input gas stream. The system comprises a carboniser segment configured such that a solid sorbent reacts therein with the input gas stream to remove CO2 from the input gas stream; a calciner segment configured such that the solid sorbent from the carboniser segment reacts therein to release the CO2 into a substantially pure gas stream; a heat exchanger unit for exchanging heat between the carboniser and calciner segments; a first conditioning unit for controlling a CO2 partial pressure in the carboniser segment; and a second conditioning unit for controlling a CO2 partial pressure in the calciner segment; wherein the first and second conditioning units are configured such that a difference between the CO2 partial pressures in the carboniser and calciner segments respectively is controlled such that heat is provided from the carboniser to the calciner through the heat exchanging unit.

Owner:CALIX PTY LTD

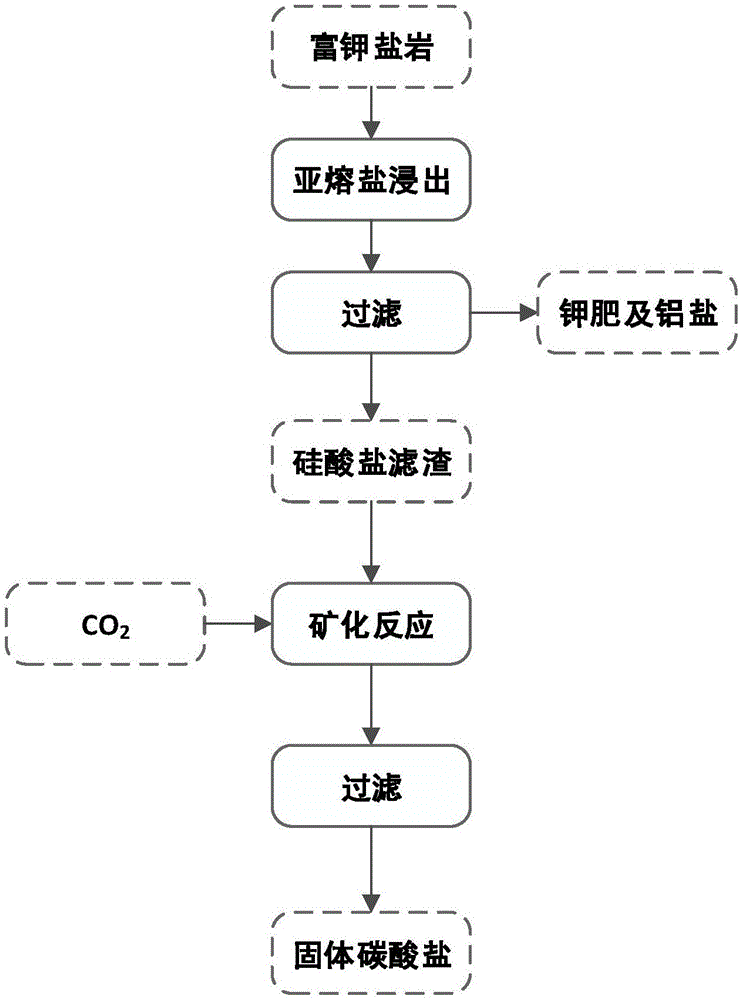

Method for mineralizing carbon dioxide by production waste residues in potassium feldspar sub-molten salt method

InactiveCN106629802ARealize comprehensive utilizationCalcium/strontium/barium carbonatesPotassium fertilisersCo2 partial pressureSolvent

The invention relates to the field of carbon dioxide mineralization, in particular to a method for mineralizing carbon dioxide by production waste residues in a potassium feldspar sub-molten salt method. The method comprises the following steps: mixing smashed and ground potash feldspar ore powder, a sub-molten salt solvent and calcium oxide, mixing and performing solid-liquid separation to obtain solid filter residues; mixing the solid filter residues and water, and putting the mixture into a reactor, wherein the solid to liquid ratio is 1:1 to 1:100; introducing CO2 gas, controlling the CO2 partial pressure to be greater than 0.3MPa, the temperature at 30 to 400 DEG C and the stirring rate at 200 to 800 revolutions per minute, and reacting for 1-4 hours for solid-liquid separation to obtain a calcium carbonate-containing mineralization product. By adopting the carbon dioxide mineralization method, recycling of silicate waste residues produced in a process of preparing a potassium fertilizer from the potassium feldspar is realized, and a practically-feasible novel thought is provided for mineralization fixing of CO2 and realization of CO2 emission reduction.

Owner:EAST CHINA UNIV OF SCI & TECH

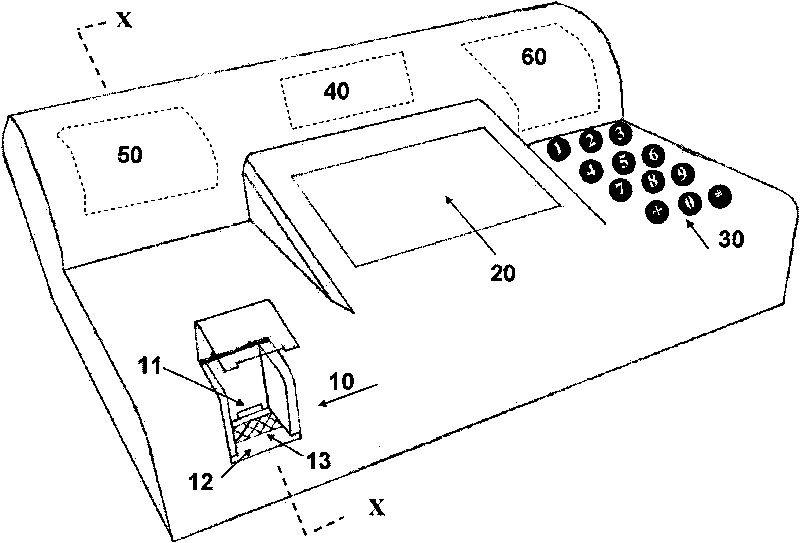

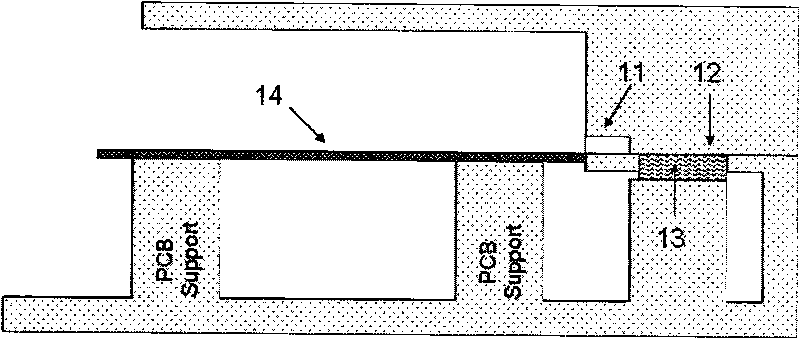

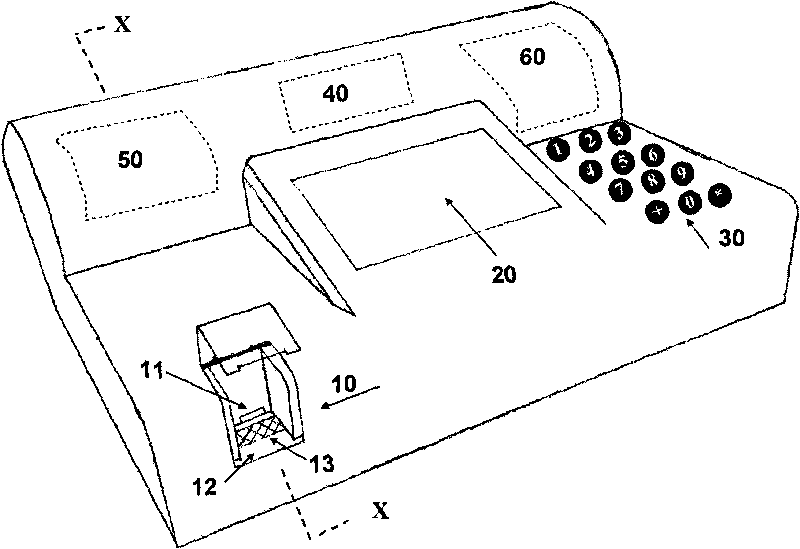

Medical analytical tester with controllable testing temperature

InactiveCN101706511AGuaranteed accuracyIdeal preset test temperatureEvaluation of blood vesselsSensorsTG - TriglycerideCo2 partial pressure

The invention relates to a medical analytical tester with controllable testing temperature, which can work normally under any environment with the temperature not higher than 55 DEG C, and can improve testing speed, precision and accuracy, in particular to a medical analytical tester used for testing blood parameters comprising cholesterol, triglyceride, blood sugar, glycolated hemoglobin, lactic acid, uric acid, pH of blood, oxyhemoglobin, potassium ions, sodium ions, calcium ions, magnesium ions in blood, HCO3-, PO43-, oxygen partial pressure, CO2 partial pressure and other indexes. The tester comprises a micro sample working chamber for accommodating and fixing testing biochips or testing strips and testing, an electronic system which is organically connected with the working chamber and used for reading and outputting a testing result, a screen for displaying the testing result, and a heating element or a setting for controlling the temperature of a tested sample.

Owner:张祥成

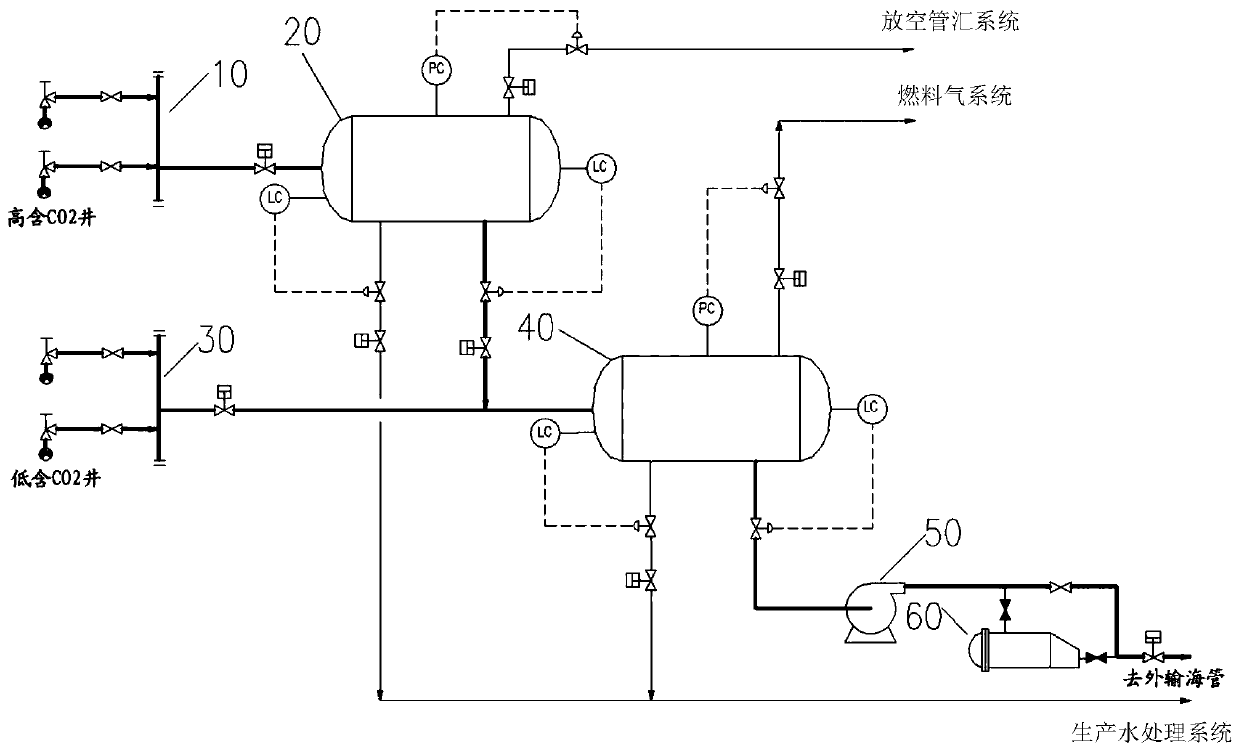

Offshore platform technology system and method for lowering exporting crude oilCO2 partial pressure

PendingCN109869636ALess investmentRealize cost reduction and efficiency increasePipeline systemsCo2 partial pressureProcess engineering

The invention discloses an offshore platform technology system and method for lowering exporting crude oil CO2 partial pressure. The offshore platform technology system comprises a high CO2 crude oilproduction manifold, a high CO2 crude oil production separator connected with the high CO2 crude oil production manifold, one or more sets of connected low CO2 crude oil production manifolds, low CO2crude oil production separators and a crude oil exporting pump. An oil phase outlet of the high CO2 crude oil production separator is successively connected with inlets of all low CO2 crude oil production separators through pipelines, and the pipelines of the oil phase outlet of the last-connected low CO2 crude oil production separator is provided with the crude oil exporting pump. The high CO2 oil phrase is separated from high CO2 production well crude oil through the high CO2 crude oil production separator, and low CO2 production well crude oil enters the low CO2 crude oil production separators so that the oil phase can be separated, oil phase CO2 partial pressure is suitable for a carbon steel material exporting marine pipe, and exporting is achieved through the exporting marine pipe ofthe crude oil exporting pump. According to the offshore platform technology system and method for the lowering exporting crude oil CO2 partial pressure, the CO2 partial pressure of the high CO2 crudeoil can be decreased, and thus the CO2 partial pressure is suitable for the exporting marine pipe made from the carbon steel material.

Owner:CHINA NAT OFFSHORE OIL CORP +1

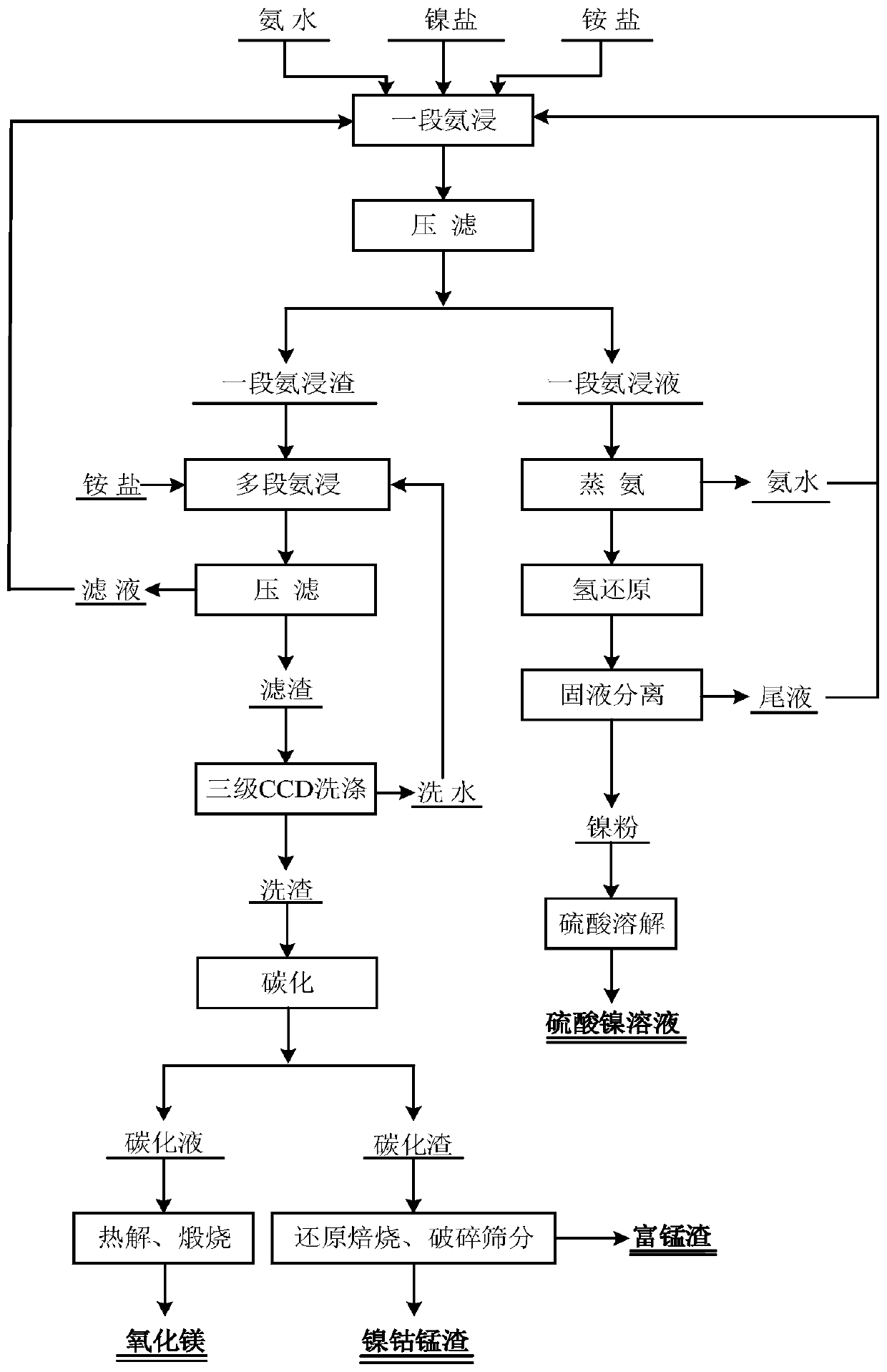

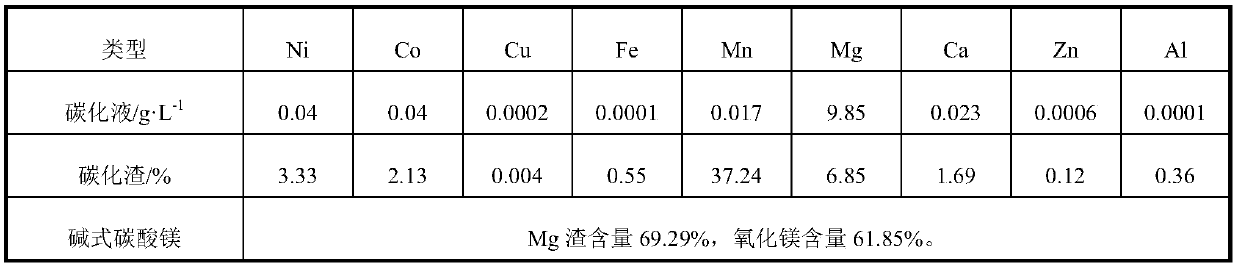

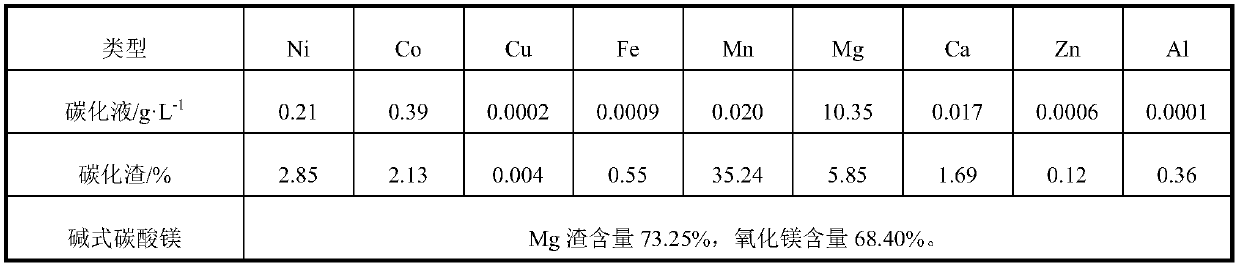

Green method for preparing battery grade nickel sulfate from nickel salt

PendingCN111057847AReduce cleaning processReduce environmental burdenNickel sulfatesProcess efficiency improvementNickel saltElectrical battery

The invention discloses a green method for preparing battery grade nickel sulfate from nickel salt. The green method for preparing battery grade nickel sulfate from the nickel salt comprises the stepsthat the nickel salt and ammonium salt are mixed, ammonia water is added, ammonia leaching reaction is carried out, a first-stage ammonia leaching solution and first-stage ammonia leaching residues are obtained through solid-liquid separation, the first-stage ammonia leaching solution is subjected to ammonia distillation, the pH of the solution obtained after ammonia distillation is adjusted, then nickel powder is prepared through adopting a pressurized hydrogen reduction method; filtrate obtained by carrying out multi-stage ammonia leaching reaction and solid-liquid separation on the first-stage ammonia leaching residues returns to first-stage ammonia leaching slurrying, filter residues is washed by using a three-stage CCD, then a carbonization process is adopted, CO2 partial pressure, reaction time and reaction temperature are controlled, a carbonized liquid and carbonized residues are obtained, and pyrolysis and calcination on the carbonized liquid are carried out, then a magnesiumoxide product is obtained; and the carbide residues are subjected to reduction smelting through a pyrogenic process, and upper-layer rich-manganous slags and lower-layer nickel-cobalt-manganese slagsare obtained after crushing and screening. According to the green method for preparing battery grade nickel sulfate from the nickel salt, the method is easy to control, green and energy-saving, the ammonia water and the ammonium salt in the system can be recycled, a new process for preparing battery grade nickel sulfate without wastewater, waste residues and extraction is realized, and the production cost is greatly reduced.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드 +1

High-strength tough titanium alloy drill stem material friction welding method

ActiveCN107350618AMeet needsHigh resistance to hydrogen sulfide stress corrosionFurnace typesWelding/soldering/cutting articlesFriction weldingHydrogen

The invention discloses a high-strength tough titanium alloy drill stem material friction welding method. A titanium alloy drill stem comprises ingredients including, by weight, 5%-7% of Al, 2.0%-3.0% of Nb, 0.5%-2.0% of Zr, 0.7%-1.2% of Mo, 0.02%-0.05% of Fe, 0.01%-0.03% of Si and the balance Ti; and the friction welding method of the titanium alloy drill stem using the above compositions includes the steps that (1) a connector is rotated; (2) pressure is applied; (3) friction welding is carried out; and (4) welding seam induction heat treatment is carried out. The high-strength tough titanium alloy drill stem material friction welding method has the beneficial effects that the combination properties obtained after titanium alloy drill stem material friction welding can meet the conditions that the strength of extension is larger than 900 MPa, and the yield strength is larger than 800 MPa; the 10 mm*10 mm longitudinal ballistic work of a welding seam at 21 DEG C can reach higher than 36 J; the welding seam hardness is smaller than 32 HRC; H2S partial pressure can be 5 Mpa, the CO2 partial pressure can be 11 Mpa, the NaCl concentration is 100000 ppmCl, the elemental sulfur shows far higher sulfuretted hydrogen stress corrosion resistance compared with a common API drilling stem when used in the 3 g / L rigor corrosion environment, the drilling stem is the best material for replacing steel in oil and gas exploitation, and the corrosion environment oil field requirement is met.

Owner:TIANJIN PIPE GROUP CORP

Device and method for reducing CO2-emissions from the waste gases of combustion plants

A method for separating carbon dioxide from a flue gas using a membrane (membrane module) is characterized in that the flue gas has temperatures above the dew line of the water vapor before entering the membrane separation stage. In this way, condensation of potentially entrained water vapor out of the flue gas is avoided, thereby regularly preventing clogging of the membrane pores. The high temperatures can be achieved in different ways. By connecting a heat exchanger or a burner upstream, the temperature of the flue gas can be easily increased to the necessary temperatures. A condenser, which is connected upstream of the membrane module and also advantageously increases the CO2 partial pressure, at the same time brings about the necessary temperature increase. As another alternative of the invention, the CO2 separation is performed even before desulfurizing the flue gas. This in particular has the advantage that the flue gas in this process stage still has temperatures above the condensate line of the water vapor, and therefore does not have to be heated separately, and in addition generally carries only little water vapor at this stage of the scrubbing operation.

Owner:FORSCHUNGSZENTRUM JULICH GMBH

Sea-air carbon dioxide flux measuring device and measuring method thereof

InactiveCN101852723BSuitable for automatic observationSimple structureWithdrawing sample devicesColor/spectral properties measurementsAir sampleCo2 partial pressure

The invention relates to a sea-air carbon dioxide flux measuring device and a measuring method thereof, belonging to the field of sea-air measurement. The sea-air carbon dioxide flux measuring device comprises a control and data acquisition module, a carbon dioxide partial pressure measuring sensor and a sampling module. Under the control of the control and data acquisition module, the sampling module respectively extracts a water sample and an air sample to the carbon dioxide partial pressure measuring sensor for measurement to obtain sea-air carbon dioxide flux. The invention realizes the device which is provided with the CO2 partial pressure measuring sensor based on acid-base indicators and an optical fiber technology and can synchronously measure the CO2 partial pressure in surface seawater and sea surface atmosphere to further estimate the sea-air CO2 flux. Compared with the prior art, the invention has the advantages that the structure is simple, the stability is high, the power consumption is low and the device is suitable for long-time serial automatic observation on anchored platforms.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI

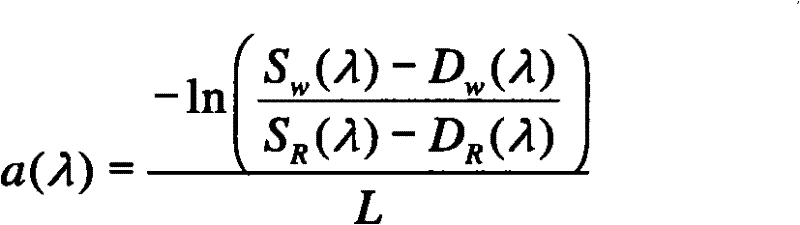

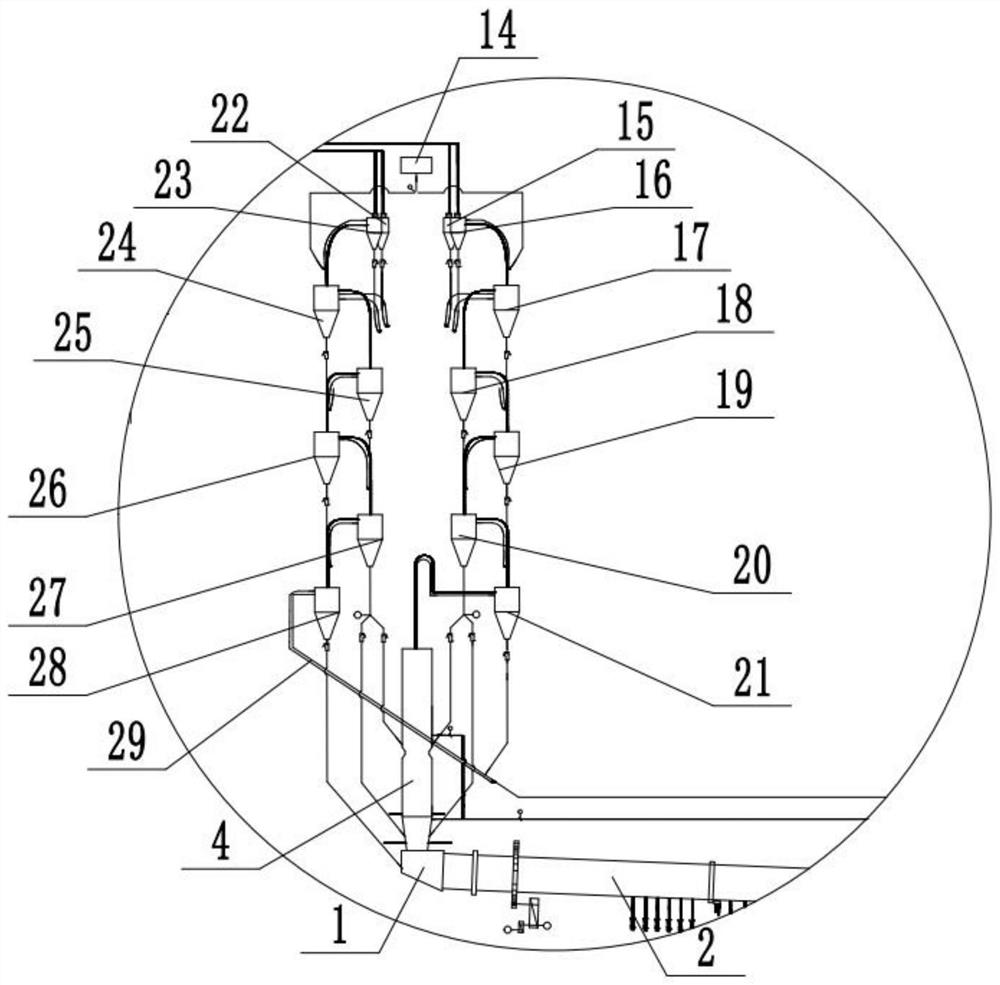

Low-CO2 partial pressure environment cement sintering system and cement clinker preparation method

PendingCN113670069AIncrease temperaturePromote conversionFurnace typesPreheating chargesAir preheaterClinker (waste)

The invention discloses a low-CO2 partial pressure environment cement sintering system and a cement clinker preparation method, and belongs to the technical field of cement production equipment. The low-CO2 partial pressure environment cement sintering system comprises a smoke chamber, a rotary kiln, a grate cooler, a decomposing furnace, a carbon dioxide capturing and purifying system, a waste heat utilization system, a multi-stage pure oxygen preheater and a multi-stage air preheater, wherein the smoke chamber, the rotary kiln and the grate cooler are communicated in sequence; a high-temperature area of the grate cooler comprises a first cooling area and a second cooling area which are mutually independent, the first cooling area is communicated with the rotary kiln and a tertiary air pipe, and the second cooling area is communicated with the multi-stage air preheater through an air supply pipe; the multi-stage pure oxygen preheater is communicated with the decomposing furnace, the air supply pipe and the carbon dioxide capturing and purifying system; and the multi-stage air preheater is communicated with the decomposing furnace, the smoke chamber and the waste heat utilization system. A low-CO2-concentration and high-temperature low-CO2 partial pressure environment can be formed in the air supply pipe, hot raw materials can be further decomposed in the air supply pipe, and then the CaCO3 decomposition rate can be increased without increasing the temperature of the decomposing furnace.

Owner:CBMI CONSTR

Non-invasive breathing end-tidal carbon dioxide detection method

PendingCN112964835AImprove efficiencyHigh precisionGas analyser calibrationGas analyser construction detailsCo2 partial pressureBreath out

The invention provides a non-invasive breathing end-tidal carbon dioxide detection method. The method comprises steps of acquiring temperature and CO2 concentration data of exhaled gas, correcting the detected CO2 concentration according to the temperature of the exhaled gas to obtain the corrected CO2 concentration of the end-expiratory gas, according to the corrected CO2 concentration, adopting a gas source component spectral analysis method to obtain CO2 partial pressure parameters, and establishing a CO2 partial pressure periodic change function model, and solving the model to obtain an analysis waveform of the CO2 partial pressure changing along with time. The method has the advantages of high efficiency and high precision.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

Fluorinated aromatic hydrocarbon polymer capillary tube gas-permeable membrane sample cell, measuring device and measuring method thereof

InactiveCN101858852AHigh precisionQuick responseColor/spectral properties measurementsMeasuring instrumentCoupling

The invention relates to the measurement field of carbon dioxide, in particular to a fluorinated aromatic hydrocarbon polymer capillary tube gas-permeable membrane sample cell which comprises (1) a sleeve, (2) a fluorinated aromatic hydrocarbon polymer capillary tube, (3) a first sample inlet tube and a second sample inlet tube, (4) a first optical liquid coupling device and a second optical liquid coupling device as well as (5) a first tracer agent tube and a second tracer agent tube, wherein the left and the right sides of the sleeve are respectively provided with an injection hole and a discharge hole; the length of the fluorinated aromatic hydrocarbon polymer capillary tube is longer than that of the sleeve; the capillary tube is inserted into the sleeve from the left end, and is inserted out of the sleeve from the right end; the first sample inlet tube is connected with the injection hole of the sleeve, and the second sample inlet tube is connected with the discharge hole of the sleeve; the first optical liquid coupling device is provided with a three-end joint, and the second optical liquid coupling device is also provided with a three-end joint; and the first tracer agent tube is connected with a second joint of the first optical liquid coupling device, and the second tracer agent tube is connected with a second joint of the second optical liquid coupling device. Compared with the prior art, the invention has high sensing sensitivity and large dynamic range, and is very suitable for researching and developing a CO2 partial pressure field measuring instrument with high accuracy, rapid response and low power consumption.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Watertight anti-pressure storehouse body for measuring ocean-atmosphere carbon dioxide flux

InactiveCN101865824ACompact structureEasy to installMaterial analysis by optical meansEngineeringCo2 partial pressure

The invention relates to the field of ocean-atmosphere measurement, in particular to a watertight anti-pressure storehouse body for measuring ocean-atmosphere carbon dioxide flux. The storehouse body comprises a lower storehouse body and an upper storehouse body, wherein the lower storehouse body is arranged on the lower half part of the watertight anti-pressure storehouse body; the upper storehouse body is arranged on the upper half part of the watertight anti-pressure storehouse body; and a carbon dioxide partial pressure optical fiber chemical sensor sample cell, which is connected with the upper and lower storehouse bodies respectively, of an atmosphere passage, a carbon dioxide partial pressure optical fiber chemical sensor sample cell, which is connected with the upper and lower storehouse bodies respectively, of an ocean passage, and an electrical connecting passage which is connected with the upper and lower storehouse bodies respectively are arranged between the lower storehouse body and the upper storehouse body. The watertight anti-pressure storehouse body designed by the invention has a compact and simple structure, is convenient to mount, has high sealability and pressure resistance, can be sequentially released for a long time, and is suitable for an anchoring platform and an ocean-atmosphere CO2 flux measuring instrument which adopts CO2 partial pressure opticalfiber chemical sensors.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com