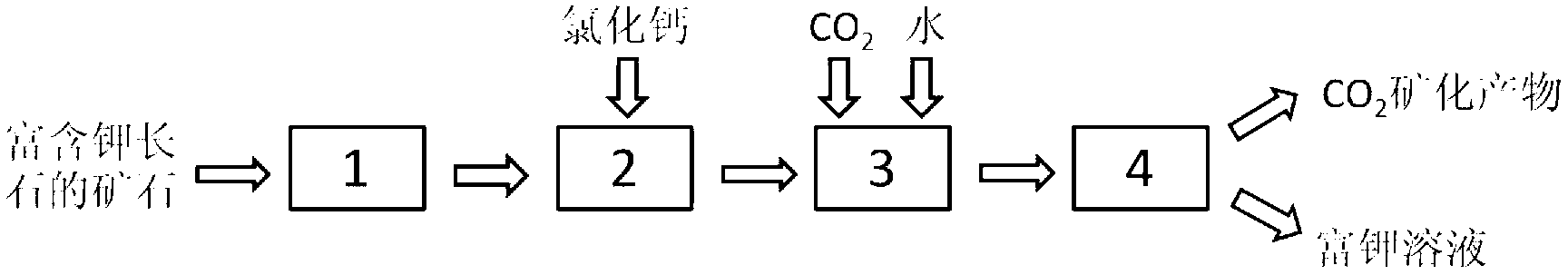

CO2 mineralization method capable of co-producing potassium-enriched solution by high temperature method

A potassium-rich, solution technology, applied in the directions of potassium fertilizer, inorganic fertilizer, calcium carbonate/strontium/barium, etc., can solve the problems of low conversion rate of mineralization reaction, and achieve the improvement of mineralization efficiency, conversion rate and utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The mined potassium feldspar is crushed and ball milled to make the particle size less than 200 mesh. Put 2.5g of potassium feldspar powder and 2.5g of calcium chloride powder into a porcelain boat and mix well, put the porcelain boat into a tubular reaction furnace, heat up to 800°C, react for 60 minutes, and take it out when it cools naturally to 80°C Porcelain boat, take out the material after the conversion reaction, add 75ml of water, put it in the reaction kettle, raise the temperature to 150°C, and pass in CO 2 The gas pressure was increased to 4MPa, the stirring rate was 250r / min, and the stirring was stopped after 120min of reaction. After the reaction kettle is cooled to about 80°C, the pressure is released to normal pressure to open the reaction kettle, and the feed liquid after the mineralization reaction is filtered to obtain CaCO 3 The solid phase, the liquid phase is a potassium-rich solution rich in potassium ions. The conversion rate of the potassium ...

Embodiment 2

[0028] The mined potassium feldspar is crushed and ball milled to make the particle size smaller than 325 mesh. Put 2.5g of potassium feldspar and 5g of calcium chloride powder into the porcelain boat and mix them evenly. Put the porcelain boat into the tube reactor and heat up to 950°C. After reacting for 30 minutes, take out the porcelain boat when it cools naturally to 80°C. The reacted material was taken out, added 75ml of water, placed in the reaction kettle, heated to 150°C, and CO 2 The gas pressure was increased to 4MPa, the stirring rate was 250r / min, and the stirring was stopped after 120min of reaction. After the reaction kettle is cooled to about 80°C, the pressure is released to normal pressure to open the reaction kettle, and the feed liquid after the mineralization reaction is filtered to obtain CaCO 3 The solid phase, the liquid phase is a potassium-rich solution rich in potassium ions. The conversion rate of potassium feldspar component in the present embodi...

Embodiment 3

[0030] The mined potassium feldspar is crushed and ball milled to make the particle size smaller than 325 mesh. Put 2.5g of potassium feldspar and 1g of calcium chloride powder into the porcelain boat and mix them evenly, put the porcelain boat into the tubular reaction furnace and raise the temperature to 600°C, after reacting for 60 minutes, take out the porcelain boat when it cools naturally to 80°C, and convert the The reacted material was taken out, added 25ml of pure water, placed in the reaction kettle, heated to 100°C, and CO 2 The pressure rises to 2MPa. The stirring rate was 250r / min, and the stirring was stopped after 120 minutes of reaction. After the reaction kettle is cooled to about 80°C, the pressure is released to normal pressure to open the reaction kettle, and the feed liquid after the mineralization reaction is filtered to obtain CaCO 3 The solid phase, the liquid phase is a potassium-rich solution rich in potassium ions. The conversion rate of potassium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com