Inhibitor suitable for corrosion prevention of pitshaft of CO2 driving extraction shaft

A corrosion inhibitor and wellbore technology, applied in wellbore/well parts, earthwork drilling and production, etc., can solve problems such as oil casing corrosion, and achieve the effects of low cost, uniform film formation, and simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0007] Specific implementation mode 1: This implementation mode is applicable to CO 2 The anticorrosion agent for wellbore anticorrosion of flooding production well consists of the following components by weight percentage: 15% diethylenetriamine, 20% sebacic acid, 10% thiourea, 4% dodecyl dimethyl benzyl ammonium chloride, 1% stearyl polyoxyethylene ether, 5% absolute ethanol, 45% water.

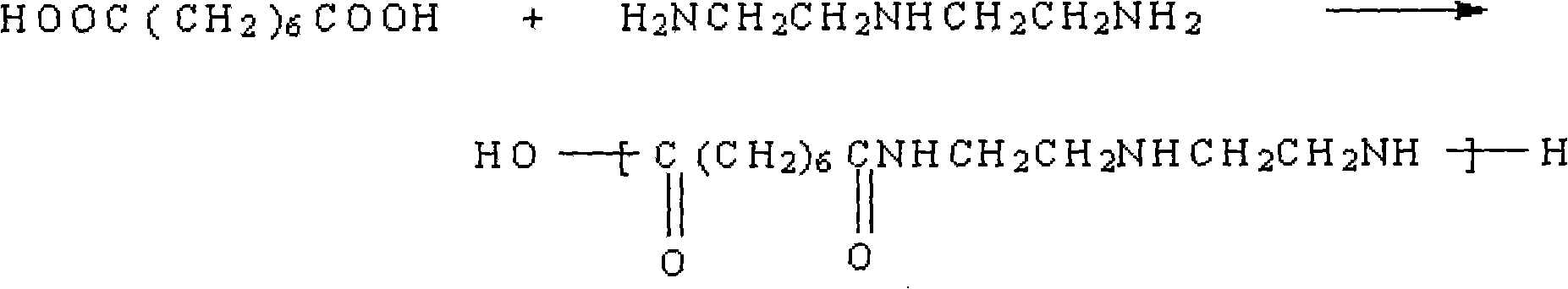

[0008] This applies to CO 2 The sebacic acid and diethylenetriamine in the anticorrosion formulation of wellbore anticorrosion in production wells are used to synthesize polyamide prepolymer, and the reaction formula is as follows:

[0009]

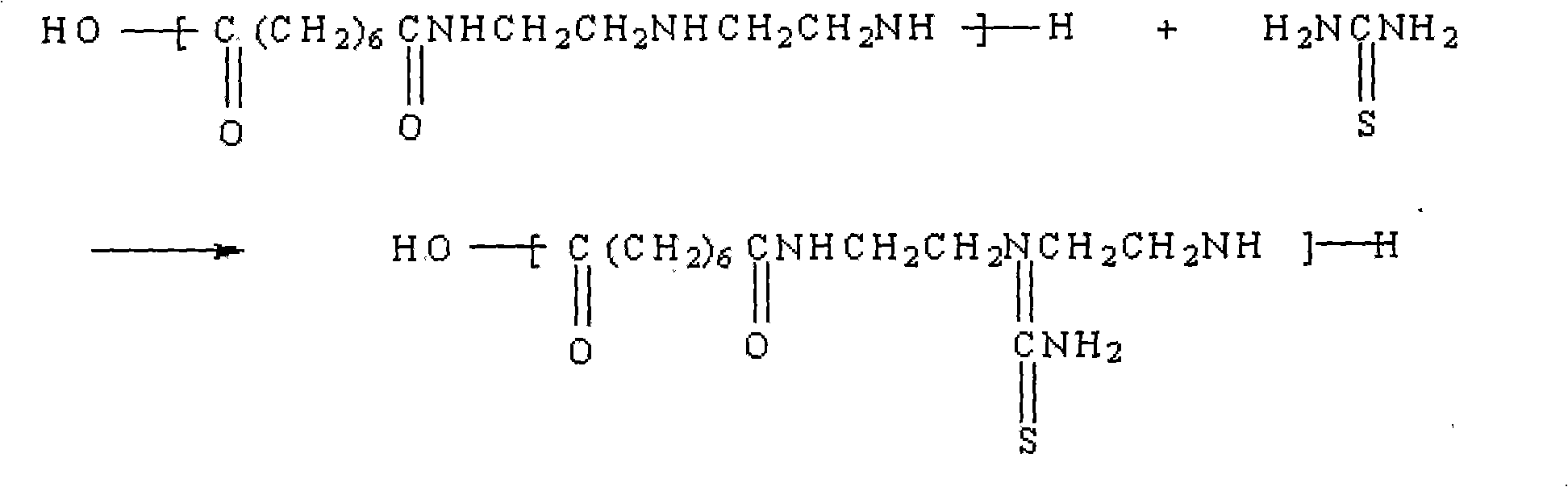

[0010] As a synergist, thiourea reacts further with polyamide prepolymer to generate thiourea-modified polyamide. The reaction formula is as follows:

[0011]

[0012] Thiourea-modified polyamide is composed of polar groups centered on O, N, and S atoms and non-polar groups composed of C, and H atoms; N, O, and S atoms are all relatively electr...

specific Embodiment approach 2

[0015] Specific implementation mode 2: This implementation mode is applicable to CO 2 The anticorrosion agent for wellbore anti-corrosion of flooding production well consists of the following components in percentage by weight: 18% diethylenetriamine, 25% sebacic acid, 12% thiourea, 5% dodecyl dimethyl benzyl ammonium chloride, 2% stearyl polyoxyethylene ether, 8% absolute ethanol, 30% water.

[0016] The preparation method of the corrosion inhibitor of this embodiment is the same as the first embodiment.

[0017] The corrosion inhibitor of this embodiment is used in downhole CO 2 Under the environment of partial pressure of 0.2MPa~2MPa, the corrosion inhibition rate can reach 93%, and there is no pitting corrosion; the film is formed uniformly on the metal pipe wall, and the adsorption effect is good; 99% demulsification, no effect on the post-dehydration treatment of crude oil. The injection process of the corrosion inhibitor is simple and easy. It is injected from the an...

specific Embodiment approach 3

[0018] Specific implementation mode three: this implementation mode is applicable to CO 2 The anticorrosion agent for wellbore anticorrosion of flooding production well consists of the following components by weight percentage: 23% diethylenetriamine, 30% sebacic acid, 15% thiourea, 7% dodecyl dimethyl benzyl ammonium chloride, 3% stearyl polyoxyethylene ether, 10% absolute ethanol, 12% water. The preparation method of the corrosion inhibitor of this embodiment is the same as the first embodiment.

[0019] The corrosion inhibitor of this embodiment is used in downhole CO 2 Under the environment of partial pressure of 0.2MPa~2MPa, the corrosion inhibition rate can reach 96%, and there is no pitting corrosion; the film is formed uniformly on the metal pipe wall, and the adsorption effect is good; 99% demulsification, no effect on the post-dehydration treatment of crude oil. The injection process of the corrosion inhibitor is simple and easy. It is injected from the annulus of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com