Method for testing pipeline steel for carbon dioxide corrosion under bending stress

A technology of bending stress and carbon dioxide, applied in the direction of weather resistance/light resistance/corrosion resistance, preparation of test samples, weighing by removing certain components, etc., to achieve the effect of simple test method, easy implementation and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

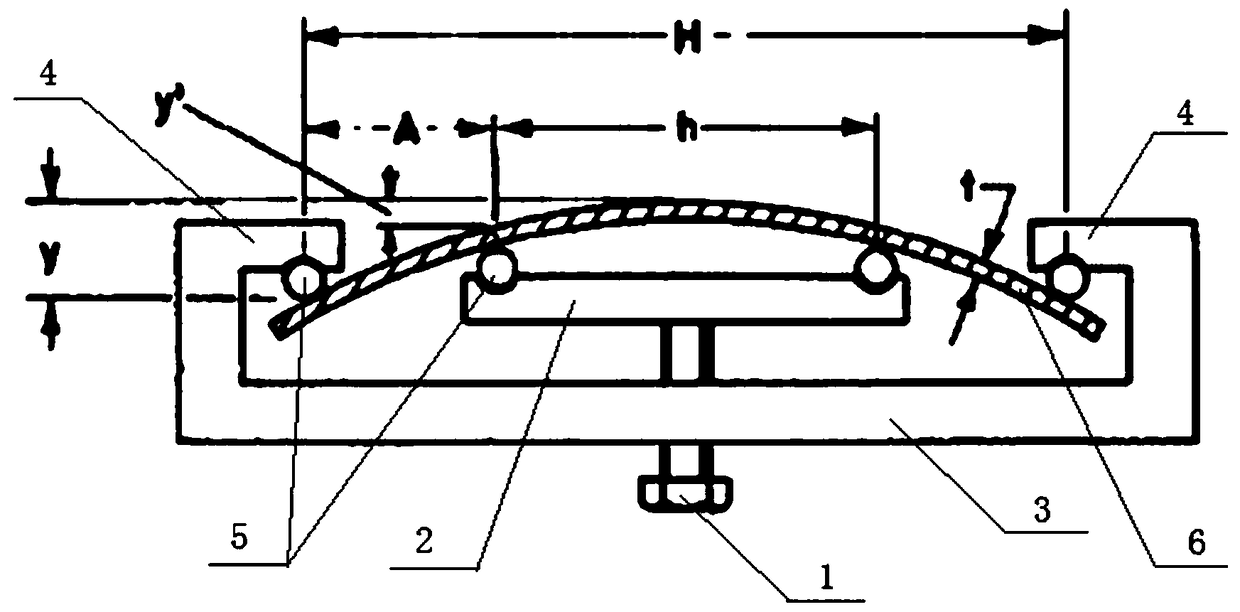

[0056] Machining obtained 1# batch of 3 parallel samples of pipeline steel, the yield strength of the sample is 450MPa, and the measured dimensions are 115.01mm×14.98mm×4.99mm, 115.02mm×14.98mm×5.01mm, 115.01mm×15.01mm×4.99 mm, weighing 67.3700g, 67.1704g, and 67.0601g respectively. Weigh 3 times the chemical reagent according to Table 1, dissolve it in 2L of deionized water, and prepare a 3L corrosion solution after fixed dissolution. The stress intensity of four-point bending loading is 0.8*450MPa, and the maximum deformation deflection y of the three samples is calculated to be 0.918mm, 0.915mm, and 0.918mm respectively. A four-point bending fixture is used to load the sample so that the maximum deformation deflection y of the sample reaches the calculated value. Put the loaded sample into the closed reaction kettle, add the corrosion solution, and pass through the CO 2 gas. Control the temperature of the reactor to 70°C, CO 2 The partial pressure is 1.0MPa, and the flo...

example 2

[0060] The 2# batch of 3 parallel samples of pipeline steel was obtained by machining. The yield strength of the sample was 556MPa. mm, weighing 67.2345g, 67.1876g, and 67.1133g respectively. Weigh 3 times the chemical reagent according to Table 1, dissolve it in 2L of deionized water, and prepare a 3L corrosion solution after fixed dissolution. The stress intensity of four-point bending loading is 0.8*556MPa, and the calculated maximum deformation deflection y of the three samples is 1.144mm, 1.126mm, and 1.135mm respectively. A four-point bending fixture is used to load the sample so that the maximum deformation deflection y of the sample reaches the calculated value. Put the loaded sample into the closed reaction kettle, add the corrosion solution, and pass through the CO 2 gas. Control the temperature of the reactor to 70°C, CO 2 The partial pressure is 1.0MPa, and the flow velocity is 1.5m / s. And start timing, end the test after 72 hours, and take out the sample. Pu...

example 3

[0062] The 1# batch of 3 parallel samples of pipeline steel was obtained by machining. The yield strength of the sample was 485MPa, and the measured dimensions were 114.91mm×14.99mm×4.98mm, 115.01mm×14.98mm×5.02mm, 114.96mm×15.00mm×5.05 mm, weighing 67.0122g, 67.1204g, and 67.1601g respectively. Weigh 3 times the chemical reagent according to Table 1, dissolve it in 2L of deionized water, and prepare a 3L corrosion solution after fixed dissolution. The stress intensity of four-point bending loading is 0.8*485MPa, and the maximum deformation deflection y of the three samples is calculated to be 0.992mm, 0.984mm, and 0.978mm respectively. A four-point bending fixture is used to load the sample so that the maximum deformation deflection y of the sample reaches the calculated value. Put the loaded sample into the closed reaction kettle, add the corrosion solution, and pass through the CO 2 gas. Control the temperature of the reactor to 70°C, CO 2 The partial pressure is 1.0MPa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com