Method and apparatus for dynamically and safely determining corrosive defects inside conveying pipeline

A technology for transportation pipelines and internal corrosion. It is used in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc. It can solve the problem of difficulty in dynamically and accurately assessing the safety status of oil and gas transportation pipelines with corrosion defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

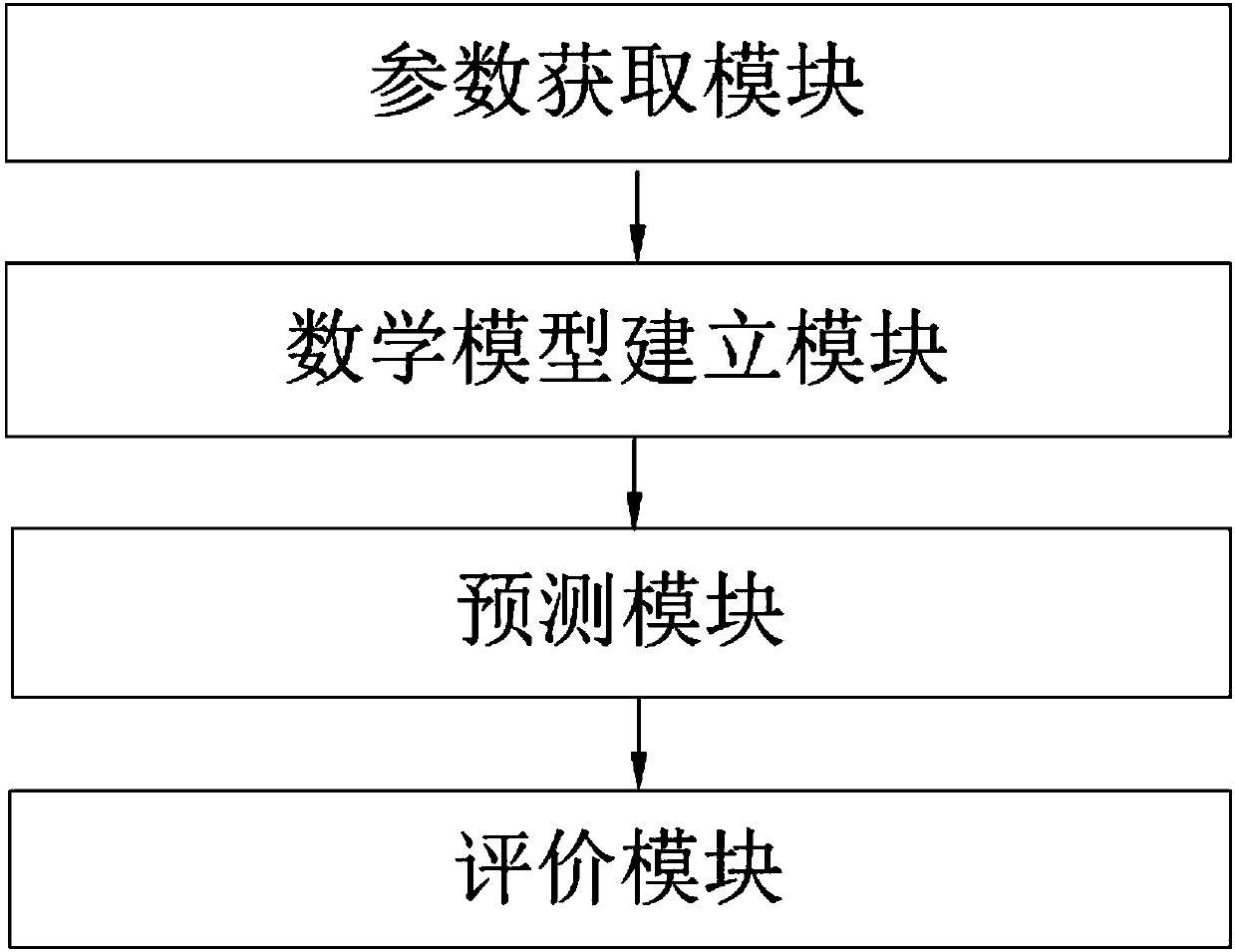

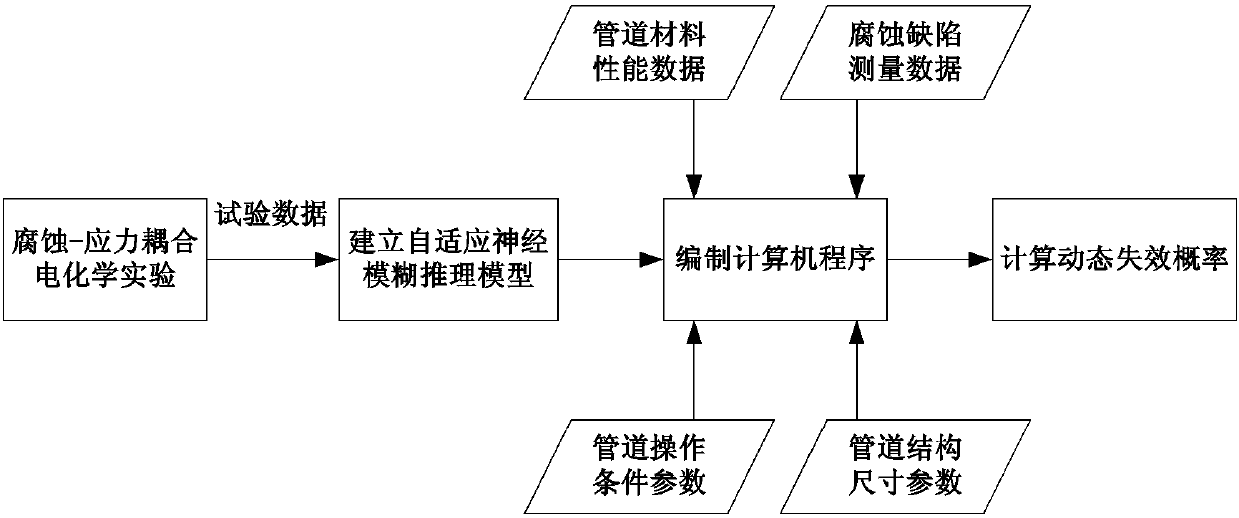

[0068] This embodiment firstly provides a dynamic safety assessment device for corrosion defects inside the pipeline, the structure of which is as follows: figure 1 As shown, the dynamic safety assessment device for corrosion defects inside the pipeline includes:

[0069] The parameter acquisition module is used to obtain the common metal materials of the pipeline in different CO 2 Partial pressure, H 2 S partial pressure, chloride content and corrosion growth rate at different stress levels;

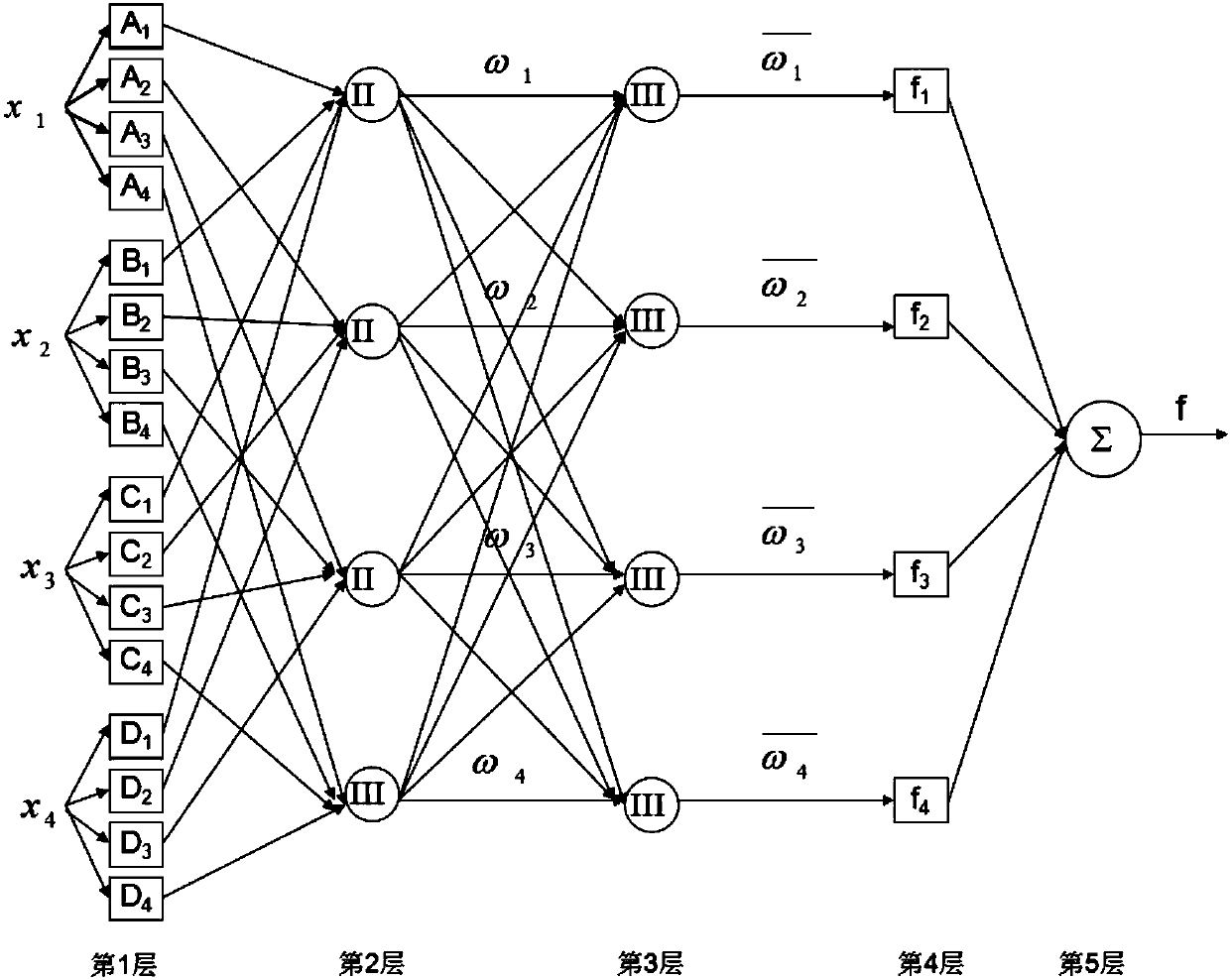

[0070] The mathematical model building module is used to use the adaptive neuro-fuzzy inference system to establish the 2 Partial pressure, H 2 Mathematical models of S content, chloride content, stress level and corrosion growth rate;

[0071] Prediction module, used to obtain CO 2 Partial pressure, H 2 S content, chloride content, stress level, based on the established mathematical model, predict the corrosion growth rate;

[0072] The evaluation module is used to establish the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com