System and method for processing an input fuel gas and steam to produce carbon dioxide and an output fuel gas

A fuel gas and carbon monoxide technology, applied in the direction of catalytic treatment of combustible gas, combustible gas purification, chemical instruments and methods, etc., can solve the problem of energy loss in the separation process step

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

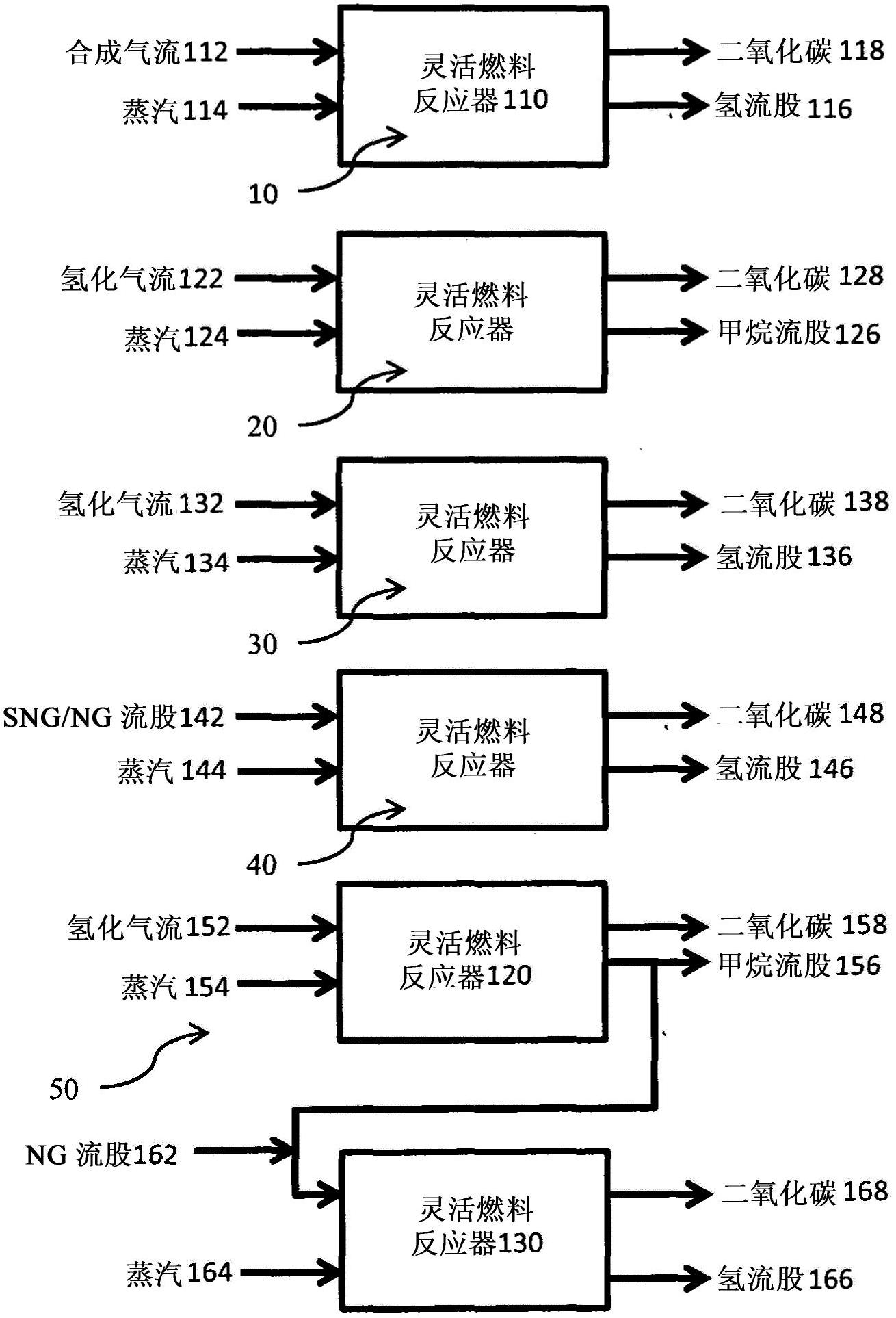

[0061] The Flexible Fuel Endex reactor decarbonizes an input fuel gas stream into an output fuel gas stream with different compositions of combustible gas and carbon dioxide gas streams. The general process flow for the flexible fuel Endex reactor for the five configurations Embodiments 10, 20, 30, 40 and 50 is shown in figure 1 middle. Embodiments 10, 20, 30 and 40 illustrate how a single reactor 110 can be configured for different fuel streams and different product fuel streams, while embodiment 50 illustrates how a pair of flexible fuel Endex reactors 120, 130 Can be configured in series for additional flexibility. As described below, these processes only show gas flow and do not include solid sorbent or catalyst input and output or auxiliary systems. Additionally, the use of various solid fuels such as various grades of coal, biomass or waste to produce input syngas or hydrogenated gas is not explicitly shown. It should be noted that the Flexible Fuel Endex Reactor may ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com