Device and method for reducing CO2-emissions from the waste gases of combustion plants

An equipment and flue gas technology, which is applied in the field of devices and methods for reducing CO2 emissions in the exhaust gas of combustion equipment, and can solve problems such as blockage of membrane holes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

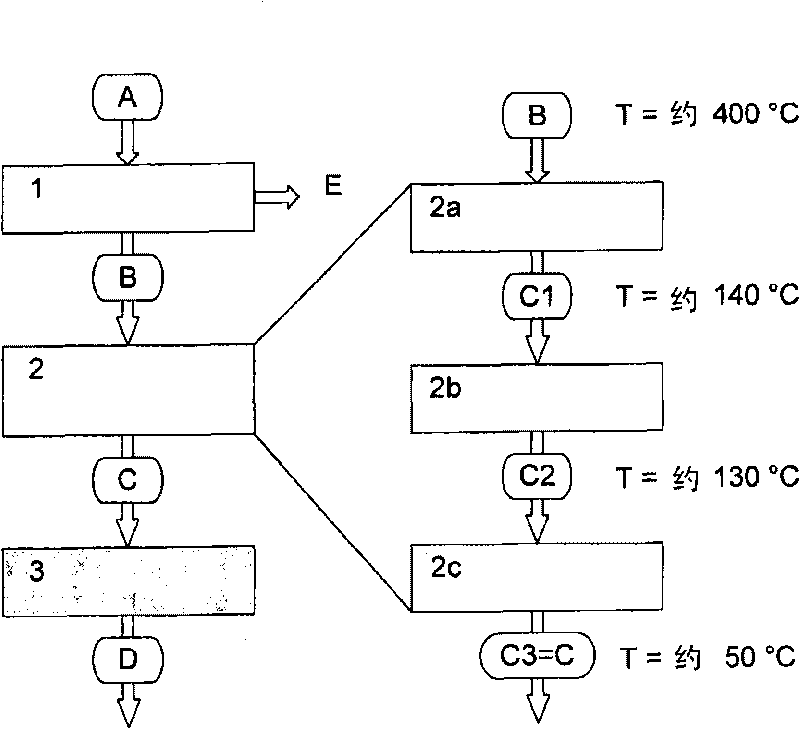

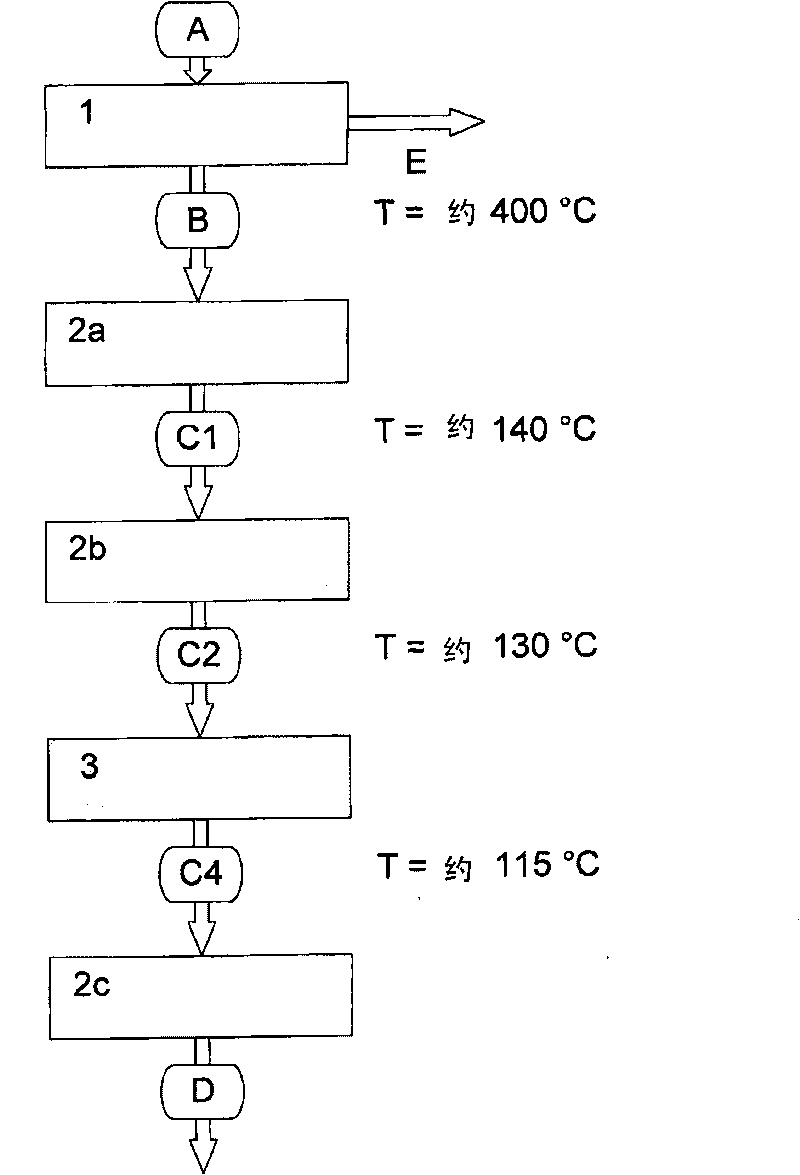

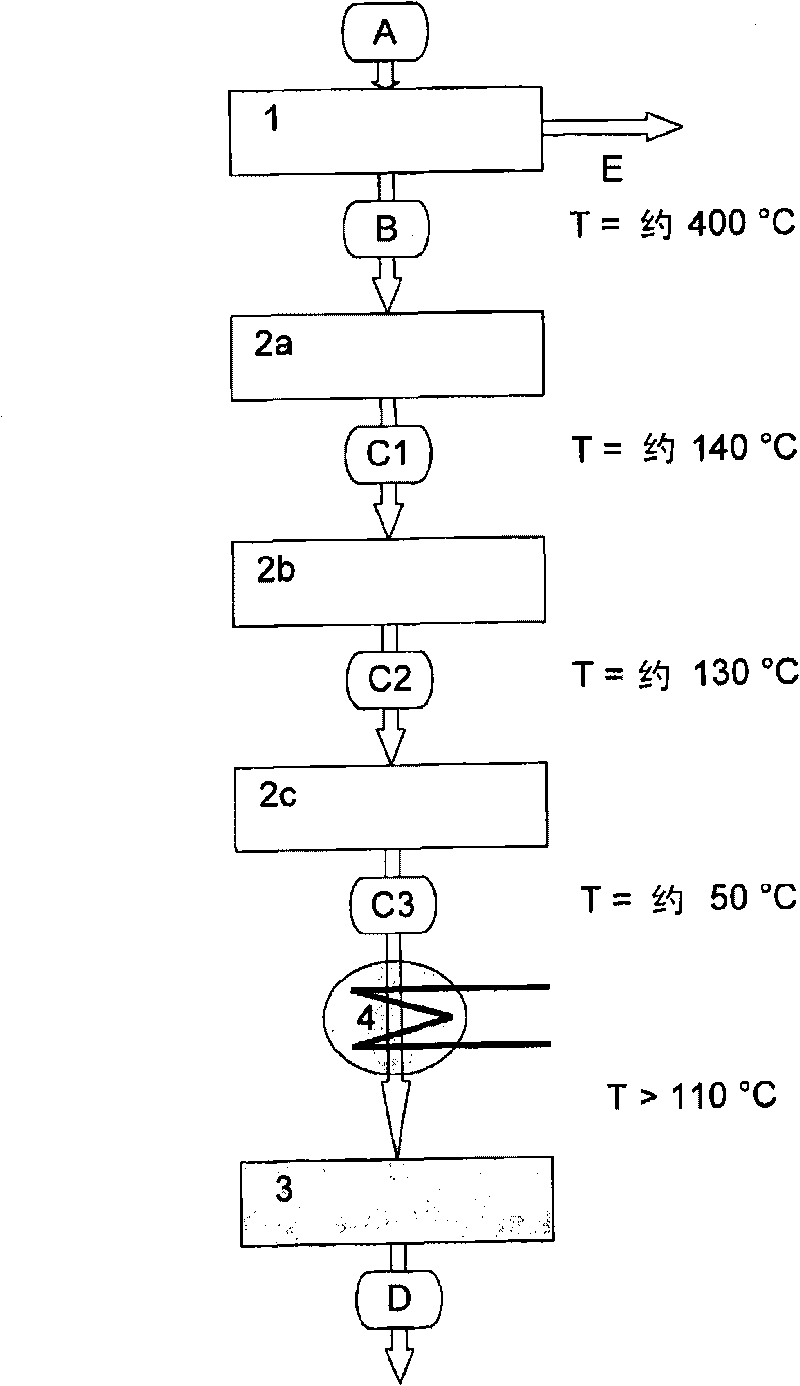

[0025] The present invention is described in detail below with embodiment, but protection scope is not limited thereby. These and other similar variations would be considered within the scope of the invention by those skilled in the art.

[0026] The ellipse in the figure means the medium:

[0027] A fuel

[0028] B Rough smoke

[0029] C Purified flue gas, where the difference is:

[0030] C1 denitrified flue gas,

[0031] C2 denitrified and dedusted flue gas, and

[0032] C3 denitrified, dedusted and desulfurized flue gas

[0033] D Pure flue gas = denitrified, dedusted, desulfurized and decarbonized flue gas,

[0034] E electricity

[0035] Rectangular boxes represent the various process steps:

[0036] 1 power generation

[0037] 2 Flue gas purification, currently includes:

[0038] 2a Nitrogen removal,

[0039] 2b dust removal, and

[0040] 2c Desulfurization

[0041] 3 CO through the membrane module 2 Separation (decarburization)

[0042] 4 heat transfer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com