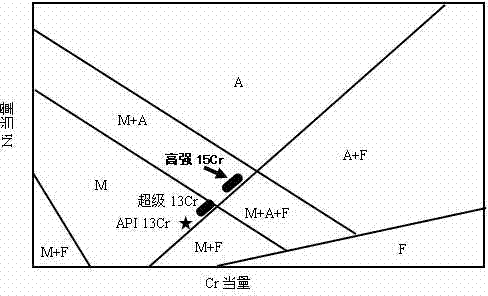

CO2 and Cl<-> corrosion resistant high-strength 15Cr oil pipe for high-temperature high-pressure wells

A high-temperature, high-pressure, high-strength technology, applied to pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of high well construction costs, reduce corrosion accidents, increase costs, and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

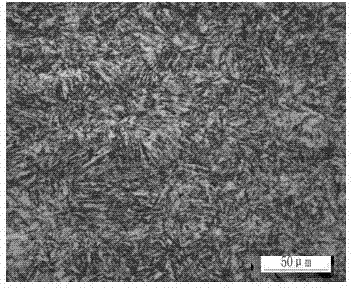

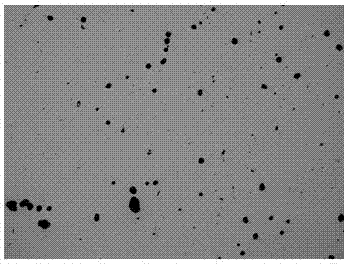

Image

Examples

Embodiment 1

[0025] The high-strength 15Cr components provided by the present invention are: carbon 0.024 wt%, silicon 0.25 wt%, manganese 0.27 wt%, phosphorus 0.016 wt%, sulfur 0.001 wt%, chromium 15.10 wt%, molybdenum 1.99 wt%, copper 0.81 wt%, Nickel 6.36 wt%, tungsten 0.5wt%; titanium 0.0051 wt%, boron 0.0025wt%, niobium 0.07wt%, vanadium 0.04wt%; nitrogen 0.039 wt%; oxygen 0.0007wt%; the controlled components are: arsenic 0.01wt%, Tin 0.01wt%, antimony 0.01wt%, balance Fe.

Embodiment 2

[0027] A CO2-resistant 2 +Cl - Corroded high-strength 15Cr oil pipes include the following components, by weight percentage:

[0028] Carbon 0.028wt%, silicon 0.35wt%, manganese 0.35wt%, phosphorus 0.013wt%, sulfur 0.0015wt%, chromium 14.8wt%, molybdenum 2.2wt%, copper 0.9wt%, nickel 6.8wt%, tungsten 0.7wt%, Titanium 0.006wt%, Boron 0.004wt%, Niobium 0.088wt%, Vanadium 0.067wt%; Nitrogen 0.08%; Oxygen 0.0008wt%; Hydrogen 0.0000048wt%. 0.027wt%, the controlled components are: arsenic 0.026wt%, tin 0.028wt%, antimony 0.027wt%, and the balance is iron.

Embodiment 3

[0030] A CO2-resistant 2 +Cl - Corroded high-strength 15Cr oil pipes include the following components, by weight percentage:

[0031] Carbon 0.02wt%, silicon 0.3wt%, manganese 0.4wt%, phosphorus 0.01wt%, sulfur 0.002wt%, chromium 15.0wt%, molybdenum 2.0wt%, copper 0.80wt%, nickel 6.58wt%, tungsten 0.55wt%, Titanium 0.005wt%, Boron 0.003wt%, Niobium: 0.07wt%, Vanadium 0.05wt%, Nitrogen 0.06%, Oxygen 0.0005wt%, Hydrogen 0.000003wt%. Antimony 0.016wt%, the balance is iron.

[0032] Anti-CO 2 Uniform and localized corrosion performance

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com