System and method for processing flue gas

A flue gas and gas flow technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve problems such as increasing the capital cost and coverage area of CCS systems, reducing power plant efficiency, and reducing net CO2

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

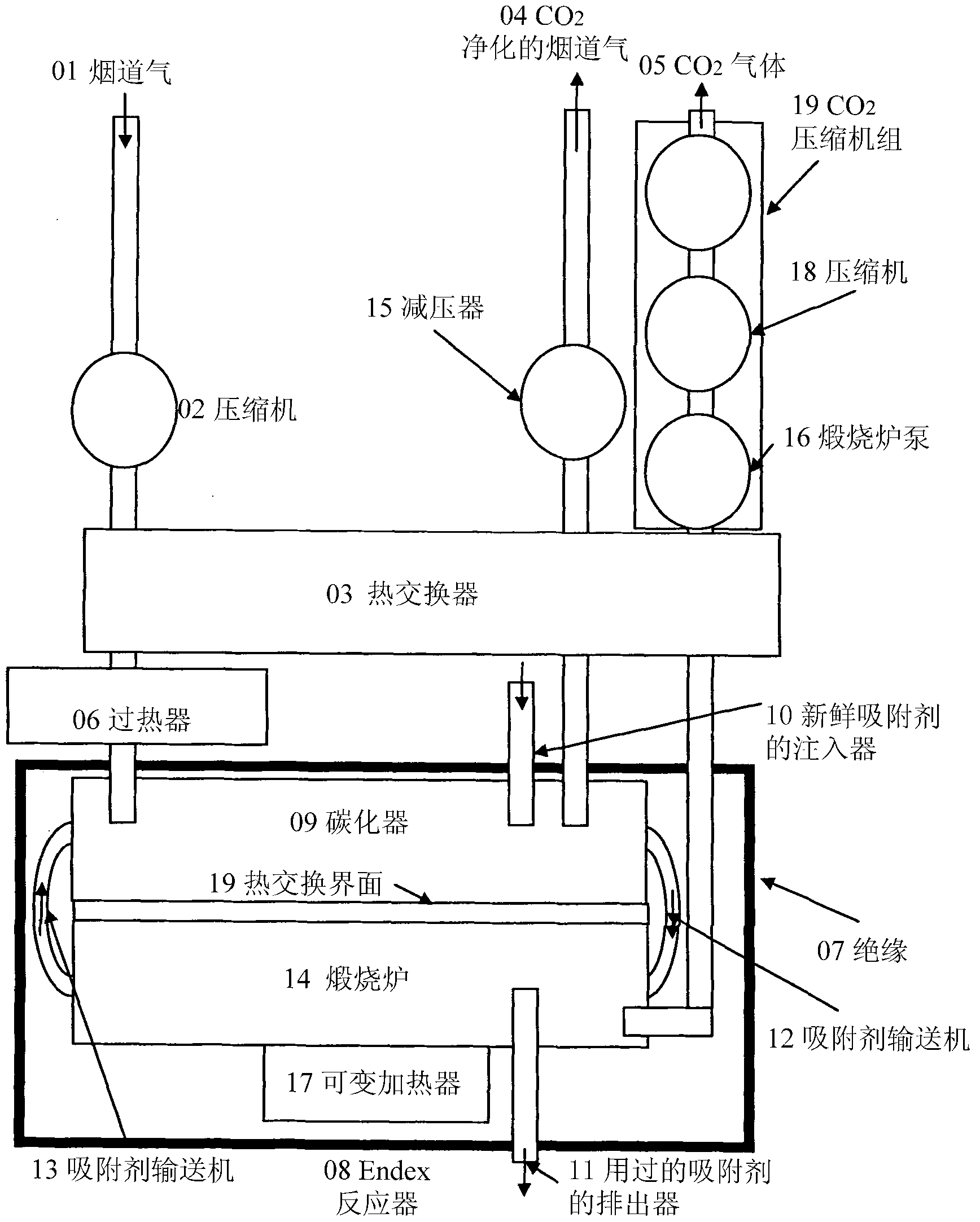

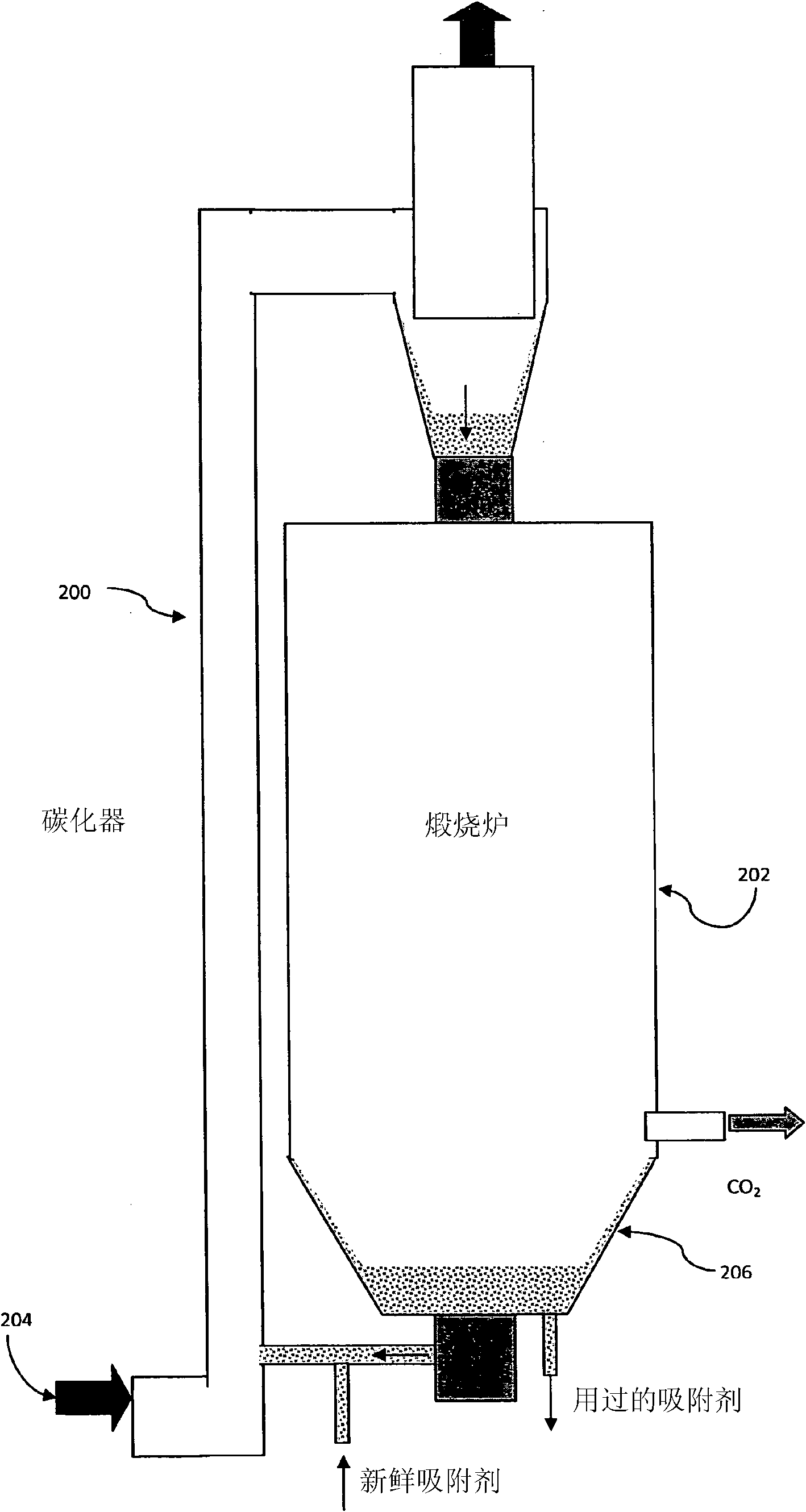

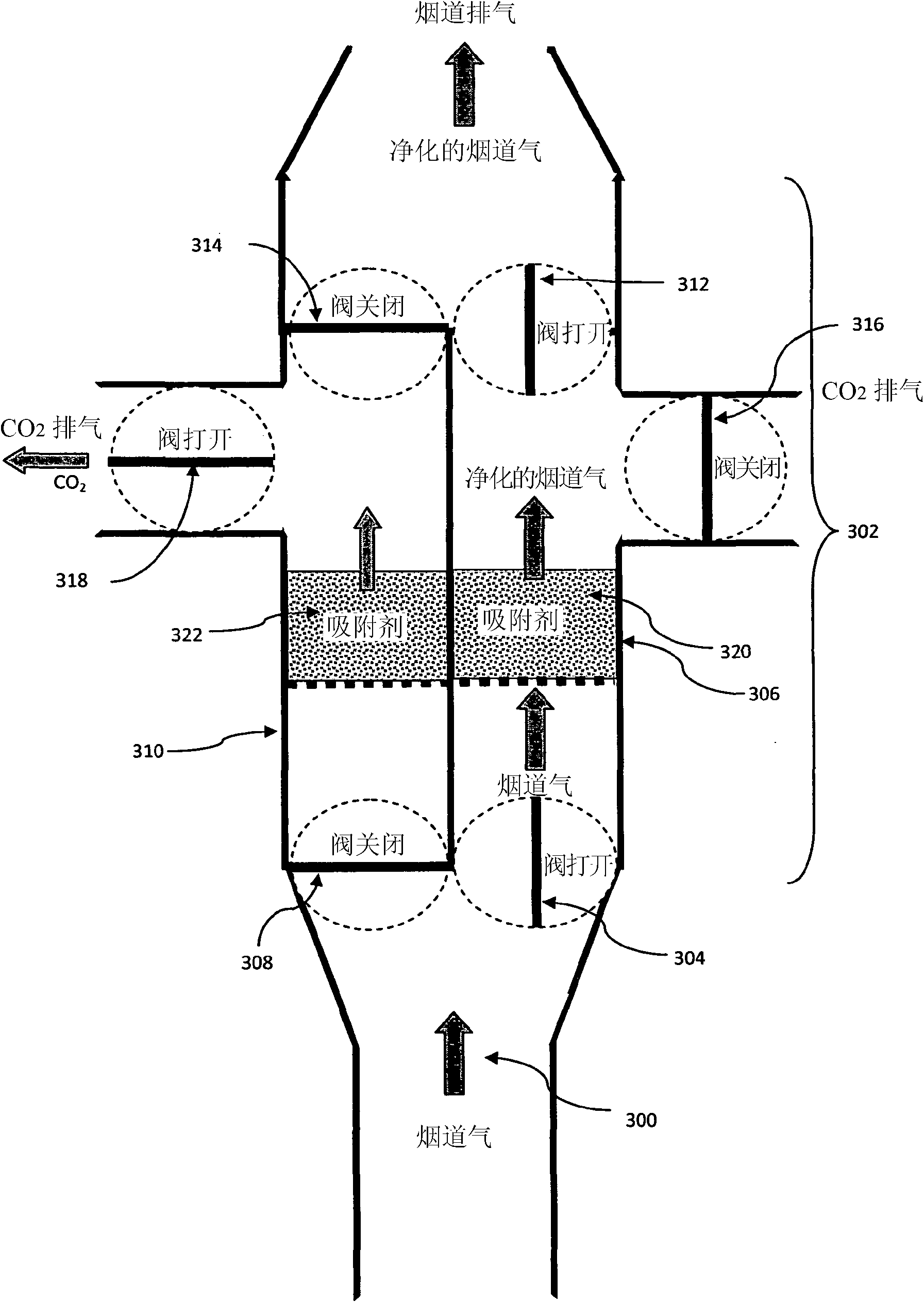

[0039] For the separation of carbon dioxide (CO2) from gas streams, such as flue gas or fuel gas 2 ) The exemplary system and method embodiments described use particles of a solid sorbent, such as lime. The system consists of: carbonizer reactor section with sorbent that extracts CO from the gas stream 2 ; the calciner reactor section, which converts CO 2 Release into (become a pure gas stream) and regenerate the sorbent; and means to allow heat to flow between them. The system is designed to reduce the net consumption of energy by setting the gas temperature and pressure in each section so that the carbonizer advantageously operates at a higher temperature than the calciner, and under these conditions it is possible to convert the CO adsorption in the carbonizer 2 The released heat is supplied to and consumed by the calciner to desorb (desorb) CO 2 . In an exemplary embodiment when CO in the calciner exhaust 2 Pressure lower than CO in the carbonator exhaust 2 When und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com