Carbon-free Ag-Cu catalyst layer-based air electrode and its making method

A technology of air electrodes and catalyst layers, which can be applied to battery electrodes, circuits, electrical components, etc., and can solve problems such as corrosion and electrocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

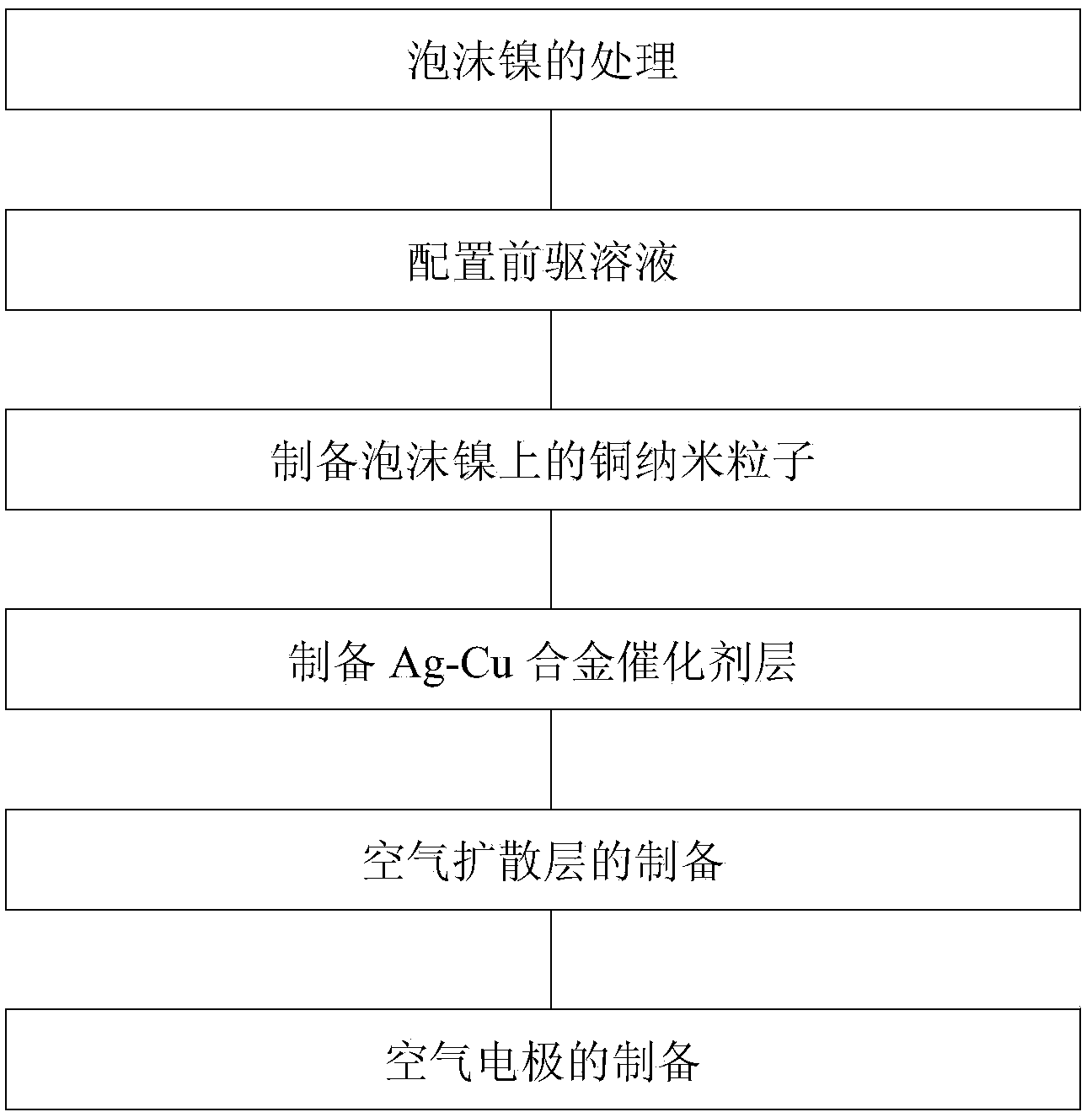

Method used

Image

Examples

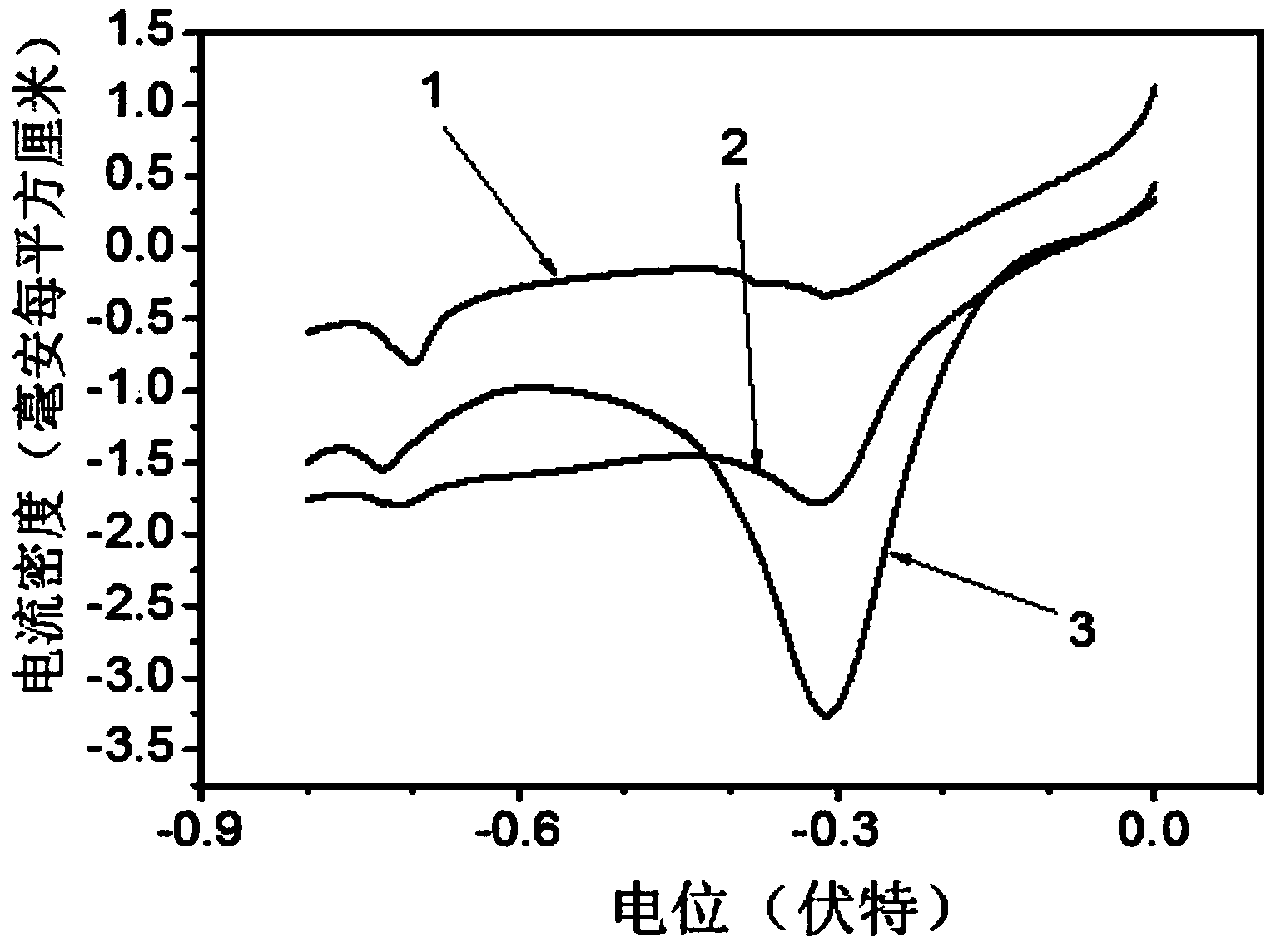

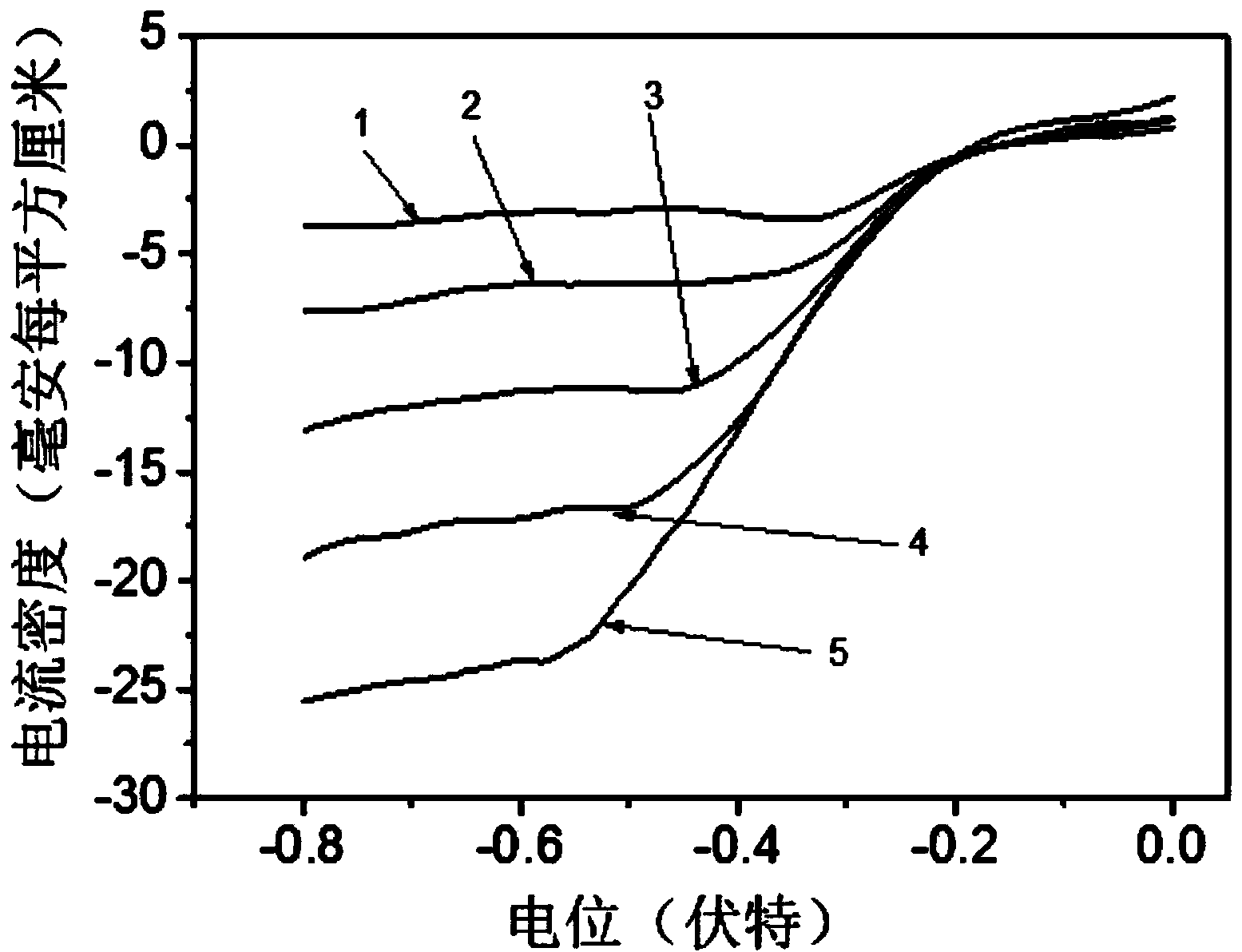

Embodiment 1

[0028] This embodiment is an air electrode based on a carbon-free Ag-Cu catalyst layer. The air electrode based on the carbon-free Ag-Cu catalyst layer is characterized in that: a layer of Ag-Cu alloy is deposited on the nickel foam, and the microscopic morphology of the Ag-Cu alloy is dendritic. The dendrites are evenly distributed on the nickel foam substrate, and the growth form is complete. The length of the primary dendrites is about 10-20 μm, and the length of the secondary dendrites is 2-8 μm. The growth direction of the secondary dendrites is 90 degrees to the primary crystal. Ag, Cu and Cu exist in Ag-Cu dendrites 2 O phase, the constituent elements are Ag and Cu in zero valence state, and there is a copper oxide layer on the surface. Primary Zn-air battery with Ag-Cu catalyst air electrode at 100mA / cm 2 Under the discharge power is 85.8mWcm –2 , the charge-discharge reciprocating efficiency of the secondary zinc-air battery is greater than 51.8%.

[0029] The pre...

Embodiment 2

[0039] This embodiment is an air electrode based on a carbon-free Ag-Cu catalyst layer. The air electrode based on the carbon-free Ag-Cu catalyst layer is characterized in that: a layer of Ag-Cu alloy is deposited on the nickel foam, and the microscopic morphology of the Ag-Cu alloy is dendrite and spherical particles. The dendrites are evenly distributed on the nickel foam matrix, and the growth form is complete. The length of the primary dendrites is about 15-23 μm. The spherical particles are randomly distributed on the primary dendrite matrix, and the diameter of the spherical particles is 0.1-1 μm. Ag, Cu and Cu exist in Ag-Cu alloy 2 O phase, the constituent elements are Ag and Cu in zero valence state, and there is a copper oxide layer on the surface. Primary Zn-air battery with Ag-Cu catalyst air electrode at 100mA / cm 2 Under the discharge power is 84.1mWcm –2 , the charge-discharge reciprocating efficiency of the secondary zinc-air battery is greater than 51.8%.

...

Embodiment 3

[0050] This embodiment is an air electrode based on a carbon-free Ag-Cu catalyst layer. The air electrode based on the carbon-free Ag-Cu catalyst layer is characterized in that: a layer of Ag-Cu alloy is deposited on the nickel foam, and the microscopic morphology of the Ag-Cu alloy is dendrite and flake. The dendrites are randomly distributed on the nickel foam matrix, and the length of the primary dendrites is about 10-15 μm. The lamellar substances are randomly distributed around the primary dendrites, with different sizes and a thickness of 0.5-3 μm. Ag, Cu and Cu exist in Ag-Cu alloy 2 O phase, the constituent elements are Ag and Cu in zero valence state, and there is a copper oxide layer on the surface. Primary Zn-air battery with Ag-Cu catalyst air electrode at 100mA / cm 2 Under the discharge power is 83.2mWcm –2 , the charge-discharge reciprocating efficiency of the secondary zinc-air battery is greater than 51.8%.

[0051] The preparation process of this embodiment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com