Patents

Literature

178 results about "Spherulite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

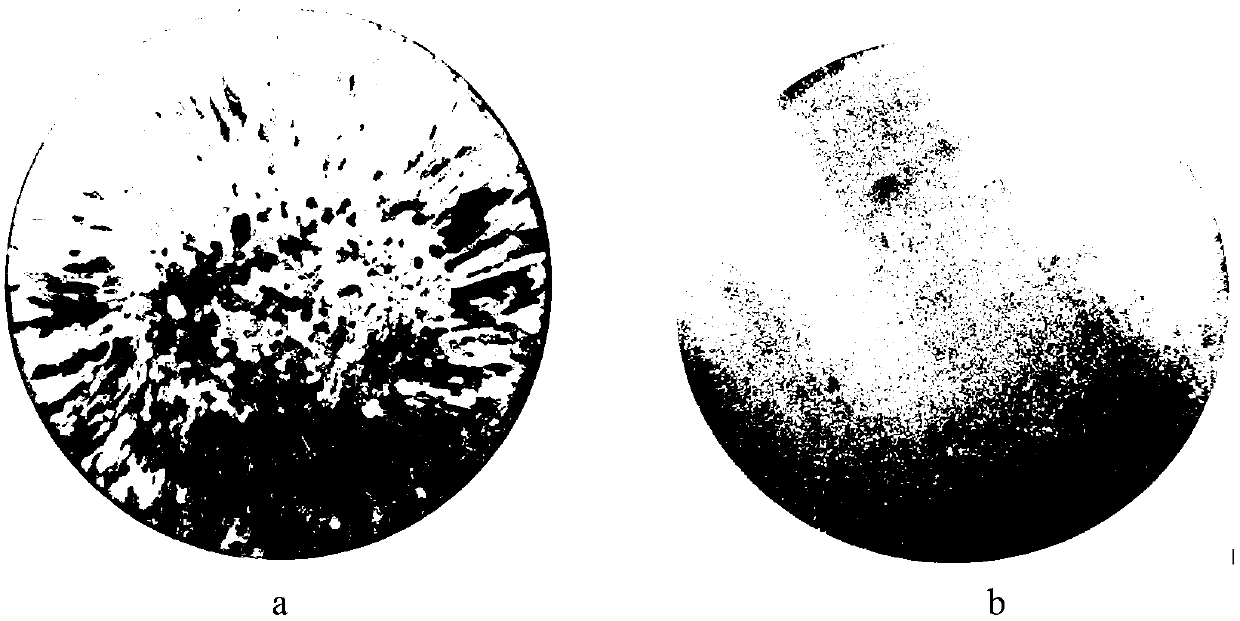

In petrology, spherulites ( /ˈsfɛrʊlaɪt/) are small, rounded bodies that commonly occur in vitreous igneous rocks. They are often visible in specimens of obsidian, pitchstone and rhyolite as globules about the size of millet seed or rice grain, with a duller luster than the surrounding glassy base of the rock, and when they are examined with a lens they prove to have a radiate fibrous structure.

Cement compositions containing flexible, compressible beads and methods of cementing in subterranean formations

Cement compositions comprising flexible, compressible beads, processes for preparing such cement compositions, and methods of cementing in subterranean formations using such cement compositions. One or more flexible, compressible beads are mixed with the cement before pumping the cement into a well bore. The flexible, compressible beads are preferably composed of an elastomeric material such as a copolymer of methylmethacrylate and acrylonitrile; a terpolymer of methylmethacrylate, acrylonitrile, and dichloroethane; a styrene-divinylbenzene copolymer; and polystyrene. The flexible, compressible beads may be heated to expand the beads before mixing with the cement such that the ensuing cement composition will have a desired density. Non-flexible beads such as spherulites may also be added to the cement compositions.

Owner:REDDY B RAGHAVA +2

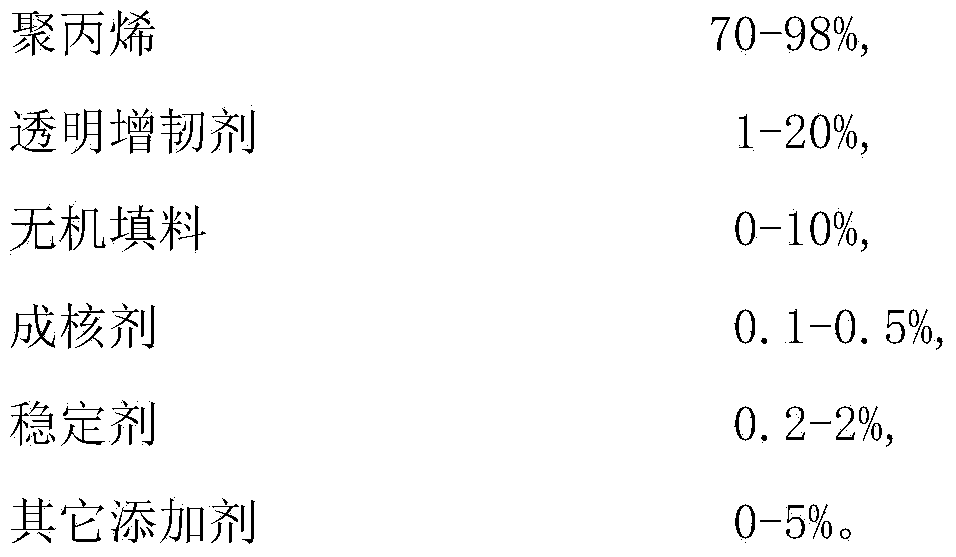

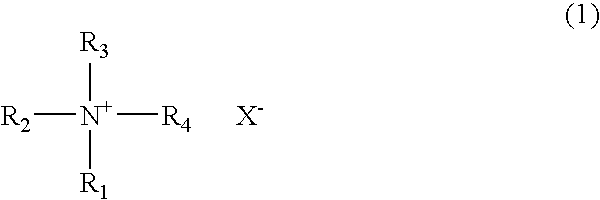

Polypropylene composite material for 3D (Three Dimensional) printing and preparation method thereof

The invention discloses a polypropylene composite material for 3D (Three Dimensional) printing and a preparation method thereof. The polypropylene composite material is composed of following raw materials in percentage by weight: 70%-98% of polypropylene, 1%-20% of a transparent toughening agent, 0-10% of inorganic fillers, 0.1%-0.5% of a nucleating agent, 0.2%-2% of a stabilizing agent and 0-5% of other additives. The polypropylene composite material has the advantages that 1 a propylene-based elastic body is used as the toughening agent for processing polypropylene so that the roughness of materials can be improved and the shrinkage rate of the materials is reduced; the transparency is not greatly influenced; a beta nucleating agent is used for accelerating a crystallization speed; the molding speed is improved, the size of a spherical crystal is thinned and the transparency is improved; the density of a crystal region is reduced and the shrinkage rate is reduced; super-pure and superfine talcum powder or calcium sulfate crystal whiskers with a high mesh number and the like are adopted so that the shrinkage rate is reduced and the good transparency is kept. The polypropylene composite material for the 3D printing has the advantages that 1 the comprehensive performance is good; 2 a manner of wholly feeding from a main feeding opening is adopted so that the dispersion effects of the toughening agent, the talcum powder and the like are improved, and the performance of the composite material is further improved.

Owner:CHONGQNG PRET NEW MATERIAL +2

Cement compositions containing flexible, compressible beads and methods of cementing in subterranean formations

Cement compositions comprising flexible, compressible beads, processes for preparing such cement compositions, and methods of cementing in subterranean formations using such cement compositions. One or more flexible, compressible beads are mixed with the cement before pumping the cement into a well bore. The flexible, compressible beads are preferably composed of an elastomeric material such as a copolymer of methylmethacrylate and acrylonitrile; a terpolymer of methylmethacrylate, acrylonitrile, and dichloroethane; a styrene-divinylbenzene copolymer; and polystyrene. The flexible, compressible beads may be heated to expand the beads before mixing with the cement such that the ensuing cement composition will have a desired density. Non-flexible beads such as spherulites may also be added to the cement compositions.

Owner:HALLIBURTON ENERGY SERVICES INC

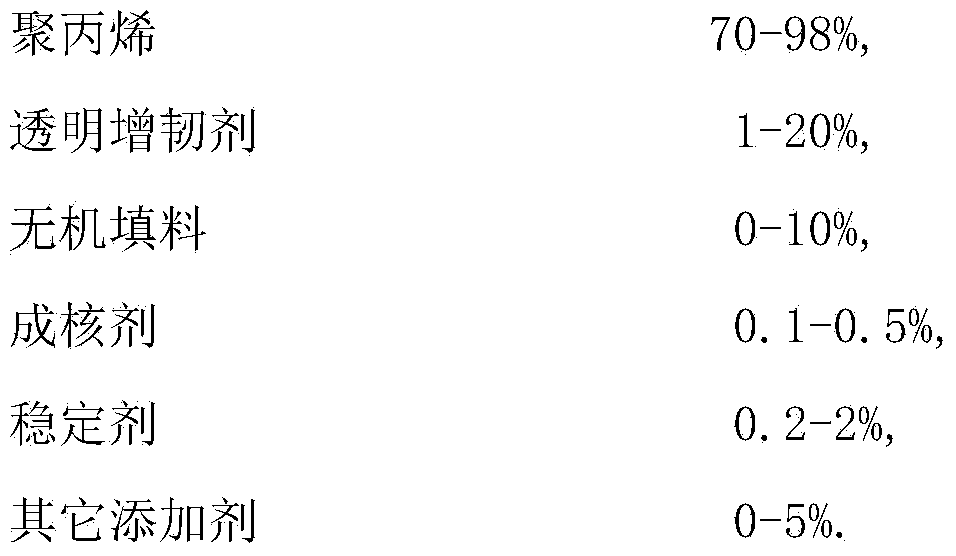

Sintering technology of ferrochrome mineral powder

Owner:CENT SOUTH UNIV

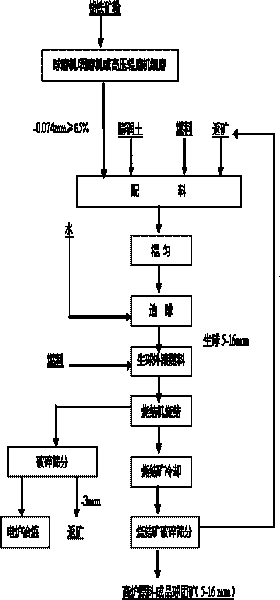

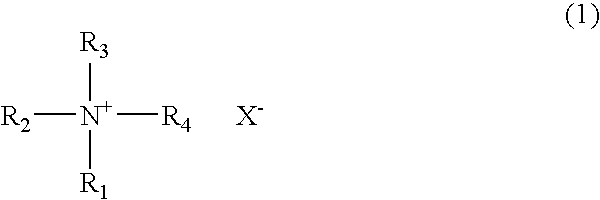

Structured surfactant compositions

InactiveUS20050233935A1High optical clarityHigh shear mixingCosmetic preparationsCationic surface-active compoundsPersonal careOrganic chemistry

An optically clear aqueous structured surfactant composition that includes from 0 parts by weight to less than 2.5 parts by weight sugar per 100 parts by weight of the composition, and from greater than 7.7 parts by weight to about 50 parts by weight of an anionic surfactant per 100 parts by weight of the composition, and wherein at least a portion of the anionic surfactant is in the form of spherulites, is useful as a ingredient in personal care compositions.

Owner:RHONDIA INC

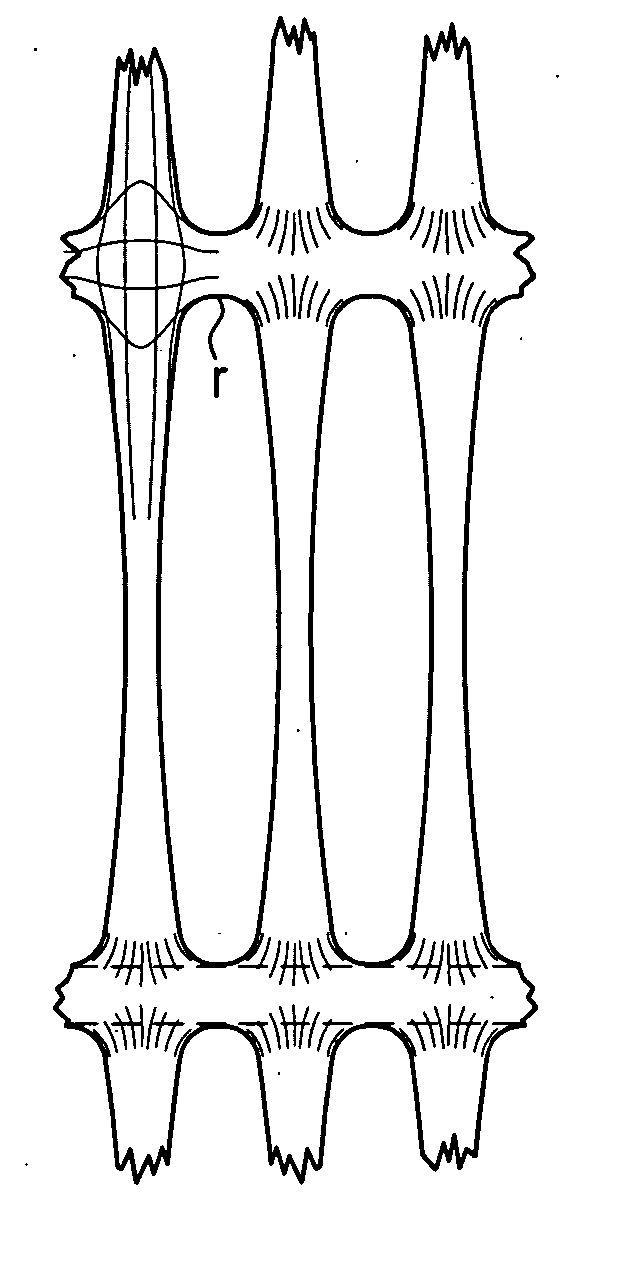

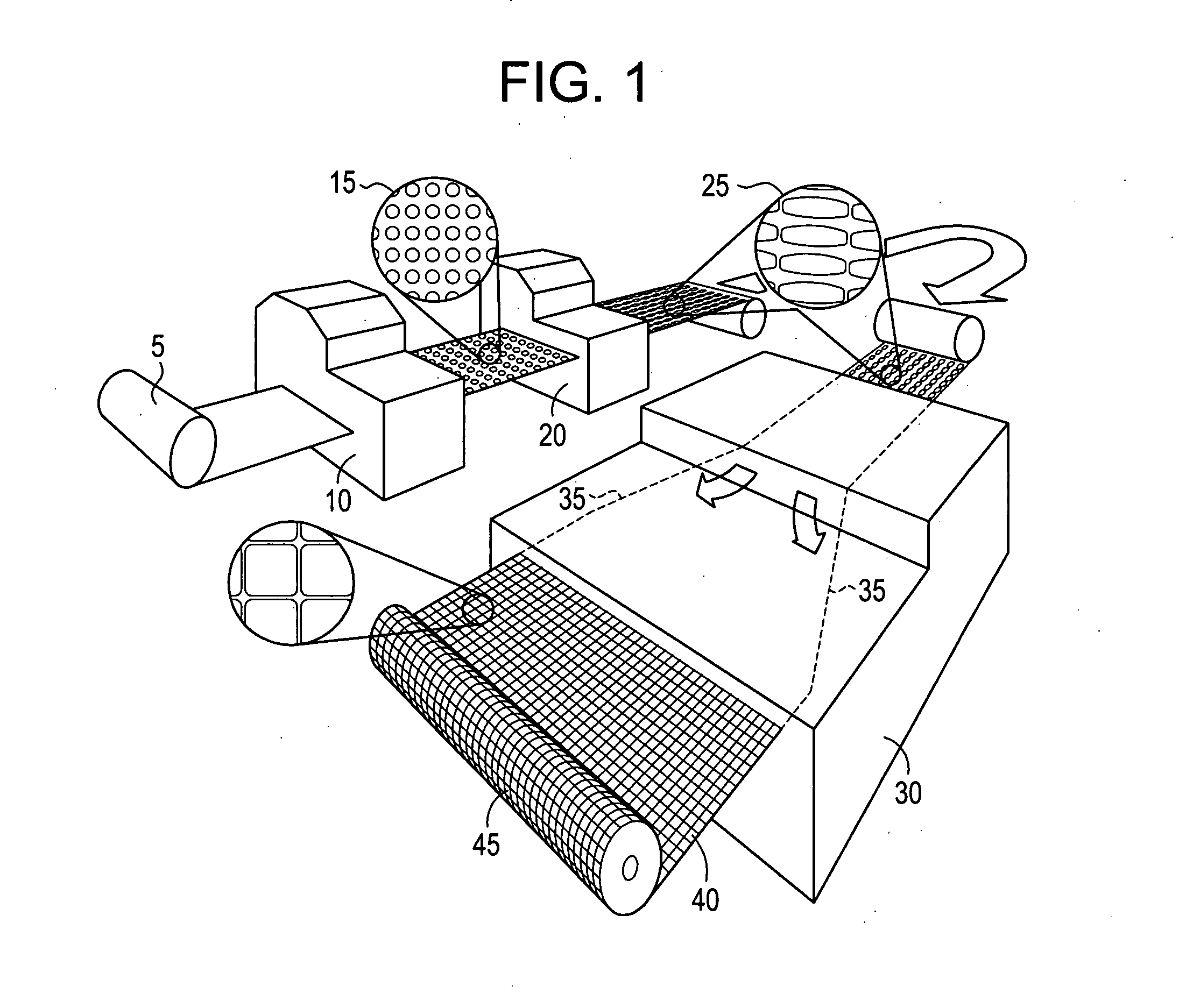

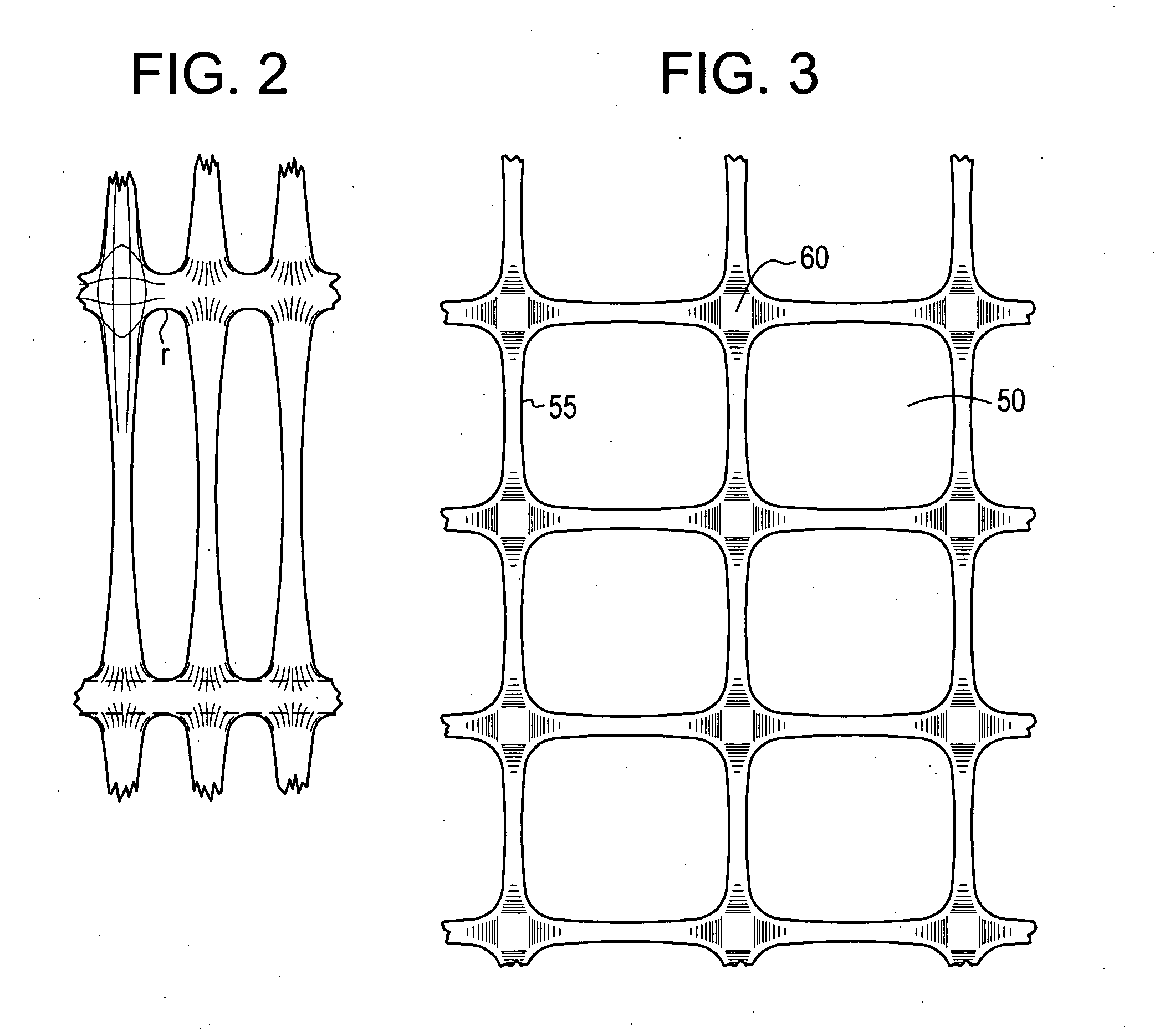

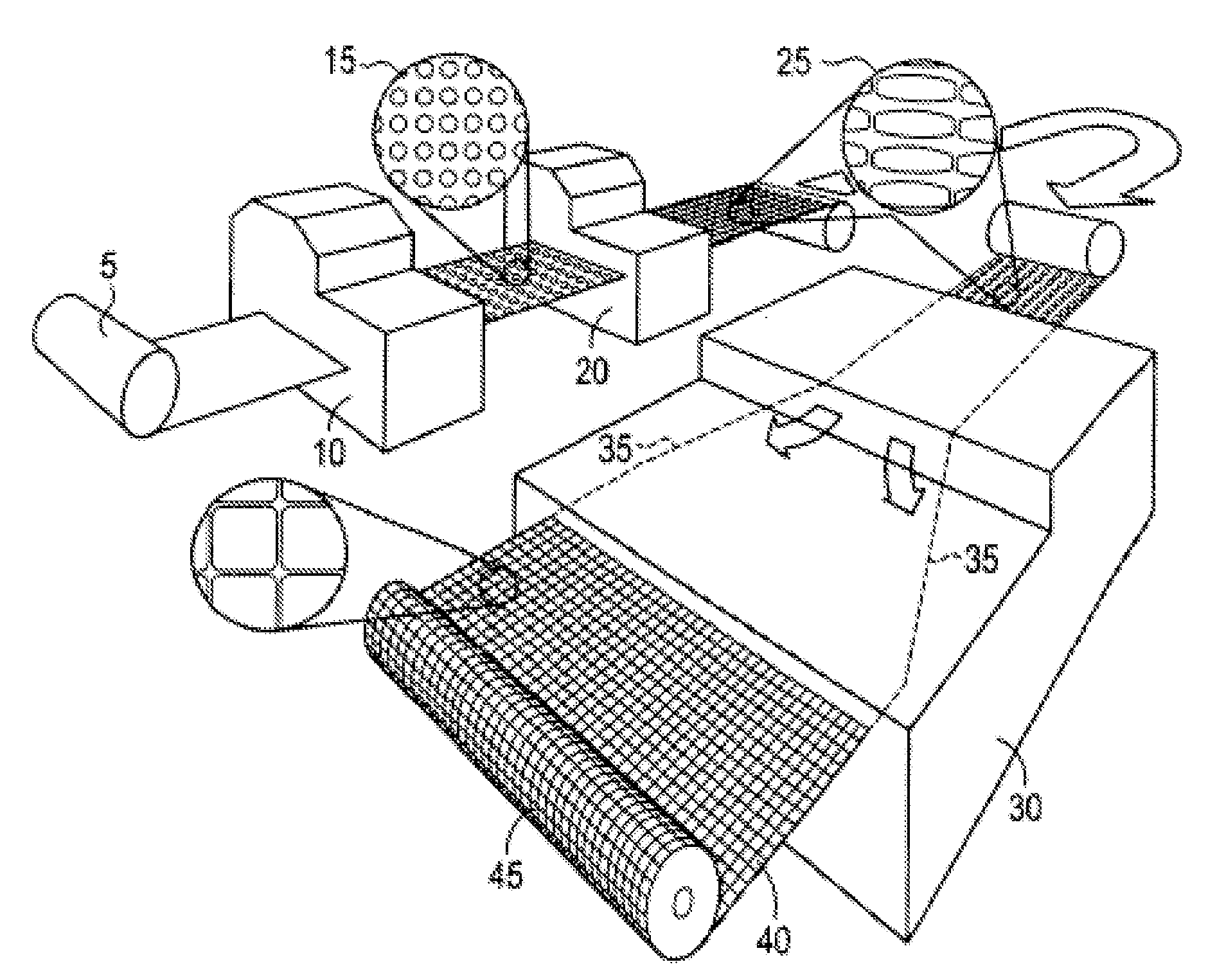

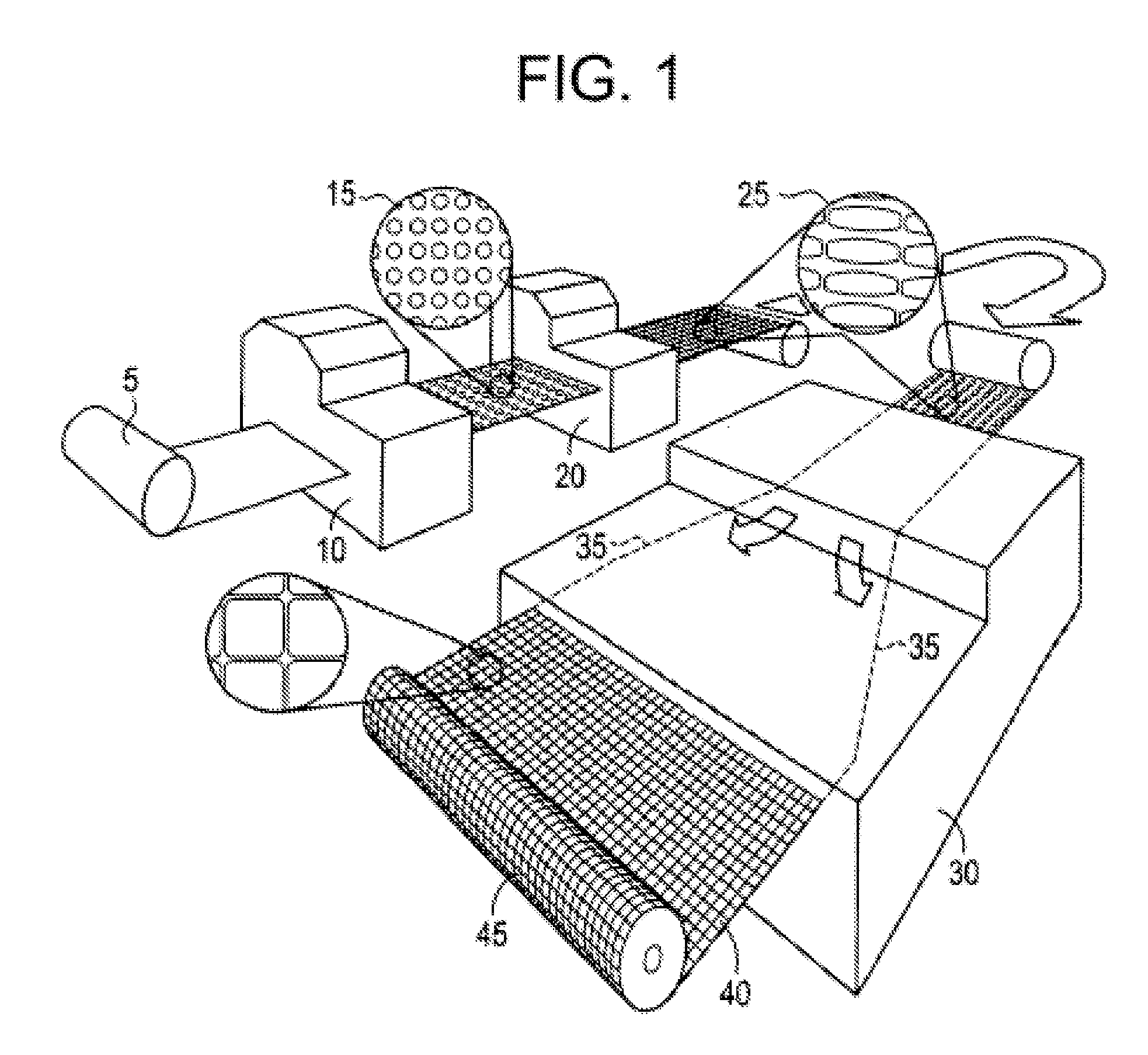

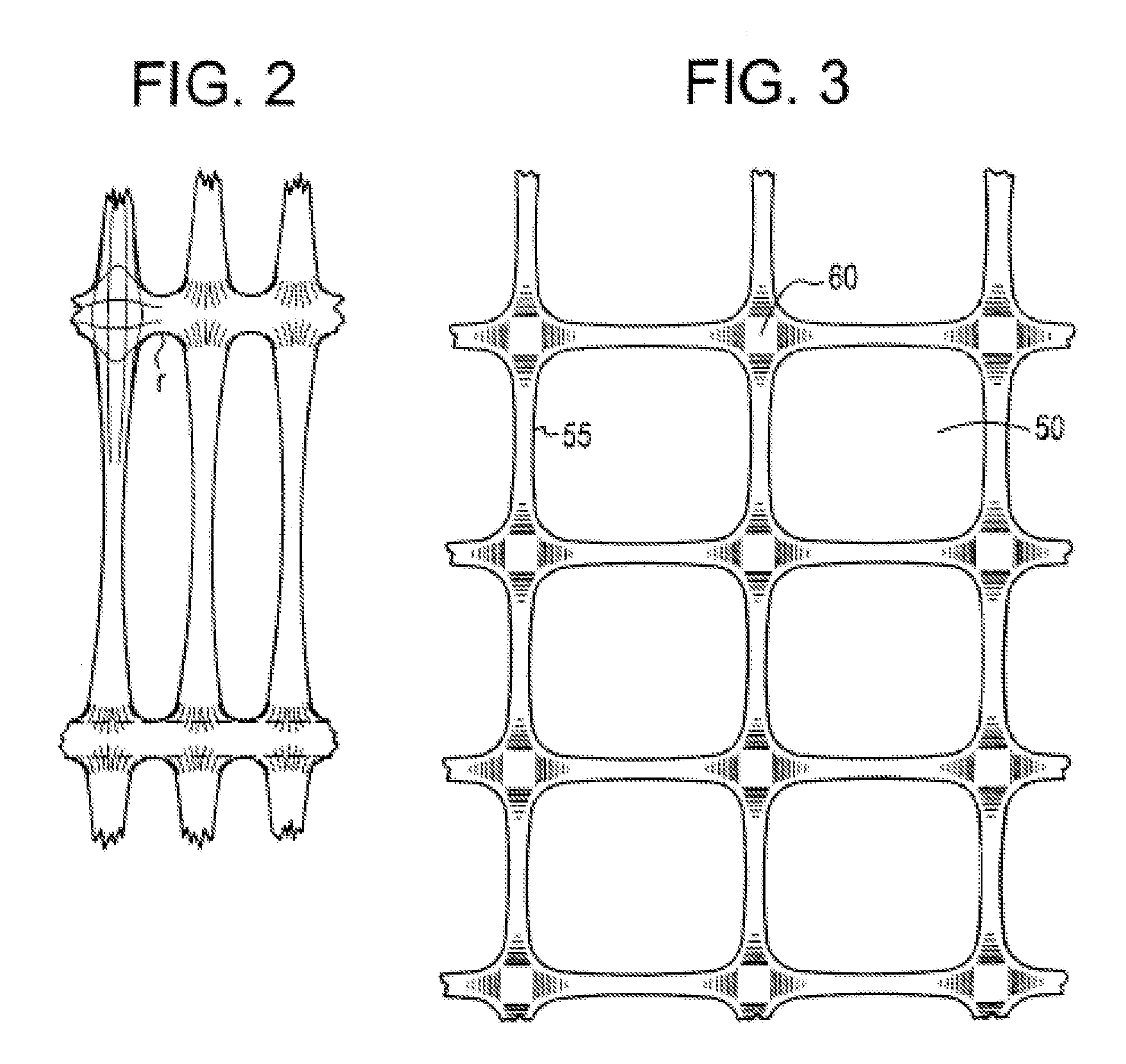

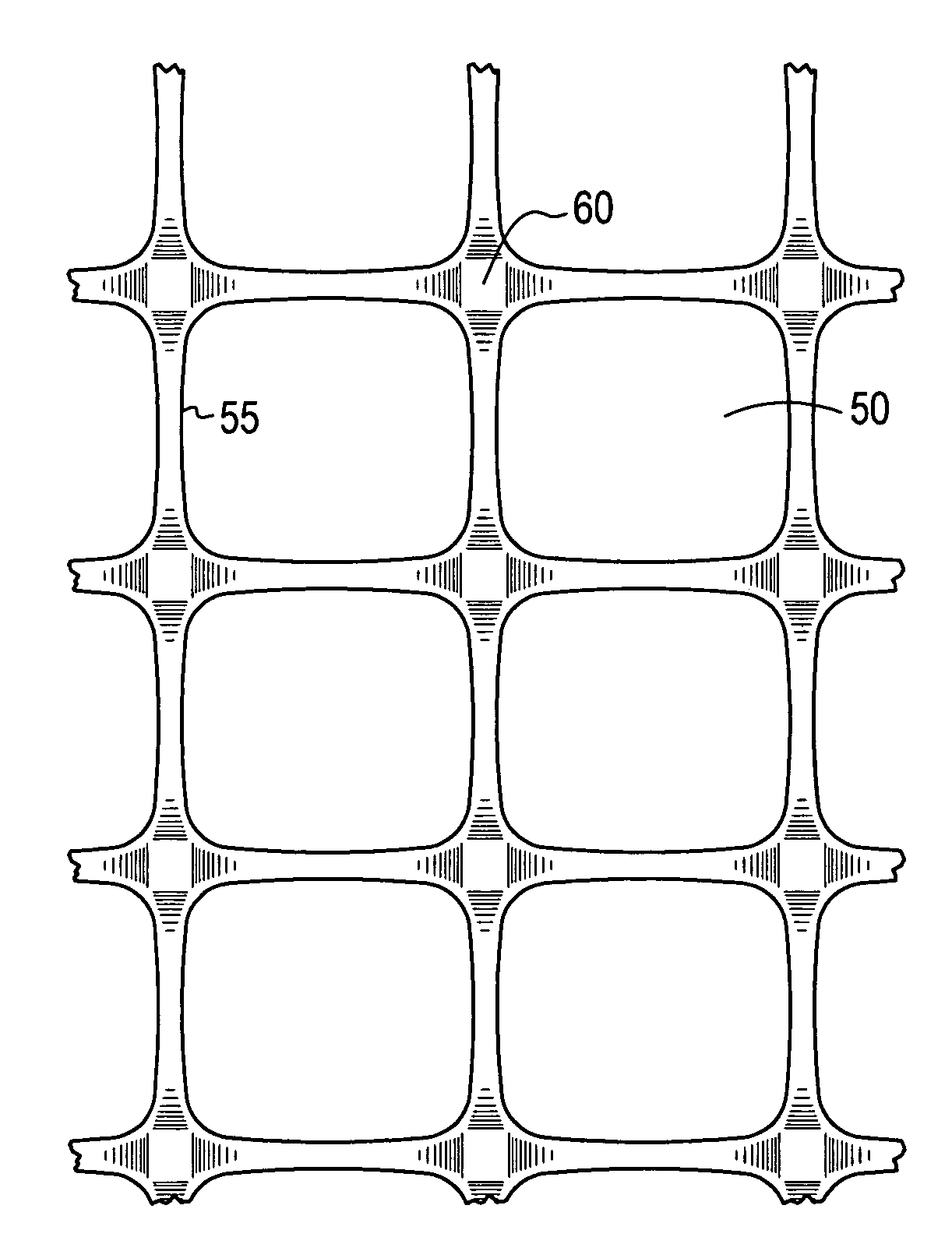

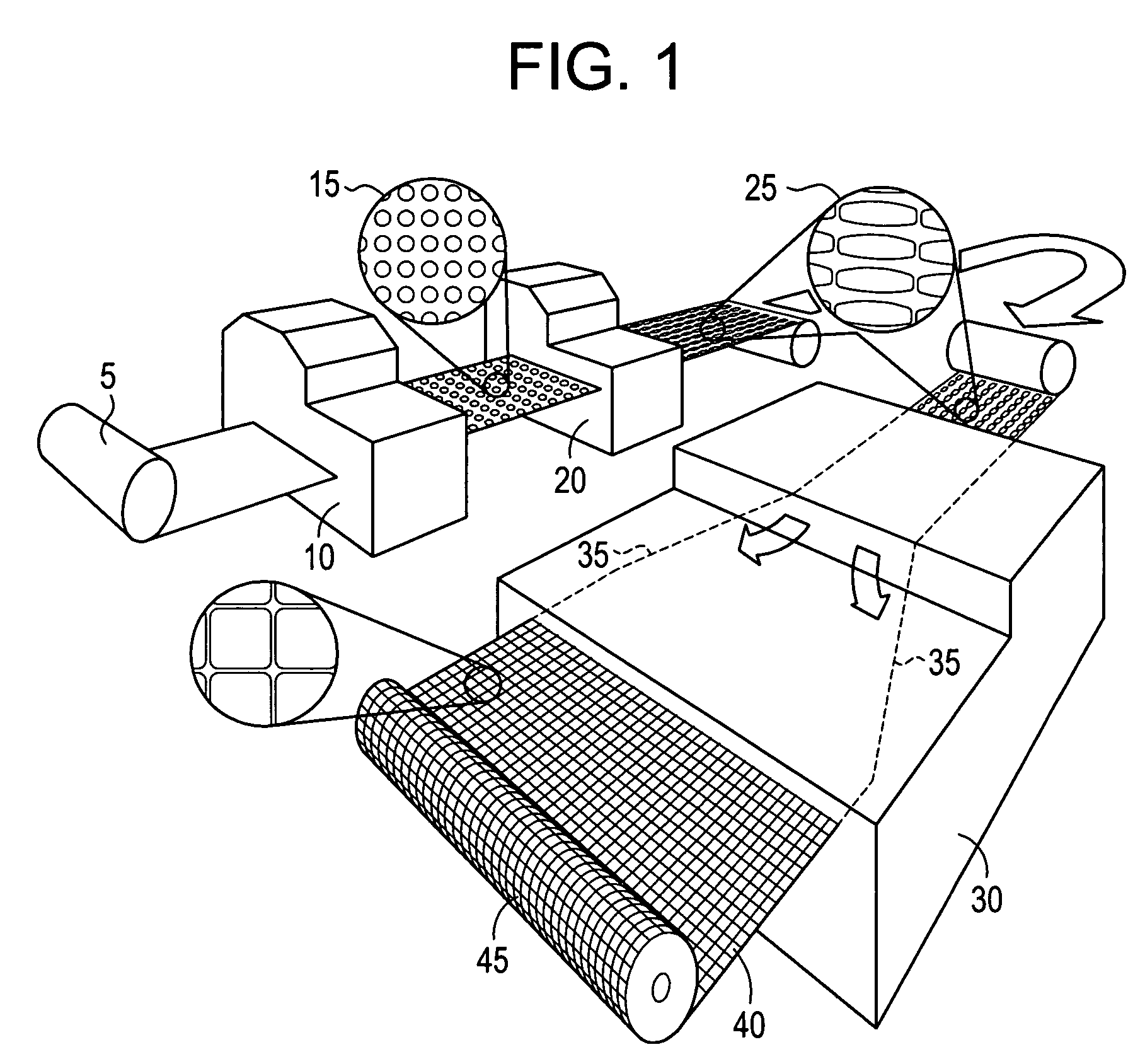

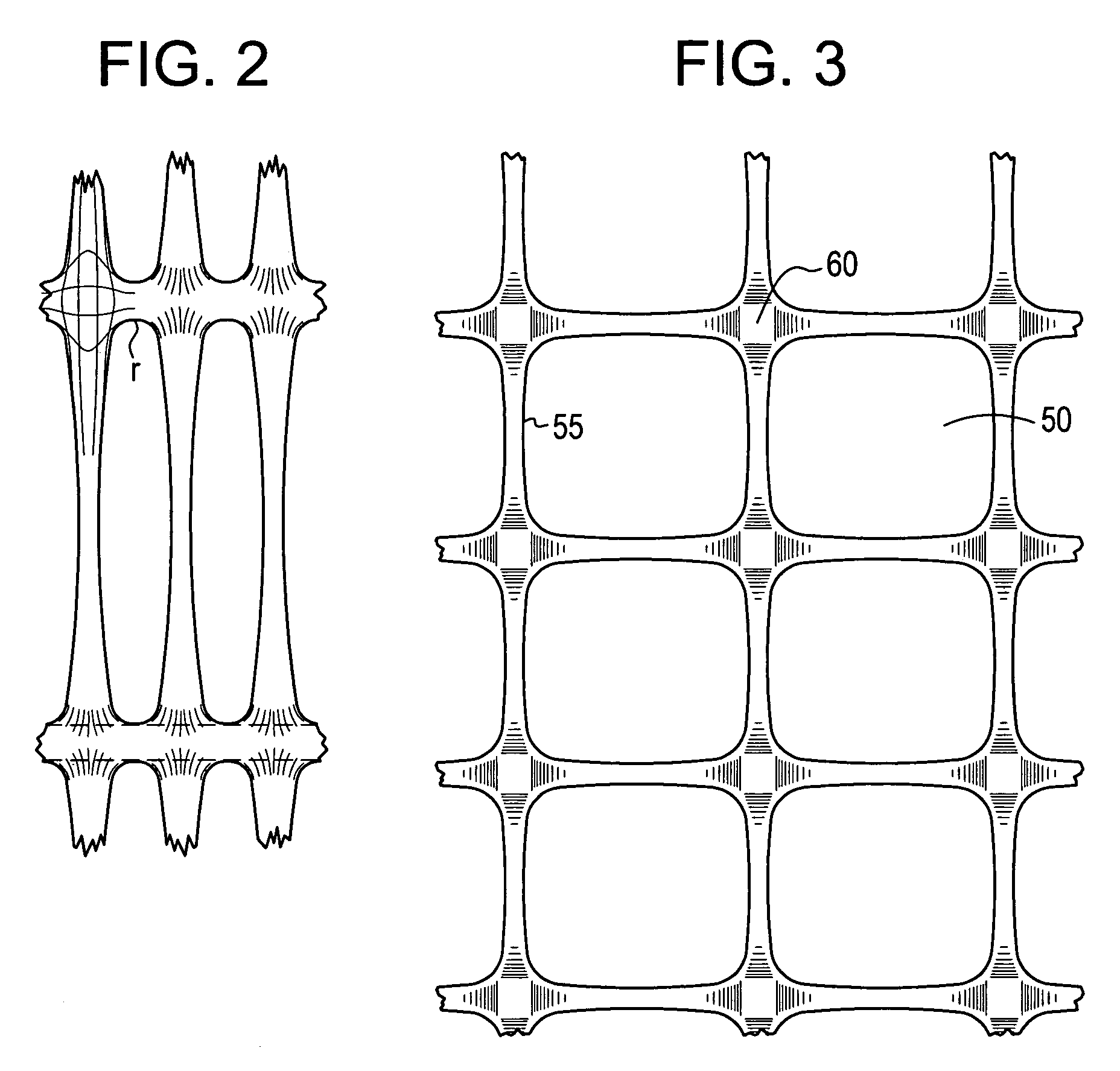

Extruded polypropylene sheets containing beta spherulites

ActiveUS20050003151A1Improve the level ofLow densityLayered productsFlat articlesPolymer sciencePolypropylene mesh

An improved extruded polypropylene sheet that contains a high level of beta crystallinity and a process for making such sheets are disclosed herein. The polypropylene sheet contains at least one layer of a resinous polymer of propylene and an effective amount of beta spherulites. The beta spherulites in the sheet are produced by the incorporation of a beta nucleating agent in the polymer. The presence of the beta spherulites in the sheet facilitates the process of post-stretching the perforated sheet to produce a uniaxially or biaxially oriented mesh structure, and also broadens the temperature range over which this stretching can be performed. The final mesh has a lower density than a polypropylene mesh without beta spherulites. The perforated beta nucleated sheet also exhibits different stretching characteristics during the orientation steps such that more resinous polymer is drawn out of the node junction region between the machine direction and transverse direction oriented strands and a greater percentage of the web area has a solid polymer structure. This altered stretching behavior results in an oriented web that has higher strength and torsional rigidity characteristics. Thus lighter weight mesh structures which meet all of the physical property requirements for end-use applications, such as reinforcing grids to stabilize concrete and soil in civil engineering and landfill applications, are produced. The lighter weight extruded beta nucleated sheet can also be stretched at higher line speeds, thereby reducing the manufacturing costs.

Owner:MAYZO

Extruded polypropylene sheets containing beta spherulites

InactiveUS20090258212A1Synthetic resin layered productsCeramic shaping apparatusManufacturing cost reductionVolumetric Mass Density

Improved extruded polypropylene sheets containing a high level of beta crystallinity and a process for making such sheets are disclosed herein. The polypropylene sheets comprise a resinous polymer of propylene and an effective amount of beta spherulites. Uniaxially or biaxially oriented mesh structures produced from the disclosed sheets exhibit lower density, higher strength, and higher torsional rigidity than polypropylene meshes without beta spherulites. Thus, lighter weight mesh structures which meet all of the physical property requirements for end-use applications, such as reinforcing grids to stabilize concrete and soil in civil engineering and landfill applications, are produced. The lighter weight extruded beta-nucleated sheet can also be stretched at higher line speeds, thereby reducing manufacturing costs. This abstract is intended as a scanning tool for purposes of searching in the particular art and is not intended to be limiting of the present invention.

Owner:MAYZO

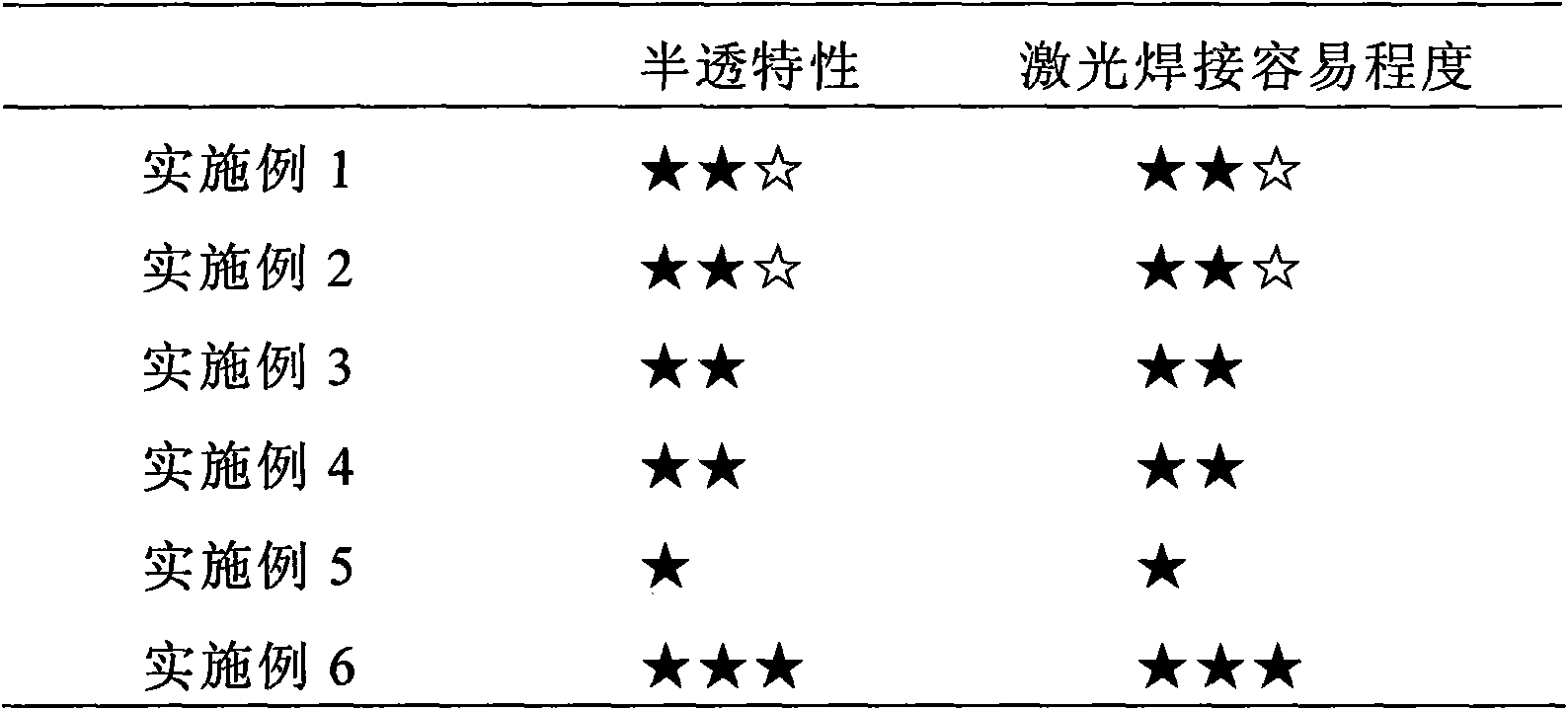

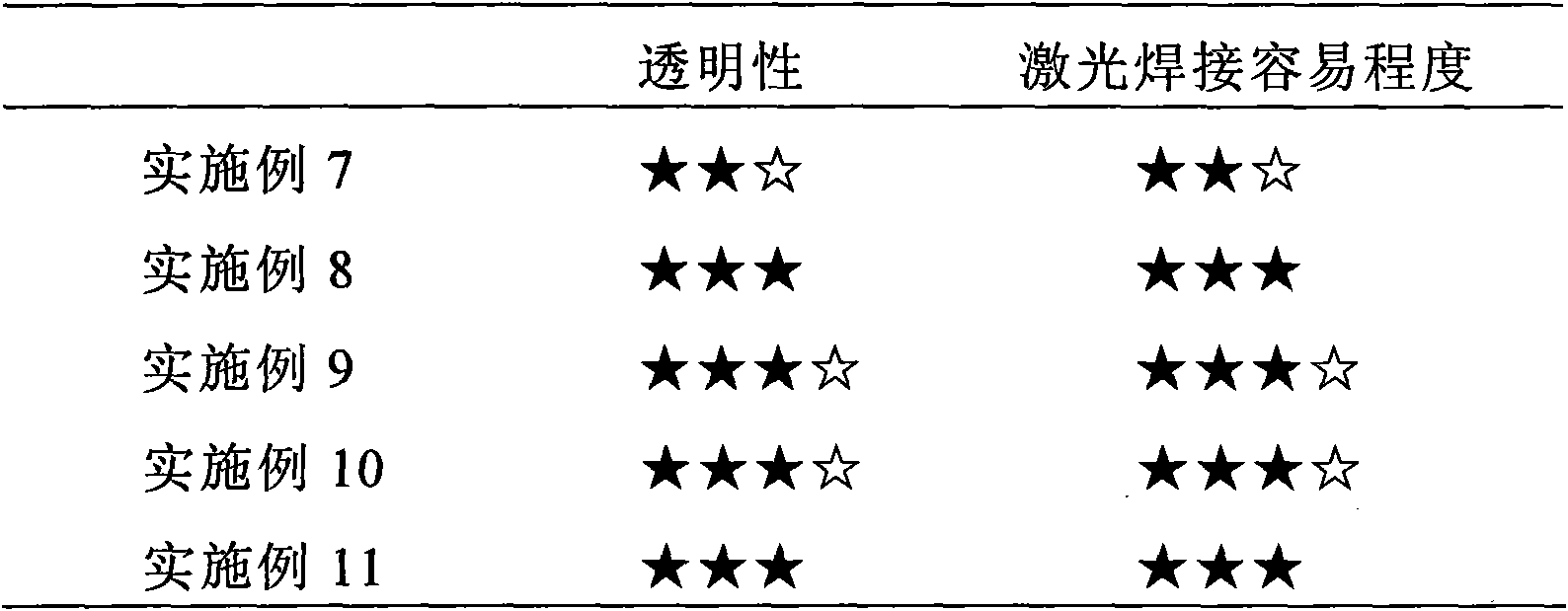

Microcrystal PBT (Polybutylece Terephthalate) resin and preparation method thereof

The invention relates to a microcrystal PBT (Polybutylece Terephthalate) resin and a preparation method thereof. The microcrystal PBT resin comprises the following components in parts by weight: 100 parts of PBT resin, 0.1-2.0 parts of nucleating agent, 0.1-2.0 parts of lubricant, 0.1-1.0 part of antioxidant and 0.1-2.0 parts of processing aid. The preparation method comprises the following steps of: drying PBT, stirring and mixing the PBT and the raw materials in a high-speed mixer, and then feeding into a twin-screw extruder; dispersing, and then conveying and cutting by a screw rod; and carrying out extruding and grain-sized dicing to obtain a product. The defects of large spherocrystal volume, poor transparency of the product, poor laser welding and the like of the PBT under the current production condition are overcome, the microcrystal PBT resin with a semi-transparent effect is prepared by using a transparent nucleating agent adding and alloying method, the characteristics of favorable chemical character, gas barrier property, high heat resistance and the like of the PBT resin are remained, and the microcrystal PBT resin has huge market potential in the fields such as automobiles, home appliances, consumer electronics and electrics, food processing and the like.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

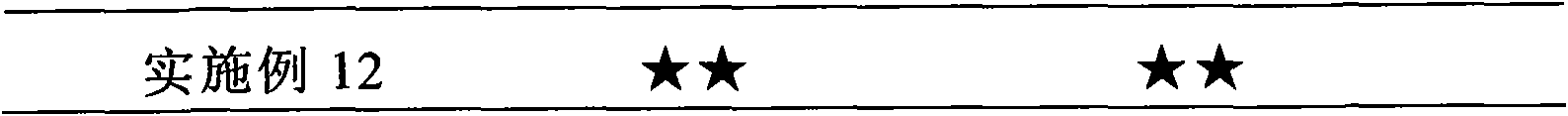

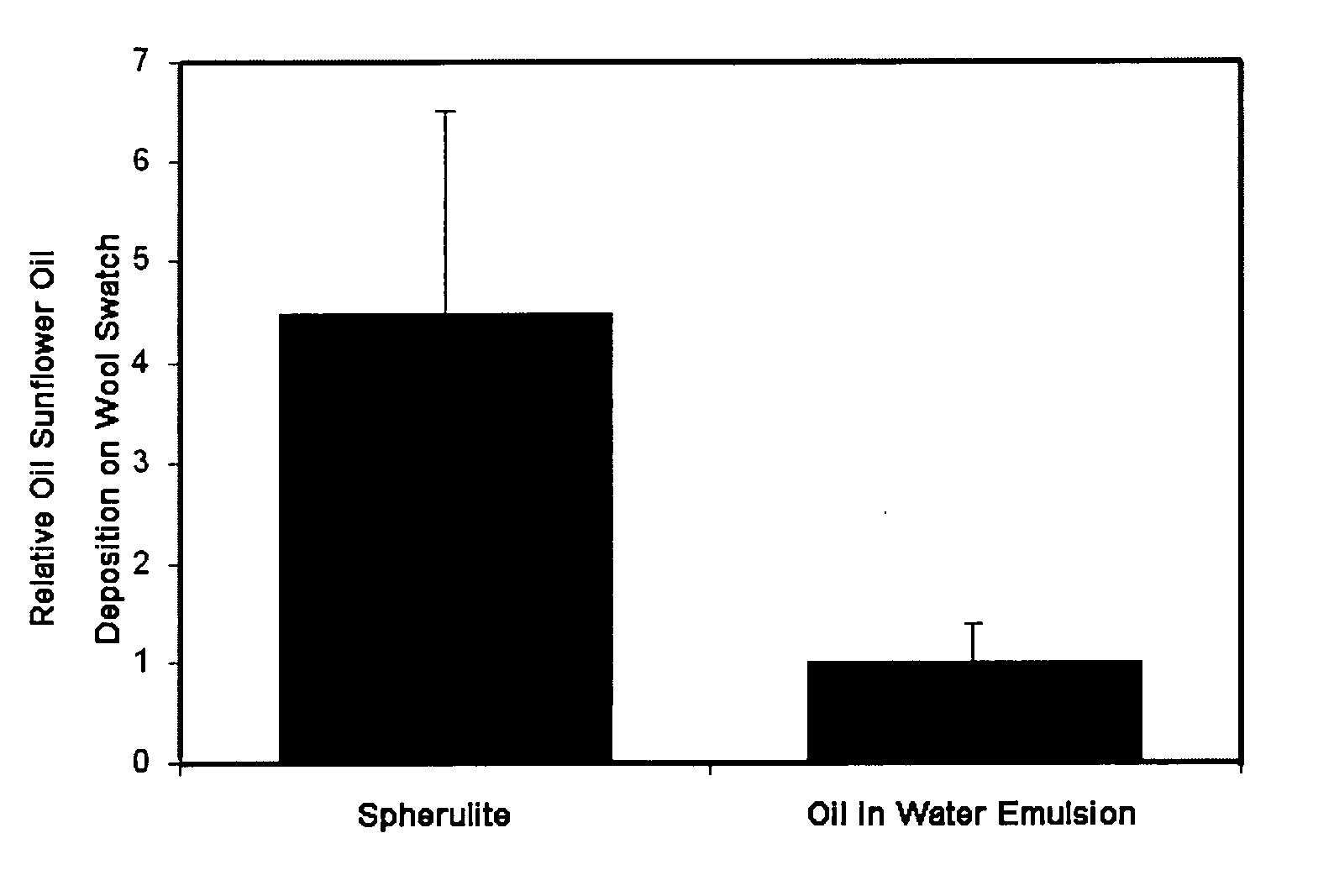

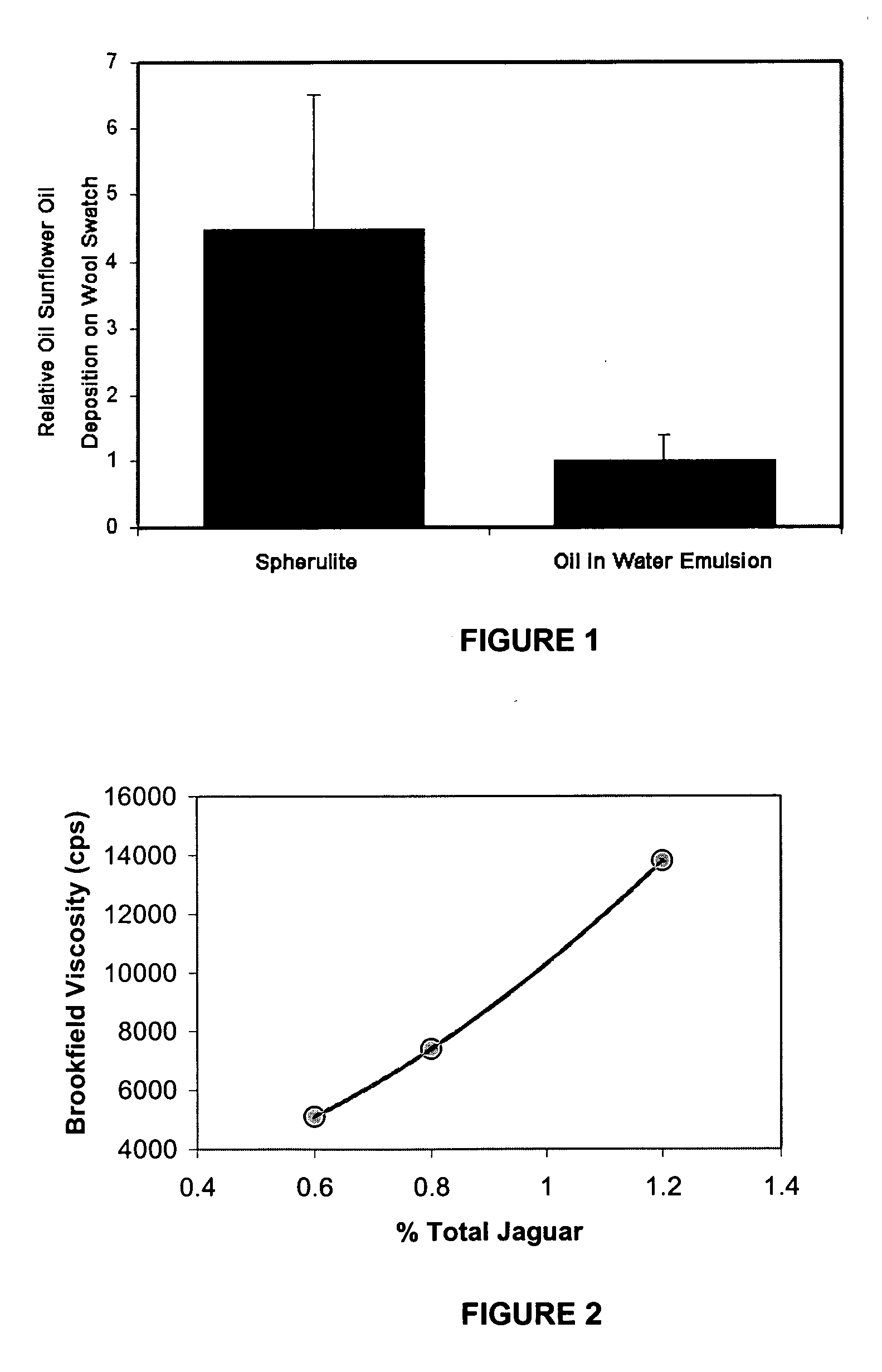

Enhanced oil delivery from structured surfactant formulations

Novel spherulite-containing compositions are described. Methods for making spherulite-containing compositions are also described. Preferred embodiments include compositions comprising a surfactant component, a salt, and an oil phase, wherein the surfactant component comprises (a) about 6 to about 10 weight % sodium trideceth sulfate; (b) about 1.8 to about 3.0 weight % of a structuring agent; (c) about 1.1 to about 3.0 weight % of a foam booster; (d) water; and (e) about 0.2 to about 0.8 weight % of a cationic guar gum.

Owner:COLGATE PALMOLIVE CO

High-temperature-resistant polylactic acid injection molded ceramic-like tableware and preparation method thereof

The invention relates to high-temperature-resistant polylactic acid injection molded ceramic-like tableware and a preparation method thereof, and belongs to the field of high polymer materials. Raw materials comprise 70-90 parts of polylactic acid, 5-15 parts of a toughening agent, 0.05-0.20 part of a chain extender, 0.5-1 part of an organic nucleating agent, 5-20 parts of an inorganic nucleatingagent, 0.05-1.0 part of an antioxidant and 0.5-2 parts of an anti-hydrolysis agent. The high-temperature-resistant polylactic acid injection molded ceramic-like tableware and the method have the advantages that the process is simple and clear, high in processing efficiency and easy to operate; the toughening agent and the nucleating agent are used for synergistically modifying the polylactic acidso that the toughness of the polylactic acid is improved, the heat resistance of the polylactic acid material is achieved, and the toughness and heat resistance of the polylactic acid can be greatly improved. The organic nucleating agent and the inorganic nucleating agent are adopted, so that when the polymer is subjected to melt crystallization, the crystallization speed of the polymer is increased, the spherocrystal size is changed, the thermal deformation temperature of the polymer is remarkably increased, the application of the product is met, in-mold crystallization is used in the injection molding process of the product, the surface gloss of the product is improved, crystallization perfection can be further promoted by using the crystallization nucleating agent, and the product has higher strength and surface gloss.

Owner:JILIN COFCO BIOCHEM +1

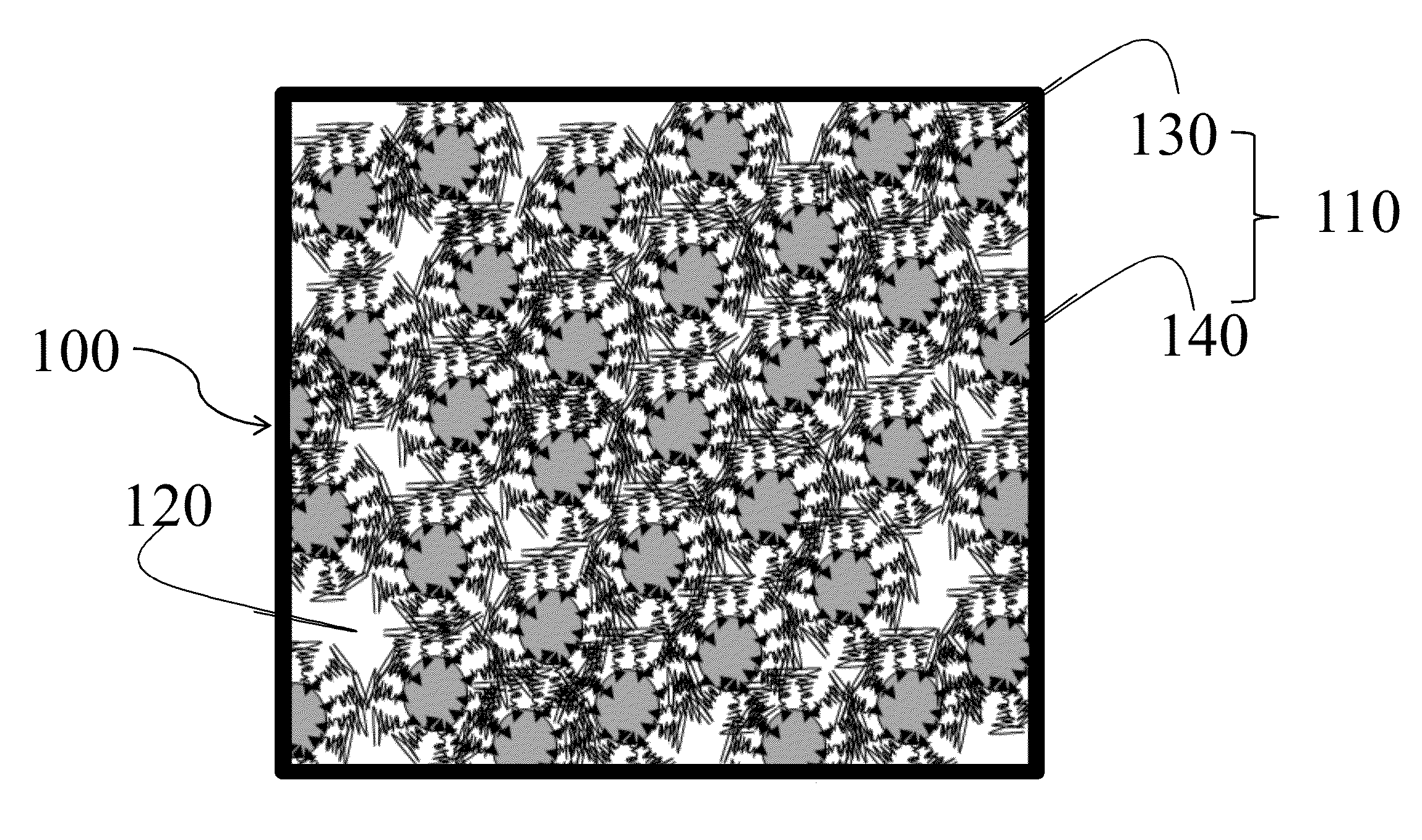

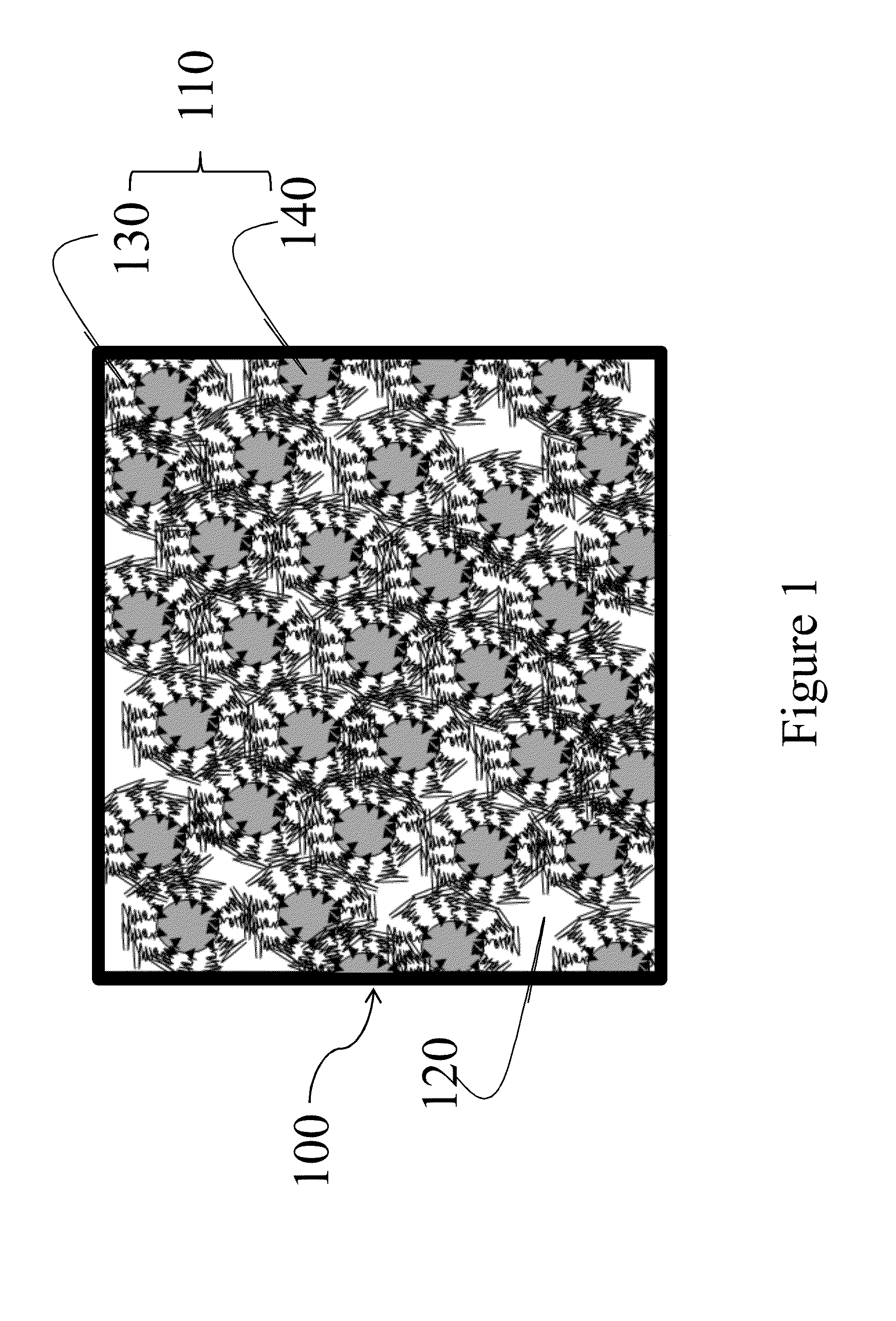

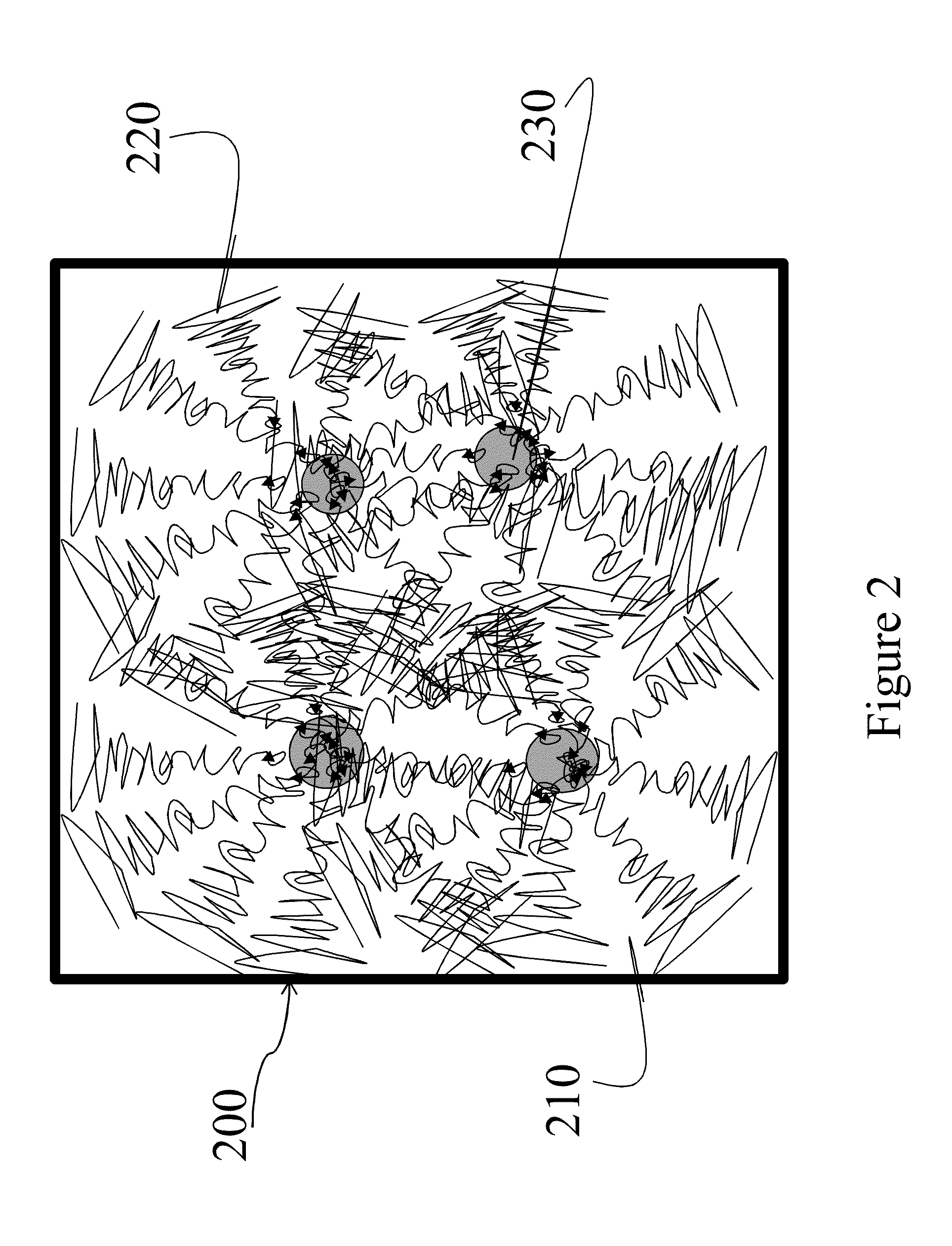

Self-healing composites

Lightweight self-healing composites comprise region-specific microstructures that dampen ballistic energy wherein the region-specific microstructures include at least one semi-crystalline thermoplastic and at least one nanoparticle nucleating agent. The distinctive region-specific microstructures allow the composites to dissipate high frequency and high amplitude shock wave into heat and reassemble itself into its original microstructure through reversible compression and decompression cycles. The region-specific microstructures comprise soft regions, comprised of highly polymeric entangled chains and hard regions, comprised of lamellae or spherullites anchored onto nanoparticle nucleating agents. The soft regions can trap the incoming energy shock wave while the hard regions provide the anchor sites, to allow the entangled chains to remain in place upon encountering ballistic impact. The anti-ballistic composites can be made in a monolithic form and do not significantly degrade under repeated fire.

Owner:TSAI FU JYA DANIEL +1

Natural Fiber-Reinforced Polylactic Acid Resin Composition and Molded Product Made Using the Same

InactiveUS20100125112A1Improve heat resistanceImprove hydrolysis resistanceOrganic dyesShell moldingCrystallization temperature

Owner:CHEIL IND INC

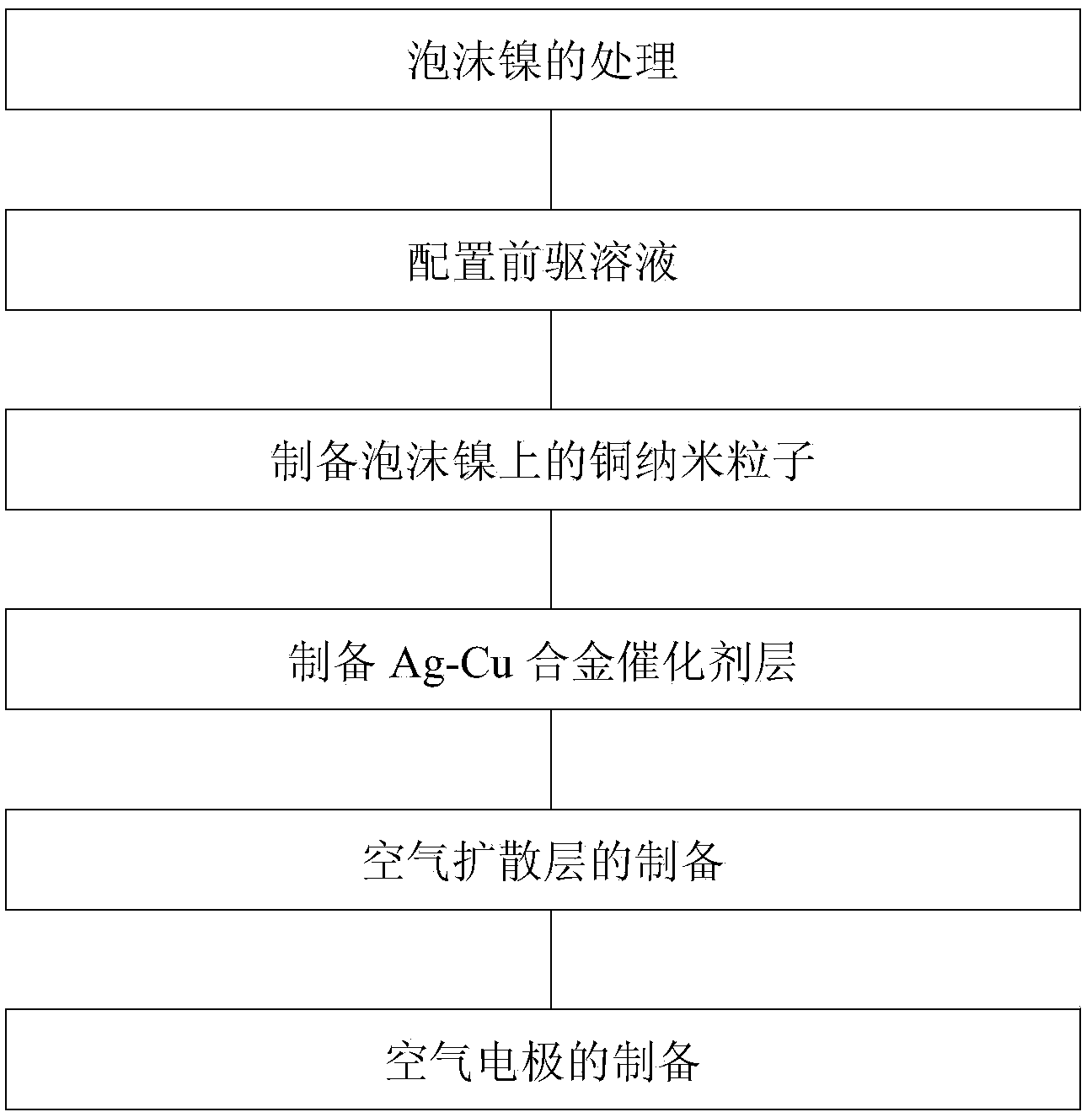

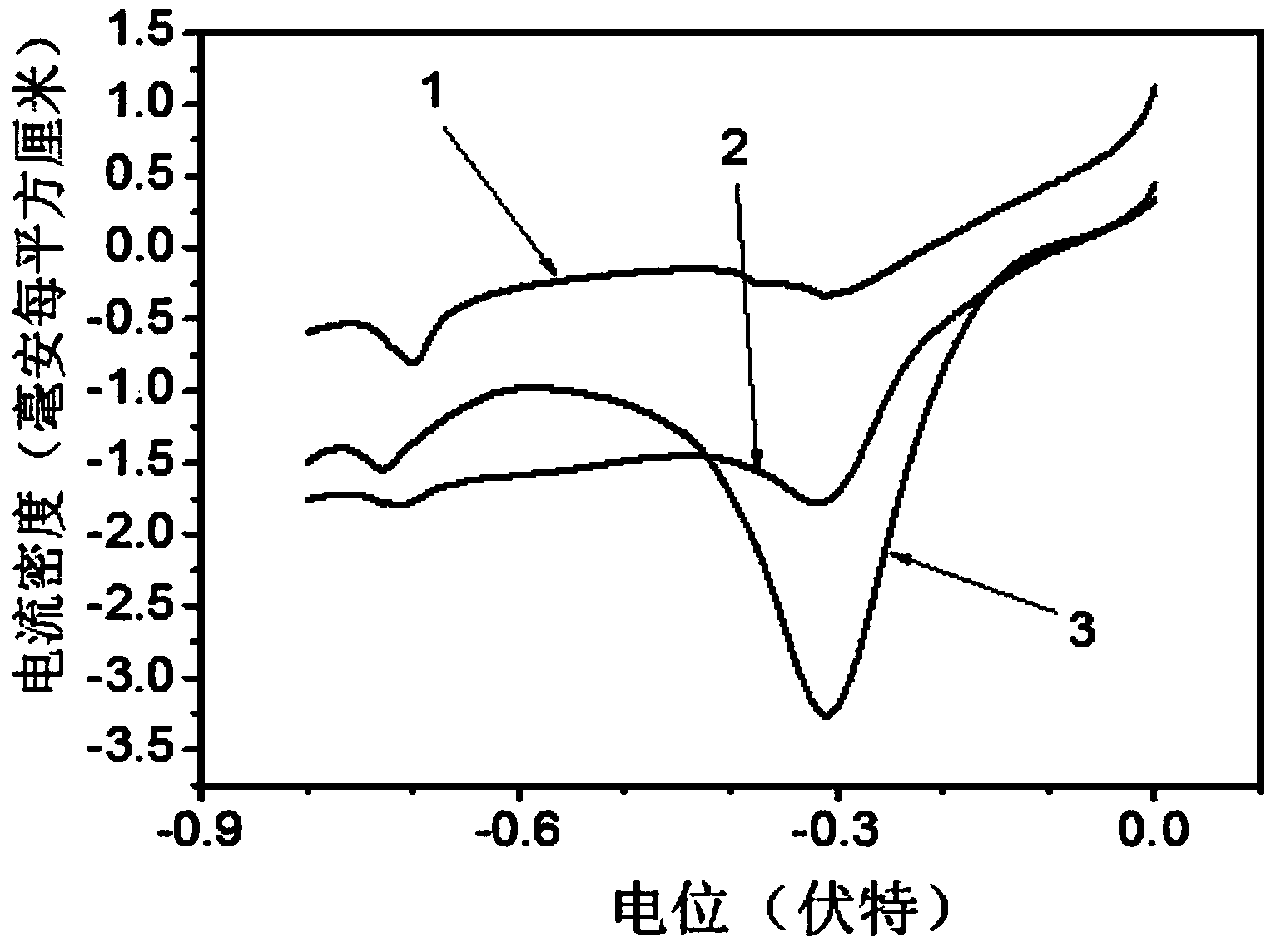

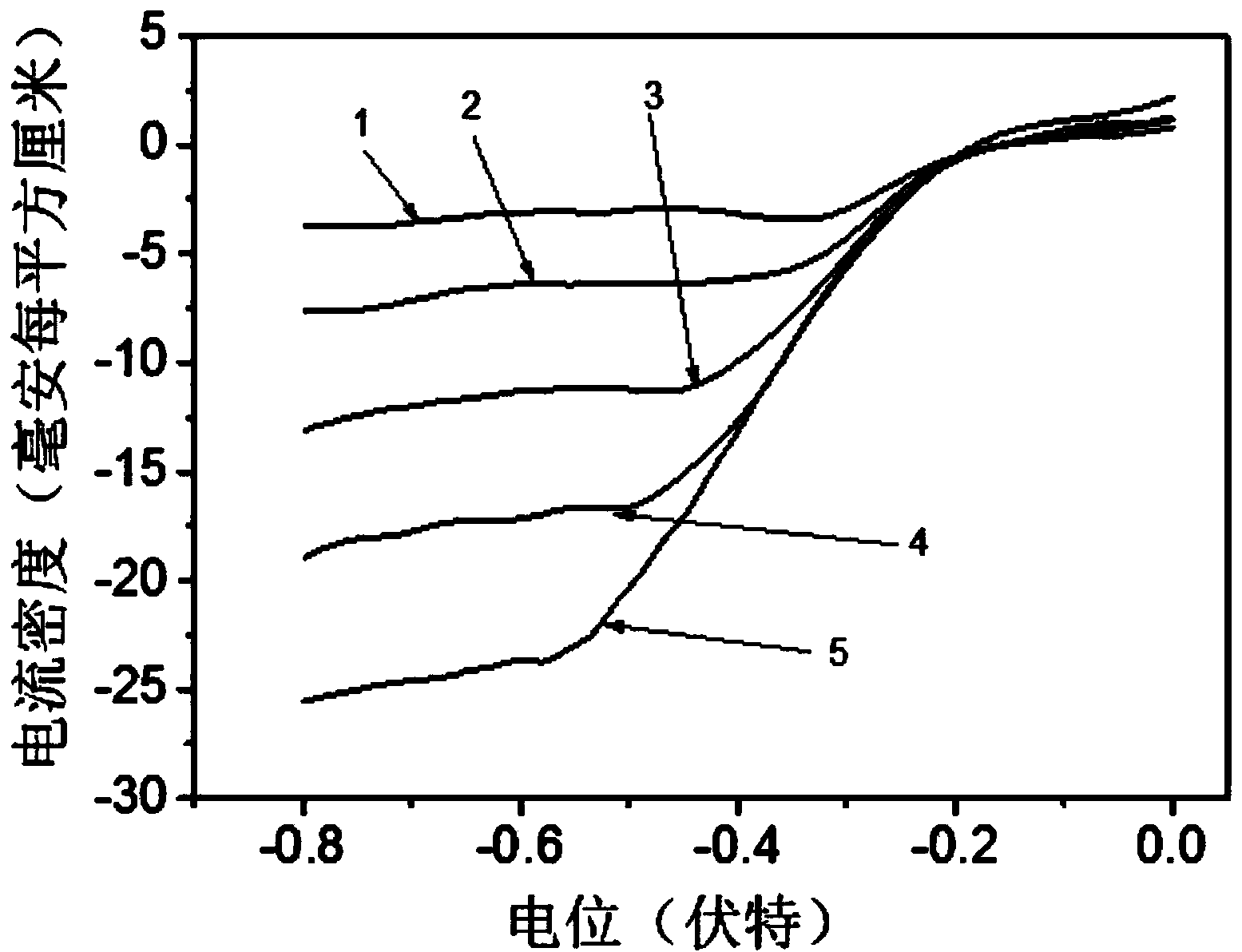

Carbon-free Ag-Cu catalyst layer-based air electrode and its making method

ActiveCN104393307AImprove electrocatalytic activityEnhanced electrocatalytic reduction propertiesCell electrodesCarbon corrosionCopper oxide

The invention relates to a carbon-free Ag-Cu catalyst layer-based air electrode and its making method. The carbon-free Ag-Cu catalyst layer-based air electrode is obtained by depositing Ag-Cu alloy on foamed nickel; the microstructure of the Ag-Cu alloy is dendrite or spherocrystal or lamella crystal; and a Ag, Cu and Cu2O phase exists in the Ag-Cu alloy and is composed of Ag in zero valence state and Cu, and a copper oxide layer is arranged on the surface of the Ag-Cu alloy. The discharge power of the primary zinc air battery of the Ag-Cu catalyst air electrode under 100mA / cm<2> is 79.9-85.8mW.cm<-2>, and the charge and discharge reciprocating efficiency of the secondary zinc air battery of the Ag-Cu catalyst air electrode is greater than 51.8%. The catalyst layer has a very good oxygen reduction electrocatalysis property and overcomes the disadvantages of carbon corrosion and low electrocatalytic activity in the prior art.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

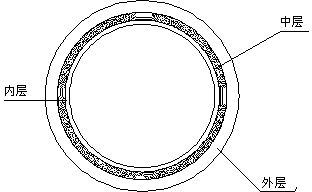

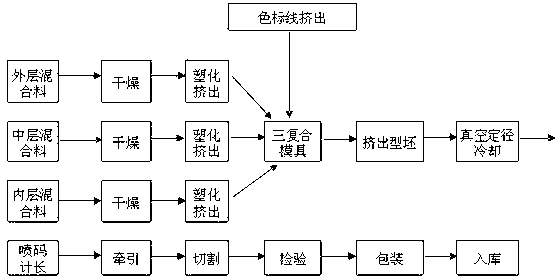

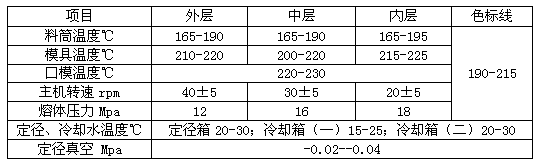

Method for preparing anti-microbial, anti-oxygen, anti-ultraviolet and light-resisting composite pipe

ActiveCN103225716AImprove mechanical propertiesImprove aging resistanceRigid pipesInternal pressureHeat deflection temperature

The invention discloses a method for preparing an anti-microbial, anti-oxygen, anti-ultraviolet and light-resisting composite pipe, relates to a technology for preparing the anti-microbial, anti-oxygen, anti-ultraviolet and light-resisting composite pipe, and belongs to the technical field of novel material and process. The method is characterized in that the anti-microbial, anti-oxygen, anti-ultraviolet and light-resisting composite pipe is formed by co-extrusion of three layers, wherein the thickness ratio of an inner layer to a middle layer and the thickness ratio of the middle layer to an outer layer are 0.618. The method has the beneficial effects that the anti-microbial performance of the pipe is improved; the anti-oxygen capacity and anti-ultraviolet capacity of the pipe are improved; by changing the crystallinity of a material and the size of a spherical crystal, the heat distortion temperature of the pipe is improved, and the coefficient of linear expansion is reduced; the impact strength, particularly low-temperature impact strength, of the pipe is improved; and the internal pressure resistance strength and hardness of the pipe are improved.

Owner:甘肃顾地塑胶有限公司 +1

Extruded polypropylene sheets containing beta spherulites

ActiveUS7407699B2Improve the level ofLow densityLayered productsDomestic articlesManufacturing cost reductionEngineering

Improved extruded polypropylene sheets containing a high level of beta crystallinity and A process for making such sheets are disclosed herein. The polypropylene sheets comprise a resinous polymer of propylene and an effective amount of beta spherulites. Uniaxially or biaxially oriented mesh structures produced from the disclosed sheets exhibit lower density, higher strength, and higher torsional rigidity than polypropylene meshes without beta spherulites. Thus, lighter weight mesh structures which meet all of the physical property requirements for end-use applications, such as reinforcing grids to stabilize concrete and soil in civil engineering and landfill applications, are produced. The lighter weight extruded beta-nucleated sheet can also be stretched at higher line speeds, thereby reducing manufacturing costs.

Owner:MAYZO

Method for realizing fine crystal solidification by controlling spherical crystal stabilization

The invention discloses a method for realizing fine crystal solidification by controlling spherical crystal stabilization. A method of combining oxide crucible, glass purifying, circulating and overheating, medium-frequency electromagnetic induction is adopted under vacuum environment, so that melt which is circulated and overheated by multiple times is slowly cooled to the liquid-phase line temperature. Temperature-equalizing and stirring are carried out by utilizing electromagnetic fields, so that temperature and solute of the whole melt are almost uniformly distributed, wherein the whole melt is enabled to be uniformly cooled integrally during the cooling process. According to the method disclosed by the invention, high-temperature alloy fine-grained structure, which is free of a tricrystal region of the conventional solidified ingot, small in microporosity, provided with fine equiaxed grains with grain size level of about ASTM (American Society for Testing Material) 5 level, small in microsegregation and high in density, can be obtained by the method disclosed by the invention. The grain size of the obtained fully equiaxed ingot is close to that of the spherical crystal and is very beneficial to the subsequent deformation, therefore, the billeting success rate of the high-temperature alloy is effectively improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

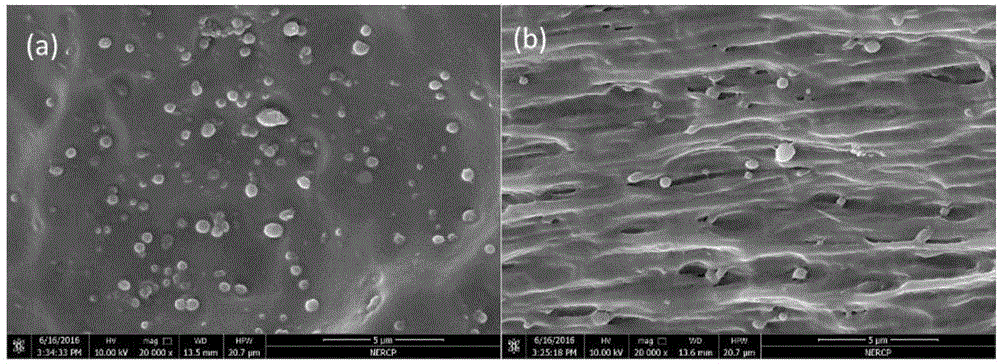

High-barrier antistatic graphene/polymer nanocomposite sheet/film and preparation method thereof

The invention relates to a high-barrier antistatic graphene / polymer nanocomposite sheet / film. Through an incomplete nanosphere crystal or shish-kebab structure of the high-barrier antistatic graphene / polymer nanocomposite sheet / film, the interfacial gap between spherulites in a large spherulite system is eliminated, amorphous area molecular chain movement is limited, a diffusion rate of gas molecules in the structure is reduced and material barrier properties are improved. The high-barrier antistatic graphene / polymer nanocomposite sheet / film comprises, by mass, 100 parts of polymer base resin, 0.005 to 1 part of graphene and 0 to 1.5 parts of a compatibilizer. Through the compatibilizer and a special flow channel structure of the multi-stage drawing extrusion system, graphene dispersion and orientation distribution are adjusted and controlled. The heterogeneous nucleation and space limitation effects of the graphene sheet induce formation of an orientation molecular chain and restricted nanosphere crystal and shish-kebab structures so that amorphous area density can be significantly increased, the interfacial gap between spherulites is reduced, amorphous area molecular chain movement is limited, a diffusion rate of gas molecules in a polymer matrix is reduced, a gas small molecule passing path is extended and the barrier properties of the nanocomposite sheet / film are improved.

Owner:GUIZHOU MATERIAL IND TECH INSTITUE

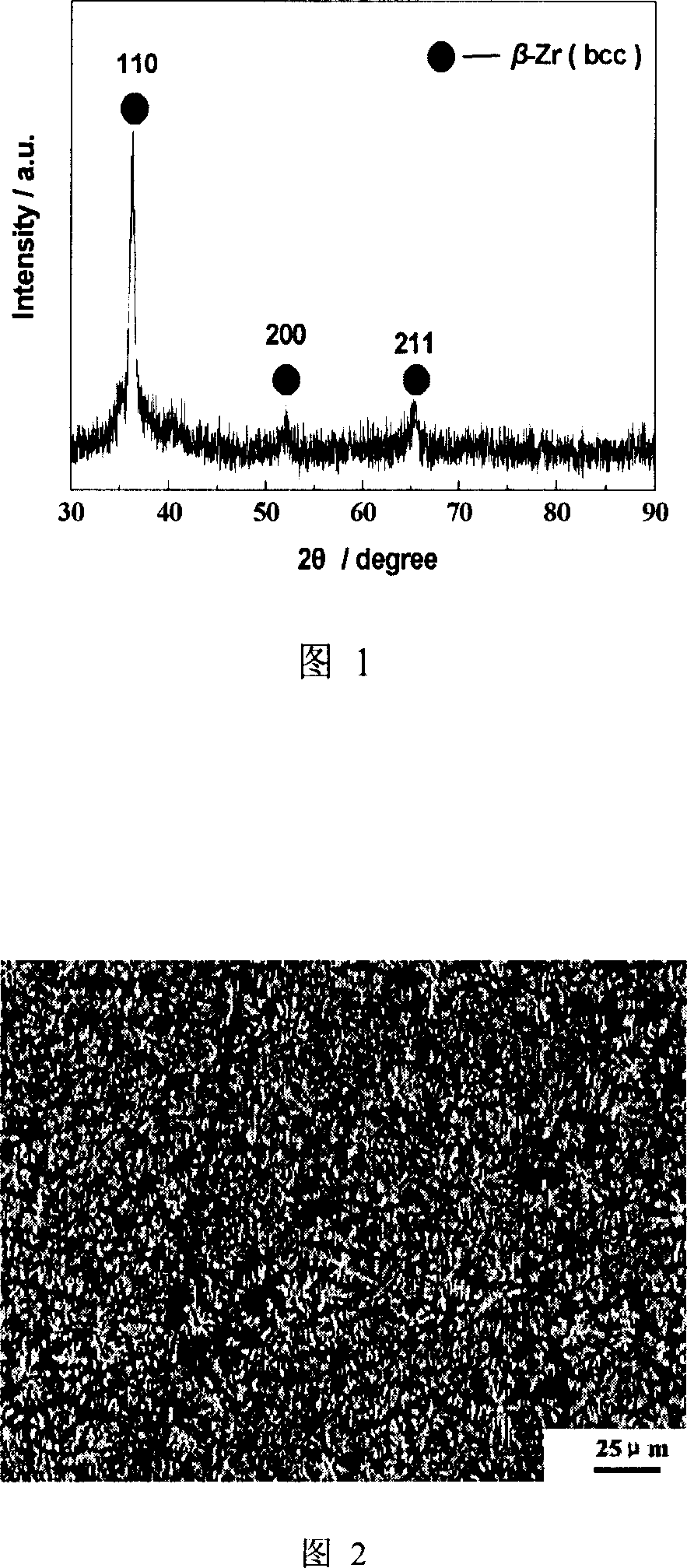

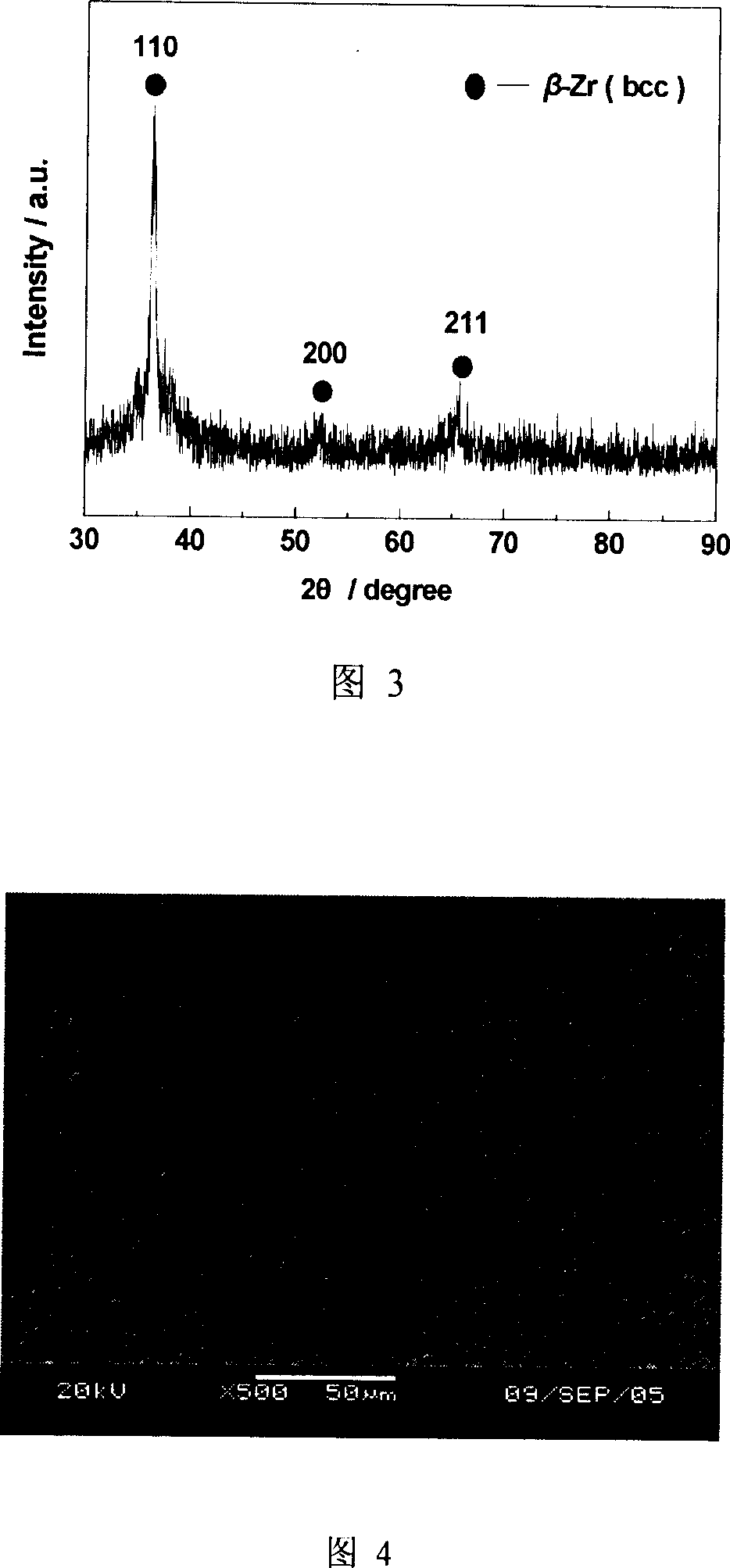

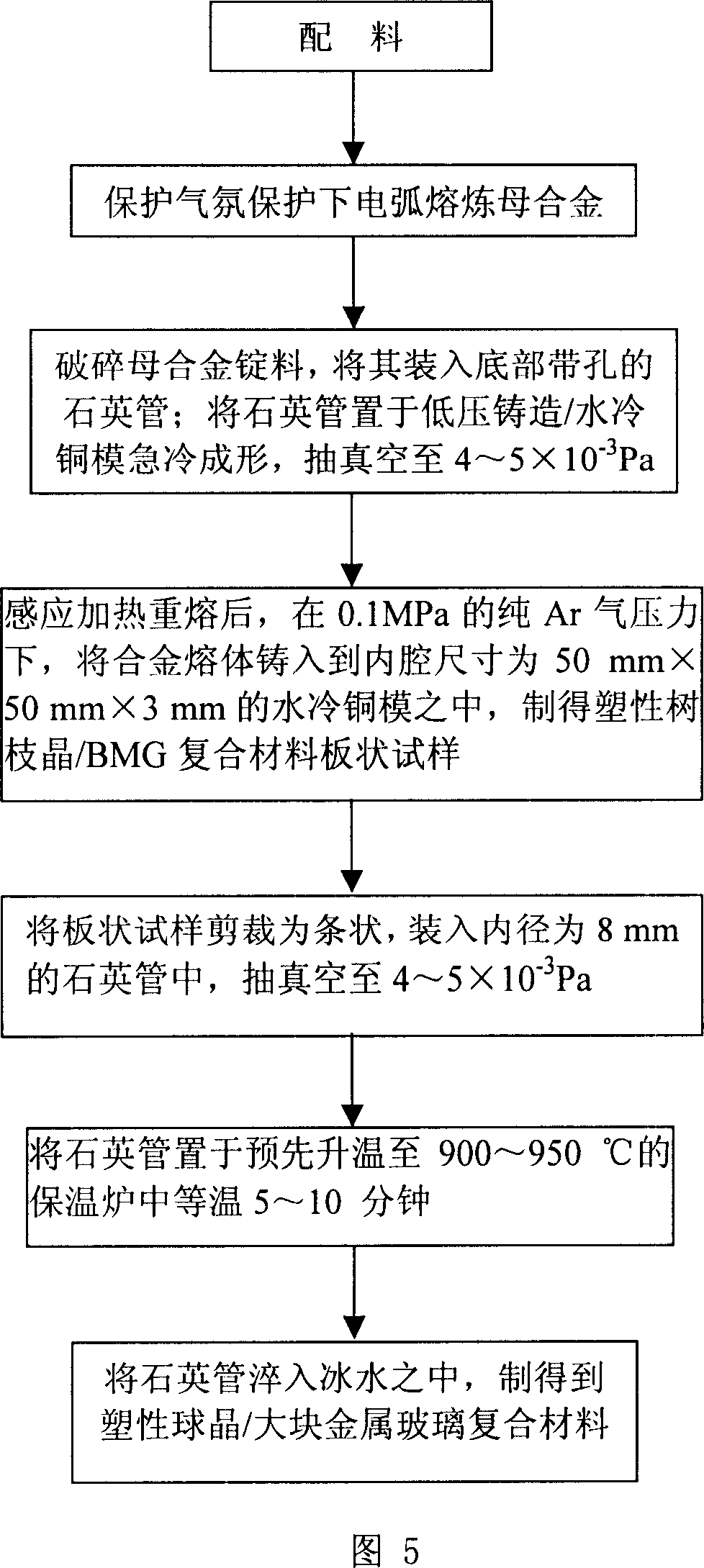

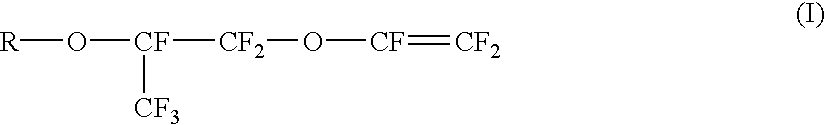

Method for branch crystal balling in large block metal glass composite

This invention relates to the method for producing plastification geode / massive metal glass composite material. The steps are: first, selecting alloy components having strong glass formation ability, regulating the components to make them offset eutectic point, and solid solution phase being separated earlier; second, the components being smelted under shield gas, then producing foundry alloy ingot; then, said ingots being broken, resmelted, subjected to low pressure casting / water-cooling copper mould quick cooling formation to produce branch like crystal / massive metal glass composite material sheet, finally, said sheet being subjected to isothermal treatment and then water-quenching to produce this invented product. The plastificiation beta phase is no longer having branch like shape but having ball shape.

Owner:NANJING UNIV OF SCI & TECH

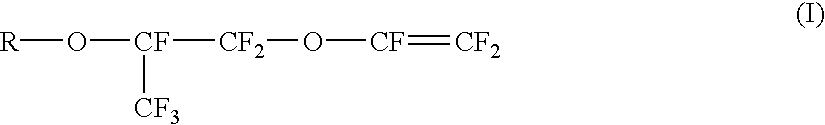

Perfluoro copolymers of tetrafluoroethylene and perflouro alkyl vinyl ethers

In preparing a fluorinated thermoplastic with good flex life, high thermal conductivity and low average spherolite diameter from tetrafluoroethylene and perfluoro n-alkyl vinyl ether, perfluoro 2-propoxyalkyl vinyl ether is additionally incorporated into the fluorinated thermoplastic. A semicrystalline, thermoplastically processable copolymer is prepared, made from units of the tetrafluoroethylene, from 2 to 10% by weight of units of perfluoro n-propyl vinyl ether and from 0.1 to 6% by weight of units of perfluoro 2-propoxypropyl vinyl ether. The novel copolymer preferably contains fewer than 70 unstable end groups per 106 carbon atoms, has thermal conductivity of at least 0.19 W / mK at 23° C. and has a smooth surface with an average spherolite diameter of <5 mum. The novel terpolymer is suitable for extrusion of hose, in particular for heat exchangers, and also for ultrahigh-purity applications.

Owner:3M INNOVATIVE PROPERTIES CO

High-temperature phase change energy storage concrete and preparation method therefor

ActiveCN105110731AGood compatibilityImprove integrityHeat-exchange elementsSuperplasticizerPhysical chemistry

The invention discloses high-temperature phase change energy storage concrete and a preparation method therefor. The high-temperature phase change energy storage concrete comprises the following raw materials in percentage by weight: 10-16% of silicate cement, 8-15% of copper slag micropowder, 33-42% of copper slag particles, 22-35% of phase change spherulites, 0.1-1% of a polycarboxylate superplasticizer and 6-11.9% of water. According to the high-temperature phase change energy storage concrete disclosed by the invention, the phase change spherulites and the concrete are organically combined, so that the concrete is good in integrality and compatibility, and the high-temperature performance of the concrete is improved; by adding the copper slag micropowder and the copper slag particles as an admixture and fine aggregate, the heat conductivity of the concrete is effectively improved, and the work effectiveness is improved. The concrete disclosed by the invention is simple and convenient in preparation method and low in cost.

Owner:UNIV OF JINAN

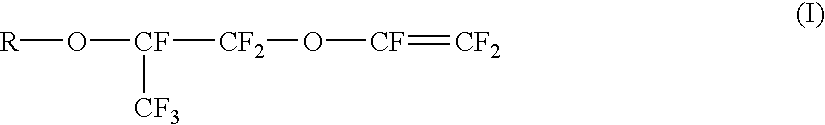

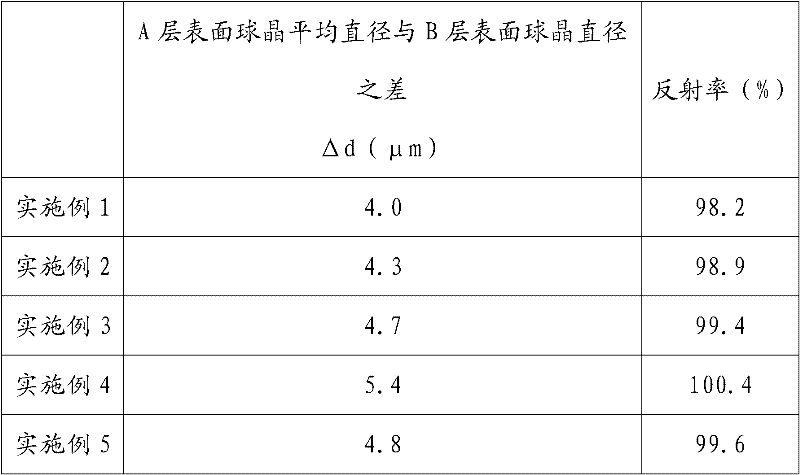

A kind of reflective film with high reflectivity and its manufacturing method

ActiveCN102267268AIncrease the refraction interfaceHigh refractive indexSynthetic resin layered productsPolyesterRefractive index

The invention discloses a high-reflectivity reflecting film and a manufacturing method thereof. The high-reflectivity reflecting film comprises a polyester B layer internally containing pore space, at least one polyester A layer is arranged on the working surface of the polyester B layer, the reflectivity of the reflecting film at 560mm wavelength position is not less than 98 percent, and the average diameter difference of the surface sphaerocrystal of the polyester A layer and the sphaerocrystal of the polyester B layer is no less than 4.0mum. In the invention, during the machining process, the polyester A layer is respectively induced to fast generate thick sphaerocrystal for two times sequentially, and the polyester B layer adopts polyester as main materials and is added with core forming agent to form fine sphaerocrystal, so that the average diameter difference of the surface sphaerocrystal of the polyester A layer and the sphaerocrystal of the polyester B layer is no less than 4.0mum, thus increasing the interlayer interface difference and reflectivity difference, enlarging light reflecting interface, improving the reflectivity of the reflecting film, and being beneficial to scattered reflection forming of the thick sphaerocrystal on the surface of the polyester A layer.

Owner:WUHAN KINGBULL ECONOMIC DEV

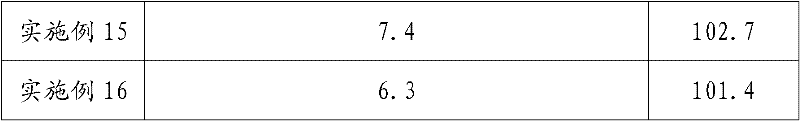

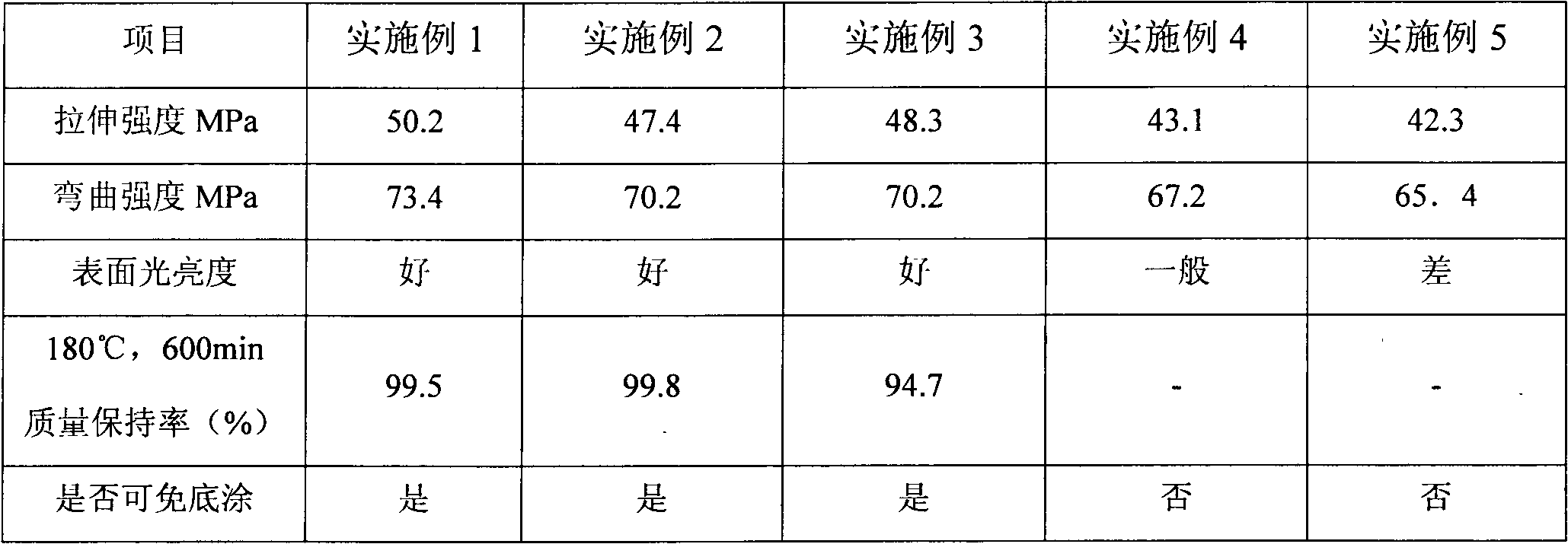

PBT material with high flow, fine finish and no basecoat and preparation method thereof

ActiveCN102660109AInhibit and prevent decomposition and deteriorationGuaranteed service lifeSurface finishAntioxidant

The invention belongs to the field of macromolecule composites and relates to a PBT material with high flow, fine finish and non-basecoat and the preparation method thereof. The PBT material of the invention comprises the following constituents: 88 to 98 parts of PBT; 1 to 5 parts of nucleation a agent; 0.5 to 4 parts of a lubricant; 0.1 to 3 parts of a antioxidant; 0.05 to 0.1 parts of a meso-material. The preparation method comprises the steps of, putting all raw materials into a twin-screw machine after 10 to 15 min of mixing in a high speed mixer; performing melt extrusion and granulation. The twin-screw machine is divided into 10 zones from a feeding inlet to a head. The PBT material of the invention has a detailed uniform micro spherulite structure and a good surface finish. An injection molding blank obtained by the PBT material can be directly aluminized in vacuum and can solve the problem of severe micromolecule migration to the aluminum layer of non-basecoat PBT material when used in high temperature. The material has strong mold reproduction capability and the obtained products are more delightful.

Owner:上海聚威新材料股份有限公司

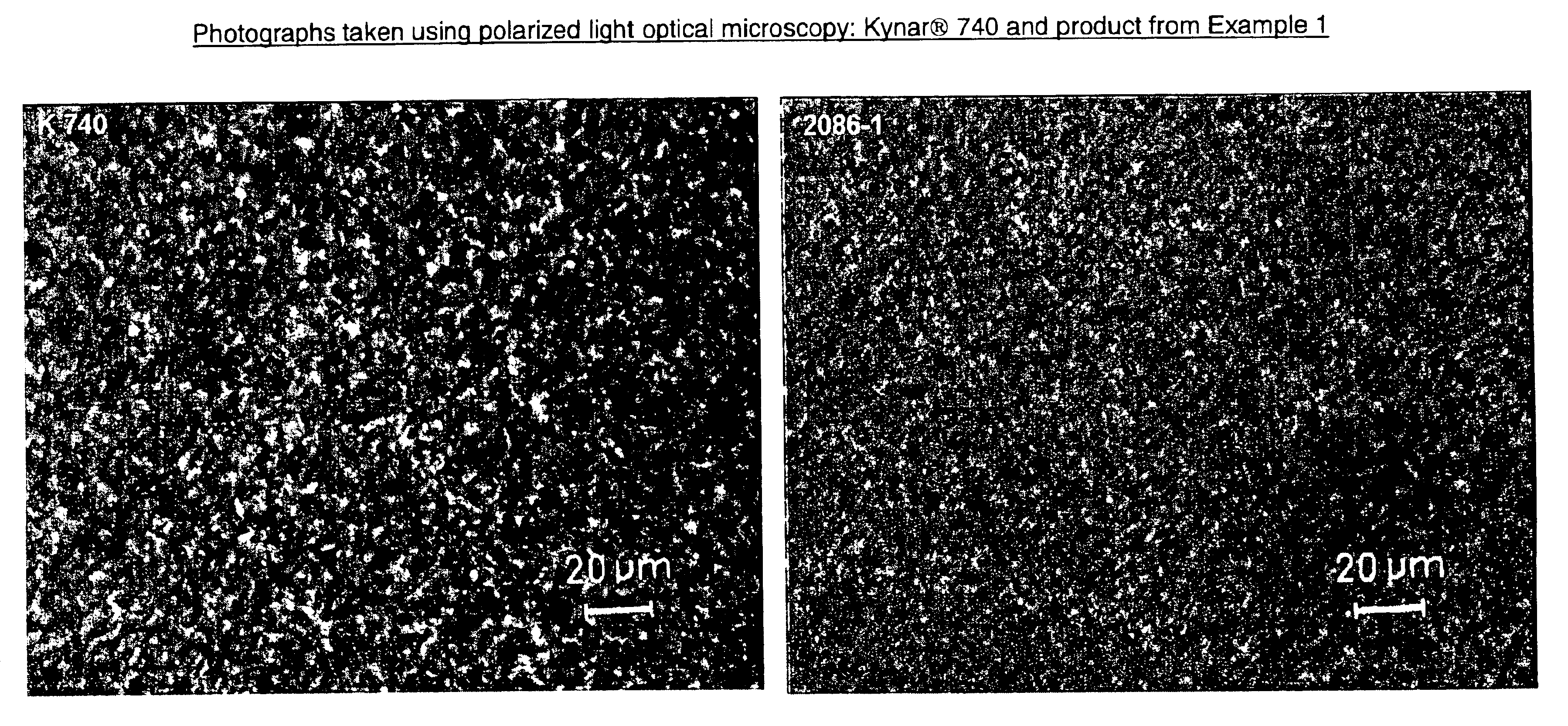

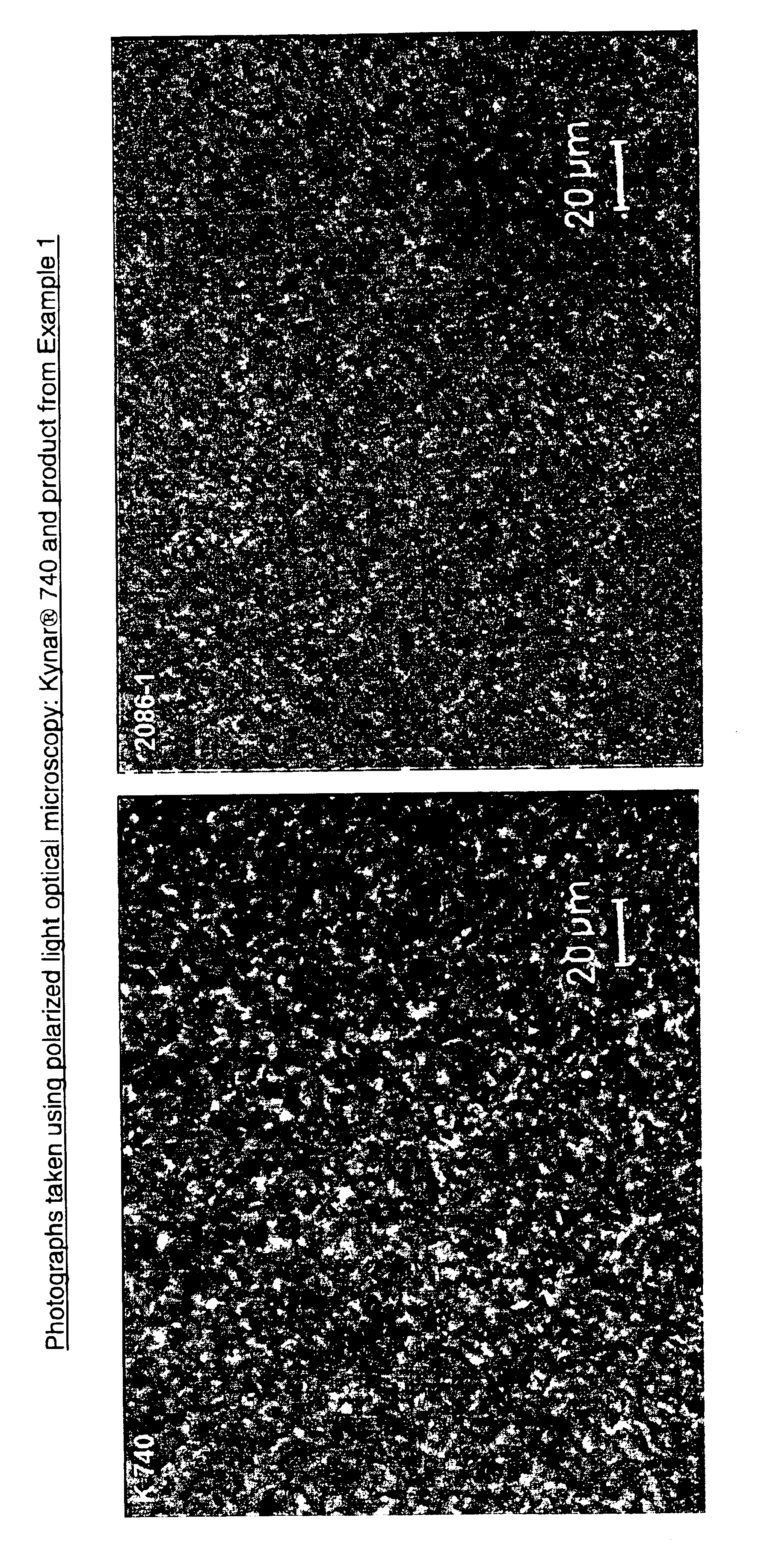

Vinylidene fluoride polymer having a fraction of non-transferred chains and its manufacturing process

The invention is a PVDF (polyvinylidene fluoride) homopolymer or copolymer, the comonomer being chosen from compounds containing a vinyl group capable of being opened by the action of free radicals in order to be polymerized and which contains, directly attached to this vinyl group, at least one fluorine atom, a fluoroalkyl group or a fluoroalkoxy group such that: it comprises a fraction of non-transferred chains of very high molar mass which are completely insoluble in the usual solvents for PVDF, such as DMF (dimethylformamide), DMSO (dimethyl sulphoxide) and NMP (N-methylpyrrolidone), the polymer fraction associated with these high-mass chains having a dynamic viscosity of greater than 50 kpoise at 230° C. and at a shear rate of 100 s<-1>, the size of the spherulites is between 0.5 and 4 mum. The invention also relates to blends of this PVDF with an ABC triblock copolymer, the three blocks A, B and C being linked together in this order, each block being either a homopolymer or a copolymer obtained from two or more monomers, the A block being linked to the B block and the B block to the C block by means of a covalent bond or of an intermediate molecule linked to one of these blocks via a covalent bond and to the other block via another covalent bond, and such that: the A block is compatible with PVDF, the B block is incompatible with PVDF and is incompatible with the A block, the C block is incompatible with PVDF, the A block and the B block. The invention also relates to the parts made of the above composition. These parts may be sheets, films, tubes, rods, centrifugal pump components and containers. The invention also relates to a process for synthesizing this PVDF, in which: a dispersion of VF2 (vinylidene fluoride) and of one or more optional comonomers in water is made, possibly with the aid of a surfactant, the said dispersion being initially brought into contact with a water-soluble non-organic initiator capable of causing the polymerization of the monomers; then, part of the PVDF having been formed in the presence of the water-soluble non-organic initiator, the following are added: either (i) a chain transfer agent capable of propagating the polymerization, the said polymerization then being initiated by a water-soluble non-organic initiator or by an organic initiator, or (ii) an organic initiator, also capable of accomplishing chain transfer, and optionally a water-soluble non-organic initiator.

Owner:ATOFINA

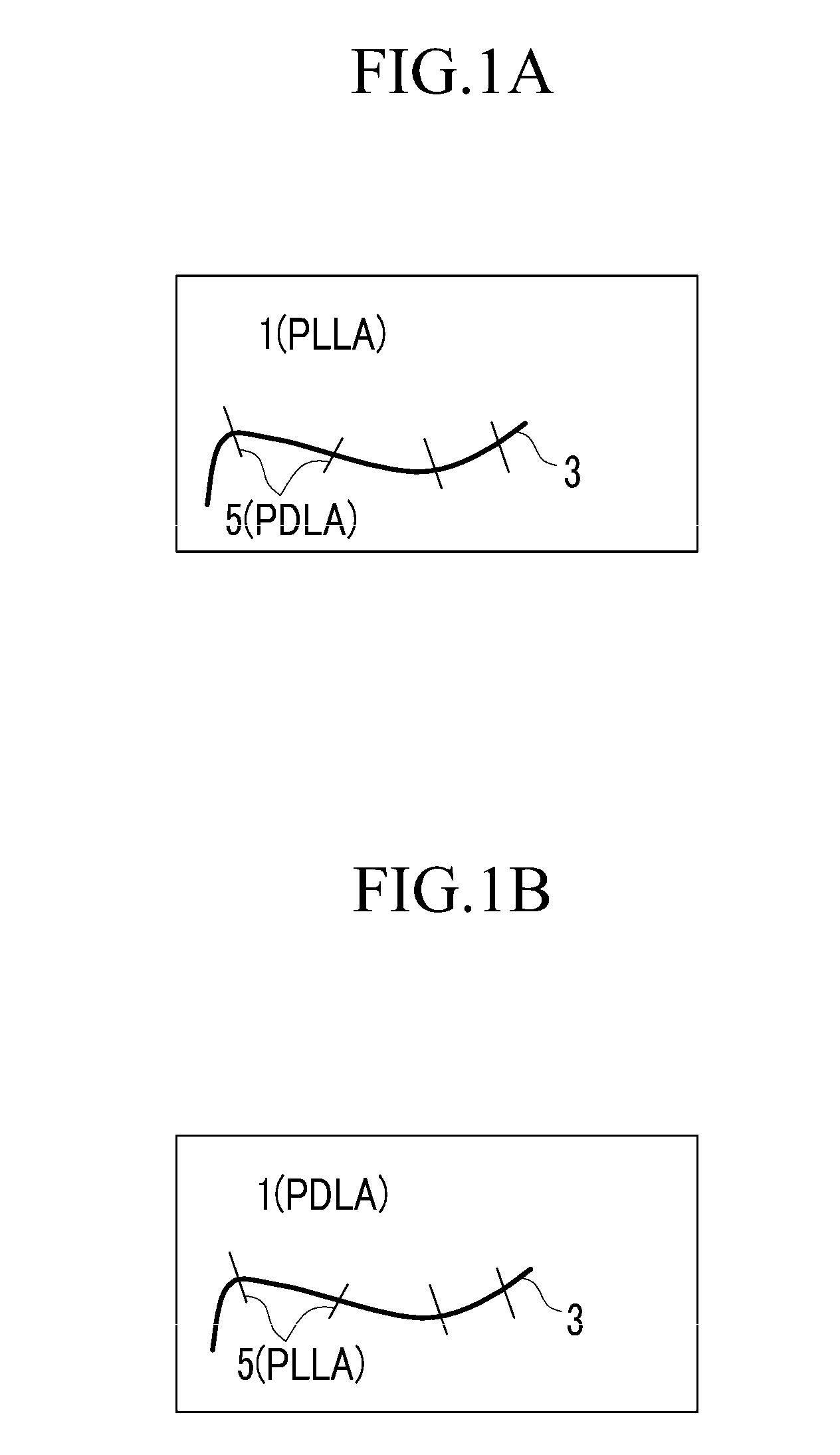

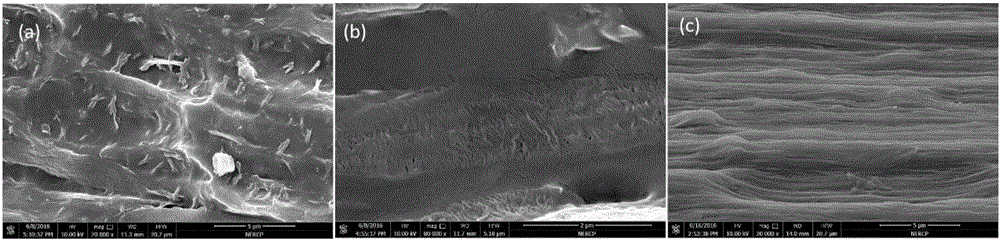

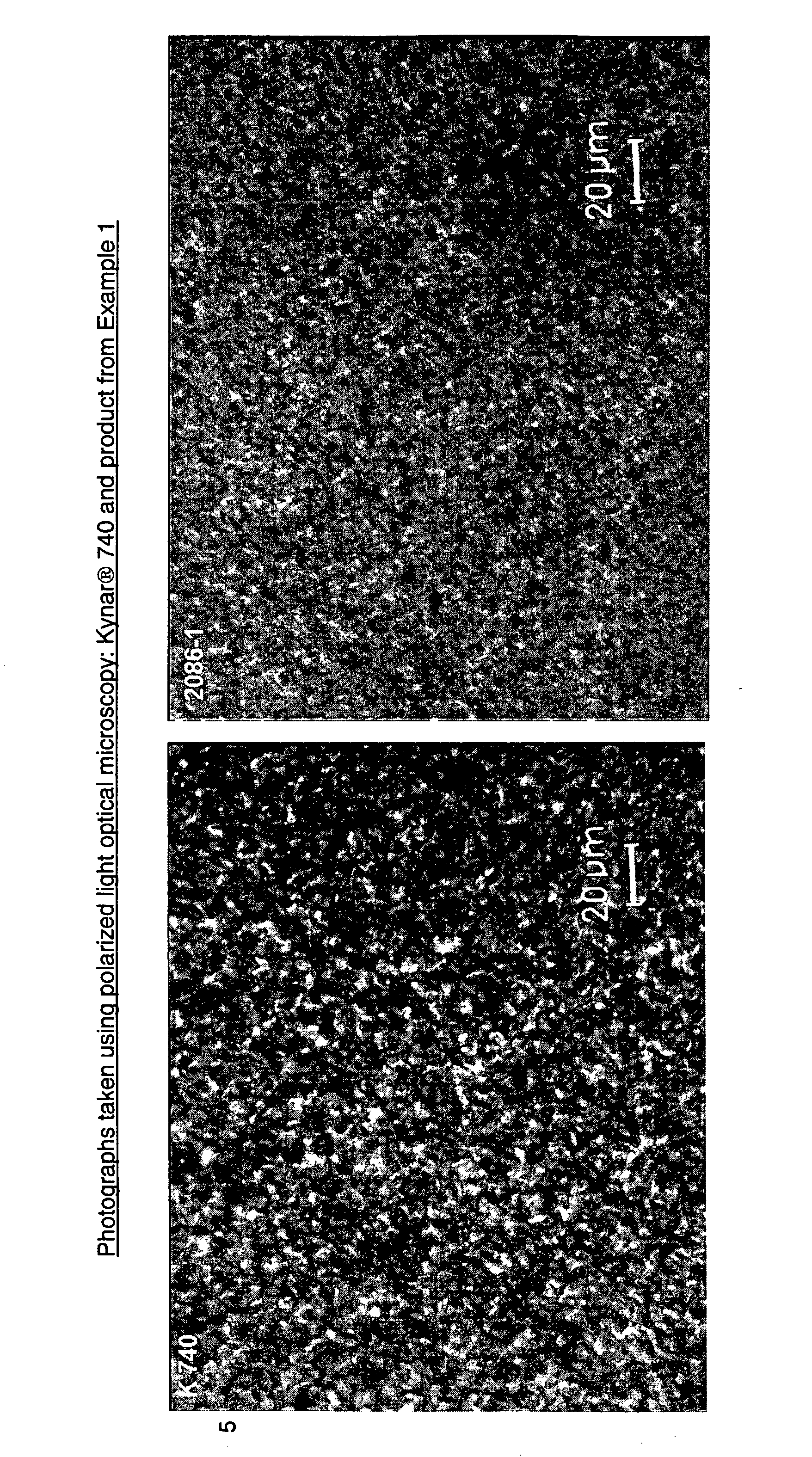

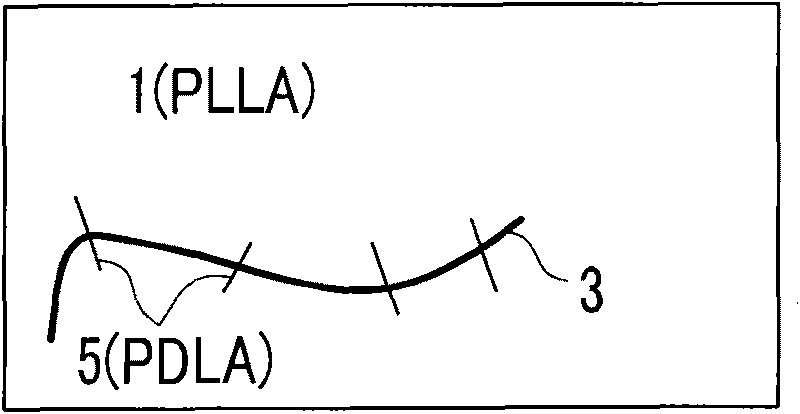

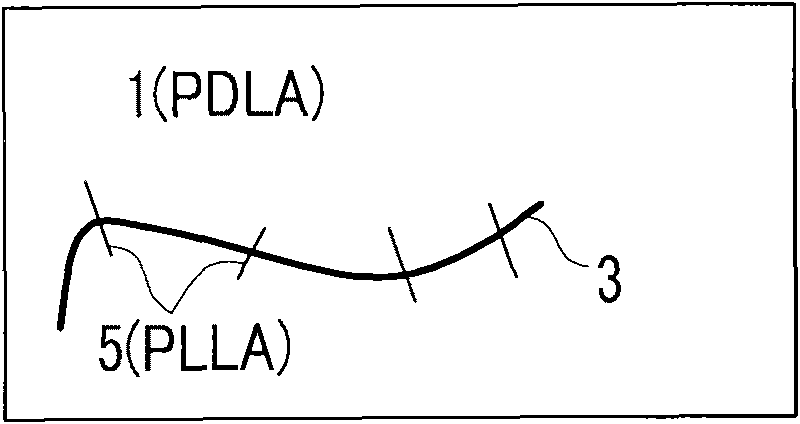

Natural fiber-reinforced polylactic acid resin composition and molded product made using the same

Disclosed is a natural fiber-reinforced polylactic acid resin composition that includes (A) a first polylactic acid resin; and (B) a natural fiber surface-treated with a second polylactic acid resin. The second polylactic acid resin can include a different isomer from the first polylactic acid resin, or alternatively, when measured under isothermal conditions after quenching from about 240 DEG C to a crystallization temperature, a spherulite crystal is first formed at a surface of the natural fiber and the growth rate at the surface is faster than at other positions. A molded product made using the natural fiber-reinforced polylactic acid resin composition is also disclosed.

Owner:CHEIL IND INC

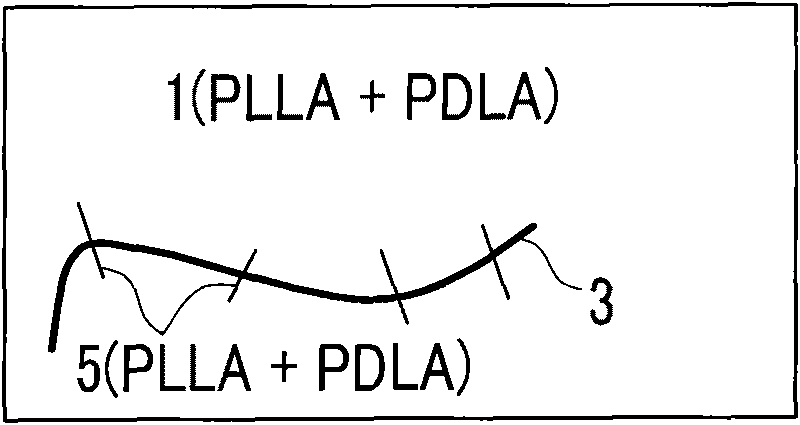

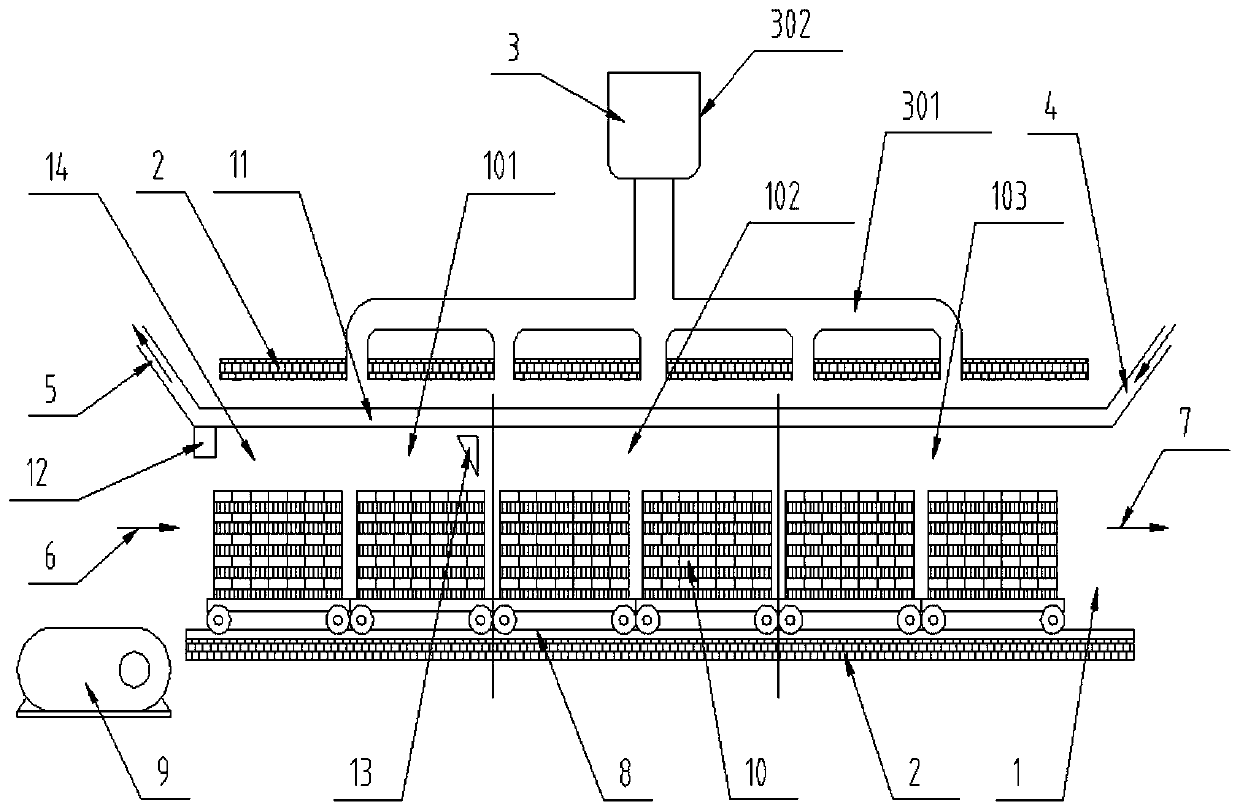

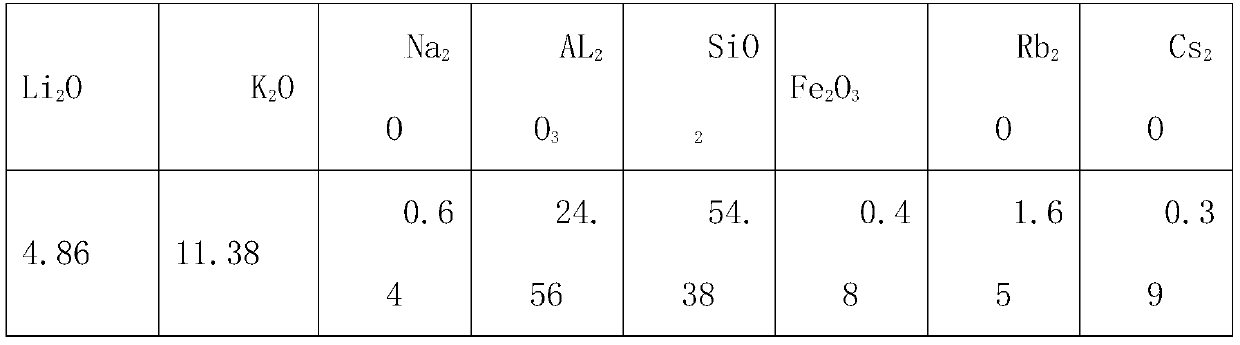

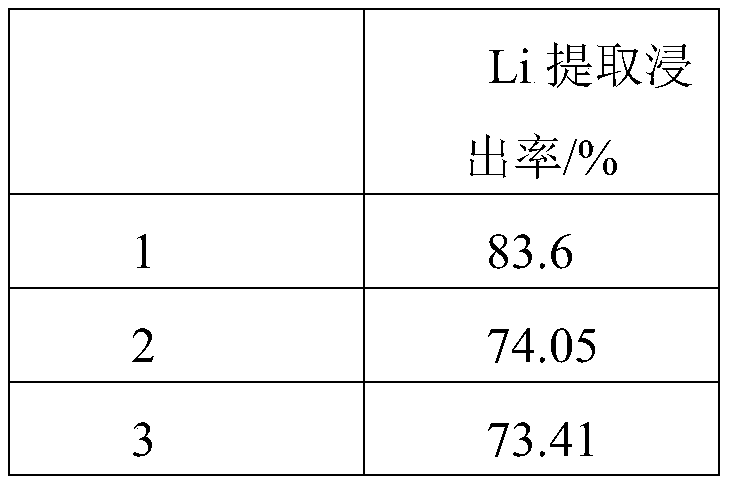

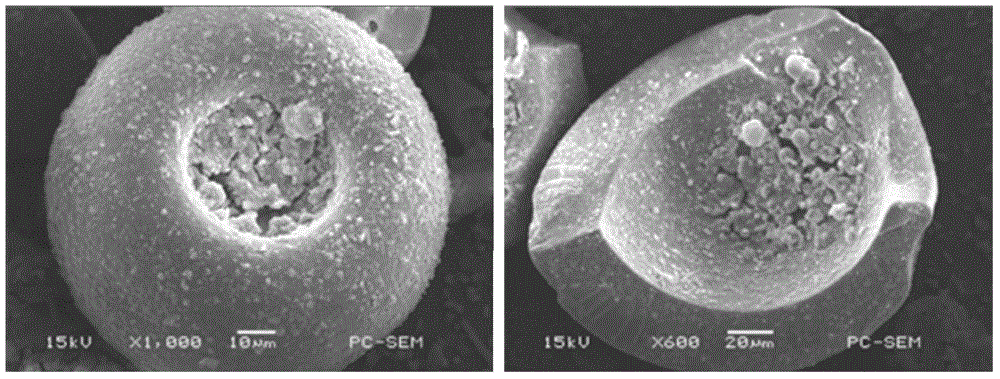

Method and roasting device for roasting and making lithium salt by taking spontaneous combustion of lithium ore as heat source

ActiveCN110396592AHigh yieldNo pinching phenomenonProcess efficiency improvementSpontaneous combustionTunnel kiln

The invention discloses a method and a roasting device for roasting and making lithium salt by taking spontaneous combustion of lithium ores as a heat source. According to the method, the lithium oresare served as raw materials, the lithium ores and roasting auxiliary materials are mixed to serve as spontaneous combustion materials, and then roasting is carried out. The combustible is added intolithium ore powder according to a composite salt method formula, the combustible and the lithium ore powder are mixed and squeezed into spherulites, columns, cylinders, plates, bricks or the like witha uniform shape, the squeezed materials are placed uniformly into a tunnel kiln material trolley by adopting a tunnel kiln, the material trolley continuously passes through the tunnel kiln for roasting the materials, the combustible in the formed materials carries out the spontaneous combustion in the roasting process, and the temperature of the materials is enabled to be consistent. The method and the device solve the problem of a rotary kiln crusting phenomenon, the problem of undercooked materials is well solved by means of formed agglomeration squeezing and spontaneous combustion inside the agglomeration body, so that the lithium recovery rate is high, meanwhile, the yield is large, the energy consumption is low, the process is stable and easy to operate, and the production process issimple.

Owner:江西南氏锂电新材料有限公司

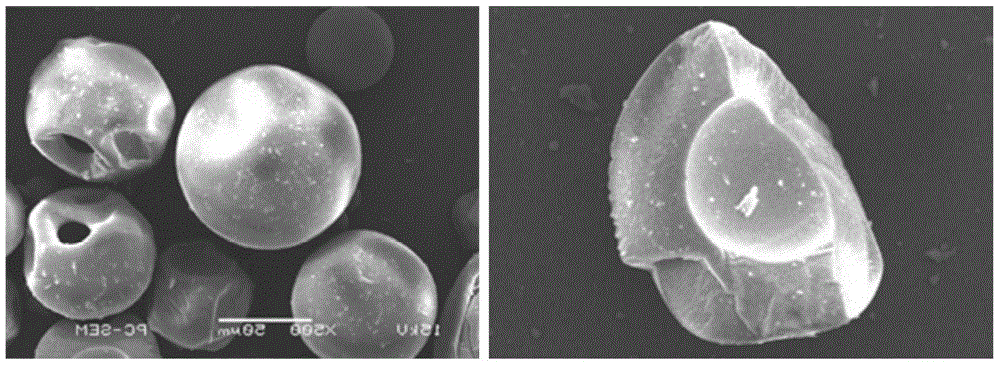

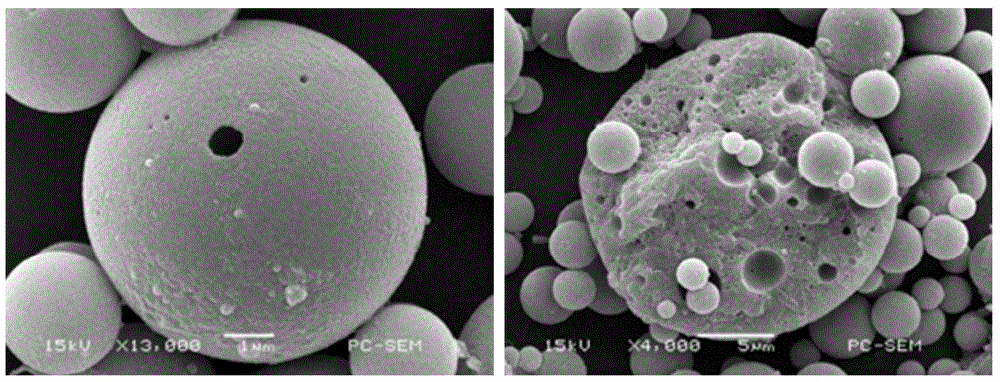

Hollow titanium dioxide microsphere based on gel sphere precursor and preparation method of hollow titanium dioxide microsphere

ActiveCN104310466AReduce usageReduce manufacturing costPhysical/chemical process catalystsTitanium dioxideMicrosphereSpherulite

The invention belongs to the technical field of inorganic functional material preparation, and particularly relates to a TiO2 hollow microsphere synthesizing technology by using gel spherulite as precursor. A hydrolyzing agent complexed tetra-n-butyl titanate is dispersed into a water solution of starch, and is subjected to hydrothermal treatment at 150 DEG C, the starch reacts with tetra-n-butyl titanate to form a gel sphere with a three-dimensional network structure; a hollow structure is formed in the gel sphere in the mineralizing and carbonizing processes due to volume shrinkage, and the carbon ingredient remained in the gel sphere is removed by a thermal treatment; and the substantial part of the hollow TiO2 microsphere is made of a porous material formed by nano-crystalline grains (8-10nm) and nano-scale passages. According to the synthesized TiO2 spheres, the specific surface area is 230m<2> / g, the porous volume is 0.34cm<3> / g, and the average pore diameter is 6.6nm. By adopting the synthesizing process, water is used as a dispersing medium, and starch participates in the reaction to form the gel spheres, and the process is environment-friendly.

Owner:佛山市卓尔特电器有限公司

Vinylidene fluoride polymer having a fraction of non-transferred chains and its manufacturing process

Blends of PVDF (polyvinylidene fluoride) homopolymer or copolymer with ABC triblock copolymers are useful for manufacturing parts which may be sheets, film, tubes, rods, centrifugal pump components and containers. The PVDF comprises a fraction of non-transferred chains of very high molar mass which are insoluble in the usual solvents for PVDF, such as DMF (dimethylformamide), DMSO (dimethyl sulphoxide) and NMP (N-methylpyrrolidone), the polymer fraction associated with these high-mass chains having a dynamic viscosity of greater than 50 kpoise at 230° C. and at a shear rate of 100 s−1, and has spherulites with a size between 0.5 and 4 μm.

Owner:ATOFINA

Laminate and stretched laminate using the same

InactiveUS20120156473A1Good impact delamination resistanceAvoid serious impactBottlesSynthetic resin layered productsBoron nitrideSpherulite

A laminate includes: a crystallized polyglycolic acid-based resin layer containing 100 parts by mass of a crystallized polyglycolic acid-based resin having a spherulite diameter of 1 to 30 μm and 0.0075 to 0.20 parts by mass of at least one nucleating agent selected from the group consisting of boron nitride particles, molybdenum sulfide particles, and tungsten sulfide particles; and a thermoplastic resin layer adjacent to the crystallized polyglycolic acid-based resin layer.

Owner:KUREHA KAGAKU KOGYO KK

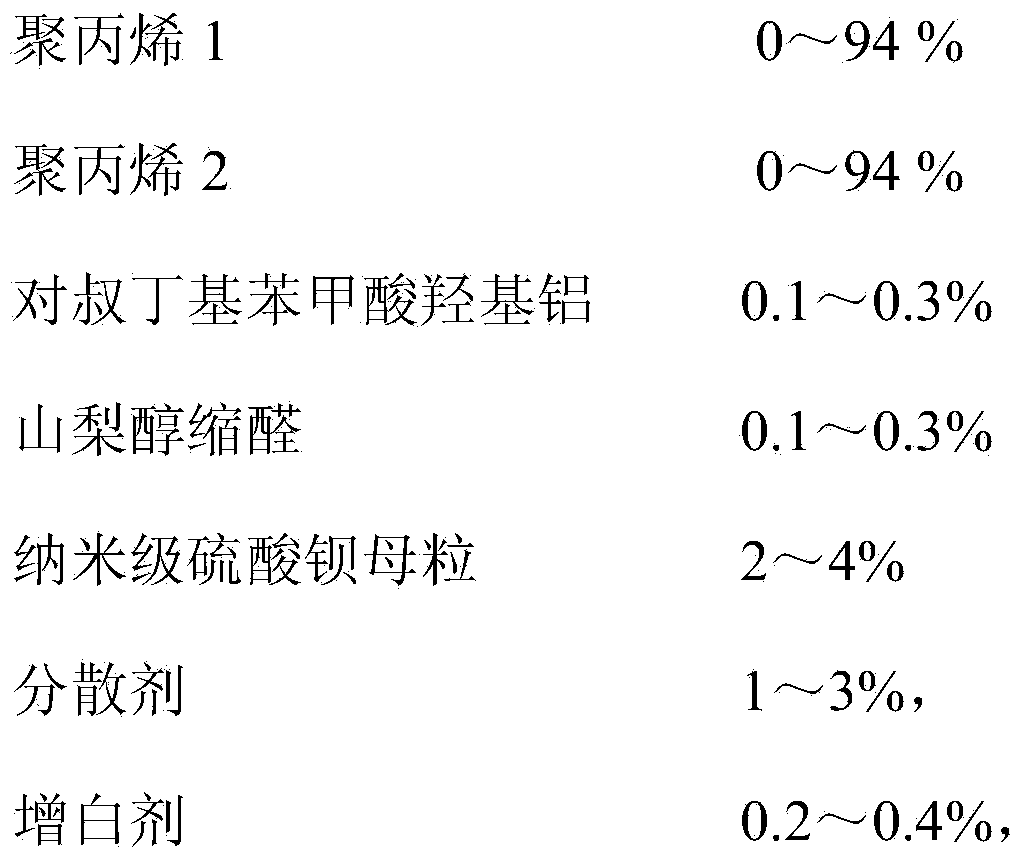

High-rigidity high-transparency polypropylene composite material

The invention discloses a high-rigidity high-transparency polypropylene composite material, and belongs to the technical field of high polymer alloy materials. The high-rigidity high-transparency polypropylene composite material is compounded by 2-4wt% of nanoscale barium sulfate master batch, 0.1-0.3wt% p-tertiary butyl hydroxyl aluminum benzoate and 0.1-0.3wt% sorbitol acetal as a nucleating agent of polypropylene. According to the high-rigidity high-transparency polypropylene composite material, the nanoscale barium sulfate master batch is added to achieve a certain compatible effect on two nucleating agents, so that the two nucleating agents are prevented from resisting against each other; and meanwhile, the effects of nucleating heterogeneously, promoting the polypropylene to quicken crystallization and refining spherocrystal effects are achieved, so that the rigidity and the transparency of a PP (polypropylene) product are further improved.

Owner:广东顺威赛特工程塑料开发有限公司

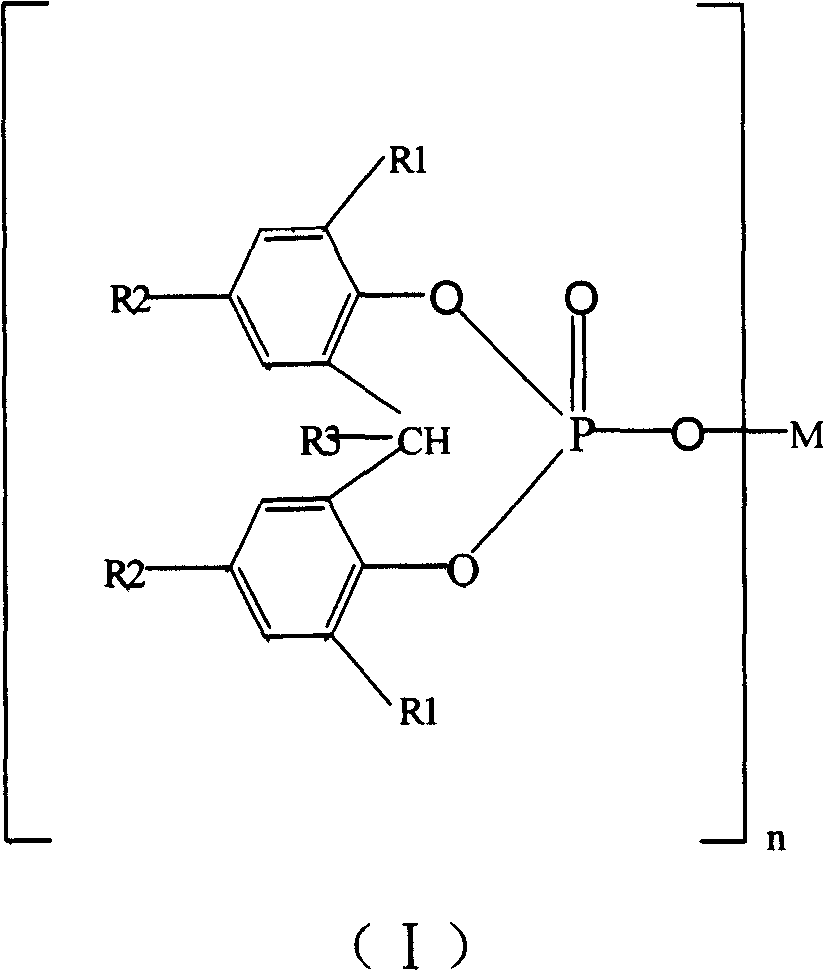

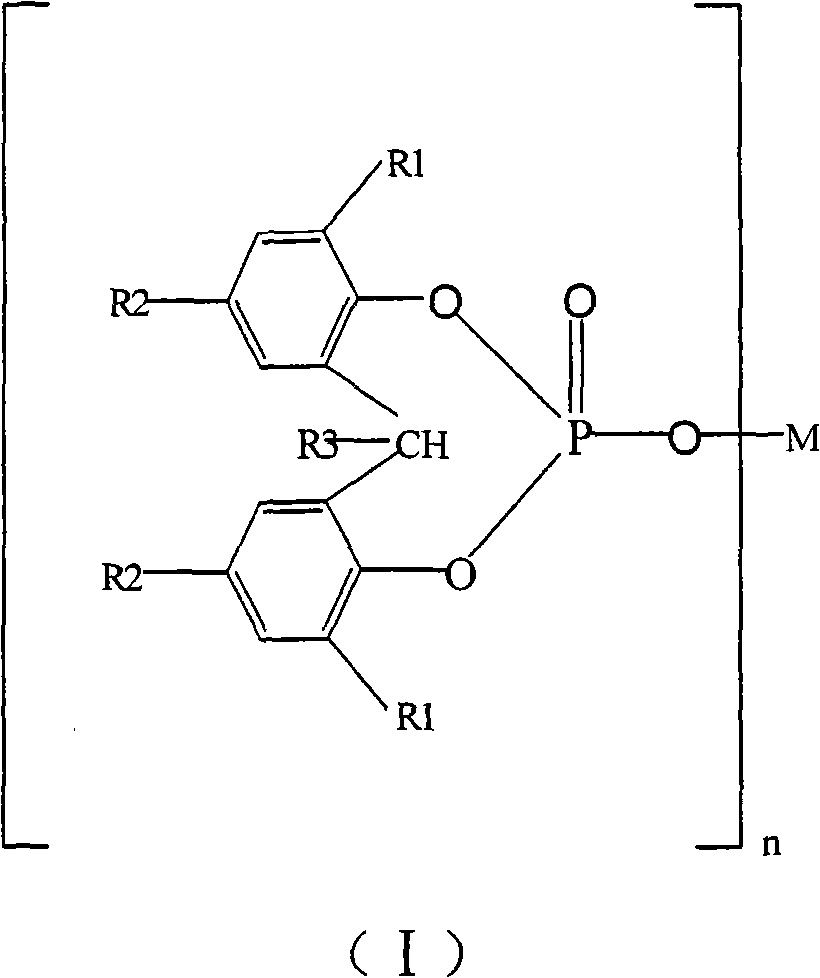

Method for preparing organic phosphate nucleating agent through ultrasonic sedimentation

The invention relates to a method for preparing an ultra-fine organic phosphate nucleating agent through ultrasonic sedimentation. The method controls the separation grain size of the organic phosphate through the condition of a solvent and the ultrasonic sedimentation to finally obtain the ultra-fine organic phosphate nucleating agent. The organic phosphate nucleating agent has high nucleating efficiency during polypropylene processing, and can finally form tiny polypropylene spherulites, thereby significantly increasing various performances of rigidity, strength, distortion temperature and the like of resin.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com