Microcrystal PBT (Polybutylece Terephthalate) resin and preparation method thereof

A PBT resin and microcrystalline technology, applied in the field of microcrystalline PBT resin and its preparation, can solve problems such as differences in crystallization activity, achieve the effects of reducing poor welding, improving laser welding, and improving opacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

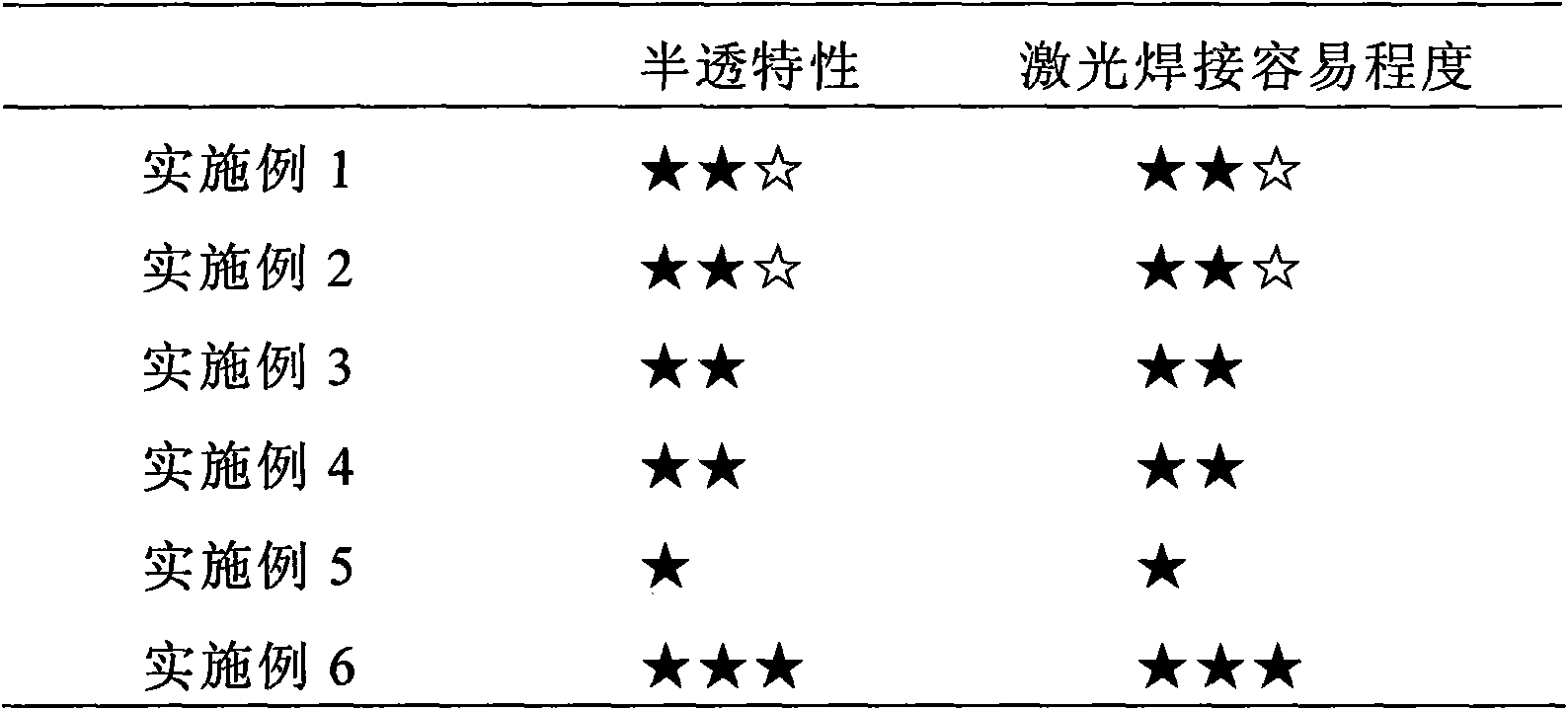

Embodiment 1

[0036] A kind of microcrystalline PBT resin with translucent effect and preparation method thereof, the method comprises the following steps:

[0037] (1) Prepare materials according to the following components and contents:

[0038] PBT resin 100;

[0039] Nucleating agent 0.2;

[0040] Lubricant 0.2;

[0041] Antioxidant 0.2;

[0042] Processing aid 0.2;

[0043] in

[0044] The PBT resin is PBT1082 of Jiangsu Yizheng Chemical Fiber Co., Ltd., and the intrinsic viscosity is 0.82;

[0045] The nucleating agent is hexamethyldisilazane modified nano silicon dioxide;

[0046] The lubricant is high molecular weight PETS (pentaerythritol stearate);

[0047] Antioxidant is four [methyl-β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, three [2.4-di-tert-butyl phenyl] Phosphite;

[0048] Processing aids are carbodiimide anti-hydrolysis stabilizers, anhydrous sodium dihydrogen phosphate transesterification inhibitors

[0049] (2) Dry the PBT resin at 1...

Embodiment 2

[0051] A kind of microcrystalline PBT resin with translucent effect and preparation method thereof, the method comprises the following steps:

[0052] (1) Prepare materials according to the following components and contents:

[0053] PBT resin 100;

[0054] Nucleating agent 0.2;

[0055] Lubricant 0.2;

[0056] Antioxidant 0.2;

[0057] Processing aid 0.2;

[0058] in

[0059] The PBT resin is PBT1082 of Jiangsu Yizheng Chemical Fiber Co., Ltd., and the intrinsic viscosity is 0.82;

[0060] Nucleating agent is sorbitol (DBS), the Millad3988 of Milliken company;

[0061] The lubricant is high molecular weight PETS (pentaerythritol stearate);

[0062] Antioxidant is four [methyl-β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, three [2.4-di-tert-butyl phenyl] Phosphite;

[0063] Processing aids are carbodiimide anti-hydrolysis stabilizers, anhydrous sodium dihydrogen phosphate transesterification inhibitors

[0064] (2) Dry the PBT resin at 130...

Embodiment 3

[0066] A kind of microcrystalline PBT resin with translucent effect and preparation method thereof, the method comprises the following steps:

[0067] (1) Prepare materials according to the following components and contents:

[0068] PBT resin 100;

[0069] Nucleating agent 0.2;

[0070] Lubricant 0.2;

[0071] Antioxidant 0.2;

[0072] Processing aid 0.2;

[0073] in

[0074] The PBT resin is PBT1082 of Jiangsu Yizheng Chemical Fiber Co., Ltd., and the intrinsic viscosity is 0.82;

[0075] The nucleating agent is NA-10[bis(2,4-di-tert-butylphenyl)sodium phosphate;

[0076] The lubricant is high molecular weight PETS (pentaerythritol stearate);

[0077] Antioxidant is four [methyl-β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester, three [2.4-di-tert-butyl phenyl] Phosphite;

[0078] Processing aids are carbodiimide anti-hydrolysis stabilizers, anhydrous sodium dihydrogen phosphate transesterification inhibitors

[0079] (2) Dry the PBT resin at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com