High-barrier antistatic graphene/polymer nanocomposite sheet/film and preparation method thereof

A nanocomposite and graphene technology, applied in the field of polymer materials, can solve problems such as difficulty in realizing industrialized production, unfavorable industrialized production, complicated process routes, etc., and achieve the effect of simple and easy-to-obtain equipment, easy industrialized production, and reduce diffusion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

[0031] Table 1 shows the dosage ratio of each component of the examples of the present invention. The preparation process of each example is the same, and the specific steps are: 1) Dry the polyethylene terephthalate in a drying tank at 120° C. for 1 hour, and then dry the The tank temperature was raised to 150°C, and then dried for 5 hours; the graphene was dried in an oven at 50°C for 24 hours to obtain dry raw material components;

[0032] 2) premixing the dried raw material components obtained in step 1) to obtain a premix;

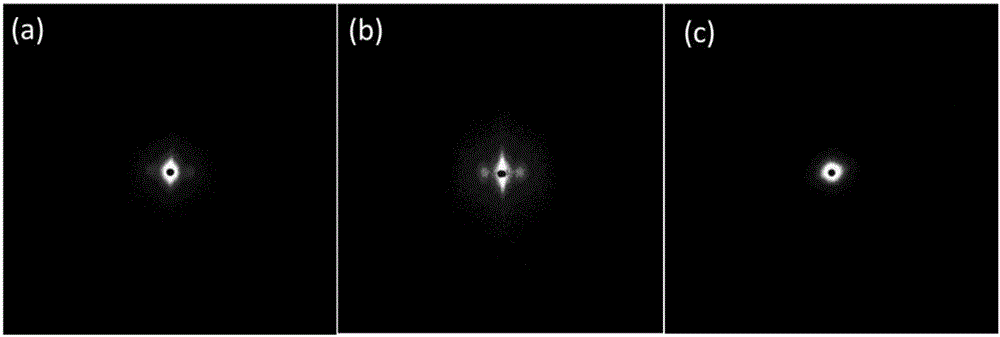

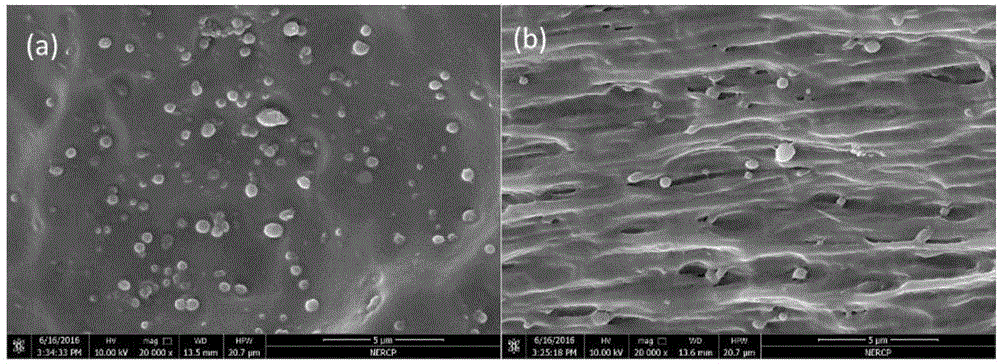

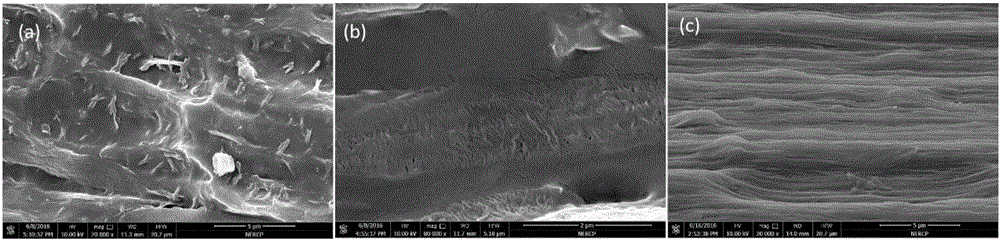

[0033]3) Put the premix obtained in step 2) into the co-rotating parallel twin-screw extruder for melt blending and extrusion, and then the extruded melt enters the layer multiplier through the connector for repeated division-shear-stretch , and finally the melt flows out through the touch head, and the graphene / polyethylene terephthalate nanocomposite sheet / film with a thickness of 0.7±0.1mm and a layer number of 256 layers is obtained by three-roll ...

Embodiment 9

[0035] Carry out according to the same procedure of embodiment 3, just control splitting-shearing-stretching condition, through three-roll calender traction, make the graphene / polyethylene terephthalate that thickness is 0.7 ± 0.1mm, the number of layers is 64 layers Glycol ester nanocomposite sheet / film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com