Stator and rotor structure of built-in permanent magnet brushless direct current motor

A DC motor, stator rotor technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, electrical components, etc., can solve large torque fluctuations and noise, inherent performance degradation of motors, and low utilization of permanent magnets and other problems, to achieve the effect of reducing vibration and noise, reducing the amount of copper used, and reducing the effect of magnetic flux leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

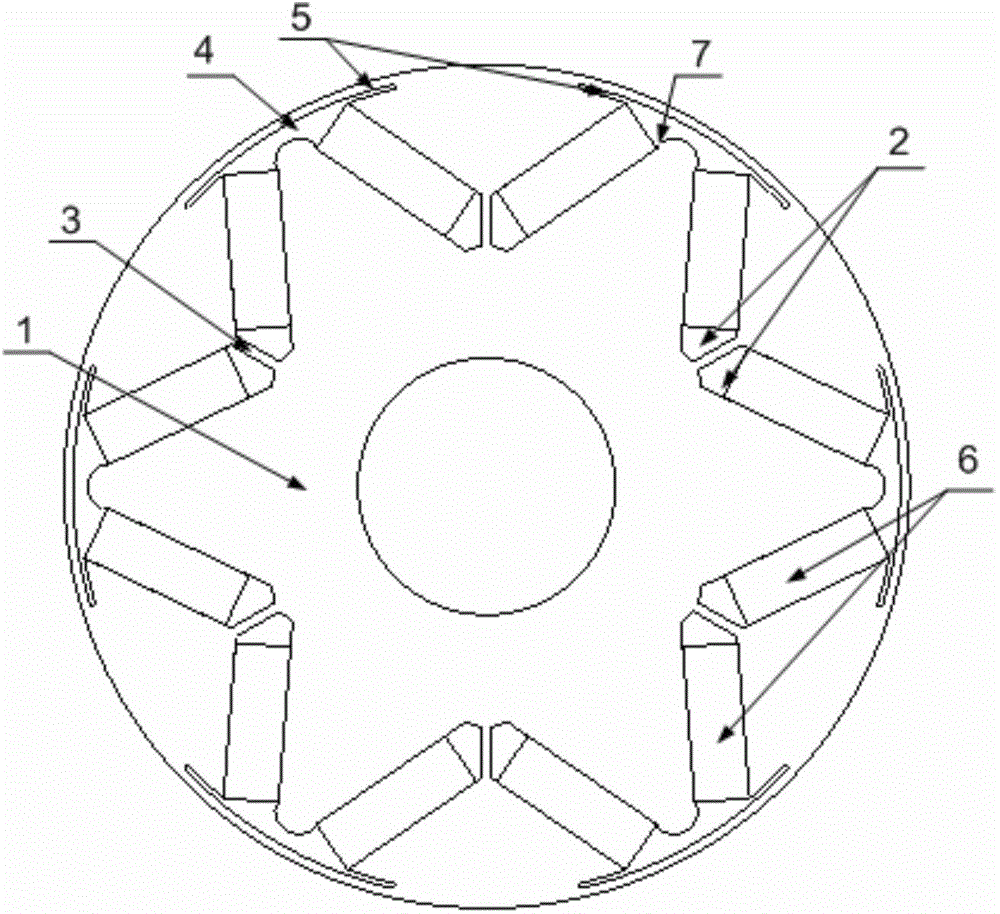

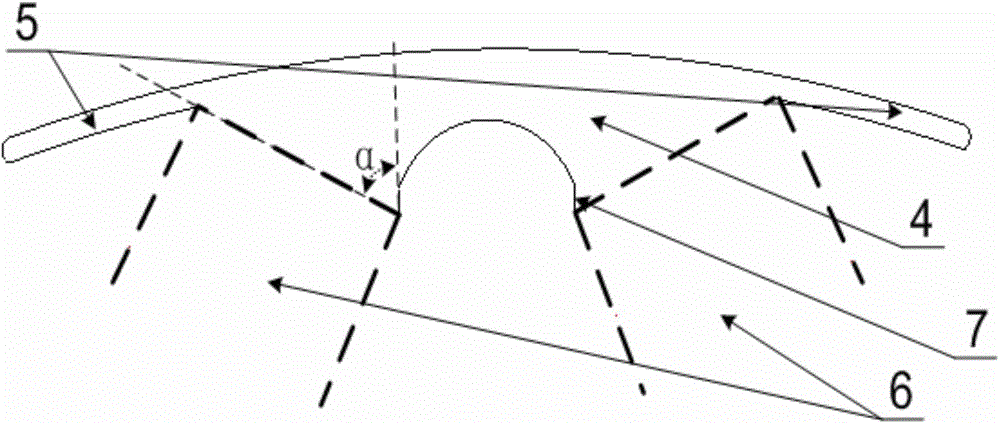

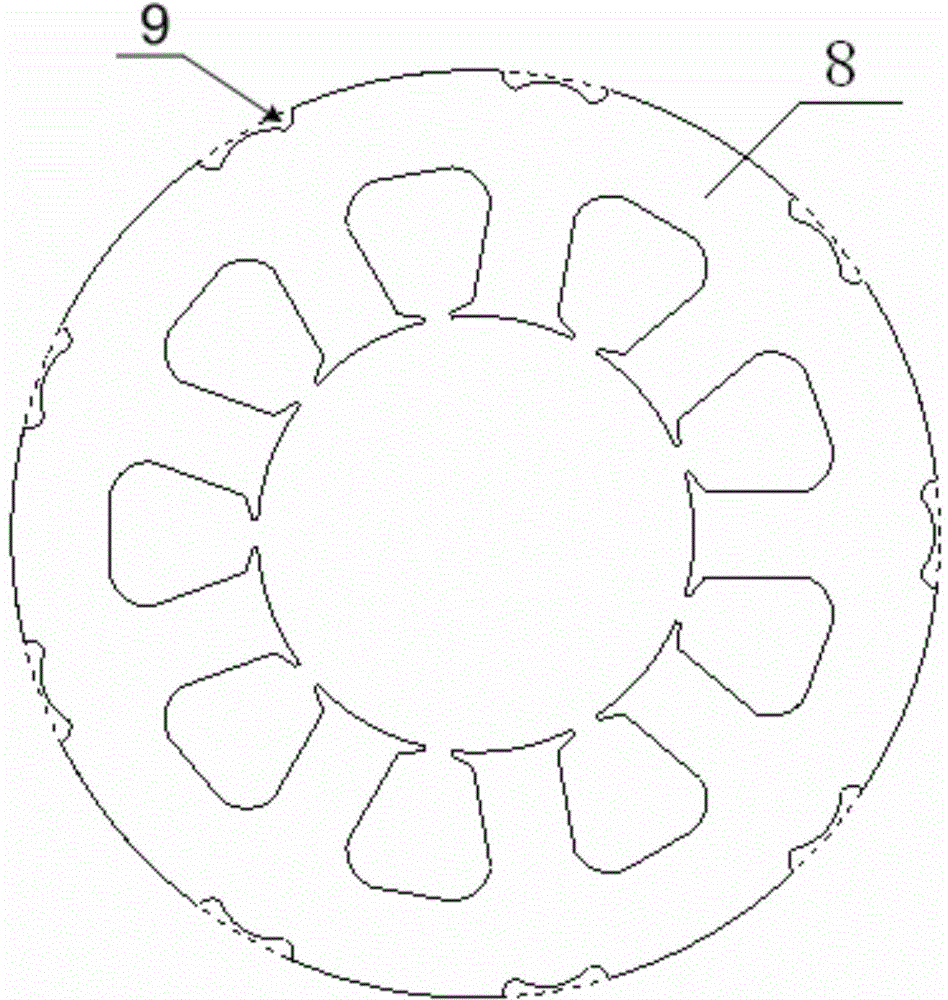

[0028] A stator-rotor structure of a built-in permanent magnet brushless DC motor, such as Figure 5 Shown: includes a stator and a rotor, the rotor is built into the stator, and the rotor is provided with more than one "V"-shaped groove (2) along the circumferential direction, and the opening of the "V"-shaped groove points to the stator; the The bottom of the other end of the "V"-shaped groove opposite to the opening is provided with a reinforcing rib (3). The opening ends of two adjacent "V"-shaped grooves are communicated through a connecting arched groove (4), and two symmetrical slot grooves ( 5); permanent magnets (6) with the same polarity are placed in the left and right grooves of each "V" shaped groove (2), and the magnetization direction of the permanent magnets (6) is perpendicular to the permanent magnet surface, while the adjacent " The polarities of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com