High-thermal-conductivity graphene heat dissipation film and preparation method thereof

A technology of high thermal conductivity graphite and olefin heat dissipation film, applied in the field of heat dissipation film preparation, can solve the problems of poor heat dissipation effect of heat dissipation film, uneven heat dissipation performance, low mechanical properties, etc., achieve light atomic mass, high thermal conductivity, and improve the problem of agglomeration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

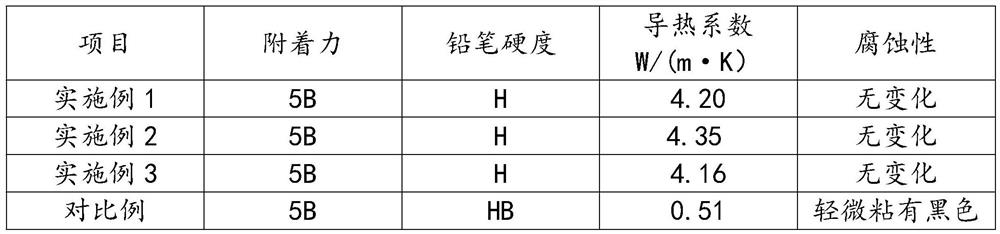

Examples

Embodiment 1

[0034]A highly conductive graphene heat prevention film, including a weight of the following weight parts: 20 parts of a styrene acrylic resin, 20 parts of a thermally conductive composite filler, 30 modified epoxy resin, 1 curing agent, 1 part and curing accelerator 2 copies;

[0035]The preparation method of the highly conductive graphene heat film includes the following steps:

[0036]In the first step, a styrene acrylic resin, a thermally conductive composite filler, a modified epoxy resin, a curing agent, and a curing promoter were added to the reaction elbow, and the temperature rising temperature rose to 75 ° C at 5 ° C / min, and the rotational speed 280R / min was stirred after 30min. Under the conditions of the addition of antifoaming agents, temperature, and speed, stirring is continued for 15 min to give the first mixture;

[0037]In the second step, the first mixture is transferred to the mold, and in a vacuum oven, the temperature is 150 ° C first solidifys 2h, and then the hig...

Embodiment 2

[0050]A highly conductive graphene heat prevention film comprising 25 parts of a styrene acrylic resin, 22 parts by heat conductive composite filler, 35 modified epoxy resins, 3 curing agents, 1 part of defoaming agent, and cure promoters 2 copies;

[0051]The preparation method of the highly conductive graphene heat film includes the following steps:

[0052]In the first step, a styrene acrylic resin, a thermally conductive composite filler, a modified epoxy resin, a curing agent, and a curing promoter were added to the reaction kettle, raised to 80 ° C at 5 ° C / min warp rate, and the rotational speed 280R / min was stirred after 40min Under the conditions of the addition of antifoaming agents, temperature, and speed, stirring is continued for 15 min to give the first mixture;

[0053]In the second step, the first mixture is transferred to the mold, and in a vacuum oven, the temperature is 150 ° C first solidifys 2h, and then the high conductive graphene heat prevention film is obtained.

[...

Embodiment 3

[0066]A highly conductive graphene heat prevention film, including a weight of the following weight, 30 parts of a styrene acrylic resin, 25 parts of a thermally conductive composite filler, 40 modified epoxy resins, 5 curing agents, 1 part of the defoaming agent, and cured promoters 2 copies;

[0067]The preparation method of the highly conductive graphene heat film includes the following steps:

[0068]In the first step, a styrene acrylic resin, a thermally conductive composite filler, a modified epoxy resin, a curing agent, and a curing accelerator were added to the reaction kettle, and the temperature was raised to 85 ° C at 5 ° C / min, and the rotational speed 280R / min was stirred after 60min. Under the conditions of the addition of antifoaming agents, temperature, and speed, stirring is continued for 15 min to give the first mixture;

[0069]In the second step, the first mixture is transferred to the mold, and in a vacuum oven, the temperature is 150 ° C first solidifys 2h, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com