Enhanced oil delivery from structured surfactant formulations

a technology of structured surfactant and enhanced oil, which is applied in the direction of detergent compounding agent, ampholytes/electroloneutral surface active compounds, hair cosmetics, etc., can solve the problems of unstable products containing high oil concentrations, and phase separation with tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1a and 1b

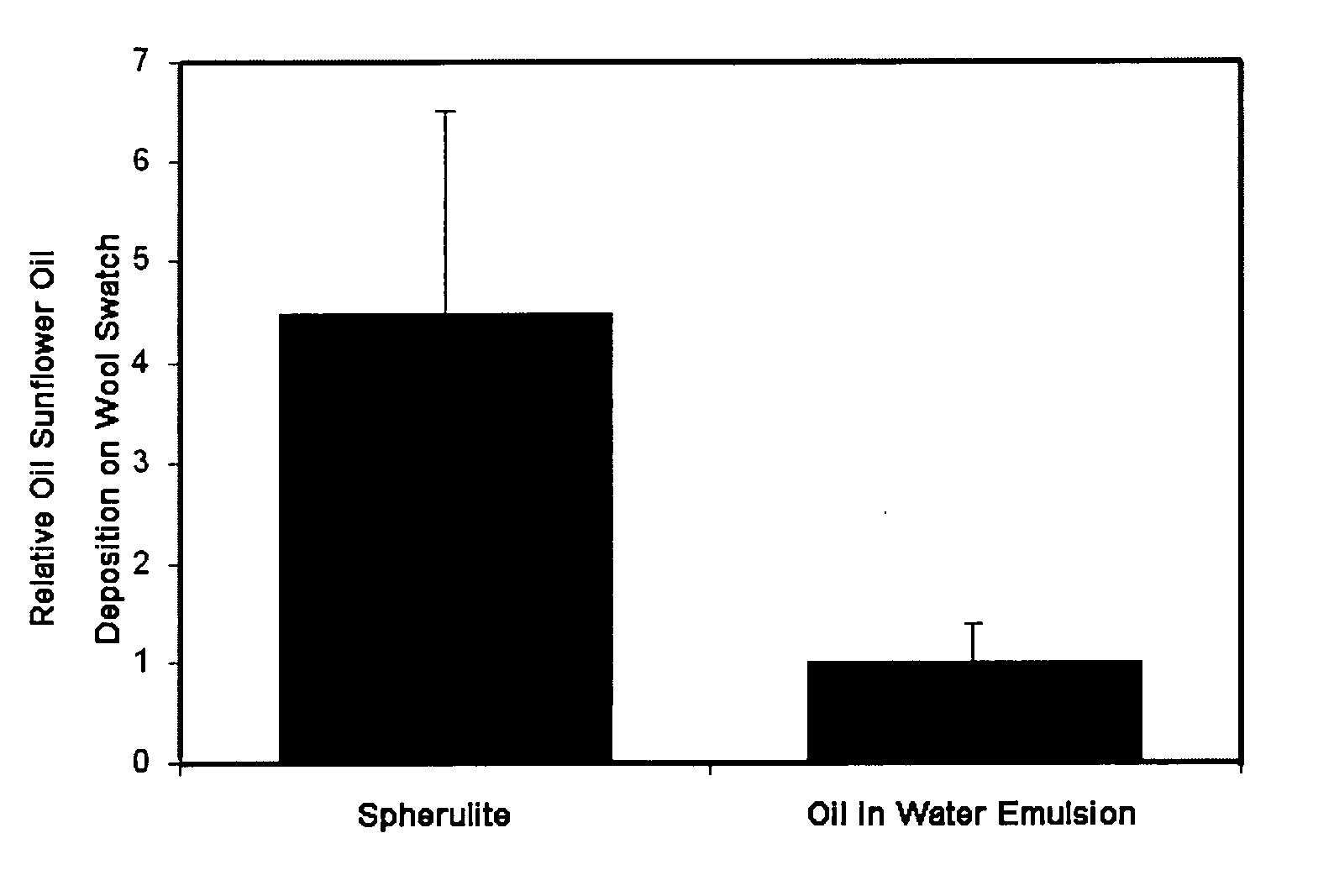

[0046] Preliminary experiments using a standard wool binding assay were performed to determine whether changing surfactant phase structure from an oil in water emulsion to a spherulitic phase structure improved the delivery of oil to the skin's surface during washing FIG. 1 and Table 1). Initial experiments showed that at the same oil concentration of 10% and total surfactant concentration of 10.8%, a spherulitic surfactant system delivered approximately 4.5 times more oil the wool substrate compared to an oil in water emulsion formula (p≦0.05, FIG. 1).

example 1a

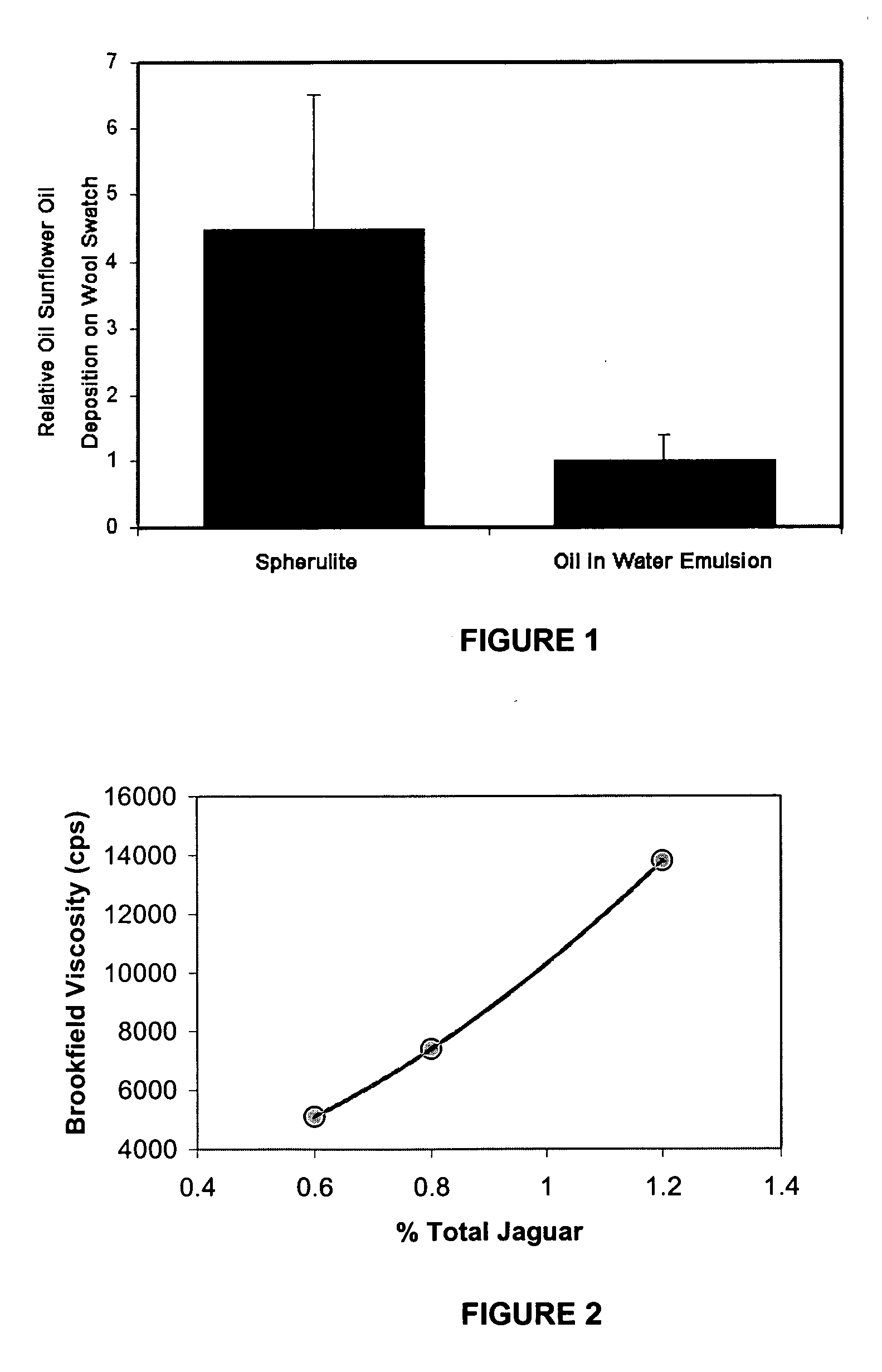

[0047] One particular method for making the invention is as follows. Note that the guar hydroxypropyl trimonium chloride (“HPTC”) (for example, as sold under the name Jaguar C-17 from Rhodia (Cranberry, N.J.)) is formed as a premix with water and mixed until fully hydrated and dispersed. The additional water in the formulation represents, 62.7 weight % of the final formula. The surfactant pre-mix which contains less than or equal to about 36 weight % sodium trideceth sulfate, less than or equal to about 10 weight % lauroamphoacetate, and less than or equal to about 6 to 11 weight % cocomonoethanolamide in water is selected. This surfactant premix can be obtained from Rhodia, and is similar to a commercial material MIRACARE SLB-365. The exact concentrations of the individual surfactant components can be modified to alter the surfactant concentrations in the final product. The surfactant premix is mixed with the Jaguar C-17 solution to yield a final concentration of the surfactant com...

example 1b

[0050] One particular method for making an oil in water emulsion is as follows. A primary phase of water is heated to 80 degrees C., and the hydroxypropylmethyl cellulose (available from Dow Chemical as METHOCEL® E4Ma) is added and mixed until fully dispersed. The decyl glucoside is then add and mixed completely. A second phase is formed by heating the sunflower oil to between 60 and 65 C, to which the acrylate crosspolymer (available as PEMULEN® TR1 from Noveon) is added, followed by dispersal with vigorous mixing. The second phase is then cooled to 60 degrees C., and the lauric acid is added. The second phase is then stirred for 30 minutes. The SLES is then added to the second phase with mixing, then all the additional ingredients for the oil in water emulsion listed in Table 1 are added in the order presented in Table 1. Each ingredient is completely mixed into the formula before the next ingredient is added. The sample is then cooled to below 40 C, and the preservative DMDMH is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight % | aaaaa | aaaaa |

| weight % | aaaaa | aaaaa |

| weight % | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com