PBT material with high flow, fine finish and no basecoat and preparation method thereof

A technology with high smoothness and high fluidity, applied in polymer modified polybutylene terephthalate material and its preparation, high fluidity, high smoothness and primer-free PBT material and its preparation field, can Solve the problems of decreased gloss on the surface of the aluminum layer, easy migration of small molecular materials, and fogging, etc., to achieve the effects of beautiful products, reduced product scrap rate, and high surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with example, the present invention is described in further detail:

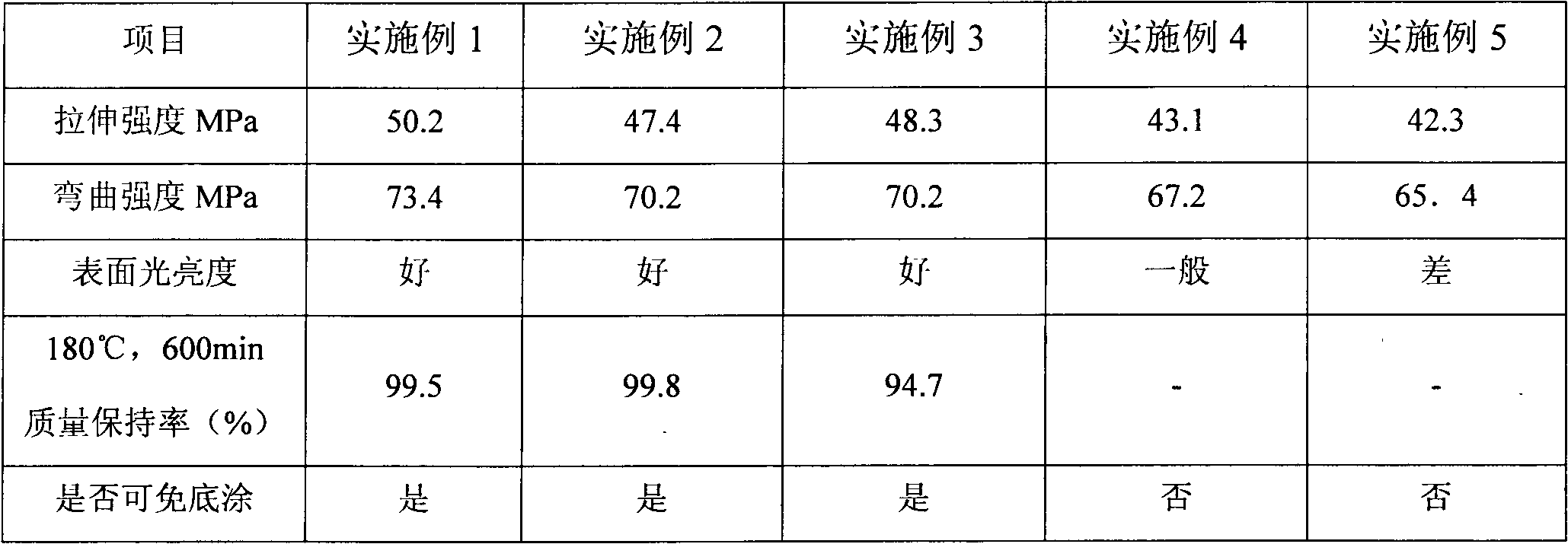

[0026] With PBT as matrix, P250 as nucleating agent, PETS, EBS, TAF as lubricant, tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and diphosphite pentaerythritol Alcohol distearate is a compound antioxidant (ratio 2:3), and the silicon-based mesoporous material is a small-molecule absorbent. The specific ratio is shown in Table 1 below.

[0027] Table 1 Experimental Proportion Table (parts by weight)

[0028] Raw material name

Example 1

Example 2

Example 3

Example 4

Example 5

PBT

92

92

92

97

93

Nucleating agent

2

1

1

1

0

PETS

2

2

0

0

2

EBS

2

0

2

0

2

TAF

0

2

2

0

0

Compound Antioxidant

2

2

2

2

2

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com