Method for branch crystal balling in large block metal glass composite

A technology for metallic glass and composite materials, which is applied in the field of preparation of metallic glass composite materials, can solve the problems of failure in the form of failure, no inelastic behavior, etc., and achieves the effect of improving the plasticity at room temperature

Inactive Publication Date: 2007-12-19

NANJING UNIV OF SCI & TECH

View PDF0 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, at the same time as its ultrahigh strength, the BMG in the plane stress state has almost no inelastic behavior at room temperature

This makes its failure form sudden failure

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

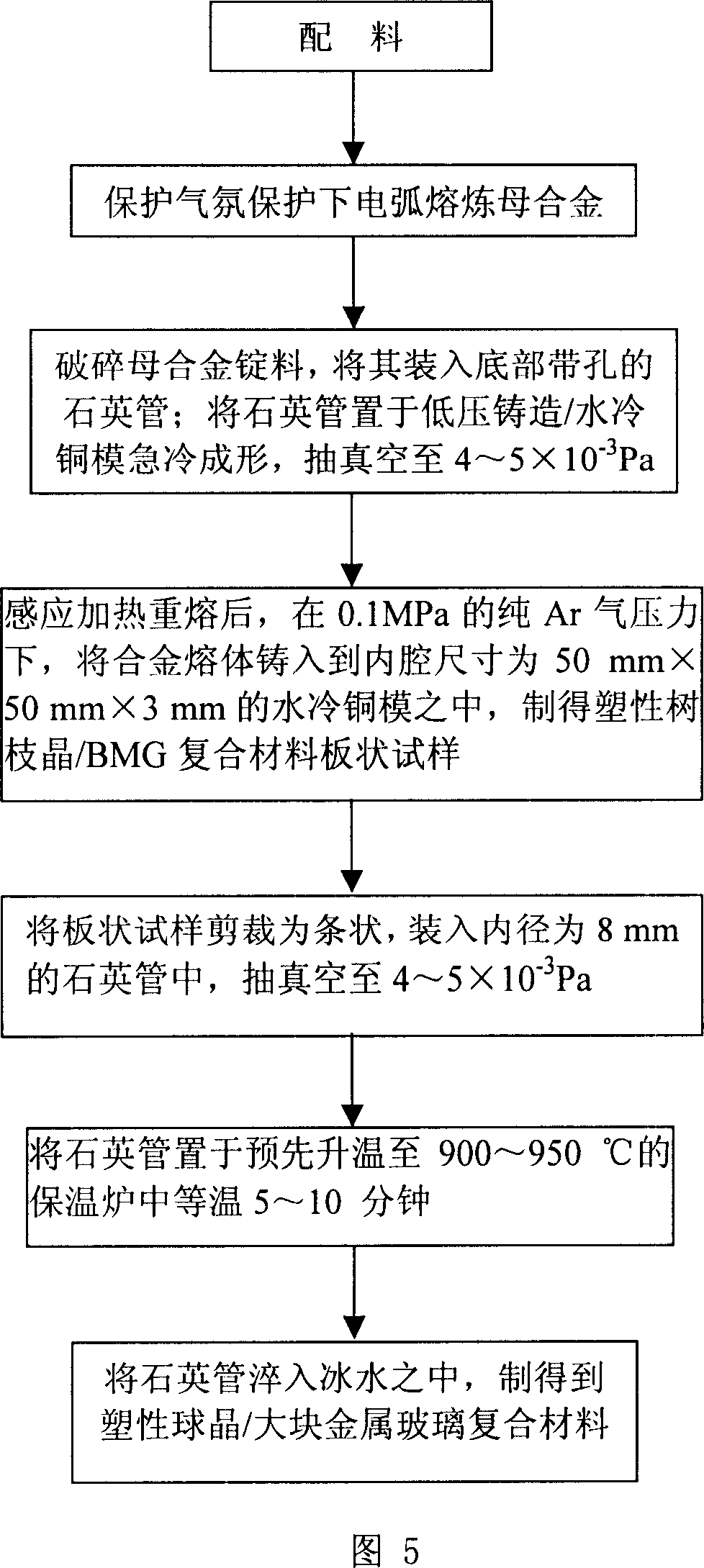

[0019] The present invention will be described in further detail in conjunction with the accompanying drawings.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

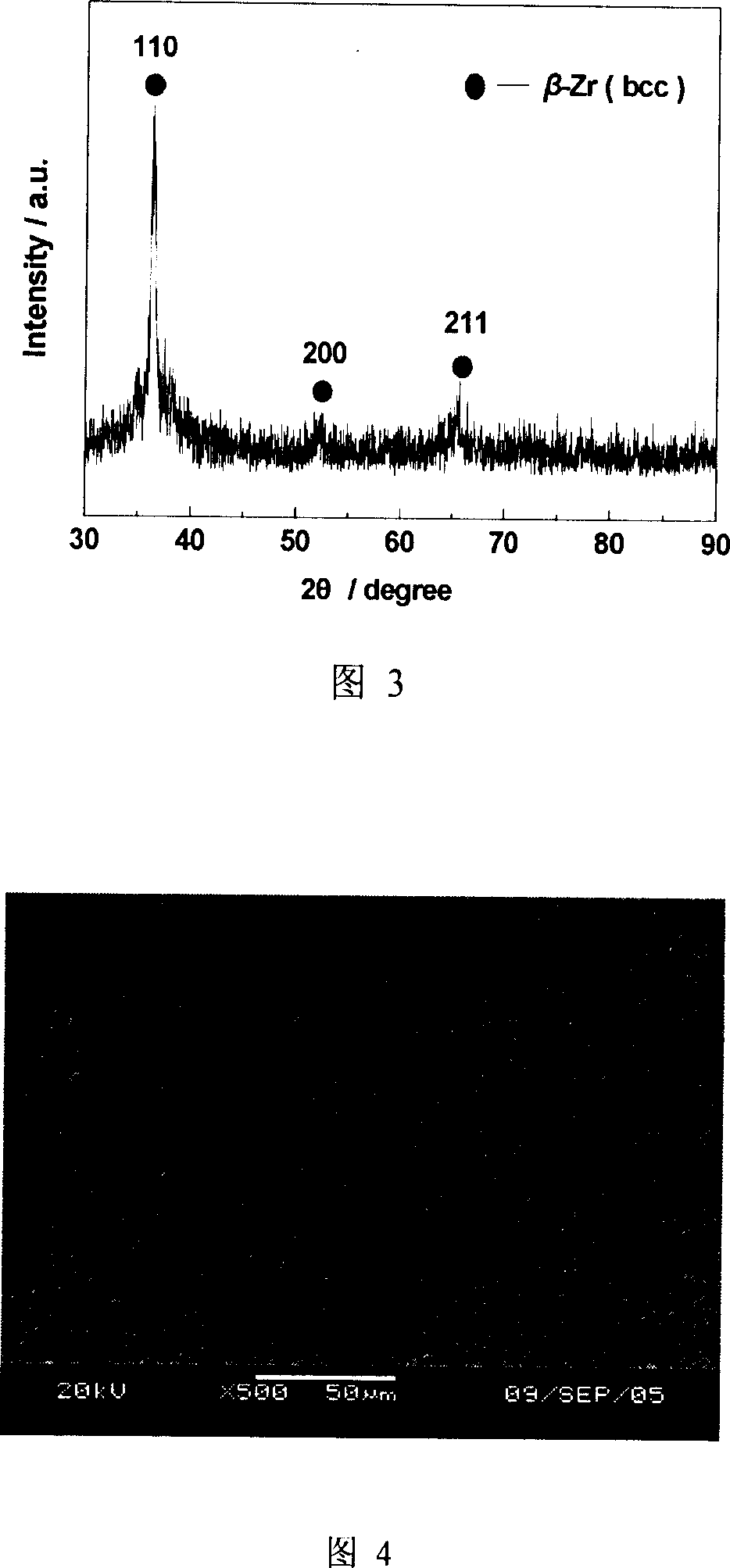

This invention relates to the method for producing plastification geode / massive metal glass composite material. The steps are: first, selecting alloy components having strong glass formation ability, regulating the components to make them offset eutectic point, and solid solution phase being separated earlier; second, the components being smelted under shield gas, then producing foundry alloy ingot; then, said ingots being broken, resmelted, subjected to low pressure casting / water-cooling copper mould quick cooling formation to produce branch like crystal / massive metal glass composite material sheet, finally, said sheet being subjected to isothermal treatment and then water-quenching to produce this invented product. The plastificiation beta phase is no longer having branch like shape but having ball shape.

Description

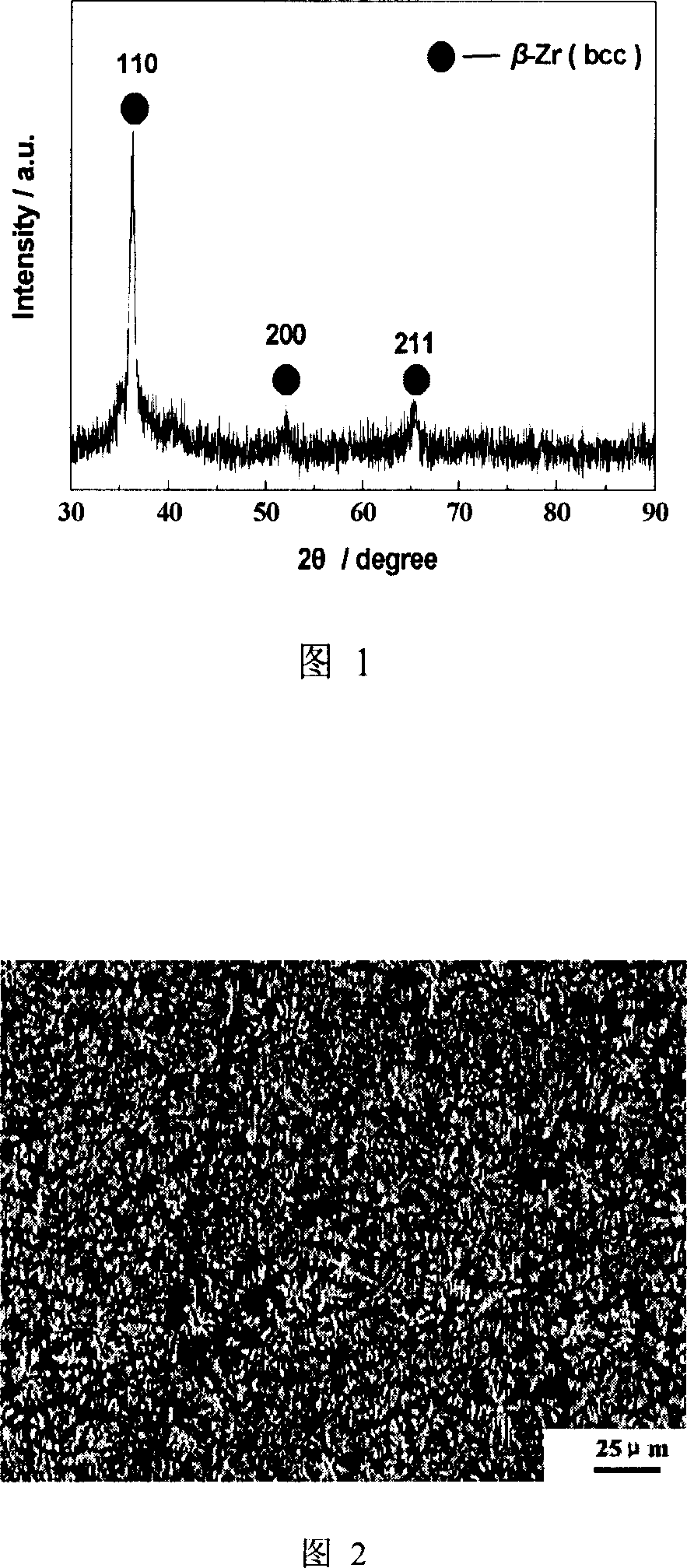

a technical field [0001] The invention relates to a preparation technology of a metallic glass composite material, in particular to a method for spheroidizing dendrites in a bulk metallic glass composite material. Two background technology [0002] Bulk metallic glass (BMG) has a series of excellent properties different from crystalline alloys, and has been involved in five major engineering applications, including military products, electronic product casings, medical devices, sports and leisure products, and space engineering materials. In particular, it has 3 to 4 times the strength of the corresponding crystalline alloy, making it very attractive in terms of weight reduction of weaponry. However, in parallel with its ultrahigh strength, BMGs in the plane stress state show little inelastic behavior at room temperature. This makes its failure form a sudden failure. [0003] In order to solve this problem, after introducing the crystalline phase on the BMG matrix, a cryst...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C16/00C22C1/03B22D27/04C22F1/16

Inventor 陈光孙国元陈国良

Owner NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com