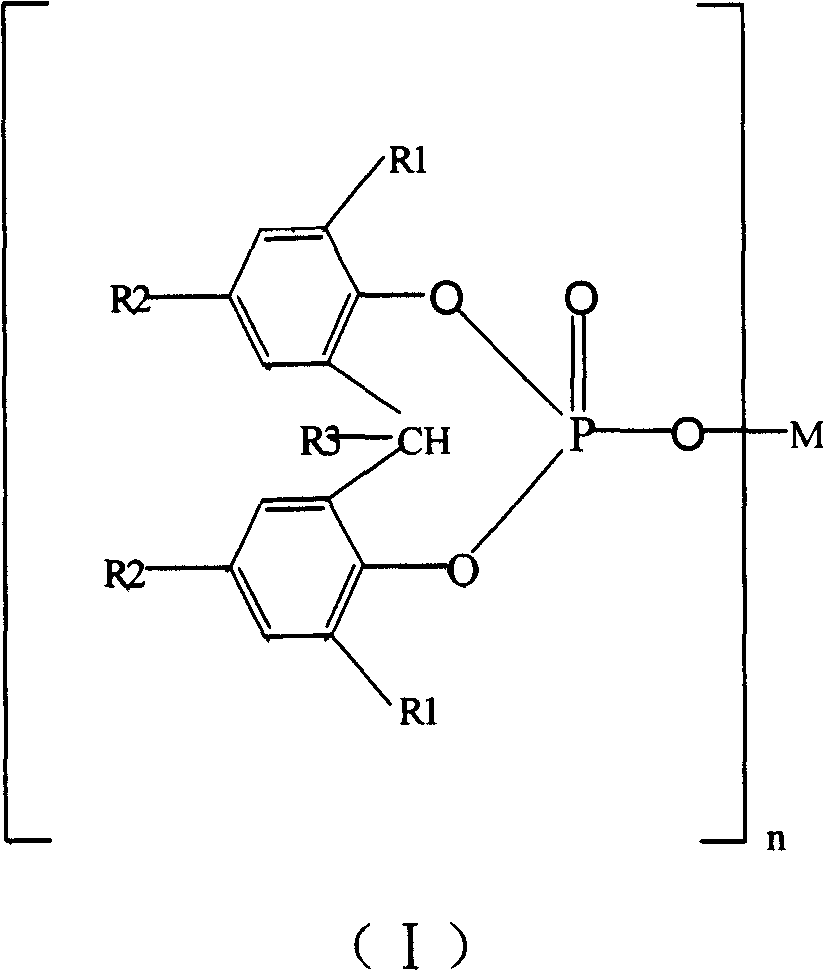

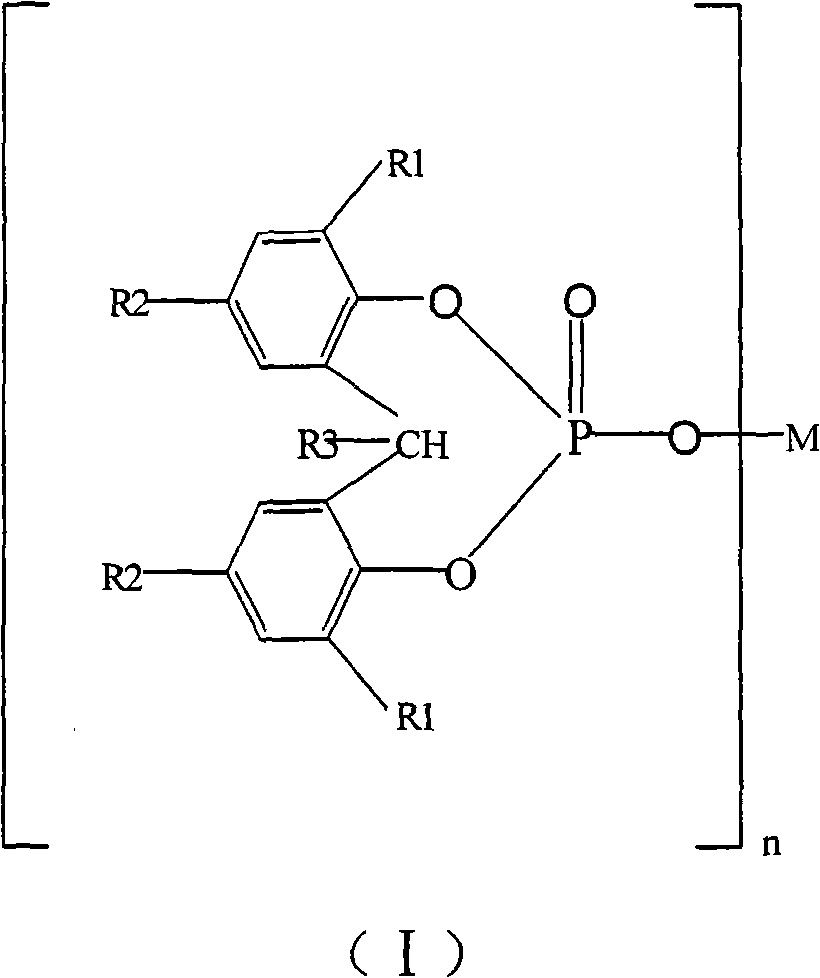

Method for preparing organic phosphate nucleating agent through ultrasonic sedimentation

An organophosphate and nucleating agent technology, which is applied in the field of preparation of organophosphate nucleating agents, can solve the problems of large time and energy consumption, complicated operation, and reduced nucleation performance, and achieve low energy consumption and high nucleation efficiency The effect of high and narrow particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Weigh the crude material of 2,2′-methylene-bis(4-methyl, 6-tert-butylphenoxy) potassium phosphate, add it to the mixed organic solvent of acetone and 1,4-dioxane, In organic solvents, according to the mass ratio,

[0031] Acetone:1,4-dioxane=3:1,

[0032] After stirring and dissolving completely, add water to prepare a raw material solution, according to the mass ratio,

[0033] Organic solvent: water: crude 2,2'-methylene-bis(4-methyl, 6-tert-butylphenoxy) phosphate potassium = 3:0.4:1;

[0034] Place the above-mentioned raw material solution in a water bath of the ultrasonic generator at a temperature of 25°C. Turn on the ultrasonic wave and perform ultrasonic oscillation for 45 minutes, the ultrasonic frequency is 59kHz, the ultrasonic power density is 150 watts per liter of solution, and white flocculent precipitate is produced. Then suction filtration, and the filter cake was dried at 80°C for 2 hours to obtain the corresponding 2,2'-methylene-bis(4-methyl, 6-tert-butylp...

Embodiment 2

[0035] Weigh the crude material of 2,2'-methylene-bis(4,6-di-tert-butylphenoxy) sodium phosphate, add it to the acetone solvent, stir to dissolve completely, then add water to obtain a raw material solution, press Mass ratio,

[0036] Acetone solvent: water: 2,2'-methylene-bis(4,6-di-tert-butylphenoxy) sodium phosphate crude product=3:0.4:1,

[0037] Place the above-mentioned raw material solution in the water bath of the ultrasonic generator, the temperature of the water bath is 25° C., turn on the ultrasonic wave and perform ultrasonic oscillation for 45 minutes, the ultrasonic frequency is 59 kHz, and the ultrasonic power density is 100 W / L of the solution. A white flocculent precipitate is produced, and then filtered with suction. The filter cake is dried at 80°C for 2 hours to obtain a free-flowing white powder, which is the corresponding 2,2'-methylene-bis(4,6-di-tert-butyl) Phenoxy) sodium phosphate nucleating agent product. The product is a free-flowing white powder with ...

Embodiment 3

[0039] Weigh bis[2,2'-methylene-bis(4,6-di-tert-butylphenoxy) phosphoric acid] hydroxyaluminum crude raw material, add it to the mixed organic solvent of ethanol and petroleum ether, press in the organic solvent Mass ratio,

[0040] Ethanol: Petroleum Ether = 1:1,

[0041] After stirring and dissolving completely, add water to prepare a raw material solution, according to the mass ratio,

[0042] Organic solvent: water: bis[2,2'-methylene-bis(4,6-di-tert-butylphenoxy) phosphoric acid] crude aluminum hydroxy = 4:0.5:1,

[0043] Place the above-mentioned raw material solution in the water bath of the ultrasonic generator, the temperature of the water bath is 25° C., turn on the ultrasonic wave and perform ultrasonic oscillation for 45 minutes, the ultrasonic frequency is 40 kHz, and the ultrasonic power density is 100 W / L of the solution. A white flocculent precipitate is produced, and then filtered with suction. The filter cake is dried at 80°C for 2 hours to obtain a free-flowing whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com