Patents

Literature

73results about How to "High nucleation efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Refining process of Al-Ti-B intermediate alloy for pure aluminum

InactiveCN101328549AHigh nucleation efficiencyAccelerate the speed of dissolution and diffusionHigh energyUltrasonic vibration

The invention provides a process of Al-Ti-B master alloy on grain refinement of pure aluminum. In the invention, except for the addition of the Al-Ti-B master alloy grain refiner in the aluminum melt, the high energy ultrasonic vibration treatment is also adopted, thereby speeding up dissolving and dispersing of TiAl3 phase, increasing the dispersive distribution degree of TiB2 grains and further improving the grain refinement efficiency of the Al-Ti-B master alloy. Industrial pure aluminum as-cast crystal grains treated by the grain refinement process of the invention are all fine isometric crystals, the average size of which is less than 150 mu m, thereby not only improving the quality of aluminum materials but also meeting the requirements on the subsequent rolling of aluminum products.

Owner:BAOSHAN IRON & STEEL CO LTD

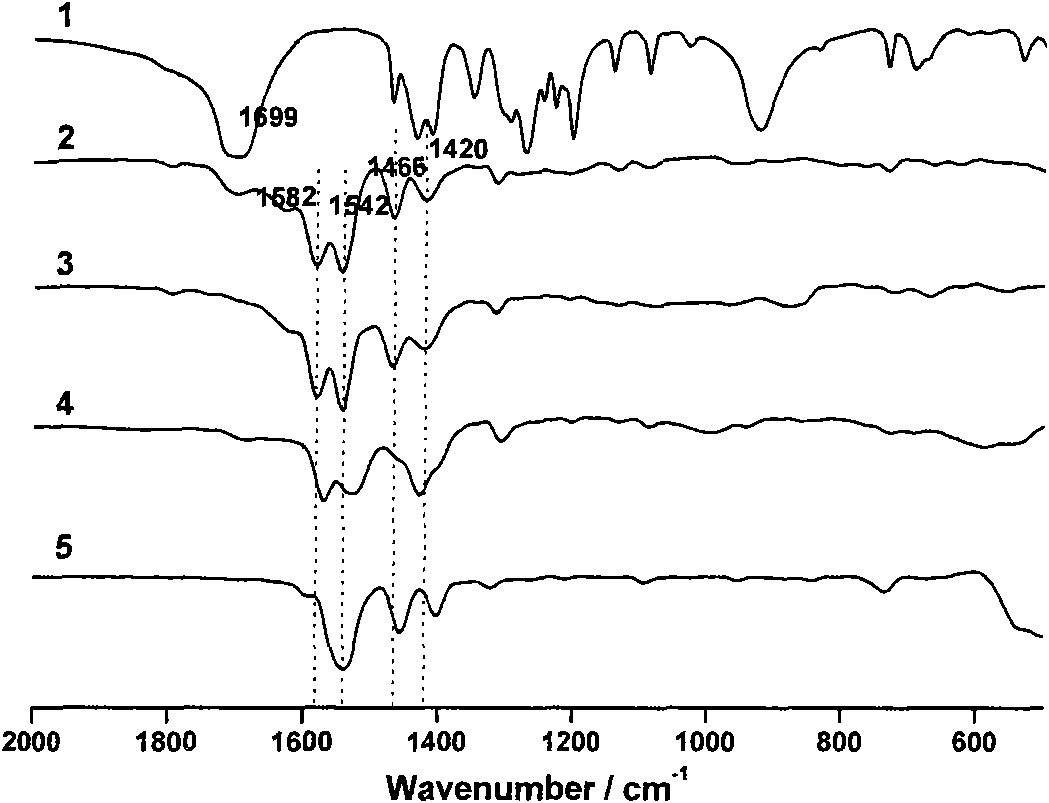

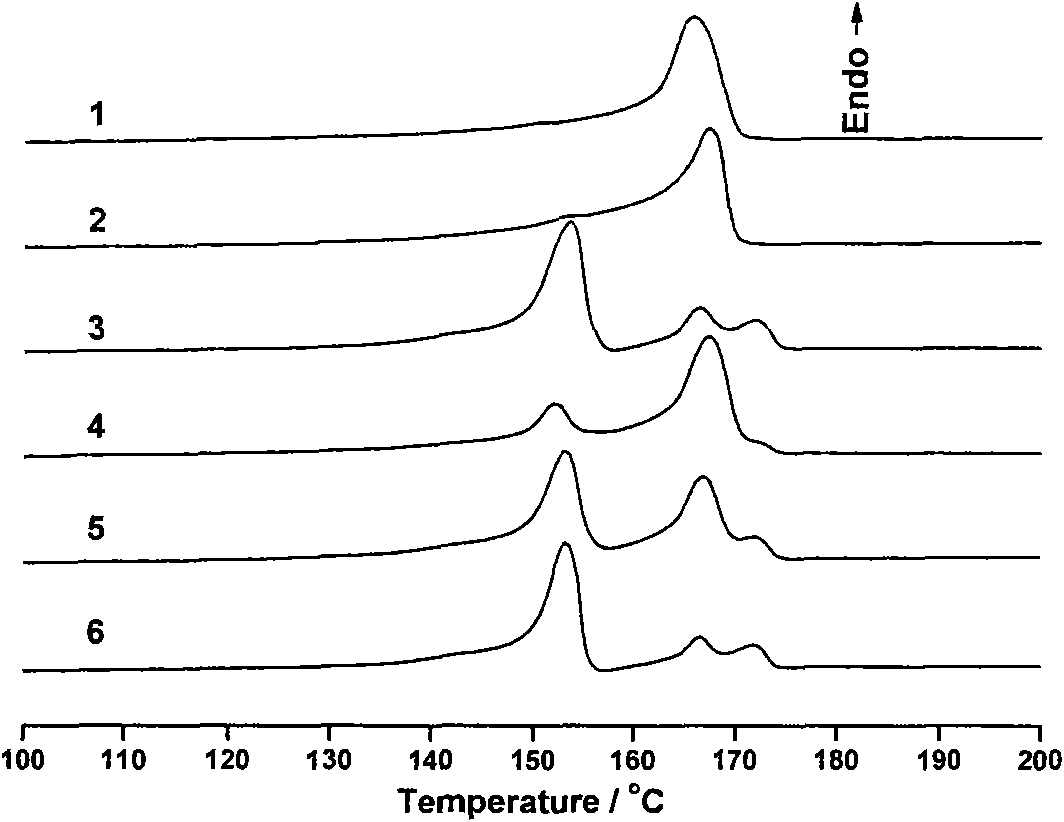

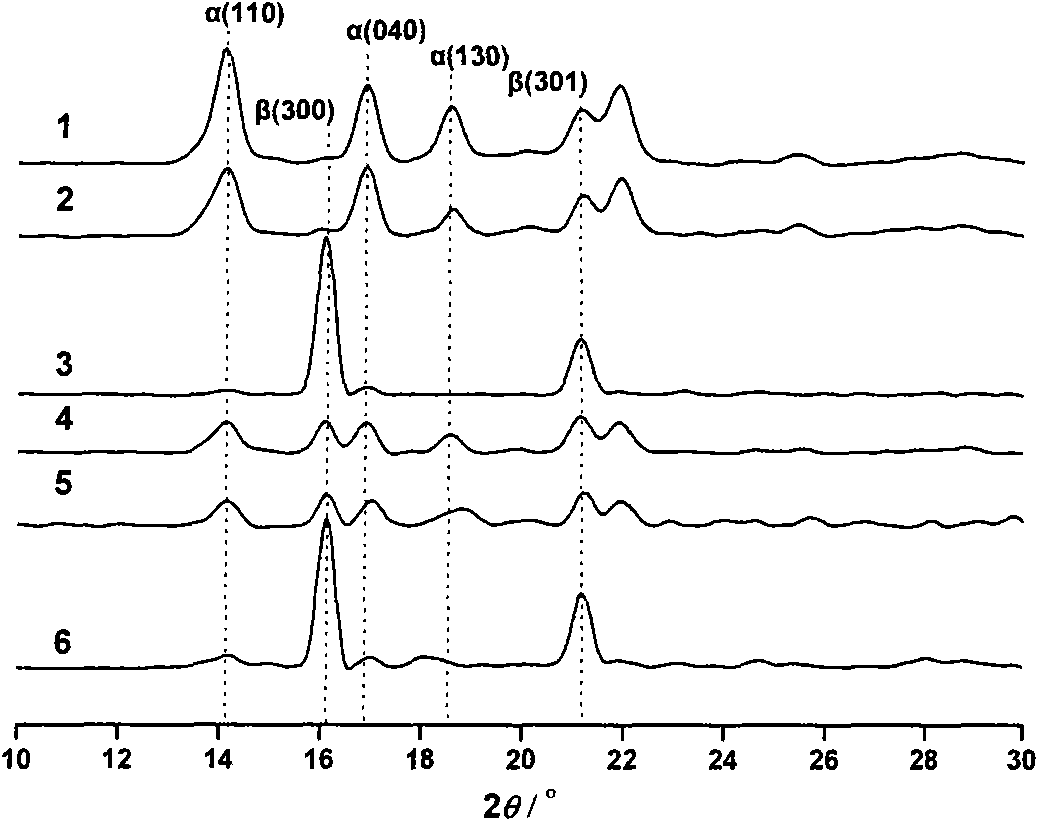

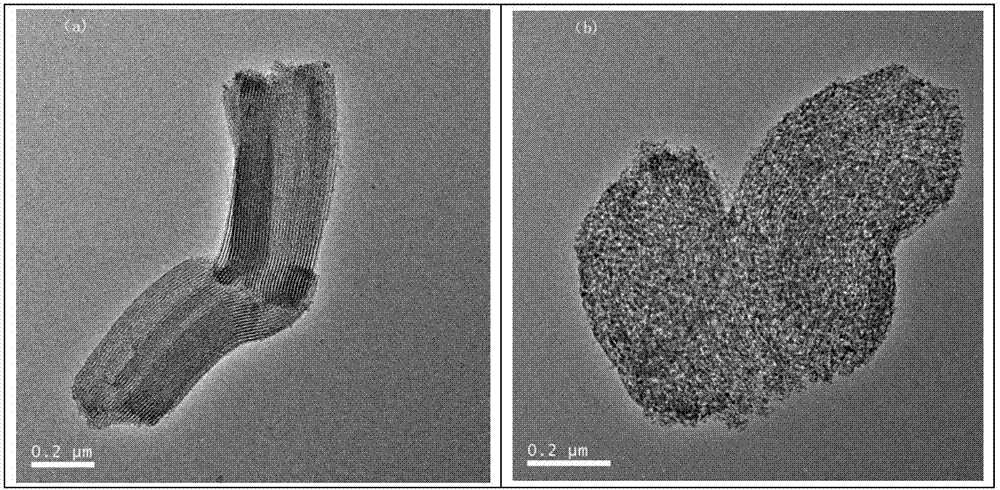

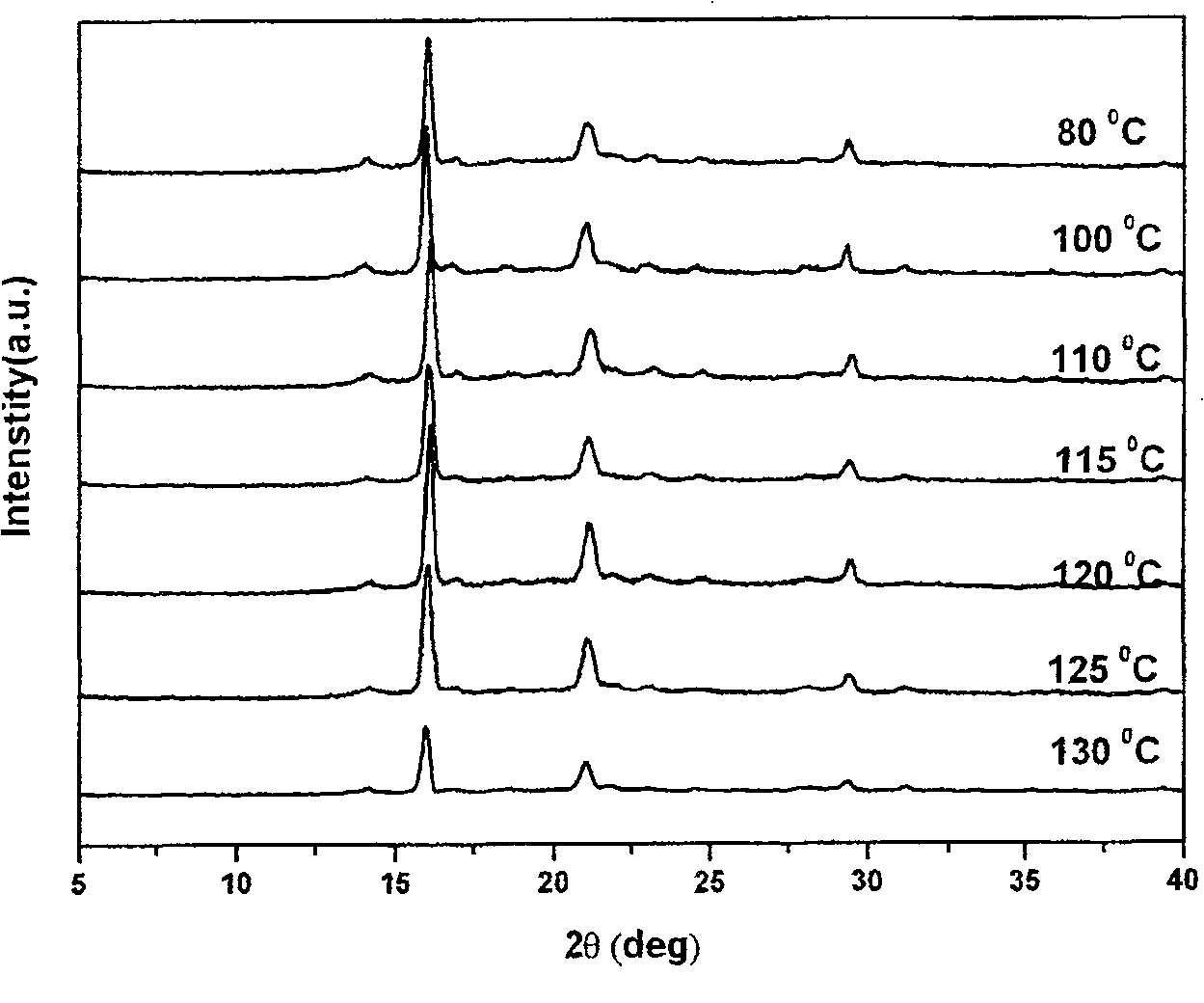

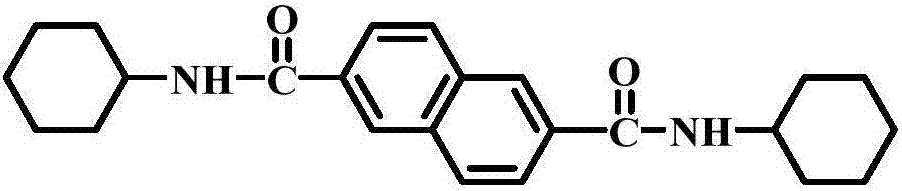

Metal oxide supported beta-crystal nucleating agent and preparation method of beta-crystal nucleating agent

InactiveCN101580601AHigh nucleation efficiencyIncreased effective nucleation sitesCarboxylic acidDicarboxylic acid

The invention discloses a metal oxide supported beta-crystal nucleating agent and a preparation method of the beta-crystal nucleating agent. The nucleating agent is prepared by mixing fatty dicarboxylic acid and the metal oxide according to the weight ratio of the fatty dicarboxylic acid to metal oxide being 1:5-1,000. The beta-crystal nucleating agent takes the metal oxide as a carrier to make the fatty dicarboxylic acid highly disperse on the surface of the metal oxide and make formed effective nucleating points increase, thereby improving the nucleating efficiency of the beta-crystal nucleating agent; and the preparation method is simple, reduces the usage of the fatty dicarboxylic acid at the same time, and remarkably reduces the cost of the beta-crystal nucleating agent. The beta-crystal nucleating agent takes the metal oxide as the carrier, has the functions of strengthening and toughening polypropylene, improves the yield strength and modulus of beta-crystal polypropylene, and enables the prepared beta-crystal polypropylene to be more beneficial to producing expanded films and other materials.

Owner:SUN YAT SEN UNIV

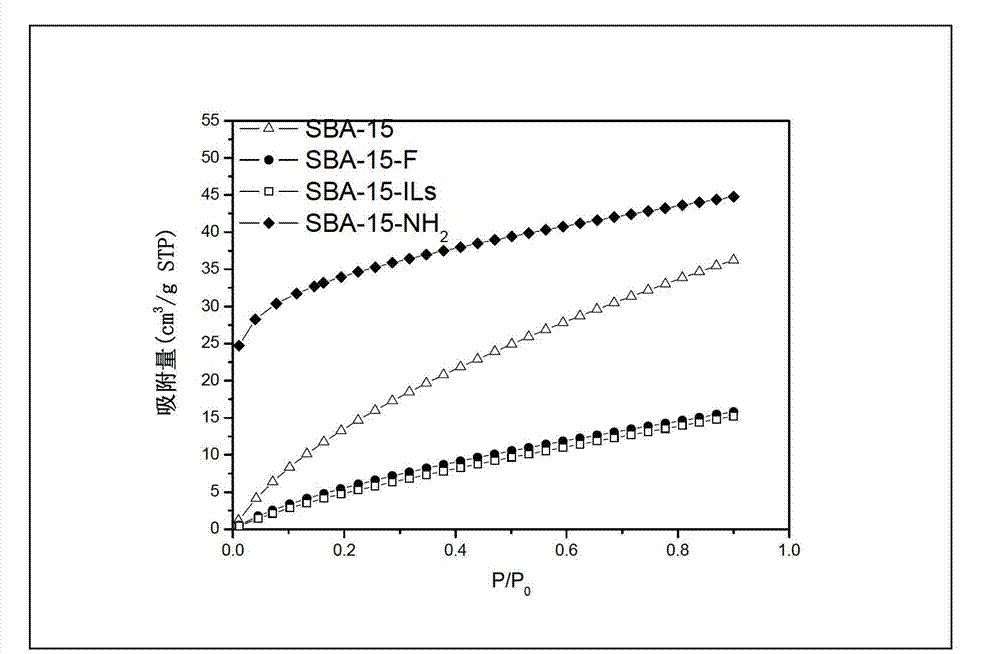

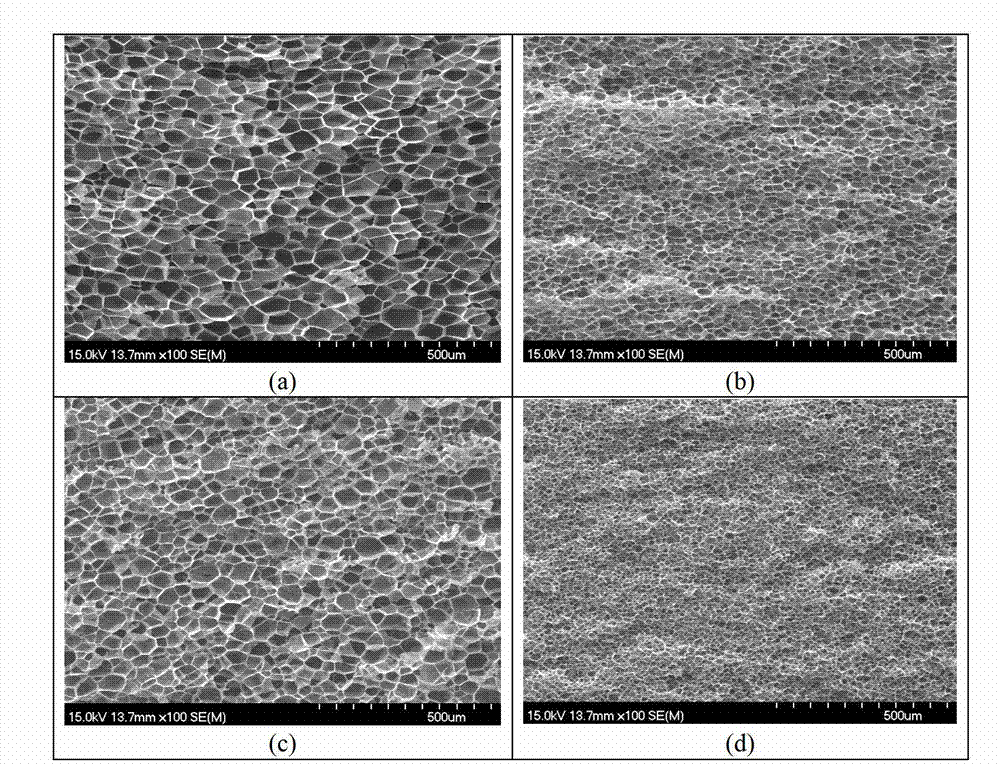

Polymer supercritical carbon dioxide foaming nucleating agent and preparation method and application thereof

The invention discloses a preparation method of polymer supercritical carbon dioxide foaming nucleating agent. The preparation method includes: adding ethanol solution dissolving CO2-hydrophilic substances into porous inorganic nano particles under the condition of 0.1MPa, sufficiently stirring and directly drying to obtain the polymer supercritical carbon dioxide foaming nucleating agent. The CO2-hydrophilic substances are ion liquid and fluorosilane or silane contained coupling agent. Mass usage of the CO2-hydrophilic substances is 8-50% of the mass of the porous inorganic nano particles. The invention further discloses application of the polymer supercritical carbon dioxide foaming nucleating agent in polymer supercritical carbon dioxide foaming. By the nucleating agent, foaming agent, namely supercritical carbon dioxide, can be enriched in holes and on the surface of particles, and accordingly, nucleating efficiency is high, and prepared polymer foaming material has the advantages of small foaming hole size, uniform distribution and high density.

Owner:HANGZHOU COLORICH CHEM MATERIALS

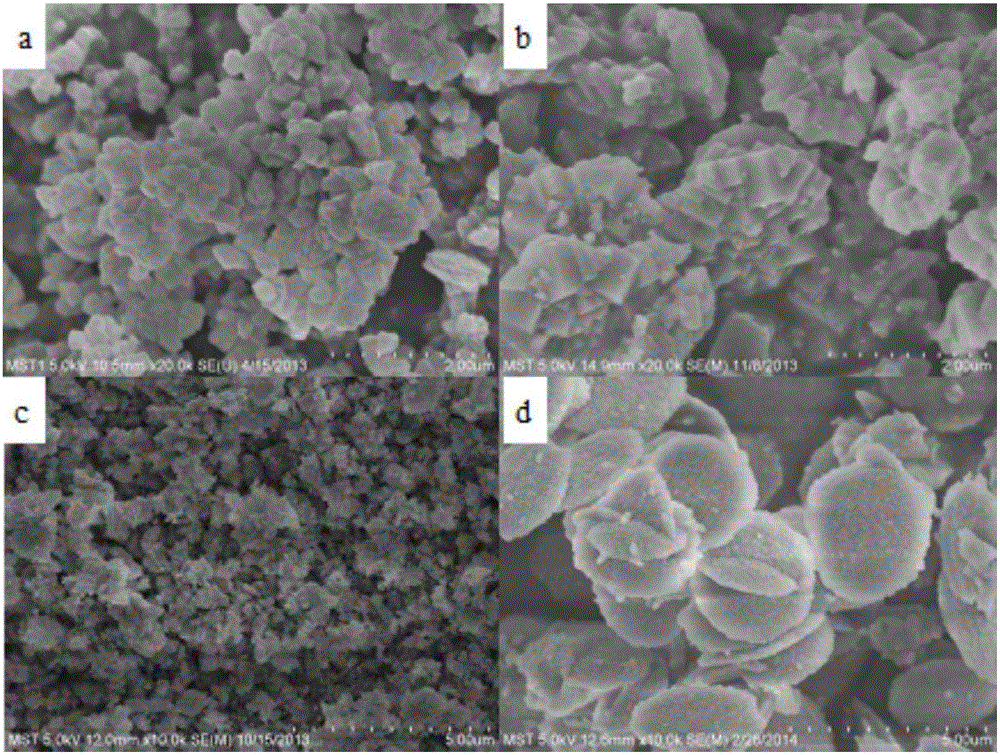

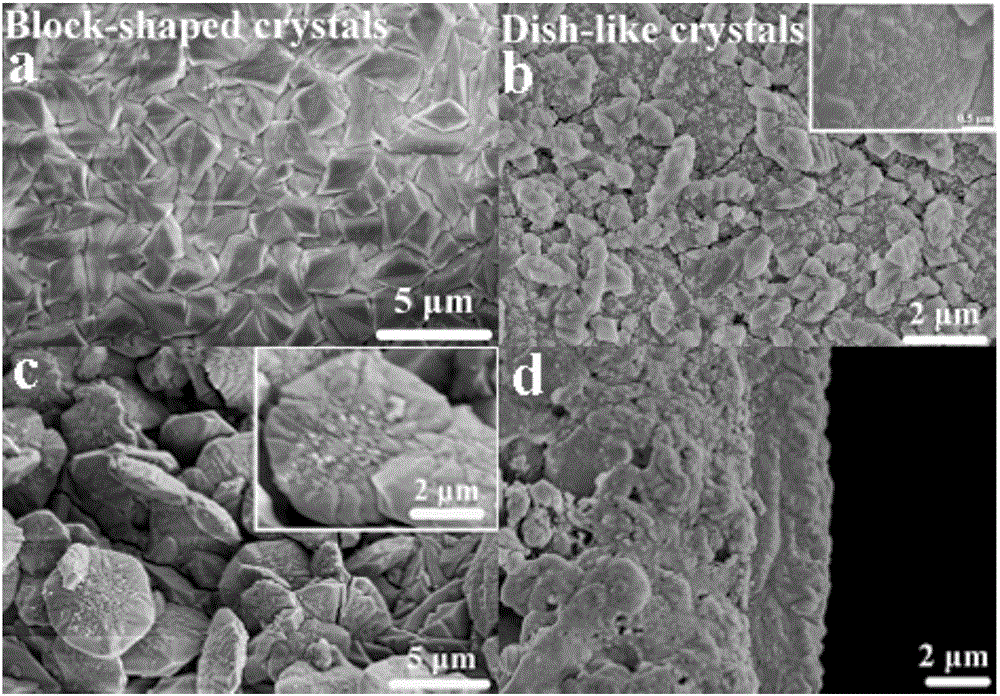

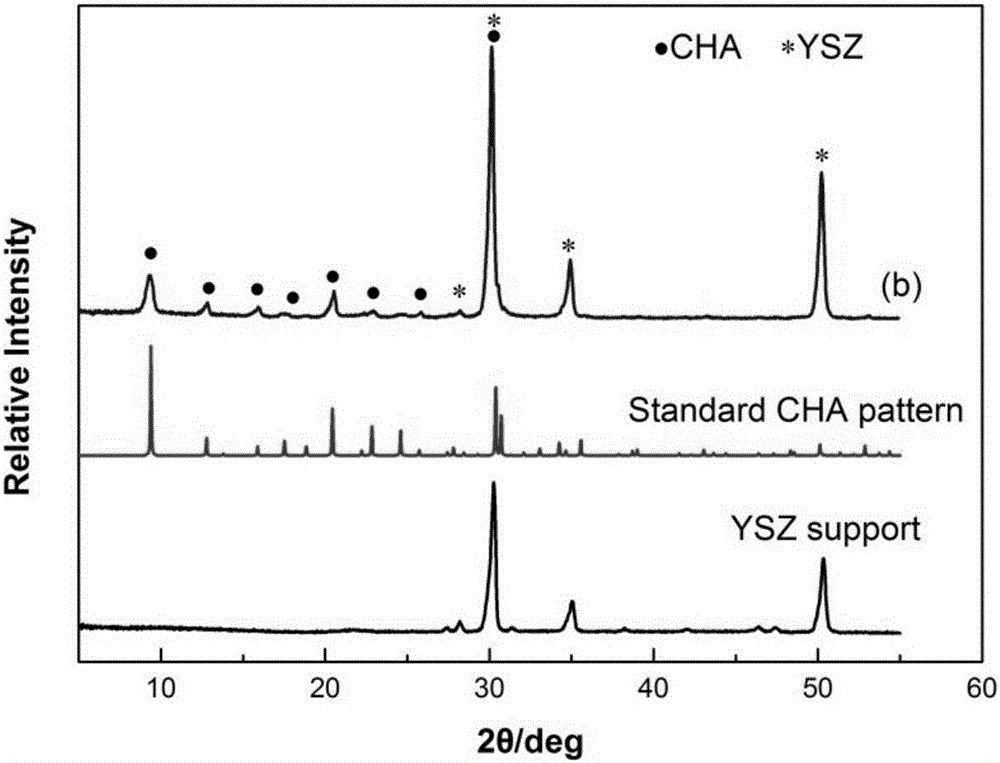

Method for preparing CHA molecular sieve membrane in clean liquid

InactiveCN105921033ALarge specific surface areaHigh nucleation efficiencySemi-permeable membranesMolecular sieveFiber

The invention provides a method for preparing a CHA molecular sieve membrane in a clean liquid, and particularly relates to synthesizing of the CHA molecular sieve membrane on the outer surface or the inner surface of a tubular hollow fiber or multiple channels. Without using a templating agent, the method regulates the molar ratio of components in a synthesis liquid and synthesizes the CHA molecular sieve membrane with high stability, high throughput and controllable morphology, and the synthesized membrane shows an excellent separation property. As no templating agent is used, the method is favorable for promotion of mass production of the CHA molecular sieve membrane.

Owner:NANJING TECH UNIV

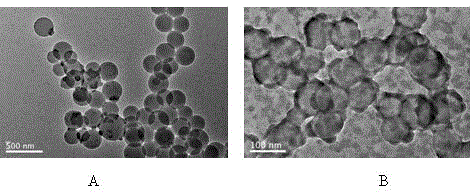

Method for synthesizing Pickering-type emulsion through semi-continuous polymerization

The invention discloses a method for synthesizing a Pickering-type emulsion through semi-continuous polymerization, and belongs to the field of high molecule polymerization. The method comprises the following steps: preparing a water phase, preparing a dropping component for semi-continuous emulsion polymerization, and preparing the Pickering-type emulsion through the semi-continuous emulsion polymerization, namely obtaining the Pickering-type emulsion. By the method, the using proportion (0.1-2.0wt%) of solid particles can be obviously reduced, latex particles with the size being about 100 nm can be formed, the coating form of the solid particles on the surfaces of the latex particles is intact, and the stability of the emulsion is high.

Owner:CHANGZHOU UNIV

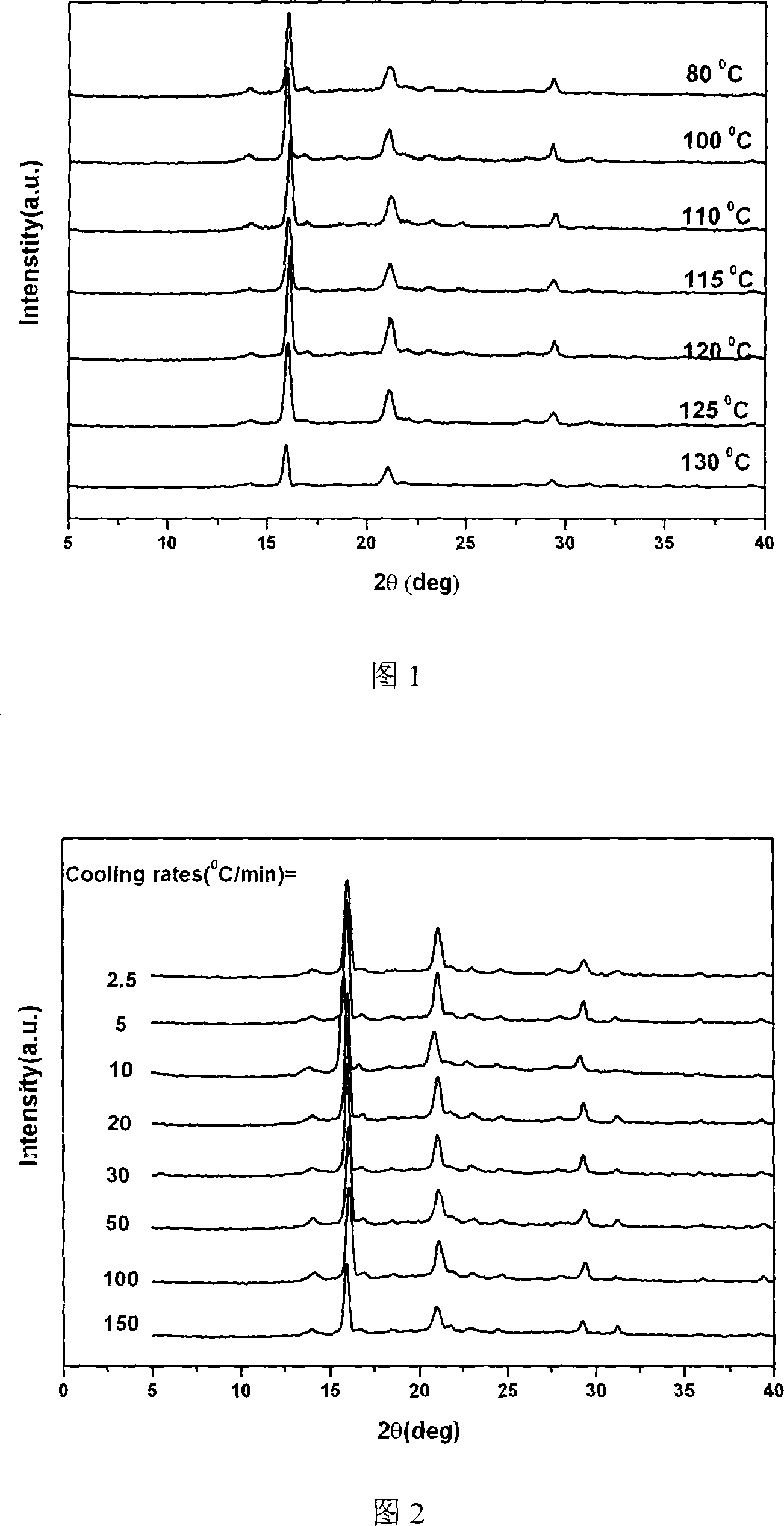

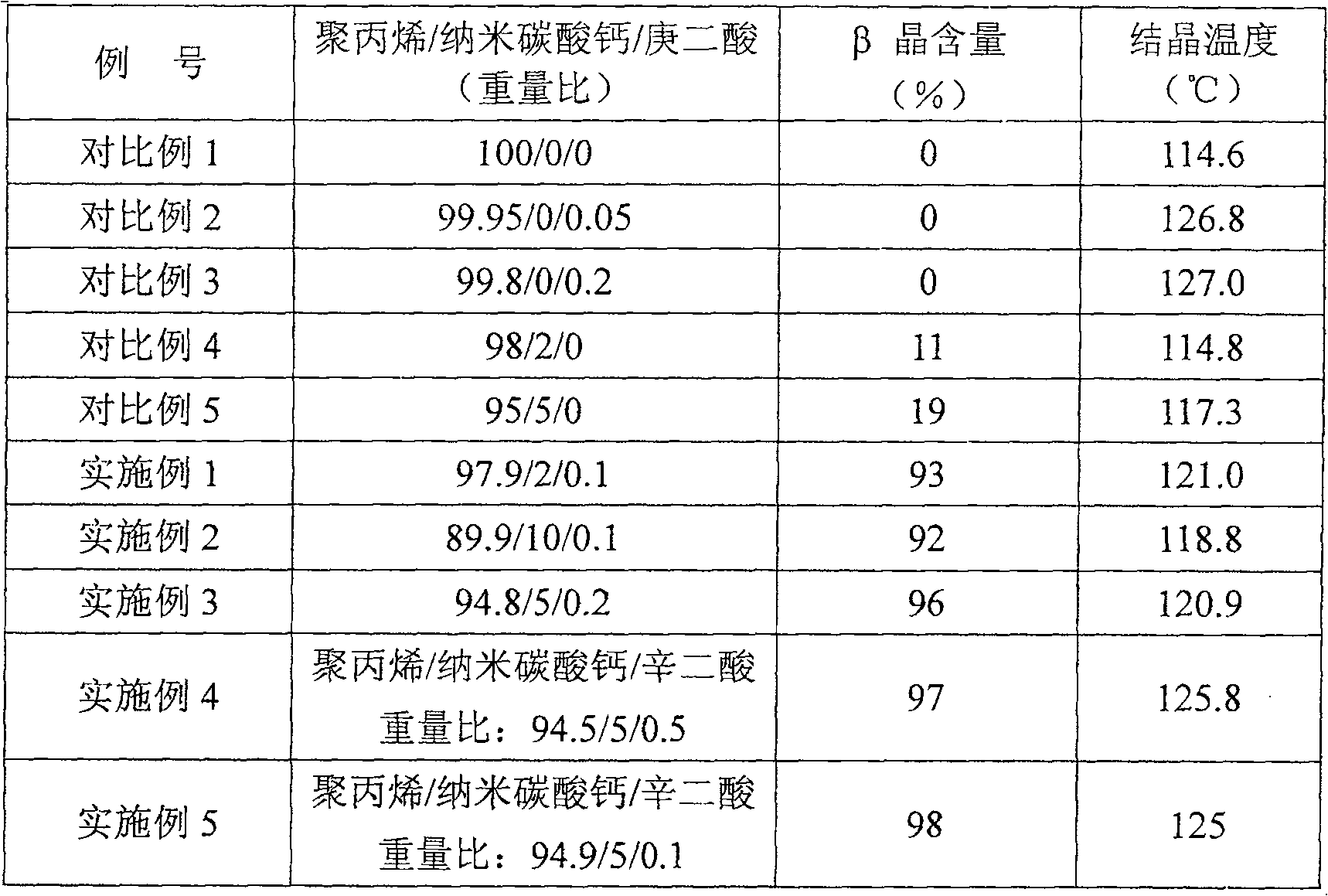

Supported beta crystal core formation agent and preparation method thereof

ActiveCN101157771AIncreased effective nucleation sitesHigh nucleation efficiencyChemical reactionCarboxylic acid

The present invention discloses a load-type Beta-nucleating agent and a preparation method thereof, the load-type Beta-nucleating agent of the present invention consists of nano calcium carbonate and aliphatic dicarboxylic acid, and the weight ratio of which is 5 to 1000: 1. The present invention adopts the nano calcium carbonate with a big surface area as a carrier, adopts a simple method to highly disperse the dicarboxylic acid on the nano-calcium carbonate surface, makes use of a chemical reaction of the nano-calcium carbonate and the dicarboxylic acid to form the high efficient beta-nucleating agent which is the same with the mixture of pimelic acid and calcium stearate aiming at the problems of the existing beta-nucleating agents. The present invention realizes the purposes of reducing the consumption of the dicarboxylic acid, reducing the cost and improving the nucleating efficiency as the dicarboxylic acid on the nano-calcium carbonate is highly dispersed and the effective nucleating points are only formed on the surface of the nano-calcium carbonate.

Owner:SUN YAT SEN UNIV

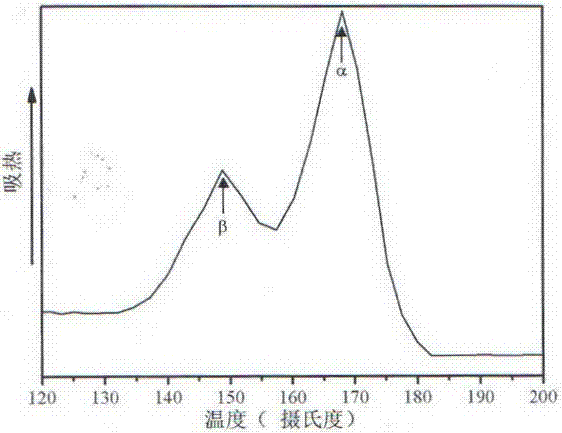

Medical polypropylene material

The invention discloses a medical polypropylene material. The medical polypropylene material comprises: by weight, 100 parts of polypropylene resin, 0.5 to 2 parts of a cooling masterbatch, 0.2 to 0.3 parts of a transparent nucleating agent, 5 to 10 parts of a flexibilizer, 0.5 to 1 part of a high-molecular antistatic agent, 0.5 to 1 part of a lubricant ethylene bis-stearamide (EBS) and 0.2 to 0.5 parts of anti-oxidants. The polypropylene resin is a homopolymer. The high-molecular antistatic agent is hydroxyethyl fatty amine. The transparent nucleating agent is an alpha-crystal form nucleating agent. The flexibilizer is an ethane-octylene-propylene copolymer. The invention also provides a preparation method of the medical polypropylene material. The medical polypropylene material has the advantages of good toughness, especially, good low temperature toughness, good liquidity, high transparency and good antistatic effects. Therefore, the medical polypropylene material can be utilized for mass production of multi-cavity molds.

Owner:CHENGDU XINJIN SHIFENG MEDICAL APP ANDINSTR CO LTD

Supported beta crystal core formation agent and preparation method thereof

ActiveCN101157771BIncreased effective nucleation sitesHigh nucleation efficiencyChemical reactionCarboxylic acid

The present invention discloses a load-type Beta-nucleating agent and a preparation method thereof, the load-type Beta-nucleating agent of the present invention consists of nano calcium carbonate and aliphatic dicarboxylic acid, and the weight ratio of which is 5 to 1000: 1. The present invention adopts the nano calcium carbonate with a big surface area as a carrier, adopts a simple method to highly disperse the dicarboxylic acid on the nano-calcium carbonate surface, makes use of a chemical reaction of the nano-calcium carbonate and the dicarboxylic acid to form the high efficient beta-nucleating agent which is the same with the mixture of pimelic acid and calcium stearate aiming at the problems of the existing beta-nucleating agents. The present invention realizes the purposes of reducing the consumption of the dicarboxylic acid, reducing the cost and improving the nucleating efficiency as the dicarboxylic acid on the nano-calcium carbonate is highly dispersed and the effective nucleating points are only formed on the surface of the nano-calcium carbonate.

Owner:SUN YAT SEN UNIV

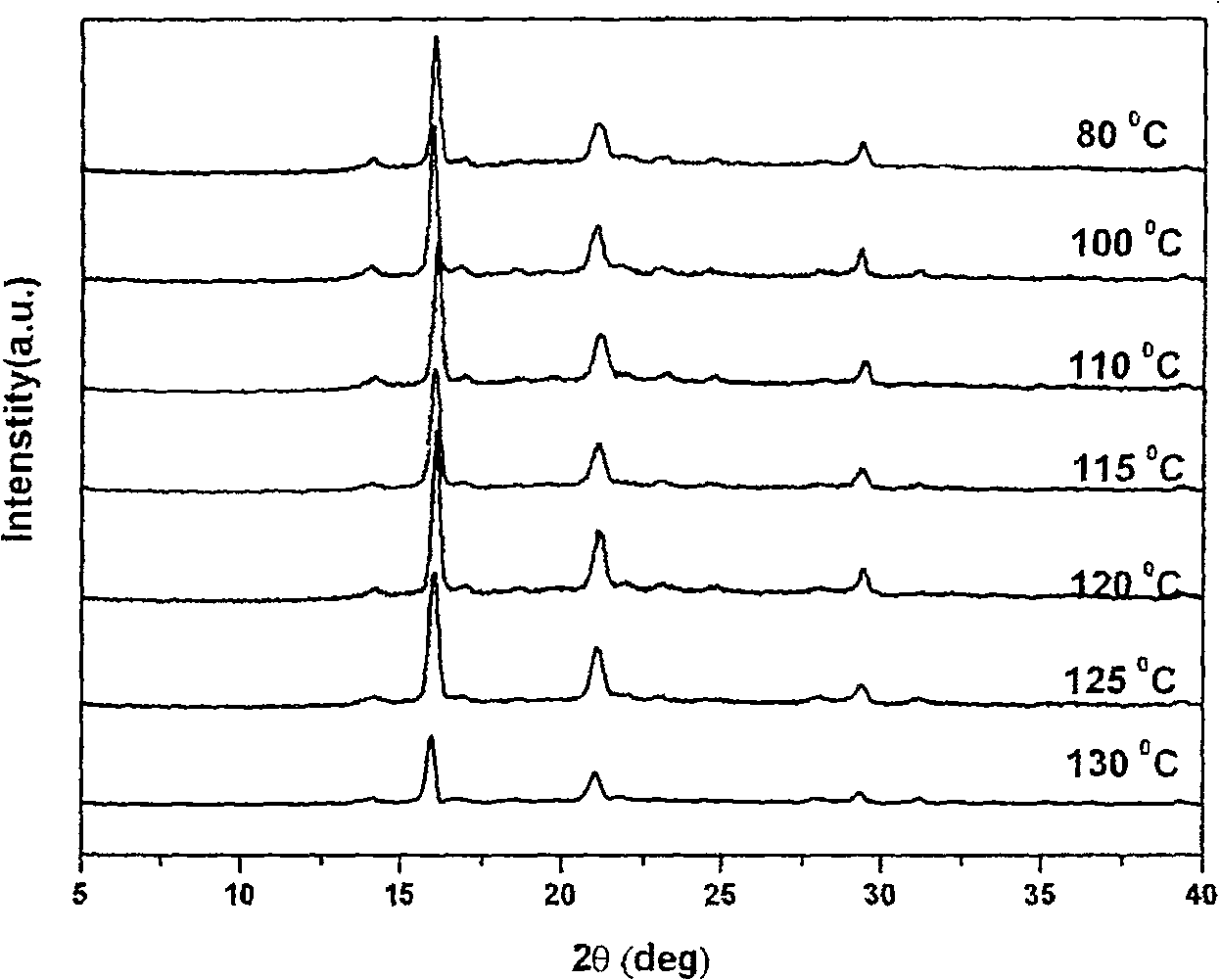

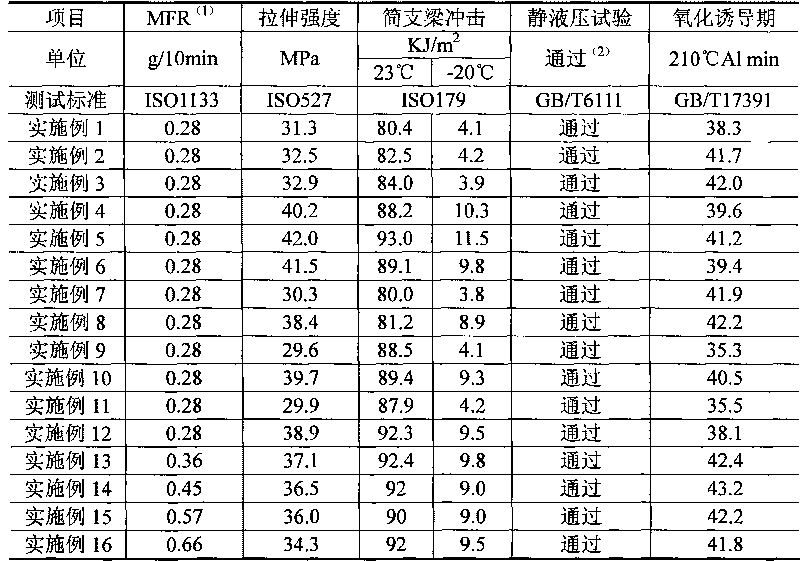

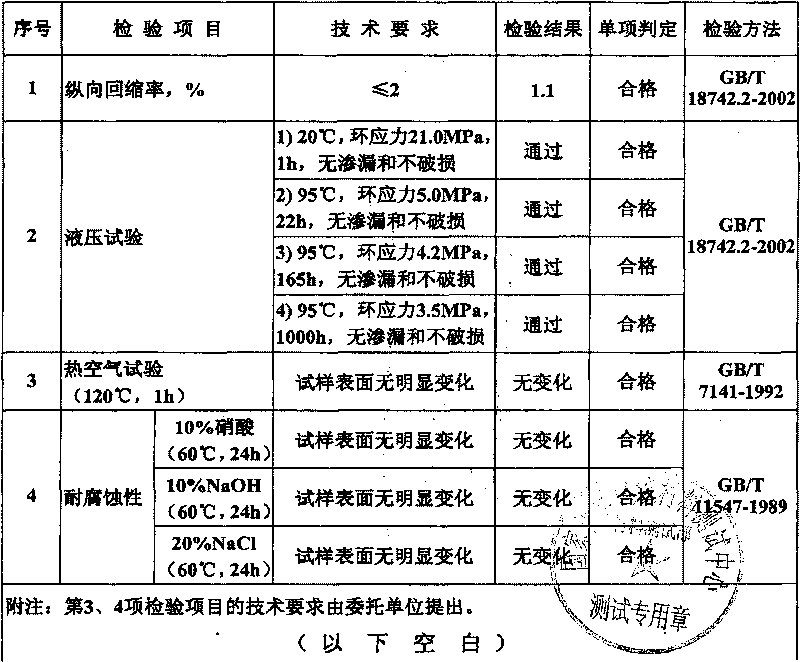

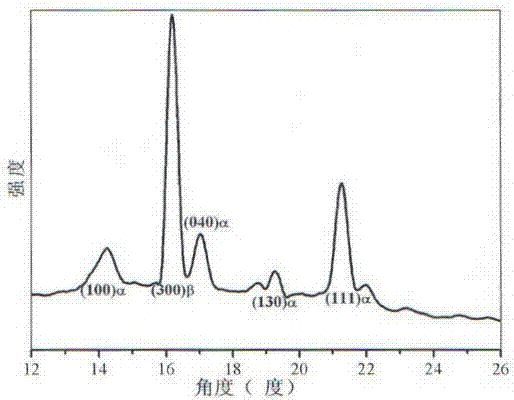

Polypropylene composition for chemical pipelines and preparation method thereof

The invention discloses a polypropylene composition for chemical pipelines and a preparation method thereof, the composition is endowed with the characteristics, including excellent impact resistance, great chemical corrosion resistance, high heat resistance and heat deflection temperature, good long-term creeping property and extrusion processability and the like, by mixing beta nucleating agentsystem, antioxidant system and gray beta crystal promoting master batch with homopolymerized polypropylene which is generated by gas phase method as basic resin. The composition is mainly applied to manufacturing pipelines and can also be used for producing storage tank and pickling tank and for the transportation and the storage of chemical fluids, and the products thereof are extensively applied to industrial fields, such as electronics, medicines, chemical industry, food, semiconductor, steel, etc.

Owner:CHINA PETROLEUM & CHEM CORP +1

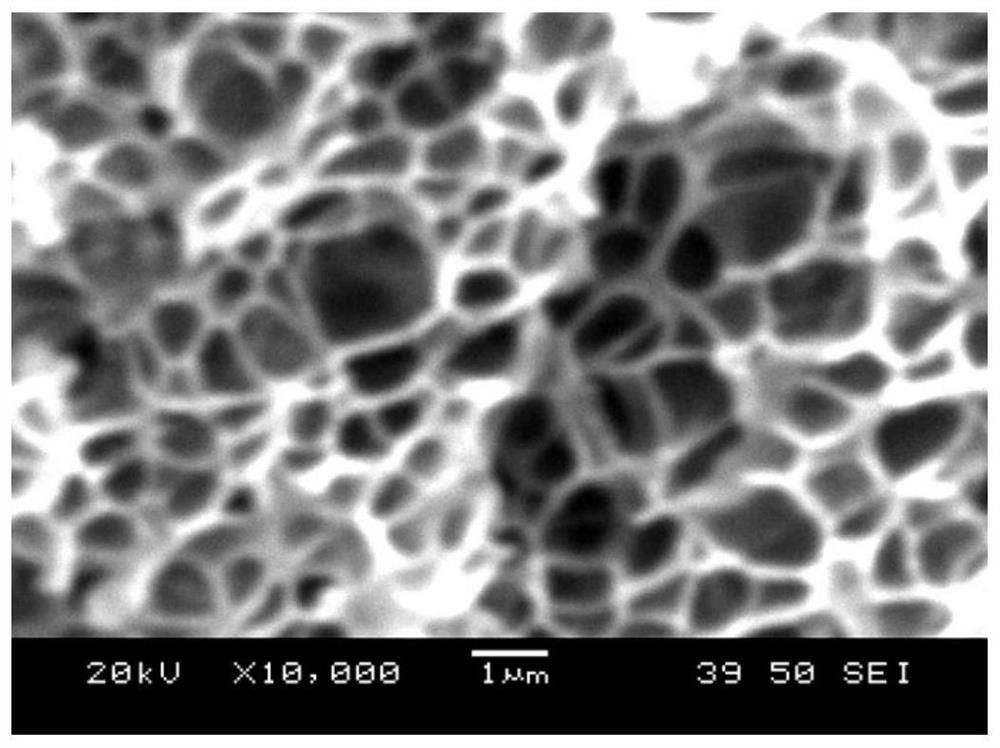

Polydopamine for Polypropylene beta nucleating agent and polydopamine/polypropylene composite

The invention belongs to the technical field of preparation of promoters for high polymer materials and particularly relates to a preparing method for a multifunctional and efficient beta nucleating agent for isotatic polypropylene materials. It is indicated that polydopamine can be used in the polypropylene beta nucleating agent. The multifunctional and efficient beta crystal nucleating agent is high in nucleating efficiency, good in compatibility with polypropylene matrixes, simple in preparing method and capable of improving the thermal oxidation stability of polypropylene materials.

Owner:SICHUAN UNIV

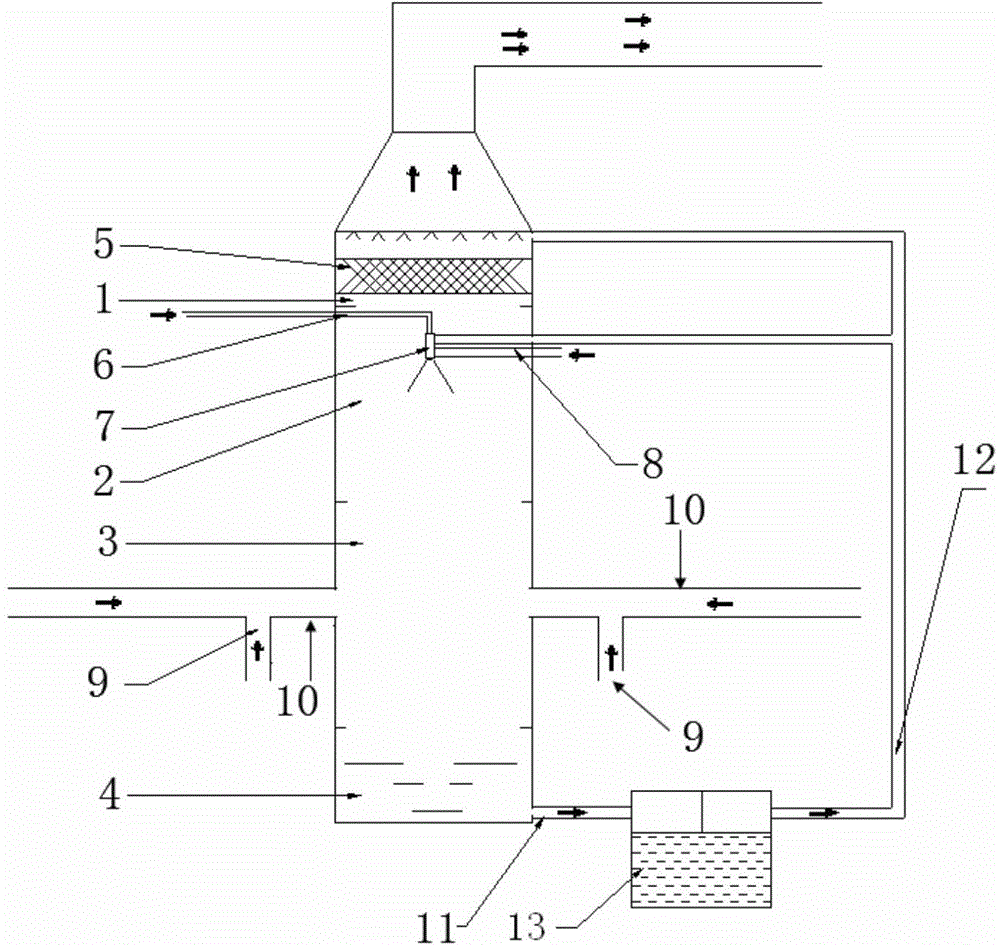

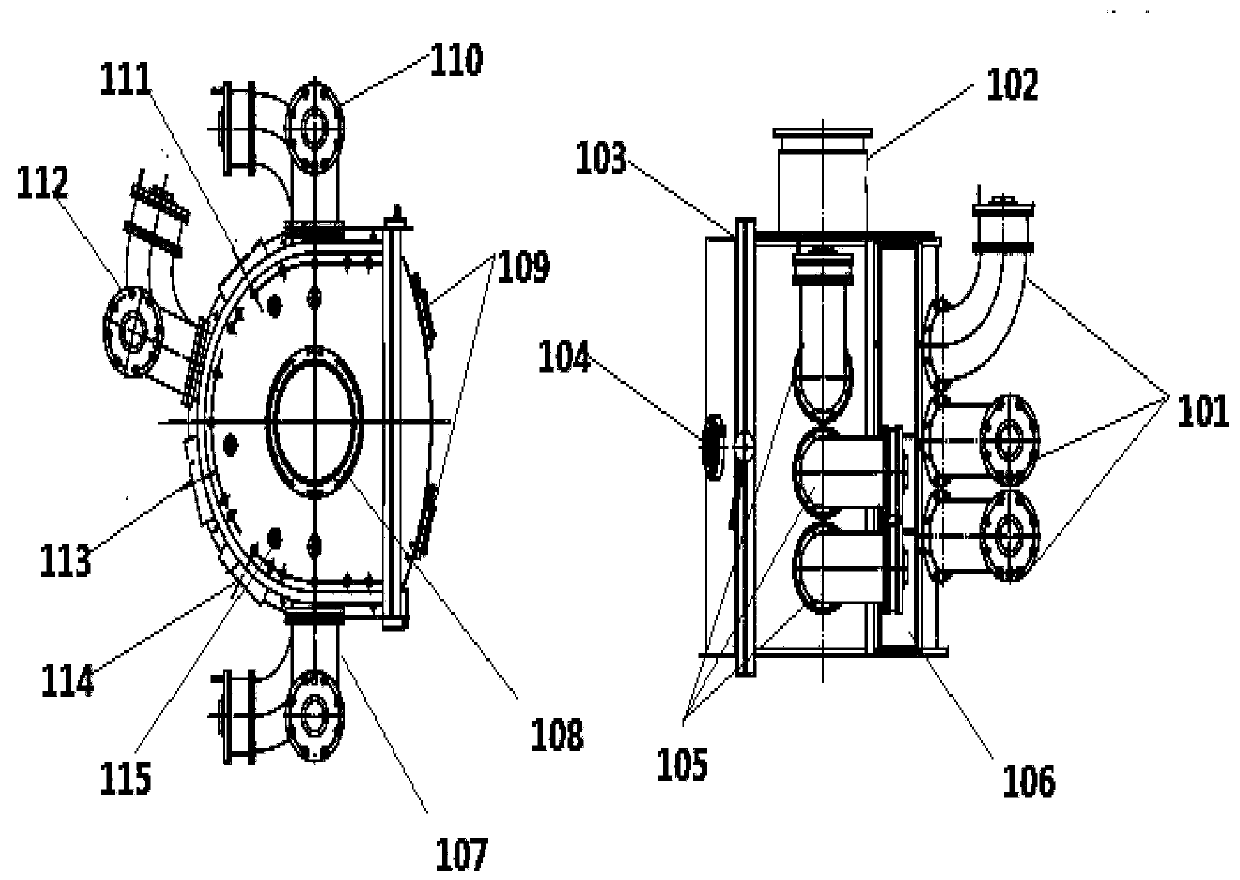

Device and method for removing fine particles from gas

ActiveCN104548824AAchieve removalIncrease supersaturationUsing liquid separation agentWastewaterSpray nozzle

The invention discloses a device and a method for removing fine particles from gas. The device for removing the fine particles from the gas is characterized by comprising a dust bearing wastewater area, a preliminary steam phase change area, a multiphase spraying phase change and disturbance mass transfer dedusting area and a demisting area sequentially from the bottom up, wherein a demister is arranged in the demisting area; the multiphase spraying phase change and disturbance mass transfer dedusting area is provided with a multiphase nozzle; an air inlet end of the multiphase nozzle is connected with a high pressure air line; a water inlet end of the multiphase nozzle is connected with a water pipe; and a steam inlet end of the multiphase nozzle is connected with a first steam line. The method for removing the fine particles from the gas is characterized by comprising the following steps: A, fabricating a separation device which comprises the dust bearing wastewater area, the preliminary steam phase change area, the multiphase spraying phase change and disturbance mass transfer dedusting area and the demisting area sequentially from the bottom up. The device and the method achieve removal of the fine particles from the gas by a steam phase change principle and spray combined manner.

Owner:CHONGQING UNIV

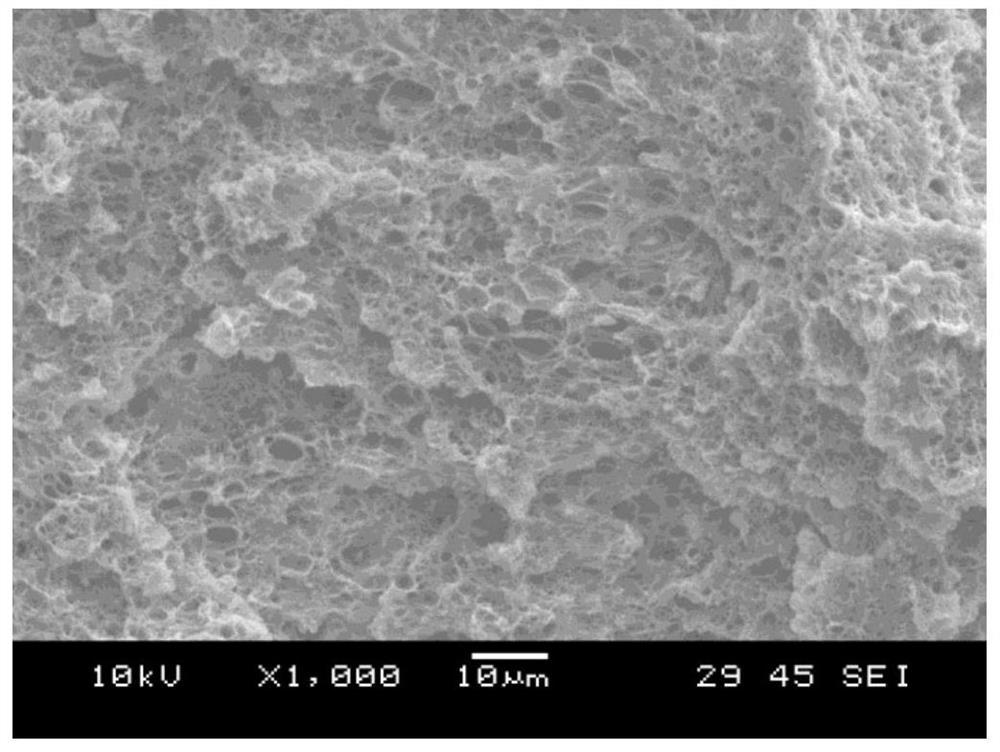

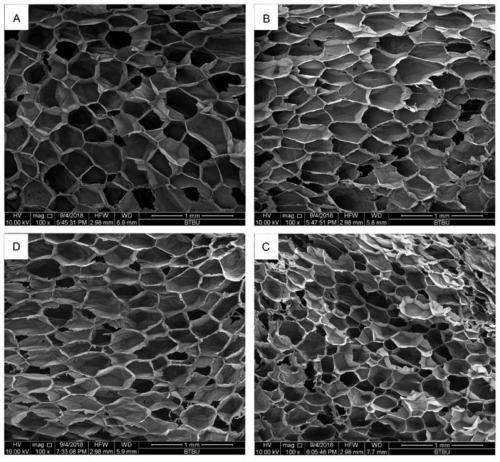

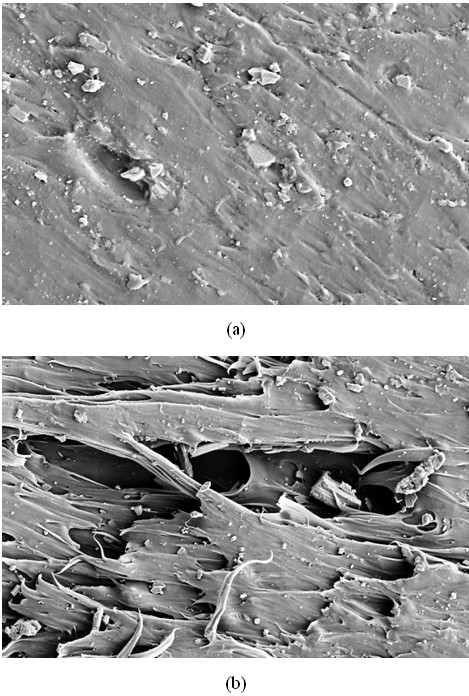

Homo-polypropylene/carbon fiber/montmorillonite composite material and preparation method thereof

The invention relates to a homo-polypropylene / carbon fiber / montmorillonite composite material and a preparation method of the homo-polypropylene / carbon fiber / montmorillonite composite material. The homo-polypropylene / carbon fiber / montmorillonite composite material is prepared from the following raw materials in parts by weight: 85 to 95 parts of homo-polypropylene, 5 to 10 parts of carbon fibers, 2 to 3 parts of organic montmorillonite, and 3 to 5 parts of foaming masterbatches, the foaming masterbatches are prepared from the following raw materials in parts by weight: 60 to 70 parts of polyethylene, 20 to 30 parts of foaming agents, 1 to 3 parts of foam stabilizers, 3 to 5 parts of nucleating agents, 0.5 to 1.5 parts of zinc oxide, 0.5 to 1 part of a titanate coupling agent NDZ-201, 3 to 5 parts of PE wax and 0.5 to 1 part of zinc stearate. According to the homo-polypropylene / carbon fiber / montmorillonite composite material disclosed by the invention, the mechanical properties are excellent, the tensile strength reaches 36.9 MPa, the impact strength reaches 55.1 kJ / m<2>, and the flexural modulus reaches 1590 MPa. The foaming material has best foaming and biggest cell density, the cell density reaches 2.3*10<7> / cm3, and the porosity of the foaming material is 17.7%.

Owner:GUANGZHOU JUZHU GENERAL TECH INST CO LTD

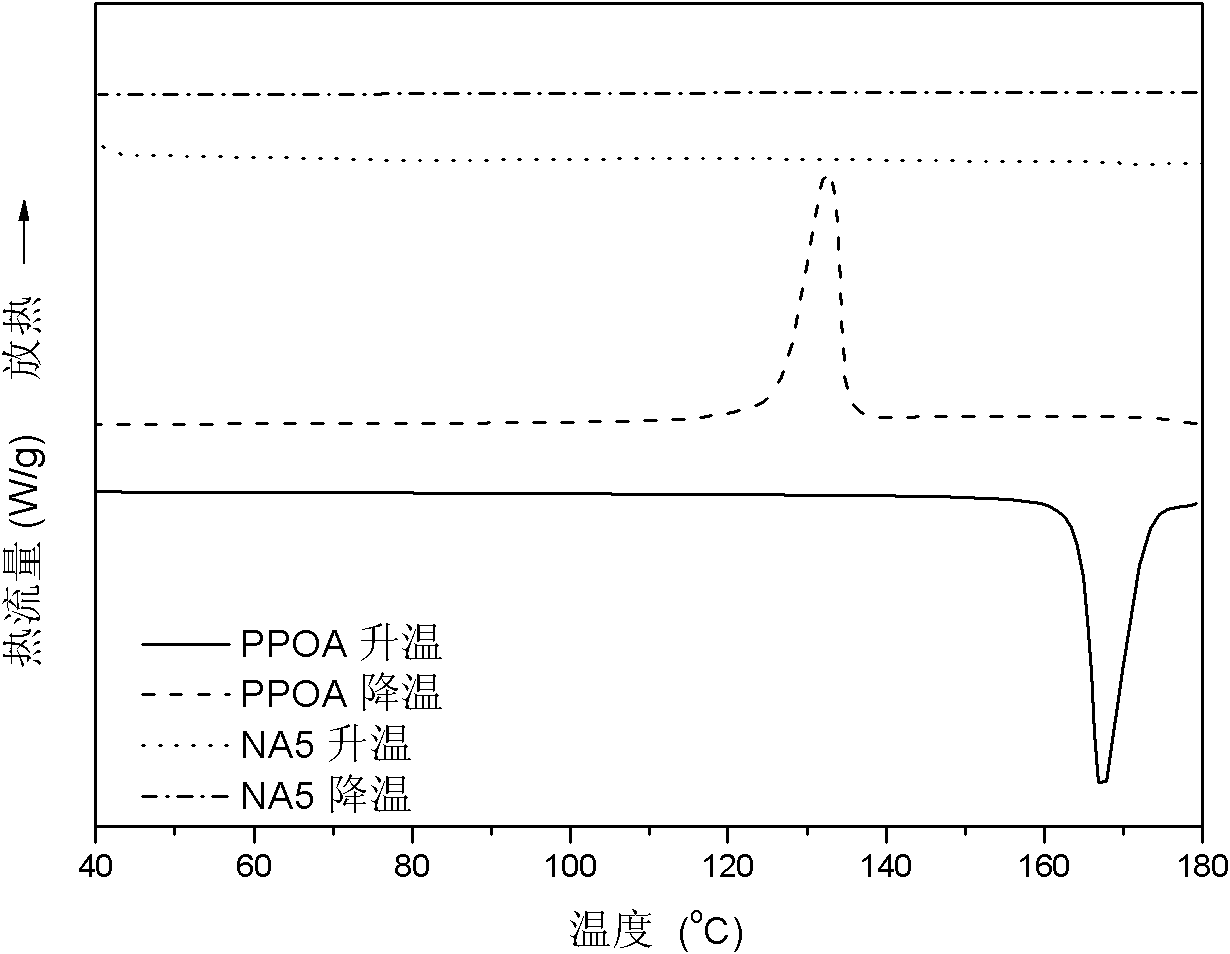

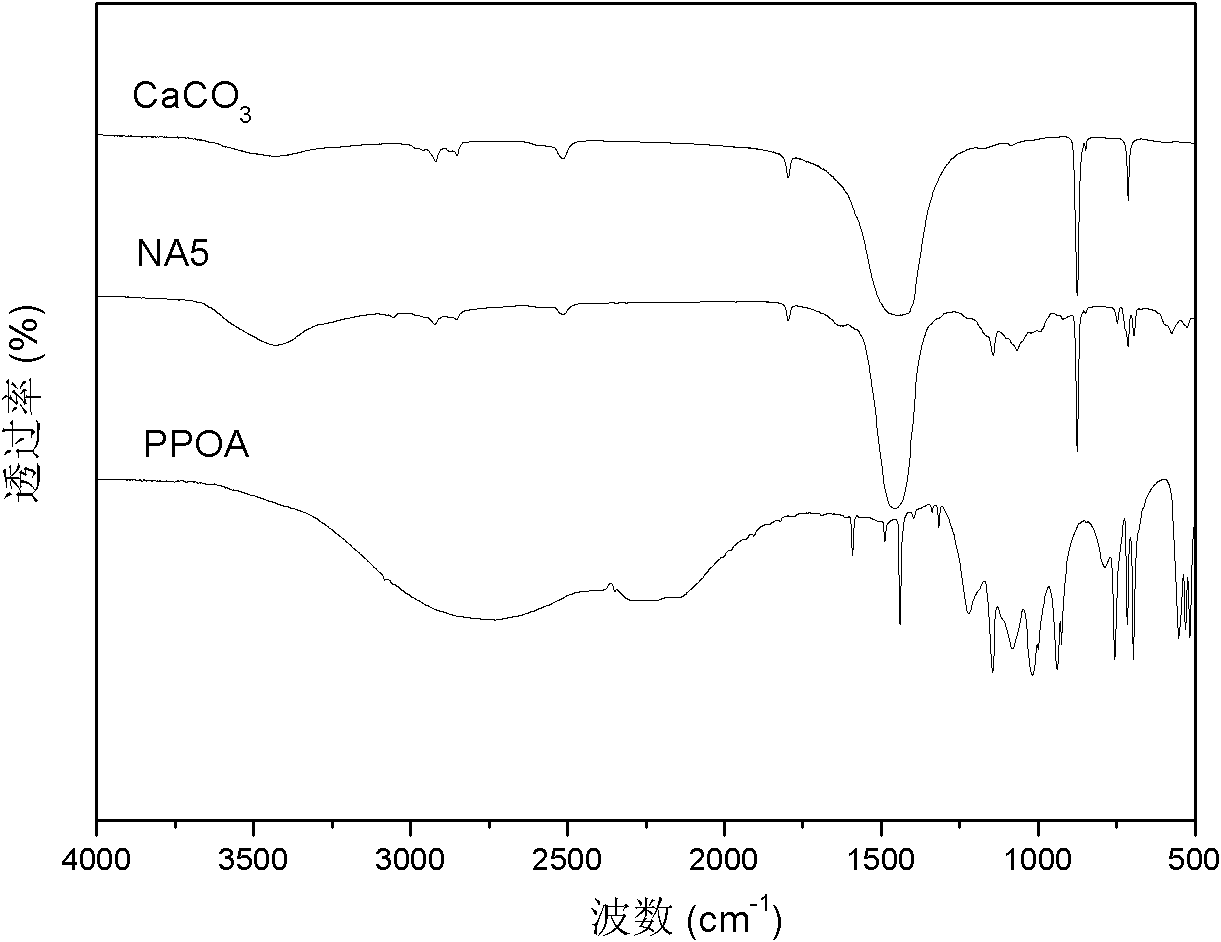

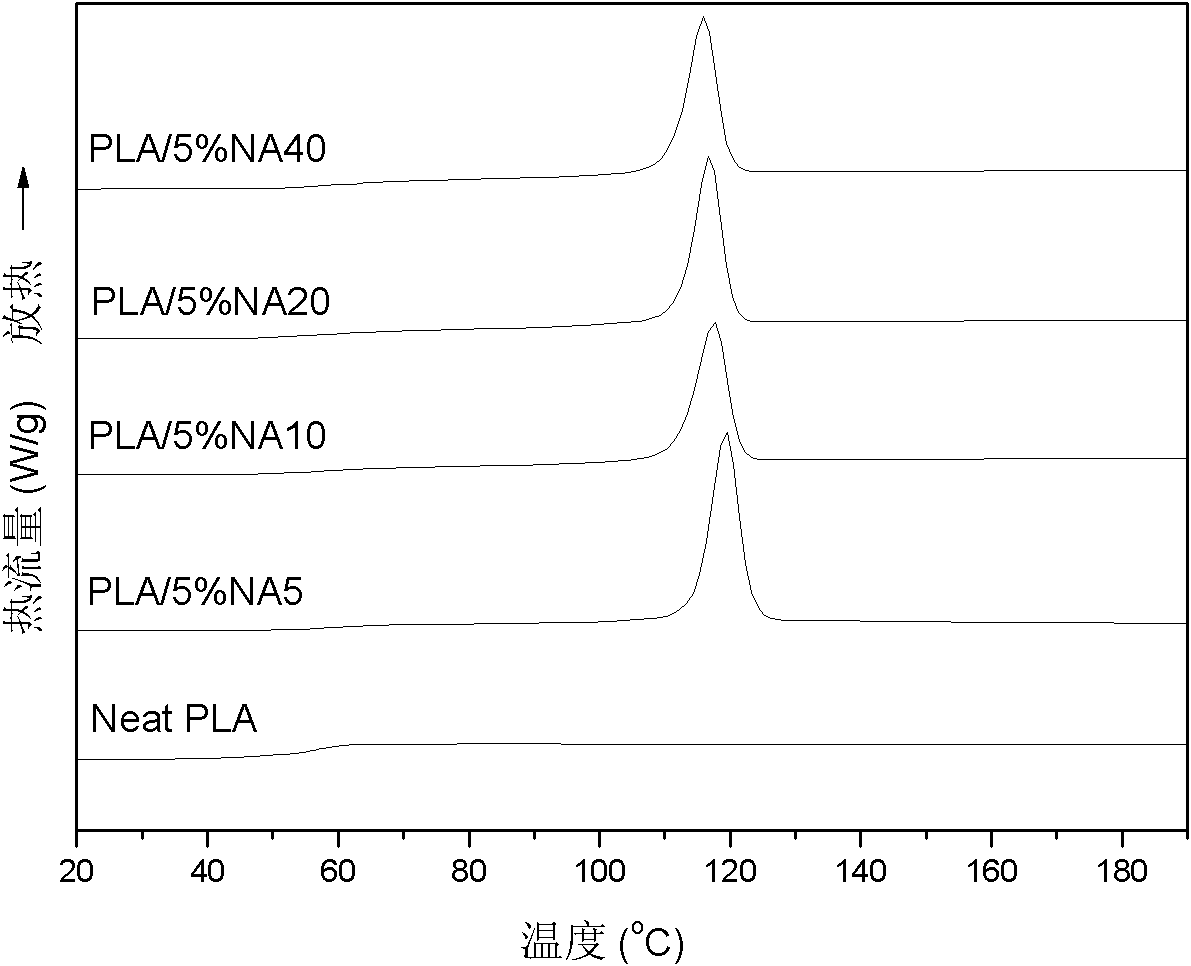

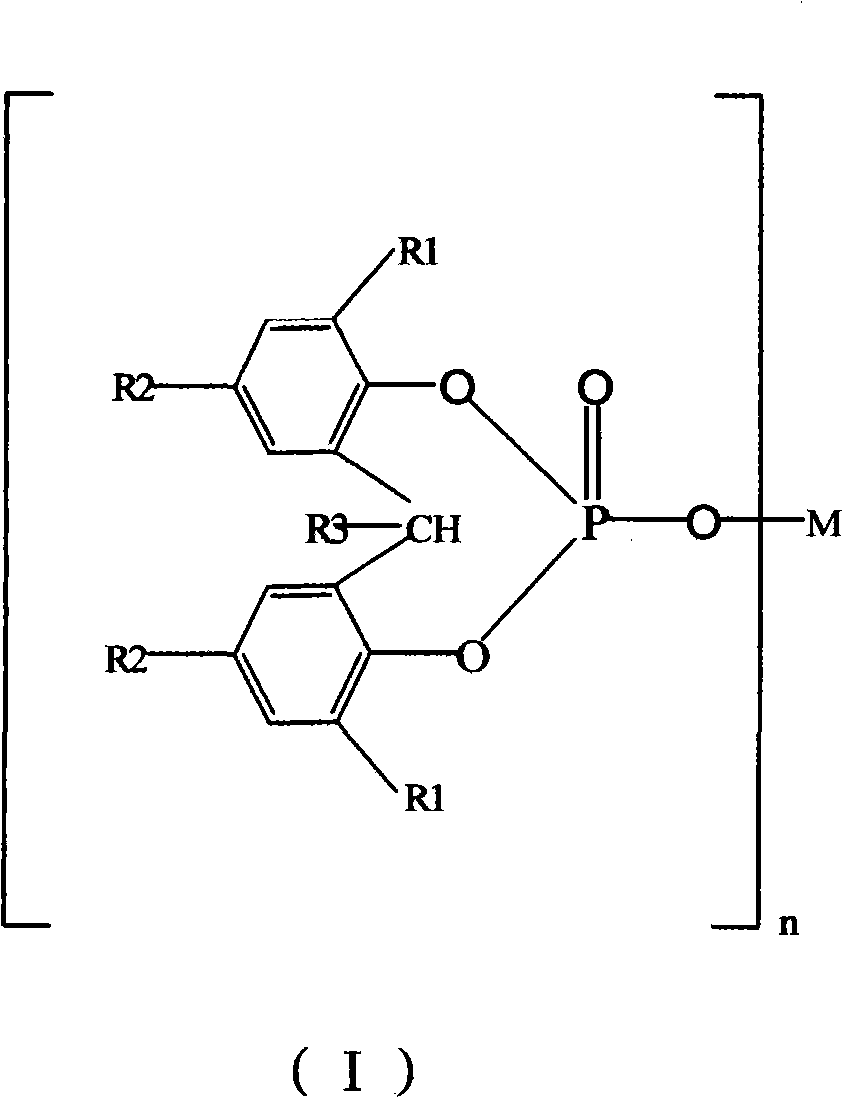

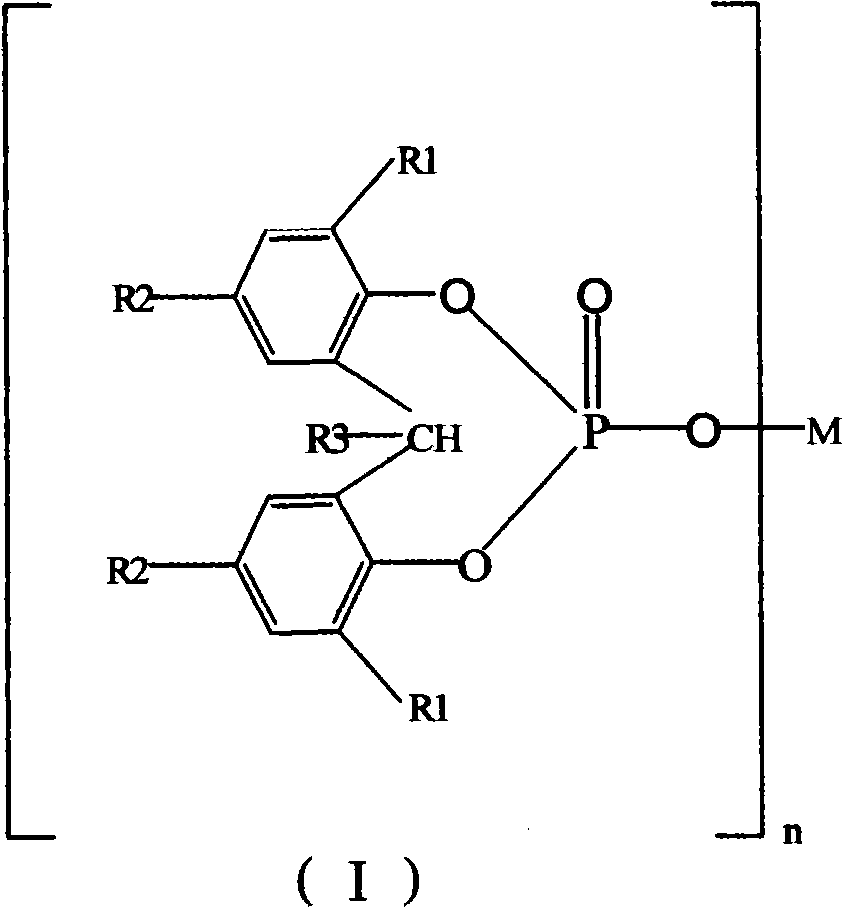

Calcium-carbonate-supported nucleating agent used for poly(lactic acid) crystallization and preparation method thereof

The invention discloses a calcium-carbonate-supported nucleating agent used for poly(lactic acid) crystallization and a preparation method thereof. The nucleating agent comprises the following composition formula: calcium carbonate and phenylphosphonic acid at a weight ratio of (5-40): 1, wherein calcium phenylphosphate generated by reaction of phenylphosphonic acid and calcium carbonate is used as an active ingredient and loaded on the surface of calcium carbonate, and phenyl phosphonic acid has a structural formula shown in the invention, in the formula, R1 and R2, the same or different, represent hydrogen atom, C1-10 alkyl or C1-10 alkoxycarbonyl. The nucleating agent can increase the effective nucleation sites formed by the high-degree dispersion of calcium phenylphosphate on the surface of calcium carbonate, thereby increasing nucleation efficiency as well as strengthening and toughening poly(lactic acid), avoiding the problem that poly(lactic acid) has poor toughness caused by non-supported nucleating agents, and facilitating the wide application of poly(lactic acid). The nucleating agent has a simple preparation method, low consumption of phenylphosphonic acid and significantly low cost.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

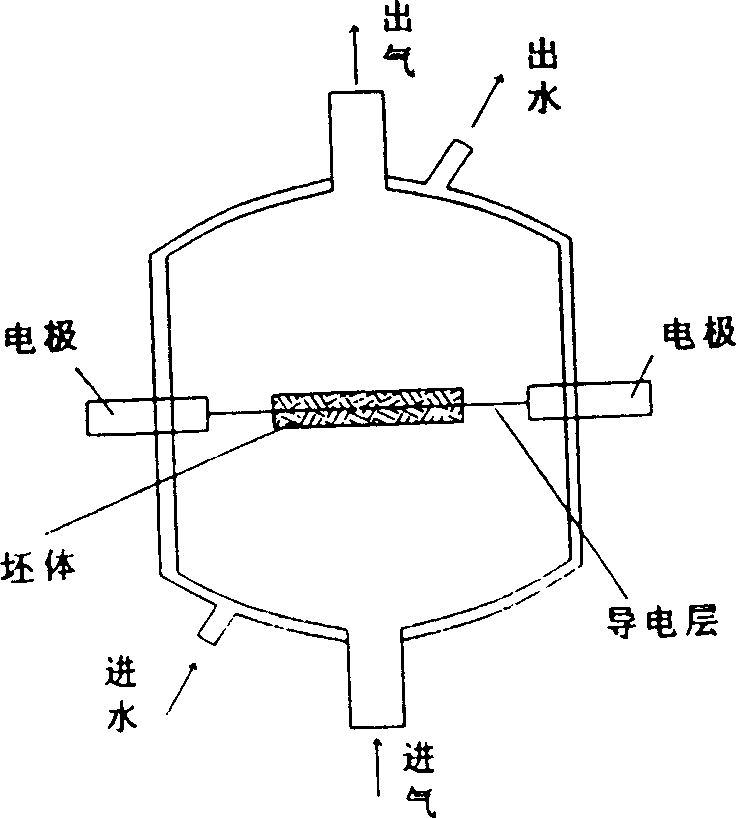

Method for rapidly preparing carbon/carbon composite material under physics field by CVD

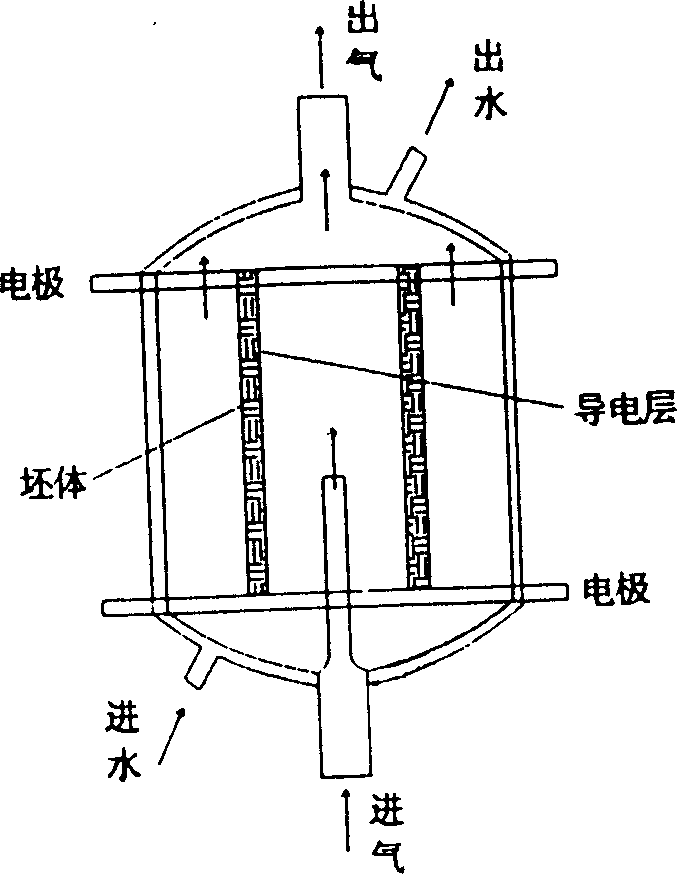

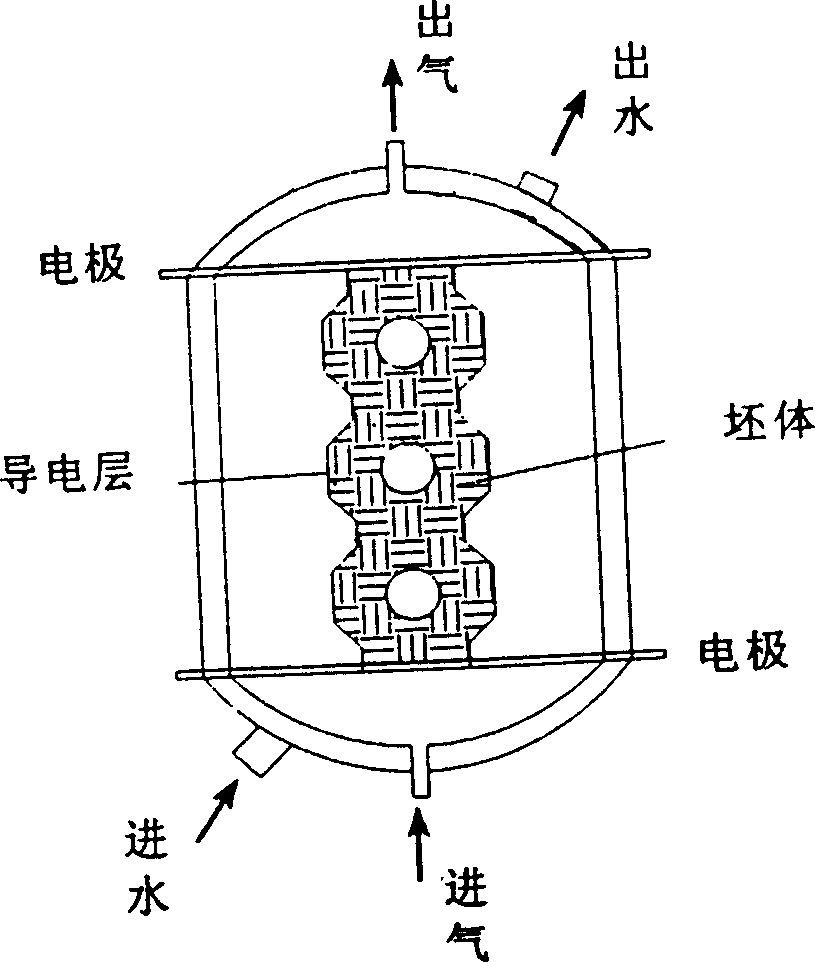

InactiveCN1676664AImprove utilization efficiencyThe heat transfer path is reasonably shortenedChemical vapor deposition coatingCarbon compositesGas phase

This invention is about the decomposition method of compound, especial about the method for depositing charcoal and carbide. The conducting layer is made up of tungsten filament, molybdenum filament and graphite layer; through the conducting layer the physical field is adjusted and controlled. We put charcoal / charcoal combined material body into the chemical gas phase depositing furnace, where the depositing temperature is controlled between 600deg.C and 1100deg.C. The carbon hydrogen gas is filled as reaction gas, while Ar or N2 is used as dilution gas. The concentration of the carbon hydrogen gas is from 5% to 100%, and the flow of the reaction gas should be between 0.2 and 1.2 square meters per hour.square meters. If you choose this invention, the densification speed of the carbon / carbon combined material can be increased, and the producing time can be reduced. You can adjust and control the structure of the thermal decomposition charcoal, and the density and uniform is good. Also, you can reduce the producing cost.

Owner:CENT SOUTH UNIV

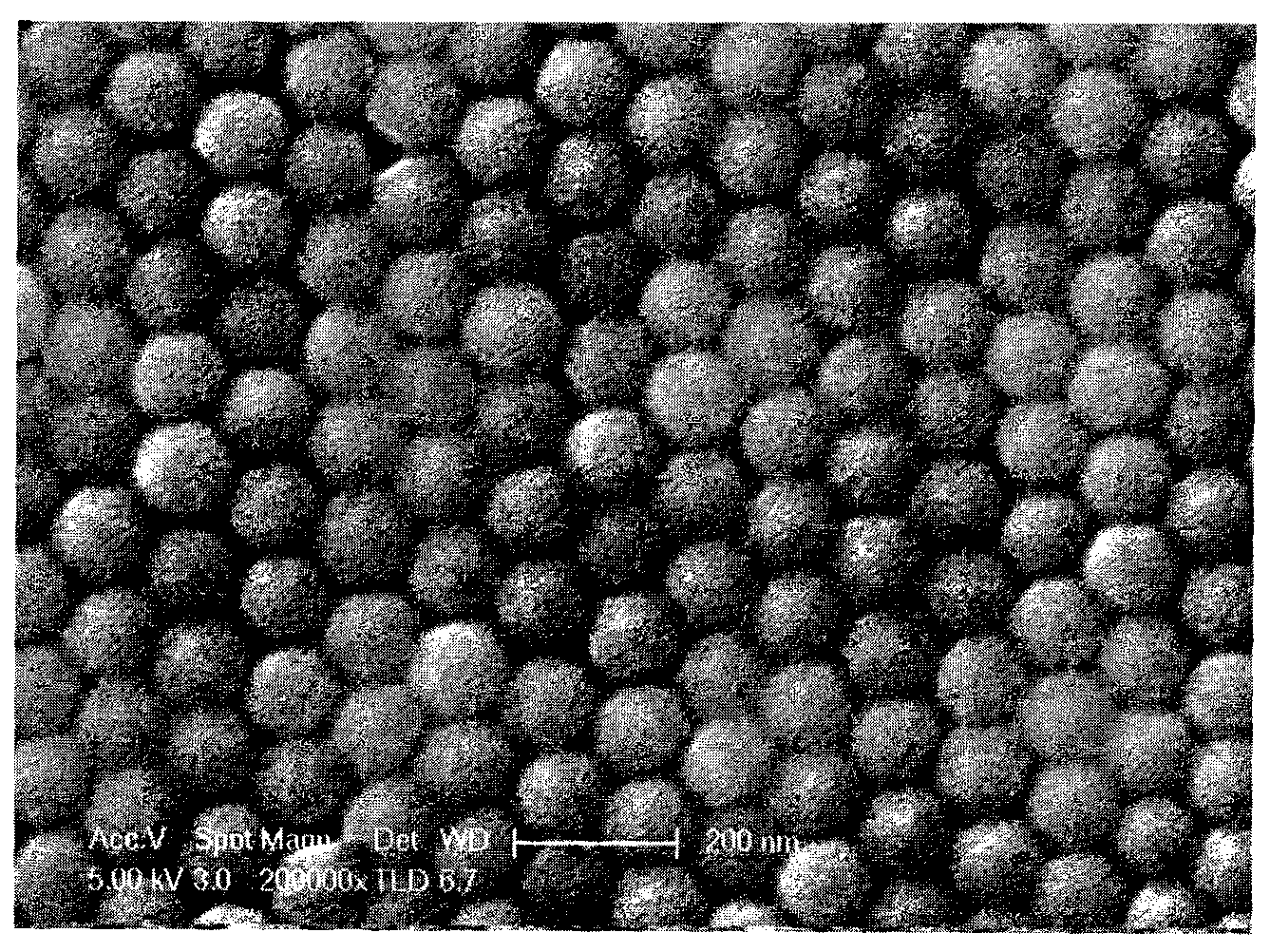

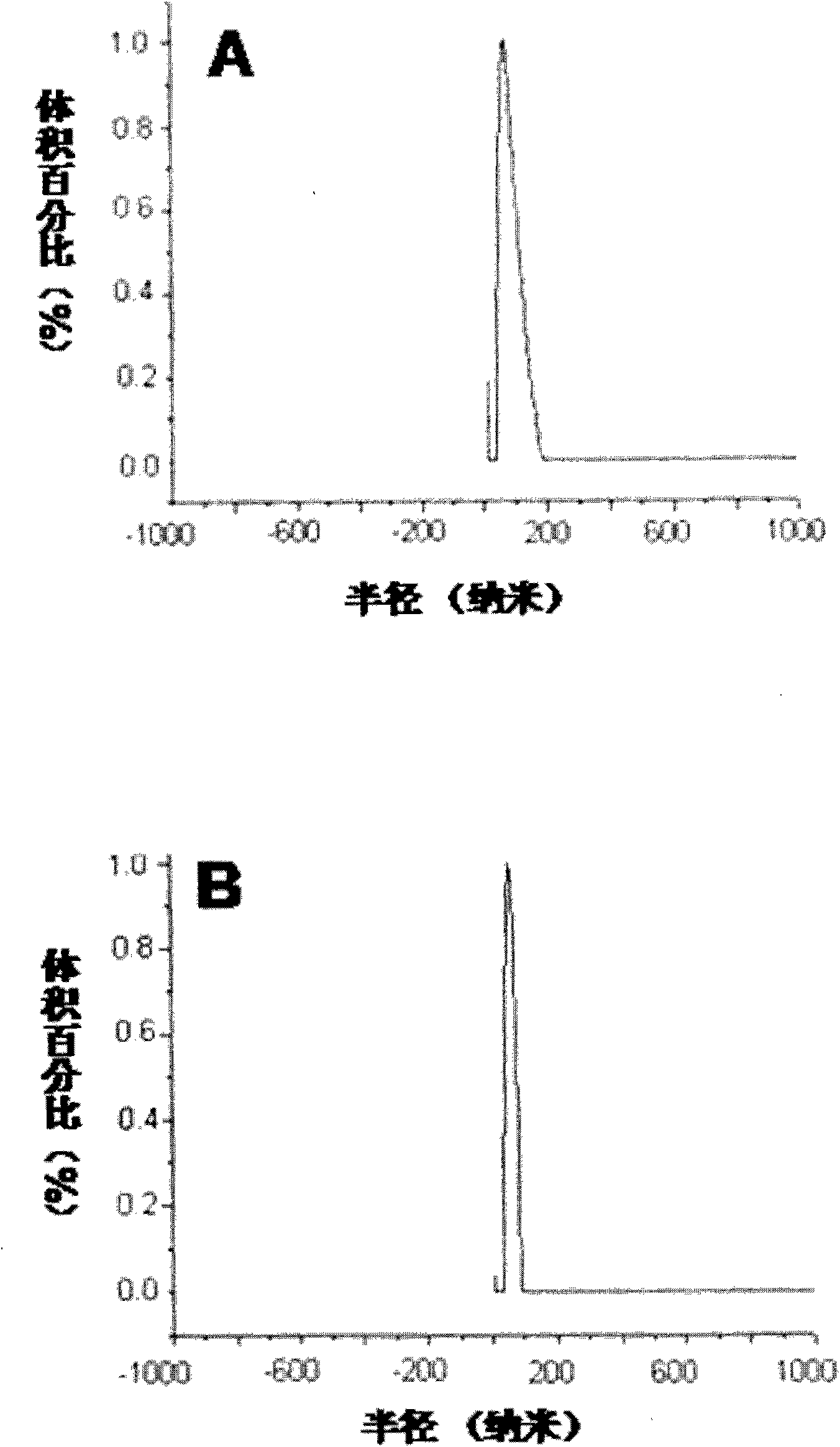

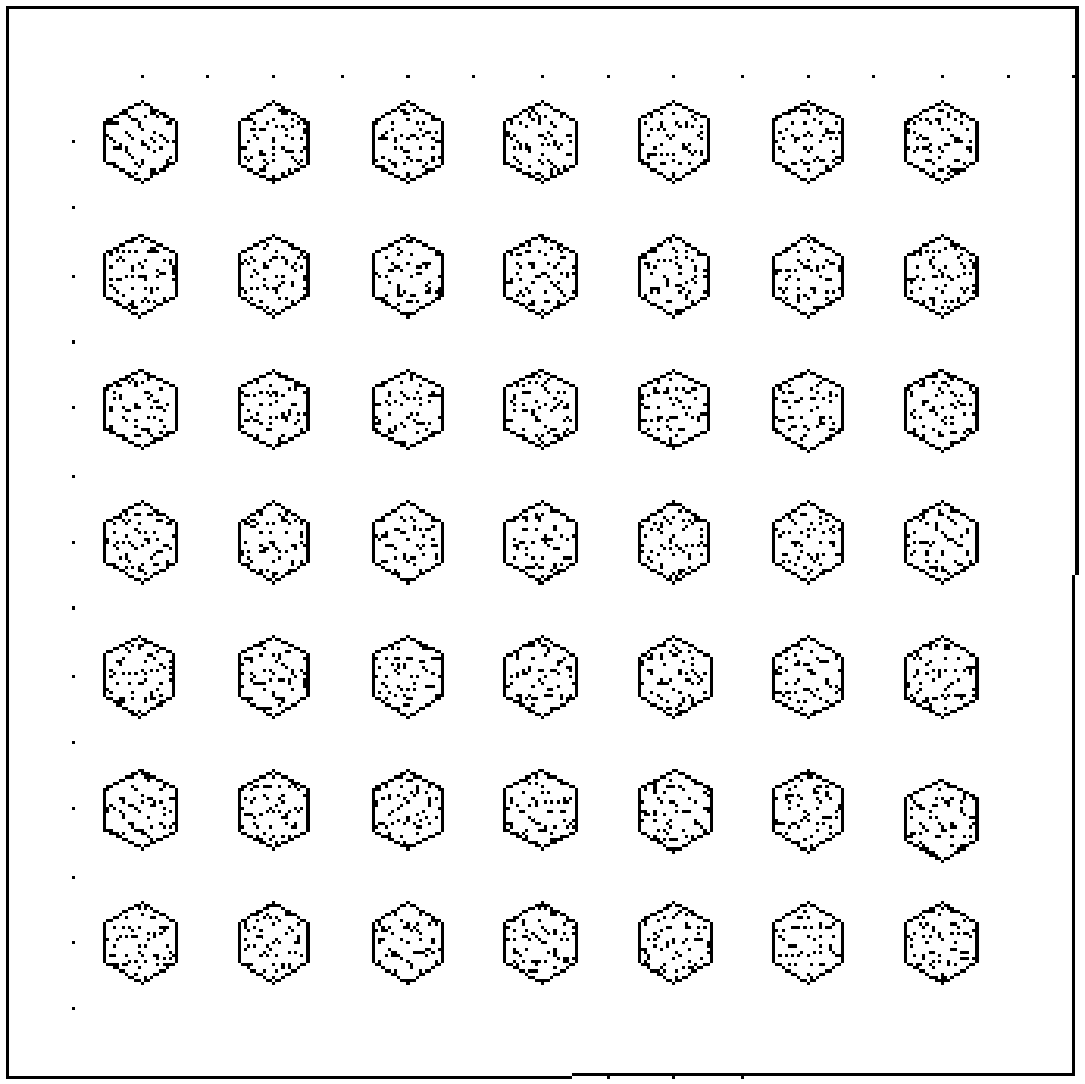

Monodispersity polystyrene nanosphere and preparation method thereof

ActiveCN102049228AEnhanced ability to capture free radicalsIncrease the ratio of nucleationMicroballoon preparationMicrocapsule preparationChemistryPolystyrene microsphere

The invention discloses a monodispersity polystyrene nanosphere and the preparation method thereof. The nanosphere adopts a solid round ball with smooth surface and the diameter of 100 to 200 nm, the polydispersity index of the round ball is 0.01 to 0.04, and the nanospheres can be closely arranged into a hexagonal configuration in a self-assembly manner. The method comprises the steps as follows: mixing styrene monomer, polystyrene microspheres, hexadecyl alcohol and Octyl phenol polyoxyethylene (10) ether according to the weight ratio of 98 to 102 : 0.98 to 1.2 : 1.98 to 2.2 : 1.98 to 2.2 and stirring for 20 min, and adding water to the mixture and continuing stirring for 30 min to obtain mixed solution, wherein the diameter of each polystyrene microsphere is 3 to 7 mm, and the weight ratio of water and the styrene monomer is 9.8 to 10.8 : 1; then placing the mixed solution in ultrasonic wave for at least 5 min to obtain miniemulsion; and after pumping nitrogen into the miniemulsionfor at least 10 min, adding potassium persulfate to the miniemulsion to perform polyreaction for 4 hours so as to manufacture the monodispersity polystyrene nanosphere. The invention can be widely applied to the fields of biomedicine, colloid science, chromatographic fractionation and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

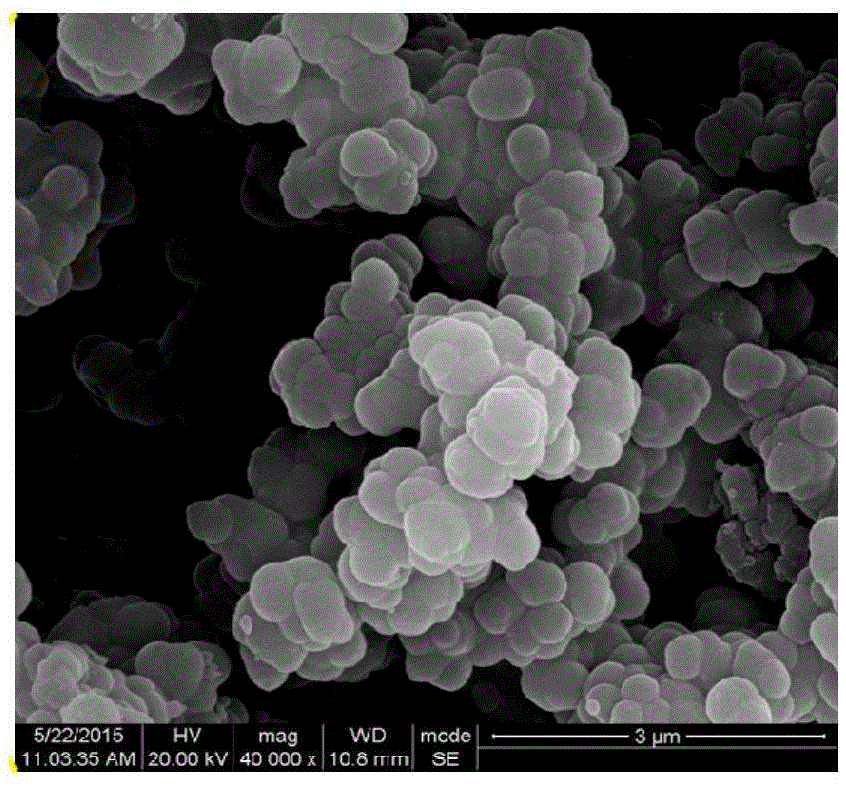

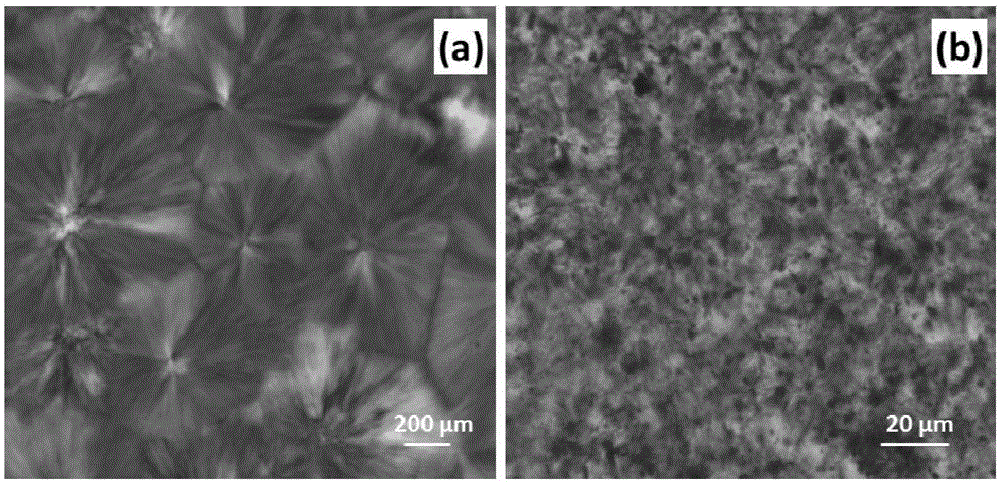

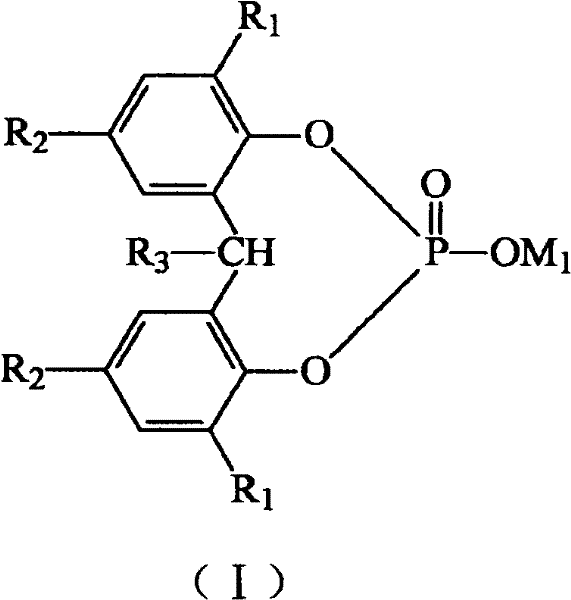

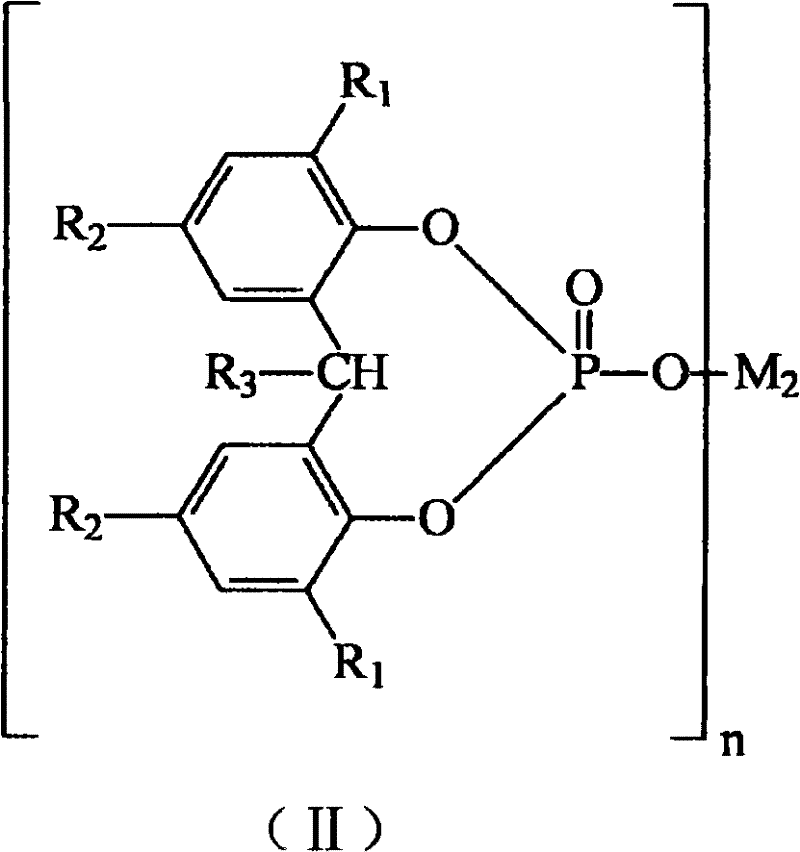

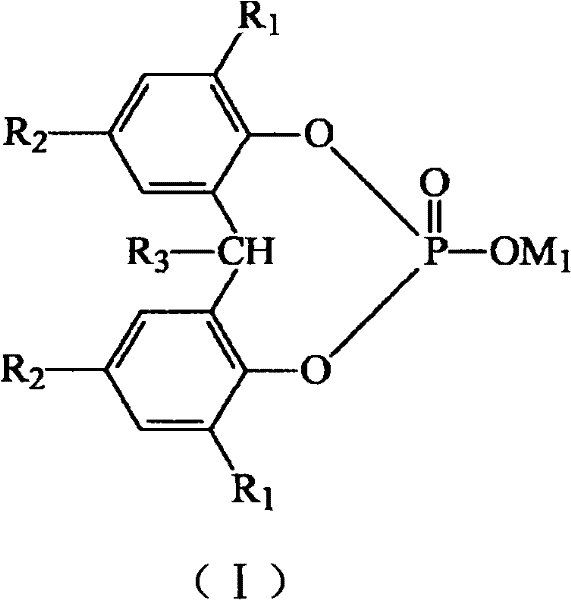

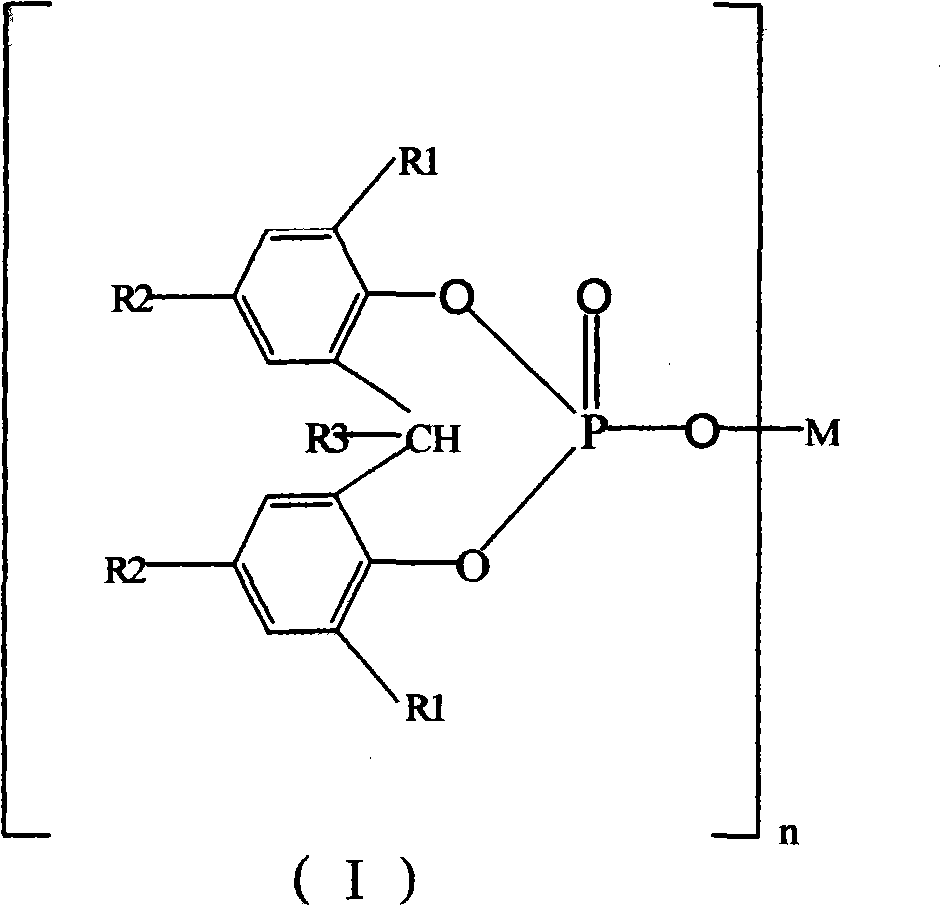

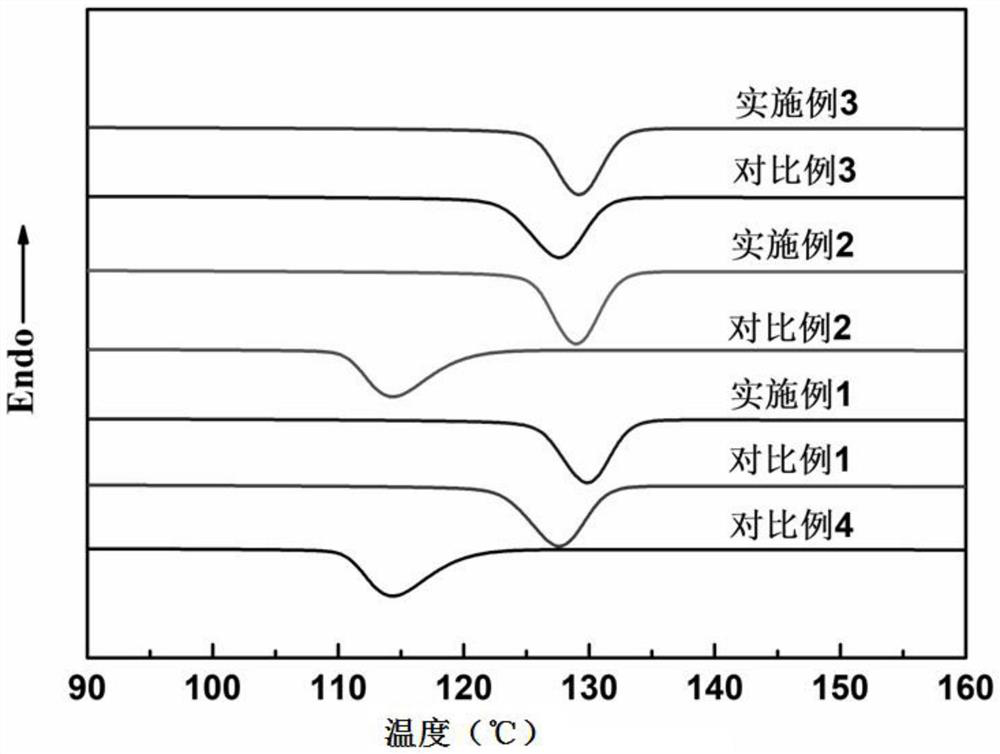

Ultrasonic preparation method of fine transparent nucleating agent

ActiveCN102408444AHigh optical transparencyImprove rigidityGroup 5/15 element organic compoundsHeat deflection temperatureOrganic phosphates

The invention relates to an ultrasonic auxiliary coprecipitation method for preparing a fine polypropylene transparent nucleating agent. The method is characterized in that an ultrasonic auxiliary coprecipitation process is employed during synthetic process of organic phosphate to obtain the fine powder particles by one step, the composition and particle size of the transparent nucleating agent can be effectively controlled by changing a synthetic condition and an ultrasonic condition, the fine transparent nucleating agent with average particle size of 1-5 micrometers can be obtained. The ultrasonic preparation method of fine transparent nucleating agent is used for the field of auxiliary agent treatment by polypropylene. The transparent nucleating agent is capable of substantially raising the nucleation efficiency during polypropylene treatment, forming minimal polypropylene spherocrystals, and substantially raising a plurality of performances of the optical transparency, rigidity, intensity, thermal deformation temperature of resin.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of ultrafine organic phosphate nucleating agent

The invention discloses a preparation method of an ultrafine organic phosphate nucleating agent, and the method comprises the following steps: dissolving a substituted diaryl organic phosphate nucleating agent crude product which is used as a raw material to obtain a raw material solution; performing spray drying of the obtained raw material solution in a spraying manner; then adding the obtainedspray-drying product into a solvent, adding water, stirring and dispersing in the combined solvent for crushing; performing liquid-solid separation of the crushed material, drying to obtain the ultrafine organic phosphate nucleating agent. The ultrafine organic phosphate nucleating agent prepared by the method of the invention has stable quality, a uniform particle size, and high yield, and the crystal form of the nucleating agent is not destroyed. The nucleating agent product can increase nucleation effect, and reduce the using amount of the nucleating agent.

Owner:CHINA PETROLEUM & CHEM CORP +1

Integrated broadband high-wave-transmissivity tough polyolefin microporous foam material and preparation method thereof

ActiveCN112111101ASimple processLow costLayered productsBulk chemical productionPolymer sciencePolyolefin

The invention relates to an integrated broadband high-wave-transmissivity tough polyolefin microporous foam material and a preparation method thereof, belonging to the technical field of communicationequipment materials. In order to meet the requirement for wave-transmitting performance by communication equipment on a broadband electromagnetic wave frequency band of 600 MHz-300 GHz, a polyolefinfoaming raw material is subjected to blending modification by utilizing an independently synthesized beta-cyclodextrin amination modifier, and a multi-layer co-extrusion process and an environment-friendly integrally-forming solid mold pressing foaming technology are employed to manufacture the integrated broadband high-wave-transmissivity tough polyolefin microporous foam material. According to the invention, a main raw material is a polyolefin material; the structure of the foam material mainly comprises a middle layer and skin layers located on the two sides, the middle layer and the skin layers are both of a foaming structure with a cell wall thickness of smaller than 100 nm, and the foaming rate of the middle layer and the foaming rates of the skin layers are different; and by means of the structure, the transmissivity of millimeter waves can be effectively improved, production efficiency is improved to a large extent, technological process is shortened, and production cost is reduced.

Owner:JIANGSU JICUI ADVANCED POLYMER MATERIAL RES INST CO LTD +1

Method for preparing polypropylene composite

The invention relates to a method for preparing a polypropylene composite. The method is characterized in that the polypropylene composite is prepared from polypropylene, a compatibilizer, glass fibers, a nucleating agent and an anti-oxidant according to a two-step process. The method comprises the following steps: the nucleating agent is utilized to induce crystal transfer of polypropylene; the glass fibers are compounded with polypropylene subjected to crystal transfer for further enhancement. Therefore, the problem that according to a traditional method in which polypropylene is directly mixed with a nucleating agent and fibers, the polypropylene crystallization behavior regulation and control functions of the nucleating agent cannot be effectively played due to introduction of the glass fibers serving as external impurities is solved. According to the method provided by the invention, regulation and control of the nucleating agent and enhancement of the glass fibers are effectively combined together to improve the combination property of the polypropylene composite, so that the polypropylene composite prepared by the method is not only excellent in comprehensive mechanical property but also high in thermal stability. Meanwhile, the raw materials (the glass fibers) are low in price and easily accessible, and a twin-screw extrusion process is simple and low in cost, so that large-scale production and application can be conveniently realized.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

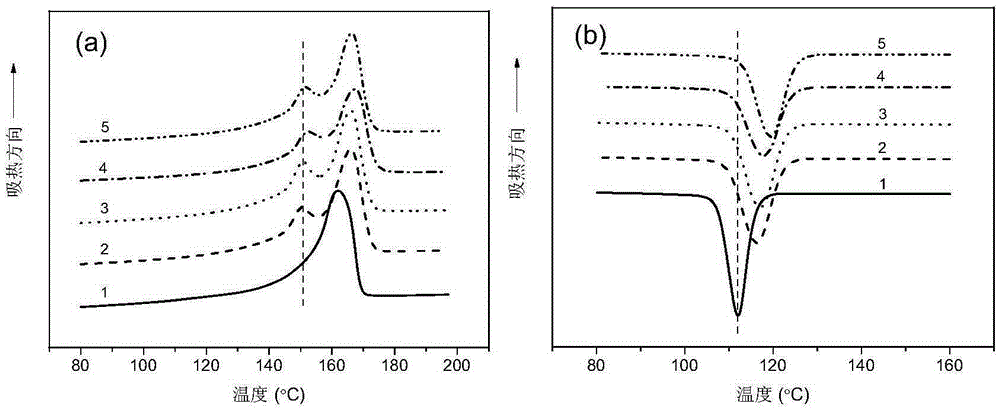

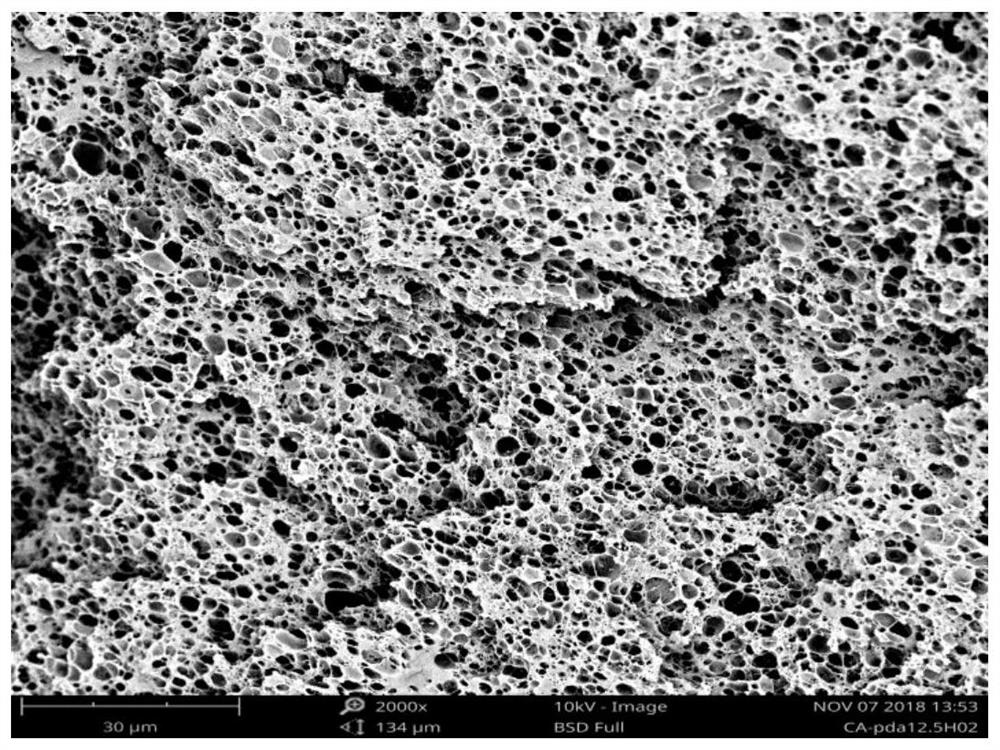

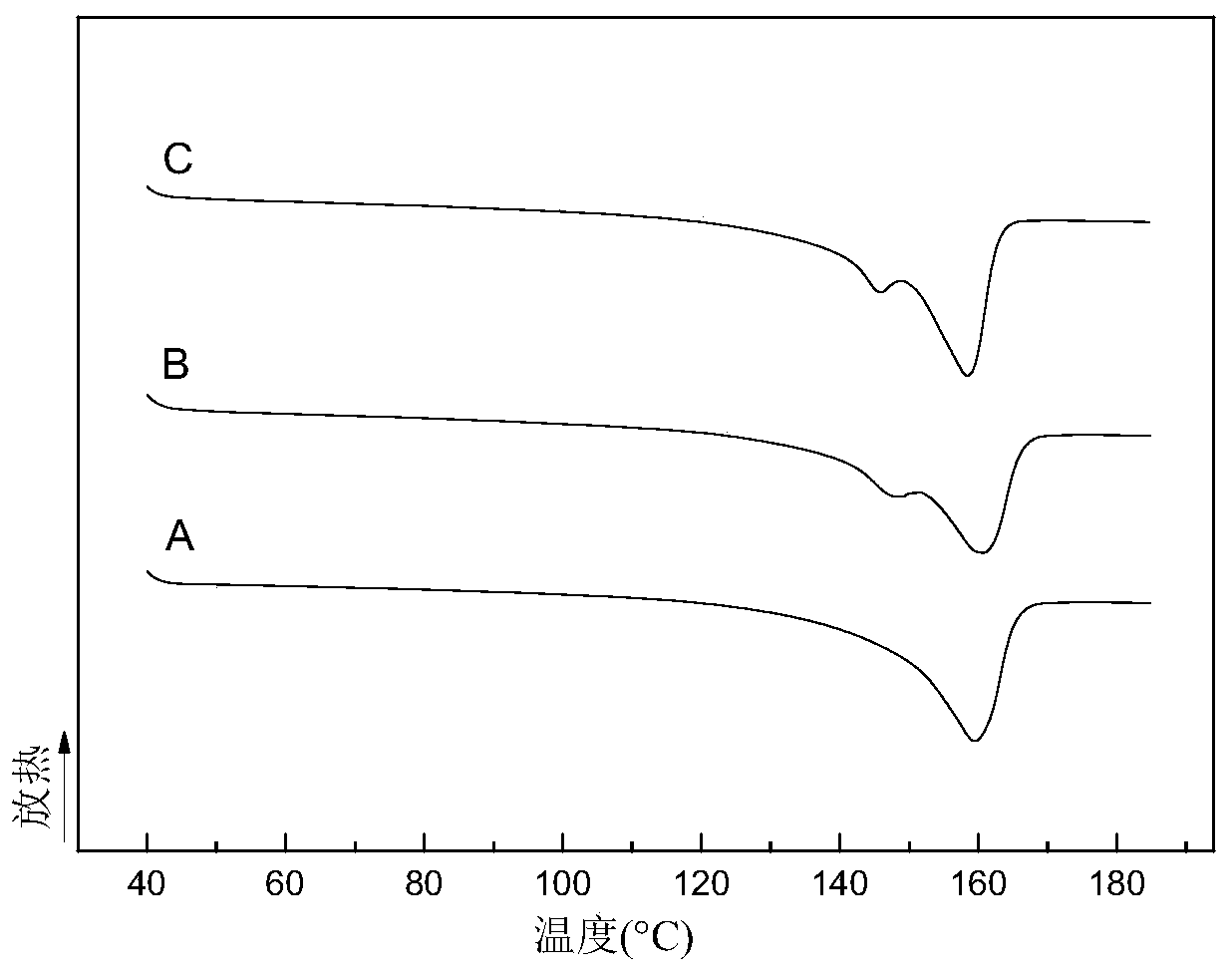

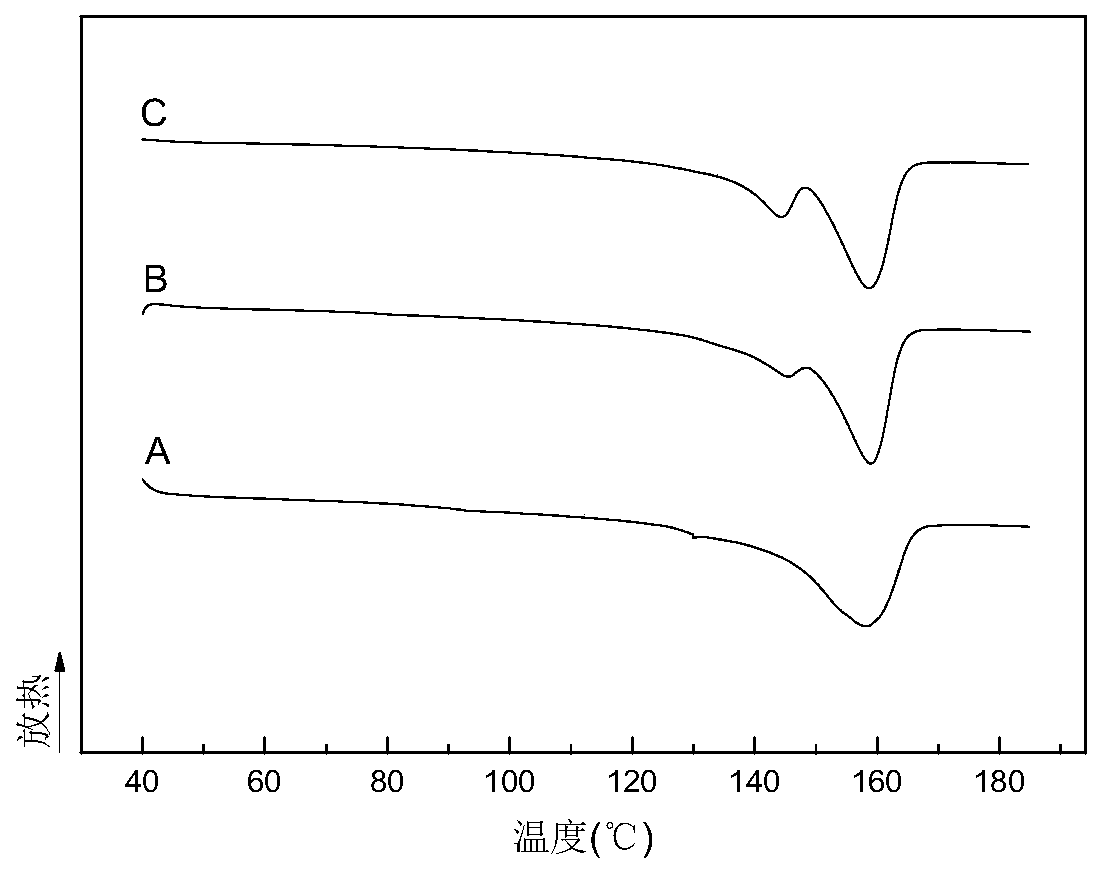

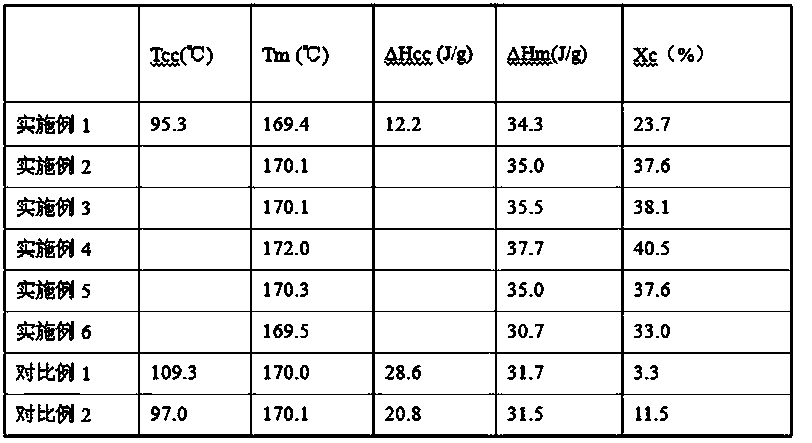

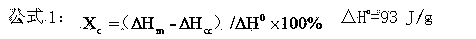

Method for improving nucleation efficiency when preparing beta crystalline long-chain branching polypropylene through beta nucleating agent

The invention provides a method for improving the nucleation efficiency when preparing beta crystalline long-chain branching polypropylene and a foaming material thereof through a beta nucleating agent. The method includes the step of adding a synergist, and the synergist is combination of one or more of 4A zeolite molecular sieve, 5A zeolite molecular sieve, silicon dioxide and calcium silicate.According to the method for improving the nucleation efficiency when preparing the beta crystalline long-chain branching polypropylene and the foaming material thereof through the beta nucleating agent, the induction efficiency of the beta nucleating agent in the long-chain branching polypropylene can be improved, the content of beta crystals is increased, meanwhile, the amount of the beta nucleating agent can further be decreased, and the cost is saved; and the synergist can improve the nucleation efficiency of the beta nucleating agent and can furtherserve as a bubble nucleating point, the size of cell holes is reduced, the density of the cell holes is increased, and the quality of the foaming material is improved.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Shell powder filler having high beta-nucleation effect on polypropylene and preparation method for filler

InactiveCN102532716AHigh β-nucleation efficiencyHigh impact strengthPolymer scienceDicarboxylic acid

The invention discloses a shell powder filler having a high beta-nucleation effect on polypropylene and copolymer thereof and a preparation method for the filler. The method comprises the following steps of: dissolving aliphatic dicarboxylic acid in acetone, mixing a solution and shell powder, volatilizing the acetone, and thus obtaining the shell powder filler having the high beta-nucleation effect, wherein a mass ratio of the aliphatic dicarboxylic acid to the shell powder is 1:(5-1,000); and mixing the polypropylene or copolymer thereof and the shell powder filler having the high beta-nucleation effect in a mass ratio of 1:99-5:1, and performing melt extrusion or mixing and pelletizing at the temperature of between 200 and 230 DEG C to obtain shell powder filled polypropylene or copolymer thereof with high beta-crystal content. The shell powder filler having the high beta-nucleation effect is easy to prepare, small in equipment investment, low in energy consumption and cost, wide in raw material source and high in beta-nucleation efficiency, and has the characteristic of reinforcing and toughening the polypropylene or copolymer thereof.

Owner:ZHEJIANG UNIV

Method for preparing high-crystallinity polylactic acid material or article with high crystallization rate

ActiveCN104109364AIncrease the rate of crystallizationHigh nucleation efficiencyPolymer scienceCrystallinity

The invention discloses a method for preparing a high-crystallinity polylactic acid material or article with a high crystallization rate. The method comprises the following steps of pulverizing a certain proportion of high-melting-point lactic acid-based polymer with an orthorhombic system crystal and sieving, annealing and adding into a polylactic acid and polylactic acid blended system and processing in a specific processing temperature range by virtue of a melt-processing method to obtain the high-crystallinity polylactic acid material or article with the high crystallization rate. The added high-melting-point lactic acid-based polymer can be used as a nucleating agent for polylactic acid to greatly contribute to the crystallization of polylactic acid, and the crystallization of polylactic acid can be efficiently promoted at a relatively fast cooling rate and thus a high-crystallinity polylactic acid sample is obtained, and since the added lactic acid-based polymer is biodegradable, the polylactic acid material or product prepared by the method has high crystallinity and can be completely biodegradable. The method has the advantages of simple process and low cost and easily operated.

Owner:SICHUAN UNIV

Polypropylene composite plastic used for water-filled barrier fence

The invention discloses polypropylene composite plastic used for a water-filled barrier fence. The polypropylene composite plastic includes, by weight, 100-120 parts of polypropylene, 6-14 parts of nitrile butadiene rubber, 8-16 parts of chlorosulfonated polyethylene, 4-8 parts of a transparent nucleating agent, 2-4 parts of a crosslinker, 2-4 parts of gamma-glycidyl ether oxypropyltrimethoxysilane, 30-40 parts of filler, 2-4 parts of a dispersant, 2-4 parts of an antoxidant, 2-4 parts of a photo-stabilizer, and 2-4 parts of an ultraviolet absorber. Mica powder composite is prepared through the steps of: mixing polyhydroxybutyrate, mica powder, disproportionated rosin, tetradecanedioic acid and dibutyltin dilaurate, and heating and stirring the mixture to prepare the mica powder composite.

Owner:芜湖盈奇塑业有限公司

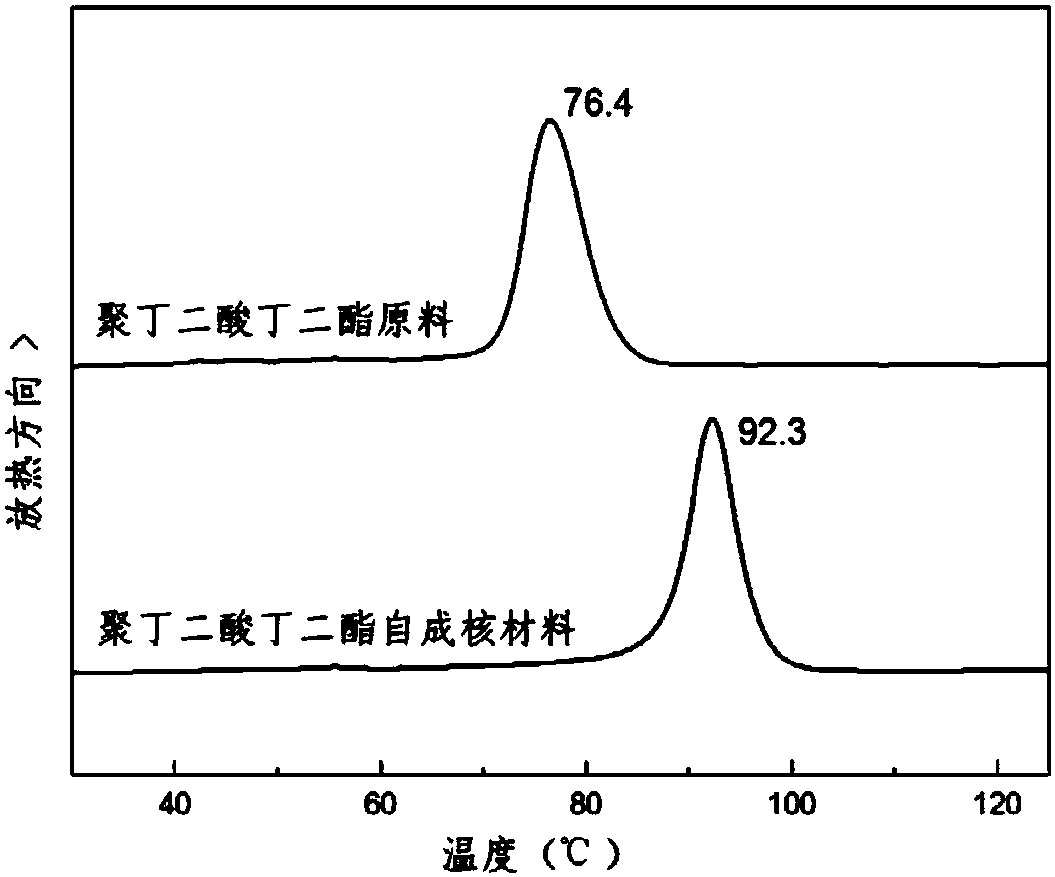

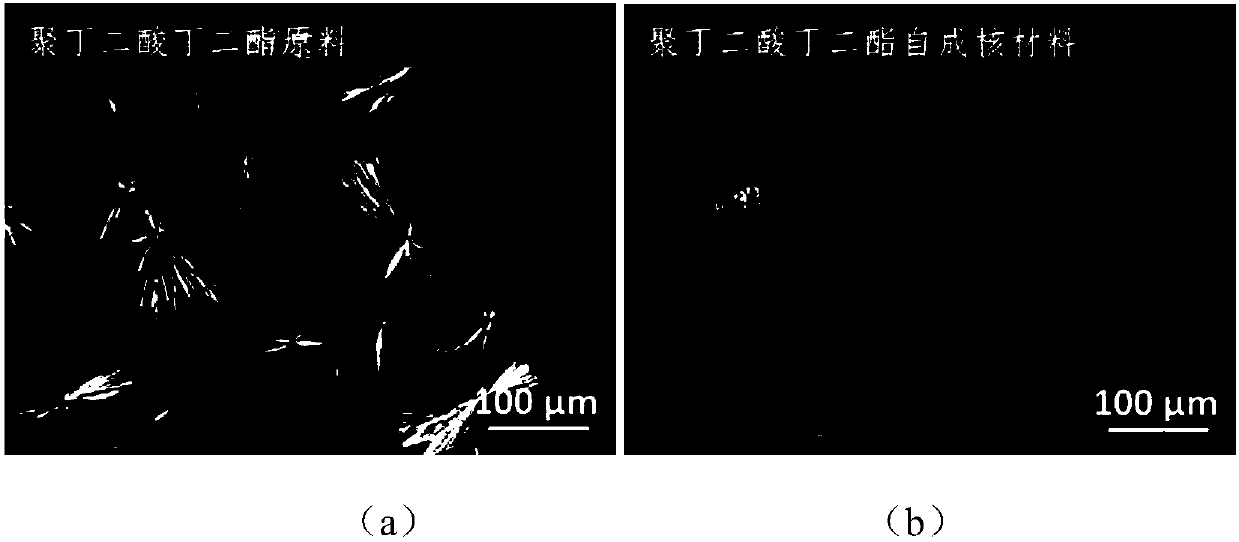

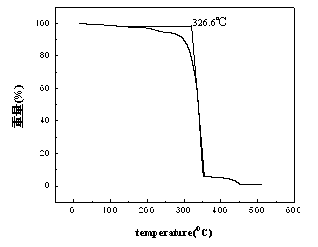

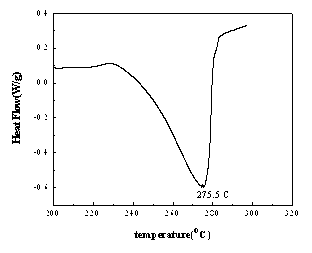

Self-nucleation method for high-polymer materials

InactiveCN107915967APromote crystallizationImprove performanceMonocomponent polyesters artificial filamentArtifical filament manufacturePolymer sciencePolymer chemistry

The invention discloses a self-nucleation method for high-polymer materials. The self-nucleation method includes steps of blending the high-polymer materials with extended-chain crystals used as self-nucleation agents to obtain high-polymer materials with the self-nucleation agents. A mass ratio of the extended-chain crystals to the high-polymer materials is 0.1-20:100. The self-nucleation methodhas the advantages that the extended-chain crystals which are prepared from high-polymer materials and have high melting points are used as nucleating agents for high-polymer matrixes, and accordinglycrystallization and the performance of the materials can be improved; the extended-chain crystals still can be kept in melt of the high-polymer matrixes and can be used as the nucleating agents for the matrixes when cooled, and accordingly the nucleation efficiency can be improved; preparation procedures are good in operability and high in production efficiency, the materials obtained by the aidof the self-nucleation method are good in performance, and accordingly the self-nucleation method has obvious economic and social benefits.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

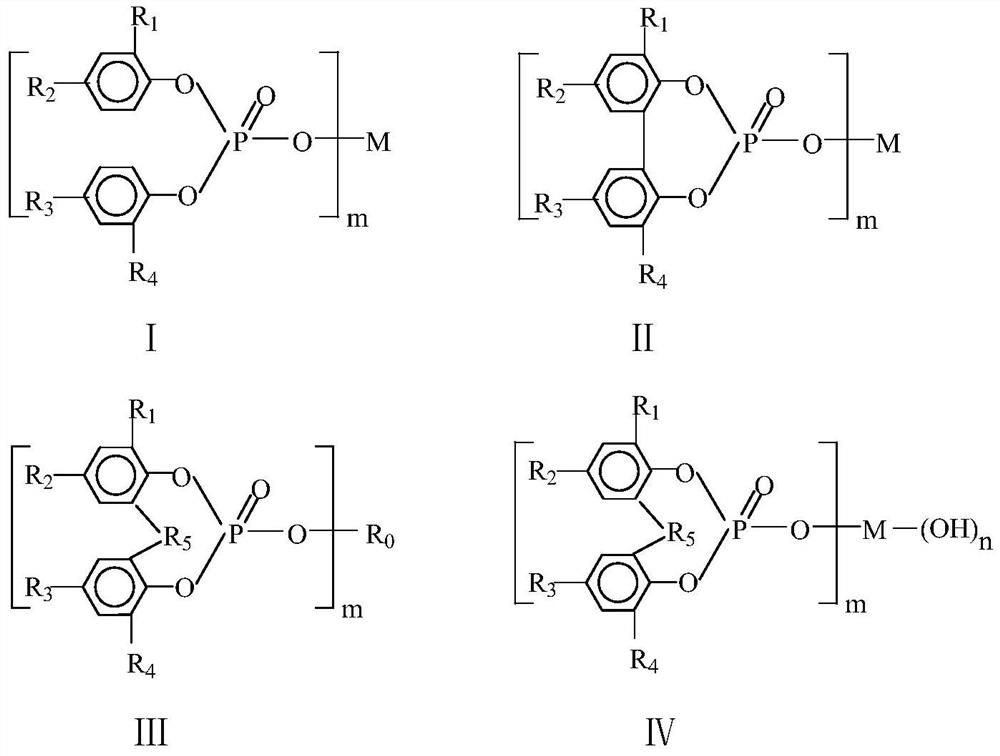

Organic ammonium phosphate nucleating agent for polypropylene transparency and preparation method thereof

InactiveCN102746577AWide variety of sourcesEasy accessGroup 5/15 element organic compoundsHydrogen atomHydrogen

The invention discloses an organic ammonium phosphate nucleating agent for polypropylene transparency and a preparation method of the organic ammonium phosphate nucleating agent. The molecular formula of the organic ammonium phosphate nucleating agent is shown in the description, wherein R1, R2, R3 and R4 are all hydrogen atoms or C1-C4 alkyl or branched alkyl; R1, R2, R3 and R4 are completely the same, completely different or partly same. The organic ammonium phosphate can be used as a nucleating agent for polypropylene transparency and has the advantages of low melting temperature, good dispersing effect, high nucleating efficiency and significant antireflection effect. The method is simple in operation and the yield is more than 85%.

Owner:贵州省复合改性聚合物材料工程技术研究中心

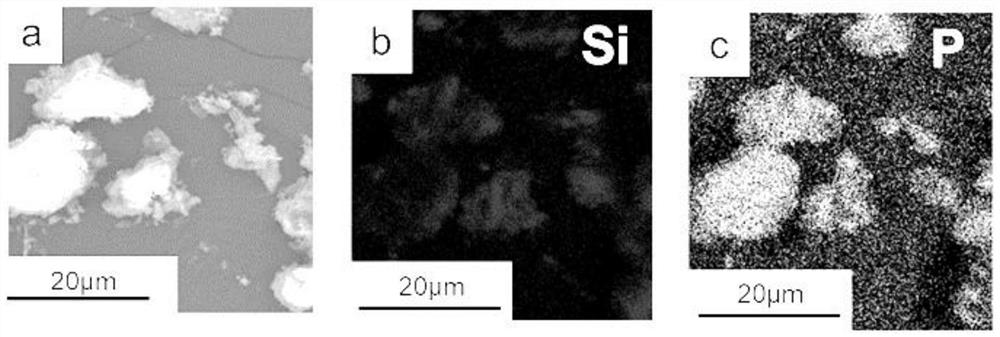

Preparation method and application of polyhedral oligomeric silsesquioxane loaded substituted aryl heterocyclic phosphate or salt nucleating agent

PendingCN112028929ASmall sizeReduce agglomeration effectGroup 5/15 element organic compoundsArylPolymer science

The invention discloses a preparation method of a polyhedral oligomeric silsesquioxane loaded substituted aryl heterocyclic phosphate or salt nucleating agent, which comprises the following steps: carrying out ultrasonic uniform mixing on 0.001-50g / ml of a nucleating agent solution and polyhedral oligomeric silsesquioxane according to the mass ratio of 1: (1-25), thereby obtaining the polyhedral oligomeric silsesquioxane loaded substituted aryl heterocyclic phosphate or salt nucleating agent, and drying and sieving to obtain the polyhedral oligomeric silsesquioxane loaded substituted aryl heterocyclic phosphate or salt nucleating agent. The polyhedral oligomeric silsesquioxane supported substituted aryl heterocyclic phosphate or salt nucleating agent prepared by the invention can provide ahigh content of nucleating sites under the condition of a low addition amount of the nucleating agent, and the nucleating efficiency is greatly improved.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Coating of light-water reactor

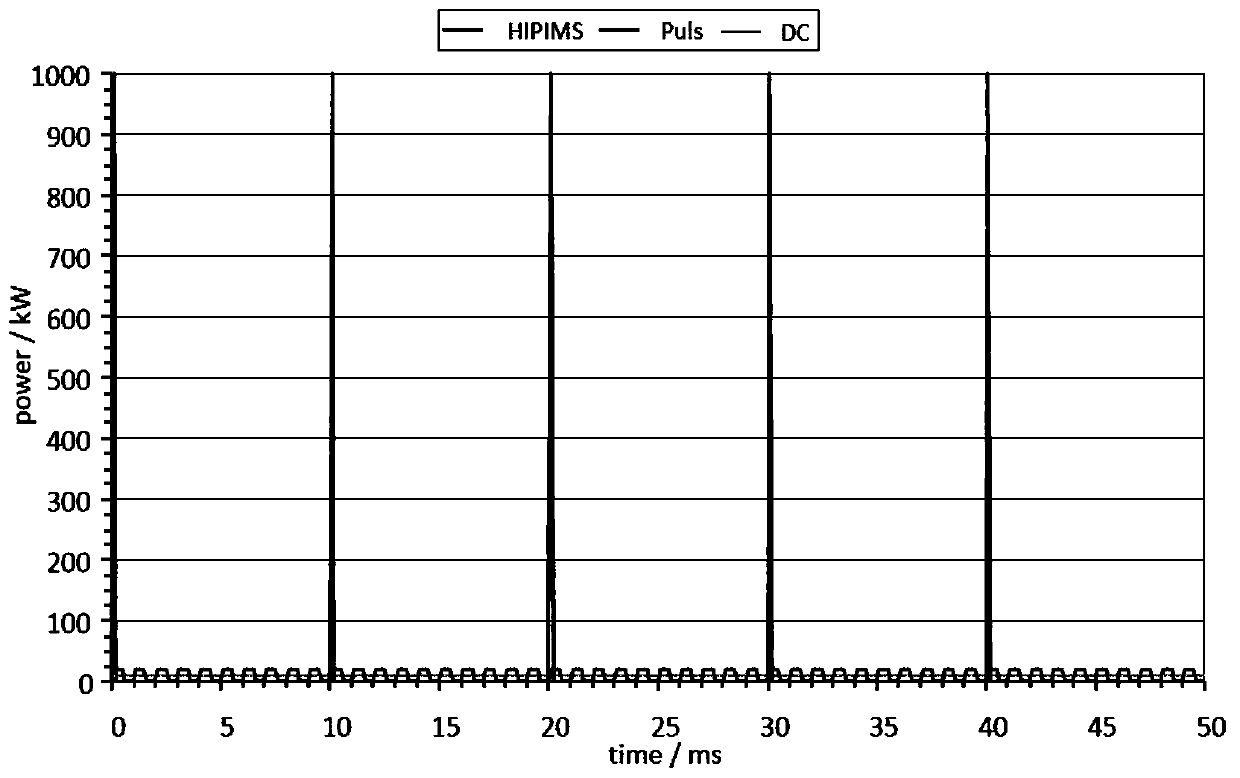

InactiveCN109913823AQuality improvementReduce human defectsVacuum evaporation coatingSputtering coatingOxidation resistantHigh pressure

The invention provides a method for preparing zirconium pipe coating of a light-water reactor. The method mainly comprises the following steps that a CrAbSi circulating nano coating and a MoNbZr circulating nano coating are alternately deposited by utilizing a high-power pulse technology and a magnetic filtration deposition technology, the thickness of the CrAbSi circulating nano coating and the MoNbZr circulating nano coating in a unit period is 0-15 nanometers, and the total thickness of the coating is 0-15 micrometres. After the nano coatings are deposited alternately, the oxidation resistance of the zirconium pipe at high temperature and high pressure in a high-pressure kettle is obviously enhanced, by implementing the method, a nano-circulation composite structure (especially the elements of Al, Cr and Si are added) is deposited alternately on the zirconium pipe, so that the inward diffusion of an oxygen element at the high temperature can be very well prevented, due to the mutualsynergistic effect of various elements, falling off, cracking and diffusion behaviors of oxygen atoms of a film layer can be effectively prevented in the high temperature and high pressure, and the safety and reliability of a fault-tolerant fuel are improved.

Owner:BEIJING NORMAL UNIVERSITY

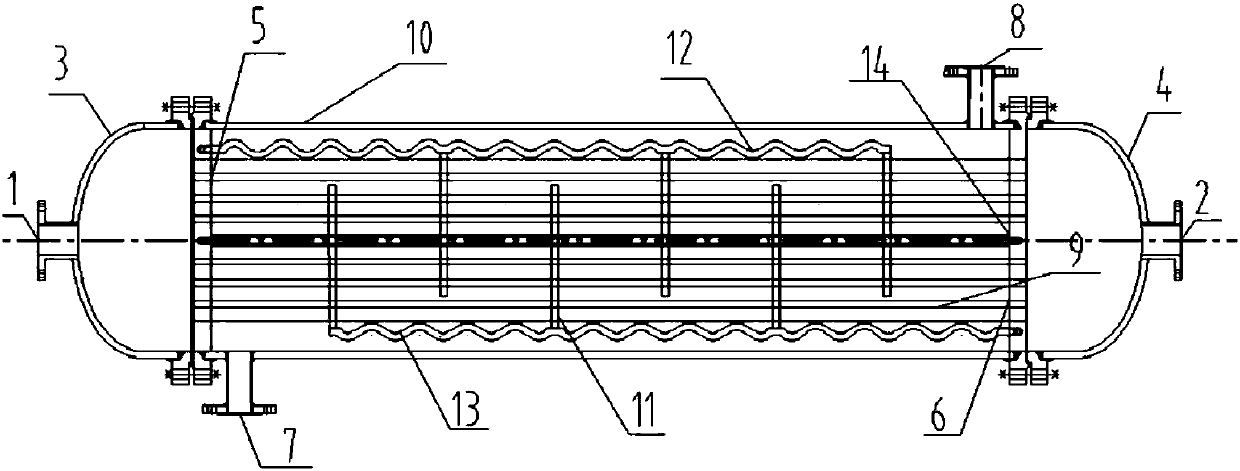

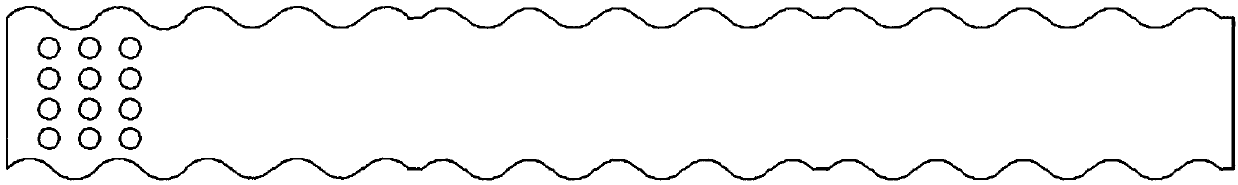

Tube-shell type heat exchanger with super-hydrophobic/hydrophilic surface

InactiveCN108020105ANot easy to depositEasy to operateHeat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerWave shape

The invention discloses a tube-shell type heat exchanger with a super-hydrophobic / hydrophilic surface. The tube-shell type heat exchanger comprises a shell, a first tube plate, a second tube plate, afirst end socket, a second end socket, and a heat exchange tube bundle arranged in the shell. The heat exchange tube bundle communicates with an inner cavity of the first end socket and an inner cavity of the second end socket. A patterned surface in a certain geometrical shape covers the surface of the heat exchange tube bundle, and super-hydrophobic areas and super-hydrophilic areas are distributed on the patterned surface at intervals. A first wave-shaped transverse plate and a second wave-shaped transverse plate which are arranged in parallel in the length direction and staggered by a certain distance are arranged in the shell. A baffle plate is arranged between the first wave-shaped transverse plate and the second wave-shaped transverse plate. The tube-shell type heat exchanger is simple in structure and easy to maintain, by the adoption of the super-hydrophobic / hydrophilic surface coating structure, the heat transfer coefficient of the tube bundle can be remarkably increased, andthe heat transfer effect is reinforced; and meanwhile, the pressure drop and flowing resistance are reduced to the greatest extent, flowing dead zones are eliminated easily, the heat exchange area isincreased, the heat exchange efficiency is improved, and the tube-shell type heat exchanger is resistant to high temperature and high pressure, even in heat exchange and good in stability.

Owner:SOUTH CHINA UNIV OF TECH

Catalyst component for the preparation of nucleated polyolefins

Catalyst composition comprising a phthalate-free electron donor, which is highly effective during polymerization in the presence of a polymeric nucleating agent, and its use and a process for its preparation.

Owner:BOREALIS AG

Ultrafine organic ammonium phosphate nucleating agent and preparation method thereof

The invention discloses an ultrafine organic ammonium phosphate nucleating agent and a preparation method thereof. The structure formula of the nucleating agent is as described in the specification, wherein R1, R2, R3 and R4 are all hydrogen atoms or alkyls or branched chain alkyls of C1-C4; R1, R2, R3 and R4 are identical, partially identical or totally different; and the partially identical structure can be a left-and-right symmetrical structure, that is, R1 is identical with R4; R2 is identical with R3; but R1 is different from R4. The ultrafine organic ammonium phosphate nucleating agent is prepared by using supercritical CO2 via a solvent dispersion method; the product is ultrafine powder particles, is dispersed uniformly, and has narrow particle size distribution and high nucleating efficiency; and finally finer polypropylene sphaerocrystal can be obtained. The preparation method is simple in process, short in processing time and low in energy consumption; and the prepared nucleating agent has good crystal forms and fine particles.

Owner:贵州省复合改性聚合物材料工程技术研究中心

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com